Have you ever noticed a part that looked perfect in the morning but suddenly fits like a story told by someone who forgot the ending?

Thermal Stability In 2026 CNC Systems: Why It Matters And How Manufacturers Engineer It

You’re standing in a shop or scrolling through a specification sheet, and thermal stability is one of those phrases that sounds both crucial and mildly supernatural. It’s the invisible temperature-related behavior that decides whether that complex aluminum bracket will be an engineering triumph or a geometry joke.

What thermal stability actually means for you

Thermal stability is about how a CNC machine maintains dimensional and positional accuracy as temperatures change. In practice, it covers how machine components expand, move, or shift heat around — and how well the system controls or compensates for those changes so your parts remain within tolerance.

You can think of it as an argument between the machine and the laws of physics. If the machine “loses” that argument, you spend time fixing parts instead of making them.

Why thermal stability matters in 2026

By 2026, tolerances are tighter, production runs are longer, and unattended manufacturing is more common. You’re asking machines to operate precisely while temperatures fluctuate due to long cycles, higher spindle speeds, hybrid processes, and denser electronics. Thermal instability translates directly into scrap, rework, and lost throughput.

Even if you don’t manufacture rocket parts, your bottom line cares. A few hundredths of a millimeter can mean the difference between a first-pass yield and a week of regrinding.

Accuracy and precision: the direct consequences

If thermal behavior isn’t managed, you’ll see drift in axis positioning, spindle runout changes, and misaligned fixtures. What looked fine at the start of the shift may morph into a part that won’t assemble.

You’ll also find that multi-axis machining and complex five-axis moves are particularly unforgiving. Small thermal shifts compound across axes and rotations, resulting in geometry errors that are hard to trace back to a single cause.

Productivity and cost: the indirect consequences

Uncontrolled thermal effects force you into conservative feeds and speeds, slower cycles, and more frequent stops for inspection and adjustment. You’ll pay for extra tooling, extra labor, and possibly expedited shipping when parts miss their delivery windows.

If your shop pursues lights-out machining or high-mix low-volume work, thermal stability is not optional. It’s the quiet partner in every profitable run.

Where thermal errors come from

The sources of thermal error are many, and they’re sneaky. They don’t always show themselves as massive temperature spikes. Often, gradual heat build-up or tiny gradients are enough to move a column or rotate a spindle by microns.

- Heat generated by the spindle, servomotors, and drives

- Heat from cutting processes (friction and plastic deformation)

- Uneven ambient conditions, sun through a window, or AC cycling

- Heat from control cabinets or nearby equipment

- Thermal gradients caused by asymmetrical machine geometry or heat sinks

Types of thermal motion and how they affect parts

You’ll encounter several familiar behaviors: linear expansion, bending due to gradients, twist due to uneven heating, and local distortions around bearings or guides. Each behaves differently and needs tailored mitigation.

A warm column might cause a Z-axis drift; a hot spindle may change runout; a warmed table may sag — and any of these translate to an out-of-spec feature on your part.

A practical table of thermal error sources and mitigation

This table helps you connect common error sources with practical fixes you might expect from manufacturers.

| Source of thermal error | Typical magnitude (order) | Common mitigation techniques |

|---|---|---|

| Spindle heat (bearing/housing) | 1–100 µm | Spindle cooling (liquid or air), thermal encoders, active compensation |

| Axis drives and motors | 0.1–50 µm | Motor heat isolation, heat pipes, active cooling, remote motor placement |

| Cutting heat (tool/workpiece) | 0.1–200 µm | Optimized cutting parameters, coolant systems, toolpath planning |

| Ambient temperature swings | 0.1–500 µm (slow drift) | Environmental control, enclosures, thermal mapping |

| Control cabinet heat | 0.1–20 µm | Cabinet air handling, thermal separation, remote mounting |

| Structural gradients (asymmetry) | 1–500 µm | Symmetrical designs, fin placement, material choice, finite element design |

You’ll notice that the numbers vary widely. That’s because your process, part geometry, and machine type change the equation. The table helps you prioritize effort: spindles and structural gradients are often the biggest culprits.

How manufacturers engineer thermal stability: overview

Manufacturers don’t rely on one trick. They combine design choices, materials, active systems, sensors, and software to produce machines that behave predictably. The result is a system where thermal events are anticipated and either prevented or compensated.

You want a machine that behaves like a well-brought-up dog: it knows the rules and doesn’t embarrass you in front of a client.

Mechanical design strategies

Mechanical design is the first line of defense. Manufacturers engineer the structure to minimize thermal gradients and to isolate heat sources.

- Use of symmetric structures to minimize differential expansion

- Separation of heat-producing components from critical geometry

- Thermal breaks and insulators where appropriate

- Robust stiffness to reduce sensitivity to small movements

Materials and coefficients of thermal expansion (CTE)

Material selection is painfully practical. You want low and predictable CTE, good damping, and manufacturing feasibility. Materials are a compromise between cost and performance.

| Material | Typical CTE (µm/m·°C) | Advantages | Disadvantages |

|---|---|---|---|

| Cast iron | 10–12 | Cheap, stiff, good damping | Moderate CTE, microstructural variability |

| Polymer concrete | 6–8 | Low CTE, excellent damping | Cost, repairability |

| Granite | 5–7 | Low CTE, stable | Heavy, brittle |

| Steel | 11–13 | Very stiff, predictable | Higher CTE |

| Carbon fiber composites | 0–5 (anisotropic) | Low CTE, light | Complexity, cost, anisotropy |

You’ll notice polymer concrete and granite offer low CTE and damping, which is why they appear on premium machine frames. But cost, weight, and manufacturing practicalities keep cast iron common in many shops.

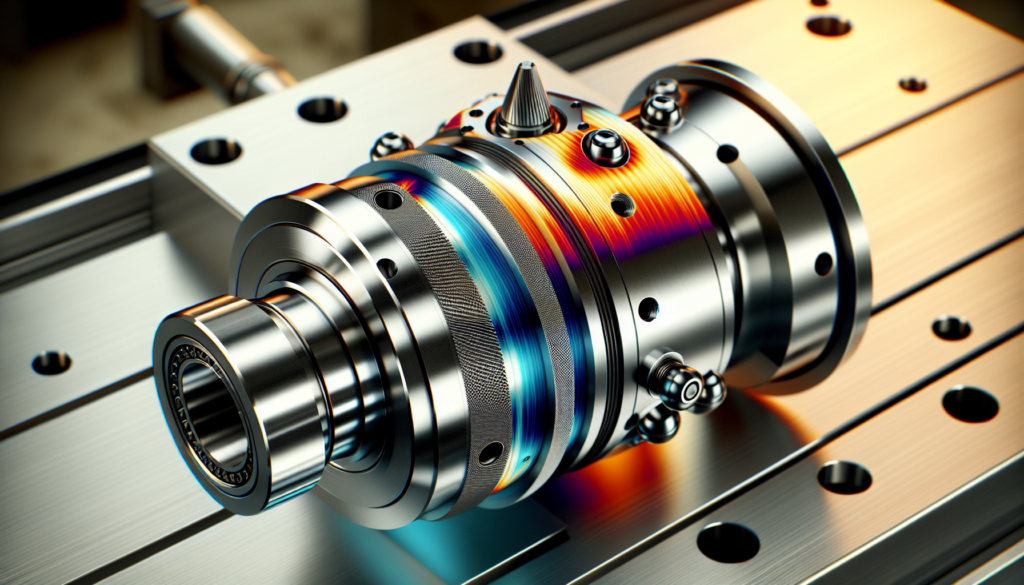

Symmetry and thermal centers

Designers aim to position heat sources symmetrically so expansion cancels out rather than compounds. You’ll see spindles centered, motors mirrored, and cable trays routed to avoid heating one side. The goal is a stable “thermal center” — a predictable point around which expansion occurs.

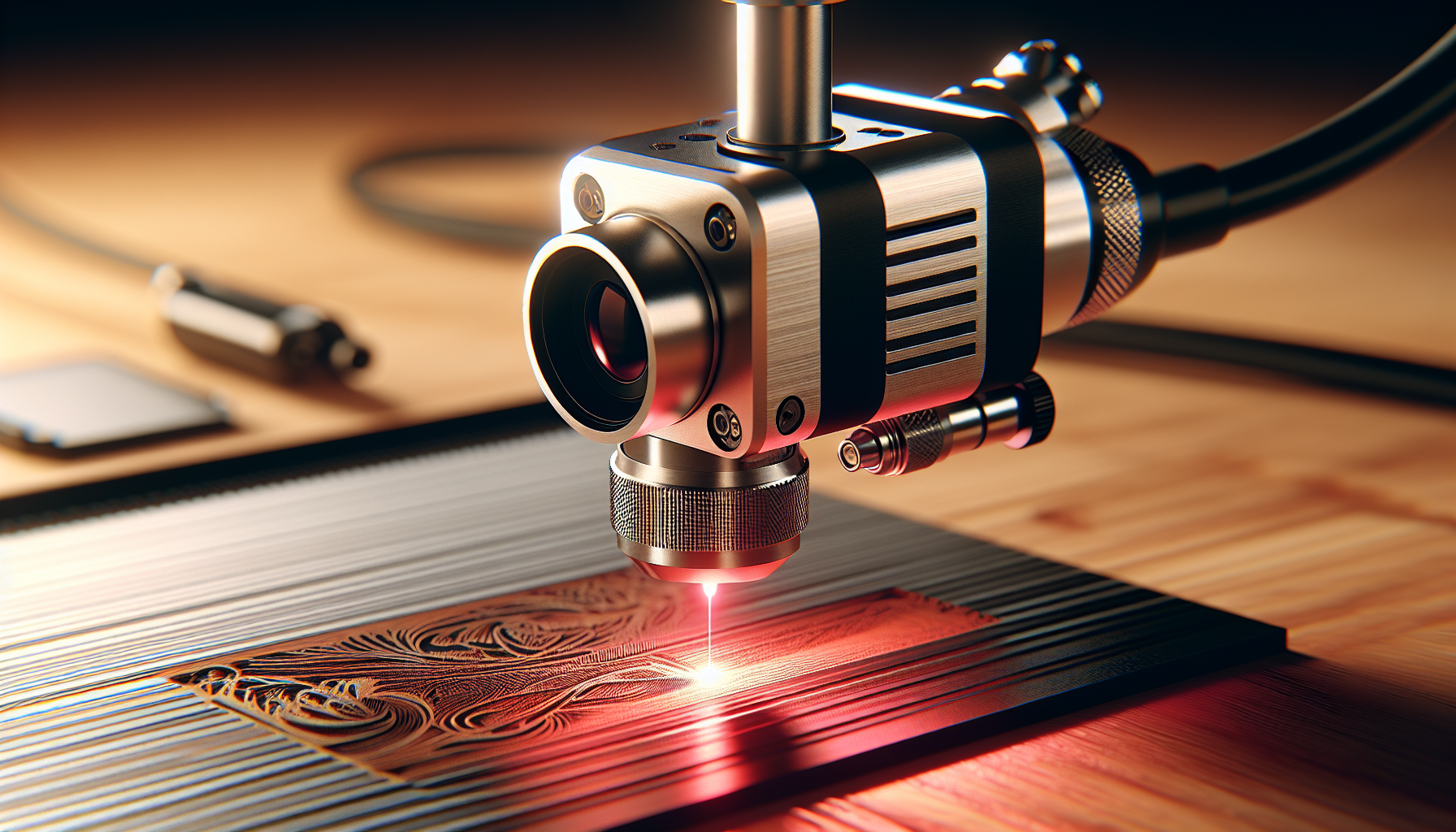

Spindle and motor thermal management

The spindle is often the hottest villain. Bearings, friction, and high-speed rotation generate heat right at the heart of your accuracy.

- Air-cooled spindles are simple and cheap but limited

- Liquid-cooled spindles transfer heat to a chiller for precise control

- Thermal isolation and Peltier elements are used for more exotic control

- Bearing type (ceramic vs. steel) affects heat generation and sensitivity

Spindle cooling methods and trade-offs

Here’s a quick comparison to help you understand what manufacturers choose and why.

| Cooling method | Typical control precision | Pros | Cons |

|---|---|---|---|

| Air cooling | Low to moderate | Low cost, simple | Less stable, affected by ambient |

| Liquid cooling (closed-loop) | High | Precise control, stable | Cost, maintenance, potential for leaks |

| Thermoelectric (Peltier) | High (local) | Fine local control | Power-hungry, limited capacity |

| Passive isolation | Low | Simple, low cost | No active control, limited effectiveness |

If your shop runs long cycles, you’ll appreciate liquid cooling or active compensation because they keep the spindle from wandering as the hours accumulate.

Thermal compensation software and modeling

You don’t have to eliminate heat entirely; you can model it and compensate. Modern CNC controls include thermal compensation algorithms that adjust offsets based on temperature readings or predicted behavior.

- Look-up tables for known warm-up behaviors

- Model-based compensation (FEA-informed)

- Real-time servo compensation using sensor feedback

- Adaptive compensation using machine learning

Manufacturers will often combine pre-calculated models with live sensor feedback so the machine corrects itself as the situation evolves.

How real-time compensation works

Your machine might read temperatures at critical points and then apply axis offsets continuously. If a column expands by 20 µm, the controller nudges the corresponding axis to correct for that movement. If this sounds like witchcraft, think of it as applying Newtonian physics in a very efficient way.

Sensors and instrumentation

Sensors are your machine’s nervous system. The better the sensory input, the smarter the compensation.

- Temperature sensors (PT100, thermistors) at bearings, motors, and structure

- Linear encoders with thermal compensation built in

- Displacement sensors (probe heads, gap sensors) for direct measurement

- Ambient sensors to monitor shop conditions

- Vibration sensors for related thermal-mechanical effects

Sensor types and practical specs

This table summarizes common sensors you’ll encounter and why they’re used.

| Sensor | Typical use | Accuracy | Notes |

|---|---|---|---|

| PT100 temperature sensor | Motor, spindle, structure | ±0.1–0.5°C | Reliable reference for compensation |

| Thermistor | Local temperature monitoring | ±0.2–1.0°C | Cost-effective, faster response |

| Linear encoder | Direct axis position | ≤0.1 µm (high-end) | Reduces reliance on thermal models |

| Displacement sensor (capacitive/eddy) | Local gap and movement | ≤0.01–1 µm | High precision, used in calibration |

| Vibration accelerometer | Spindle and structure health | Sensitive to g-levels | Useful for thermal-induced vibration trends |

You’ll see that investing in better sensors is not indulgent; it’s a way to reduce uncertainty. If the machine can measure what is happening, it can correct it.

Active thermal control systems

Manufacturers increasingly use systems that actively control temperatures rather than merely compensating for them after the fact.

- Chilled plates, fluid jackets, and embedded coolant channels

- Heating elements to keep components at stable temperatures in cold shops

- Local thermostatic control for bearings and guides

- Closed-loop systems that maintain parts of the machine at a setpoint

If you’ve ever watched a machine run a warm-up cycle, it’s because the manufacturer is trying to move the system into a predictable state before production.

Environmental and factory-level controls

Thermal stability is not only the machine’s problem. You will get far better results if the shop environment is controlled.

- Enclosures to reduce drafts and solar gain

- HVAC systems sized for machine heat loads, not just human comfort

- Separate ventilation for control cabinets

- Room-level thermal zoning and thermal buffering

You can buy all the cool systems in the machine, but if the unit sits under a skylight or next to a foundry pit, you’ll be fighting a losing battle.

Process planning and tooling strategies

Your choices in tooling and feeds matter. Heat generation happens at the cutting edge and in the chip.

- Use cutting strategies that reduce heat build-up, such as trochoidal milling

- Optimal coolant application to remove heat efficiently

- Toolholder selection to minimize thermal conduction into the spindle

- Minimize idle spindle speeds and avoid prolonged high-speed air cutting

You’ll save more by thinking about the process than by adding an extra chiller.

Calibration, acceptance testing and metrology

Even the best-engineered machine needs verification. Manufacturers provide prescribed test procedures so you can confirm thermal performance under conditions that mimic production.

- Warm-up tests and drift measurement over time

- Ballbar and laser interferometry to check axis fidelity

- Thermal mapping of structure and spindle during operation

- On-site acceptance with parts that mimic your production geometry

Recommended acceptance tests you should insist on

When you’re buying a machine, make these part of the acceptance protocol.

- Warm-up drift test: measure axis drift over standard warm-up period

- Ballbar test: checks circularity errors and servo performance

- Laser interferometer runs: measure positional stability to sub-micron levels

- Thermal mapping: correlate temperature points with geometric drift

- Process part run: machine a real part to ensure real-world performance

If the machine fails these tests, you will be happier to find out at acceptance than in the middle of a production run.

Machine learning, digital twins, and predictive maintenance

By 2026, AI and predictive models are mainstream. Manufacturers use machine learning and digital twins to predict thermal behavior and optimize compensation.

- Digital twins simulate machine thermal response for new processes

- ML models refine compensation by learning from prior runs

- Predictive maintenance flags components that cause changing thermal patterns

- Closed-loop systems update models as new data arrives

You’ll appreciate that a system which learns feels less like a rigid machine and more like a cooperative partner.

Summary table: strategies vs expected improvement

This table shows typical effectiveness you can expect from combining strategies. Your mileage will vary, but these numbers give a sense of scale.

| Strategy | Typical drift reduction | When to use |

|---|---|---|

| Symmetric mechanical design | 20–70% | New machine designs |

| Liquid spindle cooling | 40–90% | High-speed, long-run operations |

| Thermal sensors + software compensation | 50–95% | Existing machines with retrofits |

| Environmental control (room level) | 30–80% | Multiple machines or precision cells |

| Active local control (Peltier/heaters) | 30–80% | Special applications needing tight local control |

You should look at these as multiplicative gains. Combining approaches multiplies their effectiveness, but it also increases cost and complexity.

Practical case study: a hypothetical 5-axis job

You have a 5-axis aerospace bracket toleranced to ±10 µm. The shop is running 12-hour cycles with high spindle RPMs. Initially, you see features growing beyond tolerance after 4 hours.

Steps you (or a manufacturer) would take:

- Measure initial thermal map during the first 6 hours of a run and establish drift curves.

- Install additional temperature sensors on spindle, column, and table.

- Implement liquid cooling on the spindle and isolate the servo motors with thermal breaks.

- Update the control software with model-based compensation and set up live offset adjustments.

- Run a process part and validate with laser interferometry and coordinate measurement.

Result: drift reduced from ~35 µm to ~3–5 µm across the run, enabling consistent first-pass parts and supporting unattended overnight production. You’ll be the proud owner of a machine that behaves like it was raised on etiquette.

What you should ask manufacturers when buying in 2026

When you evaluate machines, you want questions that force the vendor to show their thermal thinking.

- What is the machine’s specified thermal drift per hour and across typical production cycles?

- Can you see warm-up drift test data for a machine with a similar process to mine?

- What sensors are standard and what is optional? Where are they located?

- Describe the spindle cooling system and expected temperature stability.

- How does the control software handle thermal compensation? Is it model-based, sensor-based, or both?

- What acceptance tests will you perform on-site for thermal performance?

- Is there a digital twin or simulation data for my process?

- What maintenance do thermal control systems require, and what’s the service plan?

If the salesperson answers vaguely, you should feel a little anxious. If they hand over data, diagrams, and perhaps a warm-up curve, you’ll feel like someone who has found a rare treat in a cereal box: unexpected and pleasing.

Cost vs benefit: how to prioritize

You won’t always buy every option, and you shouldn’t. Prioritize based on part tolerance, run length, and operational strategy.

- If you need tight tolerances and long runs: invest in spindle cooling, active compensation, and environmental control.

- If you do short runs and frequent tooling changes: invest more in robust calibration and sensors rather than elaborate cooling.

- If you plan lights-out machining: prioritize long-term stability and remote monitoring features.

You’ll find the best investments are those that reduce rework and increase first-pass yield.

Emerging trends to watch after 2026

Thermal engineering will continue to evolve. Expect more integration of sensors, embedded compensation, and materials with designer-tailored CTEs. Digital twins and AI will become more prescriptive, not just predictive.

- Embedded sensors throughout the structure as standard

- Increased use of metamaterials and graded composites

- Tighter integration between CAM and thermal models for process-specific compensation

- Standardized thermal performance benchmarks across manufacturers

You’ll notice machines that used to be black boxes opening up their data streams so you can be part of the behavior tuning.

Practical checklist for improving thermal stability in your shop

Use this quick checklist to decide where to start.

- Measure baseline: run a warm-up and map drift for a typical cycle

- Control the environment: eliminate direct sunlight and stabilize ambient temperature

- Optimize process: reduce heat generation with tooling and feeds

- Insist on spindle cooling for high-speed operations

- Add or upgrade sensors: temperature, encoders, displacement

- Request model-based compensation from manufacturer

- Plan acceptance tests that mimic your production conditions

- Employ preventive maintenance for cooling and thermal systems

If you follow these steps, you’ll find your parts fit better and your coffee tastes better because you sleep a little easier.

Final thoughts and practical actions you can take tomorrow

Thermal stability is less mystical than it appears. It’s a set of predictable behaviors that respond well to engineering: better materials, thoughtful geometry, active systems, and good data. You won’t fix every issue with a single purchase, but you can substantially reduce risk by prioritizing the right combination of design, sensors, and software.

Start small: measure and quantify. Once you have data, choices become clearer and less intimidating. You’ll feel empowered, not at the mercy of random thermal drama. And when you do certify that first run after implementing a thermal plan, you’ll quietly celebrate in a way that only makers can — by committing to the next job with a little more confidence and a lot less anxiety.