Have we ever wanted to shrink our workshop down to the size of a breadbox and still feel like we’re making something real?

What We’re Reviewing and Why It Matters

We’re talking about the RATTMMOTOR DIY CNC Router Kit, a 3-axis hobby CNC router that runs GRBL and targets beginners and tinkering fans like us. It’s a little desktop machine with a working envelope that’s meant to let us engrave and mill materials like wood, plastics, PCB stock, and even soft metals like aluminum and copper. If we’ve ever looked at a pile of mismatched coasters and thought, “Yes, but what if those coasters had our initials carved into them with alarming precision?”—this is our kind of project.

It’s small, modestly powered, and refreshingly affordable. What makes it interesting isn’t just what it can cut, but what it represents: a starter CNC experience that fits on a desk, takes an afternoon to assemble, and rewards patience with neat little things we made ourselves. That’s no small thing. In a world that constantly suggests we outsource our creativity, this machine whispers, “Let’s do it ourselves, even if we’re slightly terrified.”

RATTMMOTOR DIY CNC Router Kit, 3 Axis Hobby CNC Router Machine GRBL Control, Plastic Acrylic PVC PCB Wood Mini Desktop Engraving Milling Carving Machine, Working Area 300x180x45mm

Quick Summary of the RATTMMOTOR CNC in Real Use

The RATTMMOTOR kit is tidy, mostly aluminum, and surprisingly rigid for its size. The spindle is a 775-style DC motor running up to about 10,000 rpm at 24V. Motion is handled by 42-stepper motors (NEMA 17 class), and the updated GRBL control board supports PWM spindle control, an emergency stop button, and X/Y/Z limit switches (with the caveat that we’ll likely add those ourselves). It’s compatible with common G-code senders and design tools, and it’s clearly aimed at hobbyists who want an easy way in.

Is it a powerhouse? No. Is it a cheerful, steady lab partner that doesn’t talk much but gets the job done? Yes. Provided we feed it reasonable cutting settings and pick sensible materials, it’s very capable.

The Specs at a Glance

Let’s look at the most important numbers. Specs can feel like bedtime reading, but here they actually help us predict what the machine can and can’t do.

| Feature | Details |

|---|---|

| Product Name | RATTMMOTOR DIY CNC Router Kit, 3 Axis Hobby CNC Router Machine (GRBL Control) |

| Frame Size | 420 x 350 x 270 mm (16.53 x 13.78 x 10.63 inches) |

| Working Area | Listed as 300 x 180 x 45 mm (about 11.8 x 7.1 x 1.8 inches). Some materials also mention 180 x 100 x 45 mm; the 300 x 180 x 45 mm figure is the one we’d plan around. |

| Frame Material | Black injection-molded external frame with aluminum alloy working table |

| Motion and Mechanics | X/Y/Z driven by stainless steel screw rods and 42 stepper motors |

| Stepper Motors | 12V, 1.3A phase current, 2.1 ohms, rated torque about 0.25 N·m |

| Spindle | 775 DC spindle, 12–24V, about 10,000 rpm at 24V |

| Controller | GRBL-based board with PWM support, silent cooling fan, offline controller auto-identification |

| Safety/Limit Support | Board supports emergency stop button and X/Y/Z limit switches (user-installable) |

| Supported Materials | Wood, plastics (acrylic, PVC), PCB, carbon fiber, MDF/density board, and soft metals (aluminum, copper). Not suitable for hard metals, jade, glass, or other hard/brittle materials. |

| Use Case | DIY engraving, small-form milling, hobby prototyping, custom signage |

We want to call out that working-area discrepancy. The listing name says 300 x 180 x 45 mm, while some text also mentions 180 x 100 x 45 mm. In practice, the most common size for machines of this class is 300 x 180 x 45 mm, and that’s the expectation all over the hobby CNC universe. Our recommendation is to plan for 300 x 180 x 45 mm, but don’t be shocked if usable space is a few millimeters less after fixturing and margin allowances. That’s normal in small CNCs: the bed size and the actually reachable cutting space rarely match perfectly, just like our plans and our Saturday afternoons.

Who This Machine Is For

We’d suggest this kit for:

- Beginners who want to learn CNC without graduating straight to industrial complexity.

- Tinkerers who like to customize, upgrade, and squeeze performance from modest tools.

- Makers working primarily in wood, plastics, PCB, and occasional soft-metal jobs.

- Anyone who wants to engrave signage, mill small parts, produce PCB prototypes, or make gifts that look more impressive than they were difficult.

If we plan to regularly cut steel or carve gemstones, this machine politely laughs and excuses itself. But if we want to learn, make, and iterate, it’s a welcoming place to start.

Unboxing and First Impressions

We open the box and there are rails, the aluminum bed, bags of screws labeled just enough to keep us honest, and that 775 spindle that looks like it drank coffee and wants to please. The black injection-molded frame is lighter than we expect, but it doesn’t feel flimsy. The aluminum bed has that “we’re serious about flatness” vibe, though at this price point we keep our expectations in check and our shims within reach.

There’s a paper manual and a USB flash drive. The manual is the kind we appreciate: more pictures than florid prose, more steps than we thought but fewer than we feared. The USB stick includes drivers, sample G-code, and PDFs. It’s delightful to see something not stuck behind a QR code. Tradition still has a seat at the table.

Assembly: From Box to Bench in a Single Afternoon

We’re not going to pretend it builds itself, but the assembly here hits that sweet spot: purposeful without feeling like a punishment. With a small set of hex keys and a respectable amount of patience, we can build this in a few hours. We recommend laying out the parts, putting the fasteners in small cups, and listening to something five percent more soothing than our usual playlist.

Tips for assembly:

- Don’t fully tighten everything at first. Get all the pieces aligned, then cinch it down.

- Square the gantry to the bed. It’s fussy, but worth it, like a really good grilled cheese.

- Verify the lead screws are straight and parallel to the rails. It reduces binding on the steppers later.

- Route cables cleanly and avoid putting strain on connectors.

The machine is small, so we won’t need a dedicated workbench—though we’ll want a sturdy, flat surface. If our desk wobbles when we type with feeling, add a board or relocate to a steadier perch.

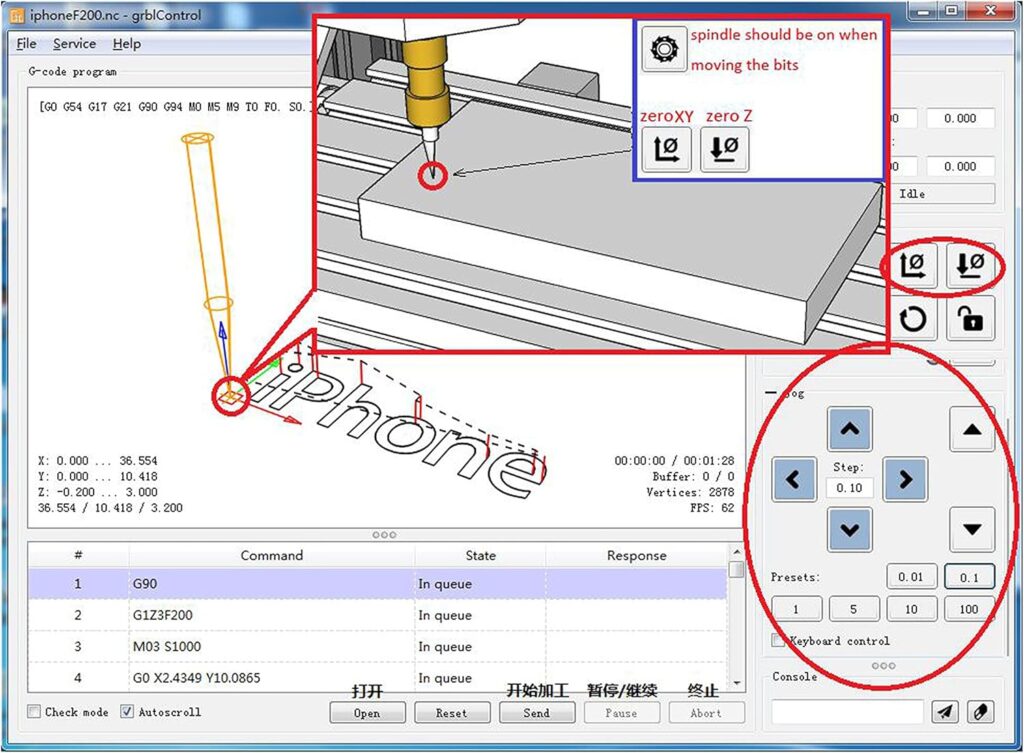

Software: What We’ll Use to Design and Cut

CNC feels like three hobbies in a trench coat: design, toolpaths, and machine control. The RATTMMOTOR uses GRBL, which is a massive win for compatibility. That means we can use common software in each phase:

- Design: Inkscape for vector work (free), Fusion 360 for 3D designs (personal use limits, but still robust), or Carbide Create for a simple 2D workflow.

- CAM/Toolpaths: Fusion 360 CAM, or plug-ins like JSCut/Inkscape extensions for generating G-code from vectors. For engraving text or logos, LightBurn-style workflows aren’t applicable unless we’re running a laser module, but V-carve tools in other software can help.

- G-code Sender: Candle, Universal Gcode Sender (UGS), or OpenBuilds CONTROL are all solid.

Connecting the machine by USB, we’ll identify the COM port and choose a basic sender like Candle. If we’re allergic to laptops in the workshop, the board can auto-detect an offline controller; that’s a separate accessory we can add later.

The Controller: GRBL, PWM, and What That Means for Us

GRBL is the heart here. It turns G-code into step pulses for the motors and PWM signals to control spindle speed on the 775 motor. The updated control board supports:

- An emergency stop button (E-stop) connection.

- Limit switches for X, Y, and Z axes.

- PWM support for spindle control.

- A silent cooling fan, which keeps the board from sweating while we work.

We like that the machine recognizes an offline controller; that gives us options. Safety matters too. The board supports E-stop and limit switches, but those don’t always arrive pre-installed. We can wire them easily enough if we’re comfortable with basic electronics. If the phrase “limit switch” induces dread, think of it as a way to stop the machine from ramming itself into the ends like a dog forgetting about sliding glass doors.

What It Cuts Well (and What It Doesn’t)

This machine is meant for:

- Wood (softwoods, hardwoods, plywood, MDF)

- Plastics (acrylic, PVC)

- PCB materials

- Carbon fiber (with care, dust extraction, and proper PPE)

- Soft metals (aluminum, copper)

It’s not meant for:

- Glass

- Jade

- Hardened steel or other hard metals

- Anything that needs heavy cutting forces or roughing at aggressive rates

With aluminum and copper, we keep cuts shallow, feed rates conservative, and bits sharp. If we’re patient, the results can be very good for hobby work. If we’re impatient, we’ll get chatter, gummy chips, and bits that one day we’ll find lodged in a wall like a tiny dart.

Everyday Performance: What We Can Expect

The 775 spindle is the guiding star here. It doesn’t have towering torque, but it spins fast and stays relatively quiet compared to routers. For engraving wood and plastics, it’s in its element. For PCB milling, it’s nimble enough to trace delicate features with the right bit and tape-and-glue workholding.

The machine’s structure—part injection-molded frame, part aluminum bed—manages a sensible balance between rigidity and ease of assembly. The stainless steel screw rods give predictable motion, and the 42-stepper motors are plenty for the forces involved.

Cut quality is a dance between the material, our bit choice, and our parameters. We like single-flute bits for aluminum, upcut end mills for wood, and V-bits for engraving. If we pick the right bit and don’t try to “prove something” with speed, we’ll be pleasantly surprised.

Accuracy and Repeatability

We know we’re not buying a metrology-grade machine. That said, small CNCs often deliver good repeatability if we keep the mechanics clean and tensioned. The RATTMMOTOR’s screw-driven axes tend to produce less backlash than belts at this price range, though the trade-off is speed.

Realistically, for wood and plastic, we’ll get clean edges and dimensions within the tolerances that craft projects and hobby enclosures require. For PCB traces, careful calibration matters: set steps/mm correctly, and don’t forget Z-axis calibration. V-carved letters and decorative pockets come out crisp if we keep the depth of cut modest and our clamping secure.

Noise, Heat, and The Joy of a Fan That Whispers

The spindle is quieter than a trim router, a small mercy for neighbors and pets. The board’s silent cooling fan does the job without whining. Cutting noise depends on material and feeds, but we can run this machine in a home office if we have reasonable sound tolerance. It’s not silent; it is, however, far less offensive than most power tools.

Heat on the spindle becomes an issue only if we push it too hard, cut without chips evacuating, or run dull bits. If it starts to smell like an electrical greeting card, we back off.

Workholding: The Difference Between Success and Slapstick

The aluminum bed is our anchor, but we still need to hold the work. Here are approaches we like:

- T-track clamps or low-profile clamps that don’t sit in the toolpath’s way.

- Double-sided Nitto tape or carpet tape for thin stock and PCBs.

- The “blue tape and CA glue” trick: painter’s tape on the bed and the stock, then thin CA glue between them. It holds well and releases with a putty knife’s gentle persuasion.

Avoid overly tall clamps. We don’t want the tool to clip hardware and reenact the worst kind of surprise party.

Learning Curve: Gentle, But Real

We can assemble it and make something the same day, but the best results appear after a few projects. The hardest part is less about the machine and more about the mental model: toolpaths are their own language. Pocketing, profiling, adaptive clearing—each has a purpose. Once we learn how to pick step-down and feed rates, we begin to feel in control. There’s a thrill in hearing the cut sound “right,” a dance between hum and whirr where the chips fly exactly as they should.

Setup and Calibration Checklist

To get good results quickly, we run through these steps:

- Square and tighten the frame after initial assembly.

- Verify the axes move smoothly with no binding.

- Set the steps/mm for each axis in GRBL, using known lead screw pitch and stepper microstepping. Most kits come with reasonable defaults, but checking is free.

- Tramming: Make sure the spindle is roughly perpendicular to the bed. On a small machine, “good-enough” tramming still matters for surface finish.

- Surface the spoilboard if we add one. Flatness makes everything better.

- Confirm spindle direction is correct. Clockwise from the top. If it’s not, address wiring polarity.

A few minutes of calibration saves hours of confusion and regret, which is also true in baking and relationships.

Realistic Feeds and Speeds for Common Materials

We’ll share general starting points, always with the reminder to sneak up on aggression slowly:

- Softwood (pine): 2-flute upcut, 1/8” bit, 0.5–1 mm depth per pass, 400–600 mm/min, high spindle speed.

- Hardwood (maple, oak): 1/8” 2-flute upcut, 0.3–0.7 mm per pass, 300–500 mm/min.

- Acrylic: Single-flute O bit, 0.3–0.6 mm per pass, 300–600 mm/min, high spindle speed; avoid melting by ensuring chips, not dust.

- MDF: 1/8” upcut, 0.7–1 mm per pass, 400–700 mm/min; consider dust control carefully.

- Aluminum: Single-flute 1/8” end mill, 0.1–0.3 mm per pass, 200–400 mm/min, high spindle speed; keep chips clear with brush or light air.

It’s fine to start even more conservatively. The moment we hear chatter or see a burnished surface, we reduce depth or speed. The machine rewards care with smooth edges and predictable results.

The GRBL Board’s Safety Features: Not Glamorous, But Worthy

We wish every hobby CNC shipped with a big red mushroom switch by default. Here, the board supports an emergency stop; some kits include one and some expect us to add it. We recommend adding it. It’s a small price for the ability to stop everything when we make a mistake (which we will, because we’re gloriously human).

Limit switches are also supported. These are little mechanical or optical switches that define the “maximum” travel and enable homing cycles. They save our machine from smacking into its endpoints and help establish repeatable origins. They require some wiring, but nothing ominous.

Materials: Let’s Talk Aluminum, Plastics, and PCB

- Wood: Beautiful results, especially with V-carving and simple pocketing. Small signs, coasters, inlays, and boxes are all fair game.

- Acrylic: Clear, glossy edges require the right bit and feeds. If we get cloudy edges, we’re rubbing instead of cutting. Try a single-flute bit and ensure chips are evacuating.

- PVC: Cuts well, just mind fumes and dust. A gentle pace yields tidy edges.

- PCB: With a small V-bit or a 0.8 mm flat, we can isolate traces for prototypes. The key is flatness; a warped board will make traces spotty. Consider a surfacing pass on a spoilboard, then use tape-and-glue to hold the PCB perfectly flat.

- Aluminum/copper: Think of these as “slow and steady.” Tiny step-downs and sharp single-flute bits are the way. We’re not making engine blocks here; we’re creating small brackets, faceplates, and tasteful ornaments.

Maintenance: Easy Rituals for Long-Term Happiness

- Keep the screw rods clean and lightly lubricated.

- Vacuum chips often; don’t let powdery MDF cake onto the rails.

- Periodically check that all frame screws remain tight.

- Replace dull bits promptly. A dull bit is a saboteur with a cheerful grin.

- Inspect wiring occasionally, especially around moving axes where flexing happens.

We give it care, it gives us accuracy.

Upgrades We Like

We love a platform that invites tinkering. A few sensible upgrades:

- Add an E-stop button if not included.

- Install X/Y/Z limit switches and enable homing in GRBL.

- Add a spoilboard on top of the aluminum bed. This preserves the bed and lets us screw into something sacrificial.

- Better end mills. The bits we use matter more than we want to believe.

- Cable chains for tidy wiring if not already present.

- Light dust shoe and a small shop-vac for cleanup.

We can go farther—Z-probe, spindle PWM tuning, even a small diode laser module if we’re into engraving (observe safety protocols). But we don’t need to do it all at once.

Comparing It to the Usual Suspects

There’s a crowded world of 3018-style CNC kits. The RATTMMOTOR fits into that familiar “300 x 180 x ~45 mm” space with a reliable GRBL base. What stands out here:

- A control board with PWM, E-stop/limit support, and a quiet fan.

- Aluminum bed and a thoughtful frame design.

- A kit focused on entry-level ease without dropping basic quality.

We’d pick it over cheaper, no-name boards that skip safety and compatibility. If we need larger work areas or more power, we’ll look at bigger spindles and heavier frames—but for desk-sized projects, this one pulls its weight.

Table: What We Can Make on Day One vs. Day Thirty

A little reality check (and a confidence booster):

| Time With the Machine | Projects That Feel Good |

|---|---|

| Day One | Nameplates in MDF, simple text engravings in pine, a test grid in acrylic to check feeds/speeds. |

| Week One | PCB trace isolation, small inlays, acrylic signs with clean edges, custom drawer labels. |

| Day Thirty | Aluminum brackets with neat holes and countersinks, multi-step layered signs, fitted boxes with pocketed foam inserts, tidy jigs for other projects. |

We don’t have to be a wizard. We just have to keep making things, one tidy project at a time.

The Learning Moments We All Encounter

- Z zero wasn’t what we thought. We forgot stock top vs. machine bed. The cutter decided to give us a gentle lesson.

- Clamp in the toolpath. The machine doesn’t know, it just obeys. Plan clamp placement carefully.

- Wrong post-processor. Use standard GRBL G-code; anything fancy confuses the controller.

- Bits slipping in the collet. Tighten properly and keep collets clean. A slipping bit is a sneaky source of ruined cuts.

- The “melted acrylic” incident. It happens when we’re rubbing, not cutting—fix with chip load and bit choice.

Each mishap is a small tuition payment to the school of making.

Safety: Not Dramatic, Just Necessary

- Eye protection is non-negotiable. Tiny chips are perpetual optimists and will try to reach our eyes.

- Ear protection helps on longer jobs.

- Dust matters, especially with MDF and carbon fiber. Use a mask, move air away, and clean up thoroughly.

- Keep sleeves and hair away from spinning parts. We like our sleeves and hair where they currently reside.

We’re not being alarmists—just sensible.

Customer Experience and Brand Notes

RATTMMOTOR has carved out a space in the hobby market with components, motors, and little machines that tend to focus on value. That means two things: 1) we get a lot for the price, and 2) we should be prepared to be slightly resourceful. In our experience, they do well with essentials: documentation that’s usable, controls that make sense, and a board that behaves as expected with GRBL tools.

We also like the way the control board is pitched: not locked down, not precious. It wants us to attach an E-stop, add limit switches, and treat it like a real machine, just small.

The Good, The Limits, and The Honest Middle

What’s clearly good:

- Compact and approachable, yet structurally decent for its size.

- GRBL compatibility makes software straightforward.

- PWM spindle control and support for E-stop and limit switches.

- Aluminum bed and stainless screw rods.

- Quiet-ish operation for a spindle.

Where we accept limits:

- The 775 spindle isn’t for heavy cuts in metal. Take small bites.

- Working area is small; we make small things or big things in pieces.

- Accuracy is hobby-grade. It’s not a machine-tool dynasty heirloom.

And the honest middle:

- The frame’s injection-molded elements are fine for intended materials, but don’t expect industrial rigidity.

- We’ll almost certainly tinker. Which, if we’re honest, is part of the fun.

Troubleshooting Guide: Little Problems, Quick Fixes

- Axis skips steps: Reduce depth of cut, check for binding, ensure current to steppers is appropriately set, and verify the couplers are tight.

- Spindle bogs down: Dull bit, too much depth or feed, wrong bit for the material, or chips not clearing.

- Wavy edges in wood: Check rigidity and reduce lateral forces. Consider climb vs. conventional cutting; conventional often gives better results on flexible systems.

- GRBL alarm on homing: Limit switch noise or miswiring. Add pull-ups/pull-downs as needed, keep signal wires away from spindle wires.

- G-code stops mid-job: USB power management can interfere. Disable USB sleep and screensaver; use a powered USB hub if needed.

Small machines are detail-driven. When something’s off, the fix is usually right there in front of us, waving politely.

Our Favorite Projects for This Machine

- Custom coasters with V-carved monograms in walnut or maple.

- Acrylic desk nameplates with frosted engravings and edge-lit LED frames.

- PCB prototypes for that gadget we promise we’ll actually finish this time.

- Small aluminum brackets for enclosures, drilled and pocketed to fit like they were ordered from a catalog.

- Engraved tags for tool cabinets, kitchen containers, and our cat’s many existential states.

Each one is a neat bit of proof: we can make things precisely, and they can look good on a shelf or in the palm of a hand.

Careful Cuts in Aluminum: A Short Love Letter to Single-Flute Bits

We can’t resist sharing one practical tip that pays dividends: in soft metals on small spindles, single-flute cutters are a quiet triumph. They evacuate chips better at lower machine rigidity and spindle power. That means our cut stays cool and our spindle doesn’t groan. Combine tiny step-downs (0.1–0.2 mm), sensible feed, and consistent coolant-free chip clearing (a soft brush, light air puff), and we get neat pockets with sharp edges. It’s not fast, but it’s deeply satisfying.

Longevity and Repairability

One of the things we admire about kits like this is how replaceable everything is. Spindle dies? We can source another 775. Stepper motor gives up? 42-stepper replacements are everywhere. Controller acts haunted? GRBL boards are plentiful. The machine is Lego-like in spirit; if something fails, we can diagnose it and swap it. That’s empowering, and it extends the life of the whole setup.

A Few Quiet Pleasures in Daily Use

- Zeroing Z with a thin shim of paper and feeling that gentle tug as the bit just kisses the surface.

- Watching a V-carve finish pass reveal impossibly crisp letterforms.

- Finding the perfect clamp placement and realizing the job will run without incident.

- Hearing the spindle settle into a sound that says, “We got it.”

These are the silly, secret joys that make hobby CNC an oddly meditative pastime.

Responsible Material Choices and Dust Control

If we plan on carbon fiber or a lot of MDF, we’ll add dust control. A small vacuum and a makeshift shroud do wonders. Carbon fiber dust is not something we want to breathe; even a simple enclosure around the machine can help contain debris. The same applies to acrylic if we want clear edges without snow-globe chaos.

For woods, remember that hardwood dust can be irritating. We wear a mask and keep the area clean. Our lungs will send us thank-you notes for years.

Real-World Footprint and Home Setup

The frame size—roughly 42 x 35 x 27 cm—means it fits comfortably on a desk or a utility cart. We reserve a bit of space to the side for the controller, the laptop (or an offline controller), and a tray for bits and collets. Good lighting is worth more than we remember; a simple LED lamp aimed at the bed makes setup and inspection kinder to our eyes.

If we share a space with others, it helps to have a predictable routine: warn about noise, run longer jobs when the house is awake, and keep chips contained. The machine’s relatively low noise floor makes it the neighborly choice among power tools.

The RATTMMOTOR Difference: Control Board Thoughtfulness

We keep coming back to the updated GRBL control board. The PWM support is table stakes now, but the fan choice and the support for E-stop and limit switches show an understanding of what beginners need as they become intermediate users. We can start simple and add safety layers as we learn.

Also, the machine’s ability to auto-identify an offline controller is small but meaningful. If our laptop hates dust or if we just want to keep things minimal, that option is a comfort.

The “I’m New to CNC” Reassurance Section

If we’re nervous, that’s normal. CNC is a set of tools that look more complicated than they are. Our first job might be a simple engraving on MDF. We’ll see it run and think, “I did that.” Then we’ll try a pocket and a profile cut. Pretty soon we’ll know words like “adaptive clearing” and use them casually at parties where they absolutely do not belong.

The RATTMMOTOR kit makes those first steps gentle. It removes the friction of proprietary software and keeps hardware fuss to a minimum, while leaving doors open for upgrades down the line.

Repair, Warranty, and Community

Because the platform is GRBL and the components are common, we’re never stranded. Reddit, forums, and hobby CNC communities can answer nearly any question we’ll have. If a part fails, replacements don’t require a treasure hunt. That kind of ecosystem is priceless for a first machine.

As for warranty, we check the seller’s terms, but the bigger story here is the widespread availability of equivalents. In a pinch, we can solve most problems with a few messages and a part from a reputable vendor.

Where It Surprises Us

- PCB isolation routing that looks surprisingly professional, given the scale.

- V-carving in hardwood that produces crisp details that feel like cheating.

- Aluminum jobs that, when done patiently, look like they came from a far more expensive machine.

No, we can’t hog out pockets like a CNC router with a one-horsepower spindle. But we can make small, precise things with a kind of charm: the charm of knowing how they were made.

Keeping It Honest: The Working Area Note

It’s worth repeating that many listings quote a 300 x 180 x 45 mm working area for this class of machine. Occasionally, we see text blurbs that mention 180 x 100 x 45 mm—likely an error or confusion with another variant. We plan our designs assuming roughly 300 x 180 mm in X and Y and up to 45 mm in Z, minus the height of the stock and the bit. That leaves room for jigs and clamps and a realistic sense of what fits.

Value: What We’re Paying For

We’re not just buying a device. We’re buying a learning platform and a tiny factory that takes orders from our laptop. The RATTMMOTOR kit offers a strong cost-to-capability ratio, especially with a controller that embraces open standards and future upgrades. For hobbyists, the value is in how quickly we can go from idea to physical object—no long setup, no cryptic software. Just us, the machine, and a procession of increasingly confident projects.

Our Verdict in One Breath (And Then a Few More)

It’s a great starter CNC for hobbyists who understand its lane. With a compact footprint, a friendly GRBL heart, a 775 spindle that behaves if we treat it kindly, and a bed that clamps and cleans without fuss, we get a practical workshop companion. The board’s support for E-stop and limit switches, along with PWM and a quiet fan, shows that the design is future-minded.

Will we outgrow it? Possibly, after many projects, when the work we want to do asks for a bigger envelope or more power. But for a first machine—or a second machine that lives on a desk and handles day-to-day jobs—it’s an easy recommendation.

Pros and Cons We’d Tell a Friend

Pros:

- Compact, beginner-friendly, and surprisingly capable.

- GRBL compatibility means easy software choices.

- Aluminum bed and stainless screw rods feel solid for the price.

- Control board supports E-stop, limit switches, PWM, and offline control.

- Reasonable noise; fits well in home workshops.

Cons:

- Modest spindle power; aluminum requires patience.

- Working area is limited to small projects.

- Limit switches and E-stop may require user installation.

- Injection-molded frame is fine for intended use but not ultra-rigid.

In short: if we know what we’re buying, we’ll be happy with what we get.

The “First Five Projects We’d Do” Playbook

- Engraved MDF calibration plate with grid lines to test accuracy and squareness.

- A small hardwood nameplate with V-carved lettering and a chamfered edge.

- An acrylic sign with a frosted engraving and clean, flame-polished-looking edges from correct settings.

- A PCB prototype for a simple LED circuit, just to prove we can do it.

- A tiny aluminum bracket with two perfectly spaced holes, the kind of part that makes us smile for no good reason.

Each project tells us something, and together they tell us we’re ready for more.

Final Thoughts: Make, Tinker, Repeat

We love the spirit of this machine. It doesn’t pretend to be a monster, and it doesn’t sulk when we treat it with patience. It’s a companion for making things we can hold, gift, and use. The RATTMMOTOR DIY CNC Router Kit—3 Axis, GRBL-controlled, with a 775 spindle and a sturdy little frame—fits beautifully into the hobbyist’s life. We set it up, we learn the rhythm, and we make. That’s the story we’re after.

And if we’re being honest, there’s a peculiar happiness in watching a tiny spindle draw our ideas into wood or plastic, one careful line at a time. It’s proof that we don’t need a warehouse to build our world; a desk will do, and a small machine will happily help us do it.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.