Have you ever bought a tool that promised to make your life simpler and then discovered it required a minor engineering degree and a healthy tolerance for swearing?

Best CNC Machines For Metalworking In 2026: Engineering-Grade Results At Any Scale

You’re about to read a pragmatic, slightly opinionated guide to the best CNC machines for metalworking in 2026. The aim is to give you clear comparisons, buying checklists, and real-world advice so you can make buying and operating decisions without being sold a fantasy.

Who this guide is for

You might be a hobbyist graduating into paid work, a small job shop owner trying to scale, or a manufacturing engineer tasked with specifying equipment for production. This guide gives you the language, benchmarks, and comparisons you need so you don’t end up with the wrong machine at the wrong price.

How to use this guide

Skim to the sections that match your operating scale — benchtop, job shop, production, or multi-tasking — and then read the buying checklist before you make any purchase. Use the comparison tables to prioritize stiffness, spindle performance, and service network over marketing copy.

Key performance metrics to compare

Before you fall in love with glossy photos, you need to know which numbers actually matter for metalworking. Those numbers will determine whether you cut aluminum like butter or file it like an antique.

Rigidity and construction

Rigidity is the single most important predictor of surface finish, tool life, and overall accuracy in metal cutting. Cast iron beds, box ways or linear guides, and well-supported spindles all add up to a machine that fights vibration instead of encouraging it.

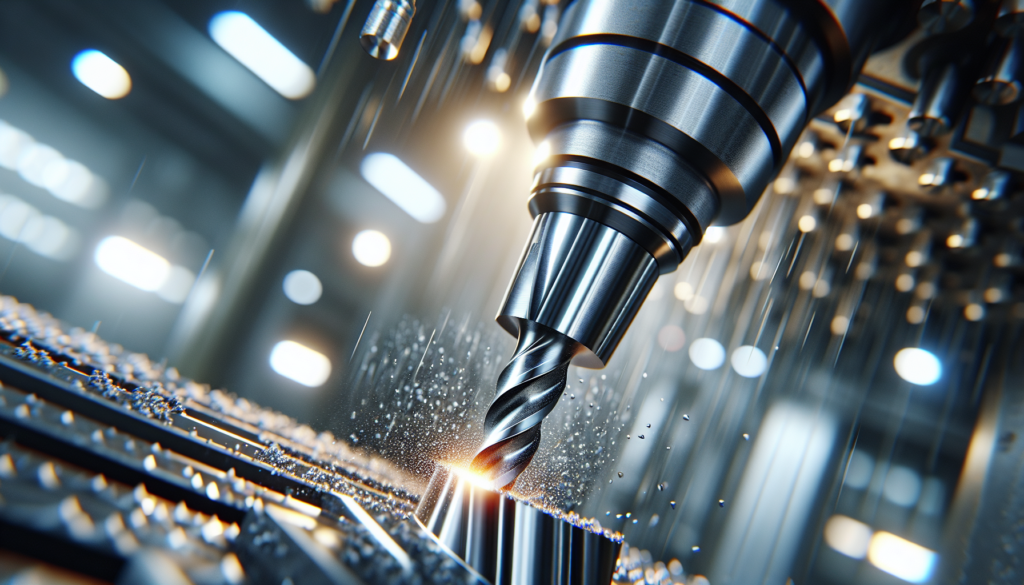

Spindle power and speeds

Spindle power and maximum RPMs dictate what materials and cutting strategies you can use. Higher power helps heavy cuts in steels; higher RPMs let you use small-diameter tooling effectively in aluminum and brass.

Axis configuration and travel

X, Y, and Z travels determine the largest part you can machine, while additional axes (C, B, full 5-axis) open possibilities for fewer setups and more complex geometries. Consider the envelope plus fixturing space required for your most common jobs.

Tooling and automatic tool changers (ATC)

ATCs save enormous time on medium- to high-volume work; more pockets in the magazine usually mean fewer interruptions. Also consider the tool holder standard: CAT/BT/HSK have different stiffness and compatibility trade-offs.

Controllers and software compatibility

Fanuc, Siemens, Heidenhain, and proprietary controllers each have ecosystems of CAM post-processors and operators. Choose a controller your programmers and operators are comfortable with — support matters more than novelty.

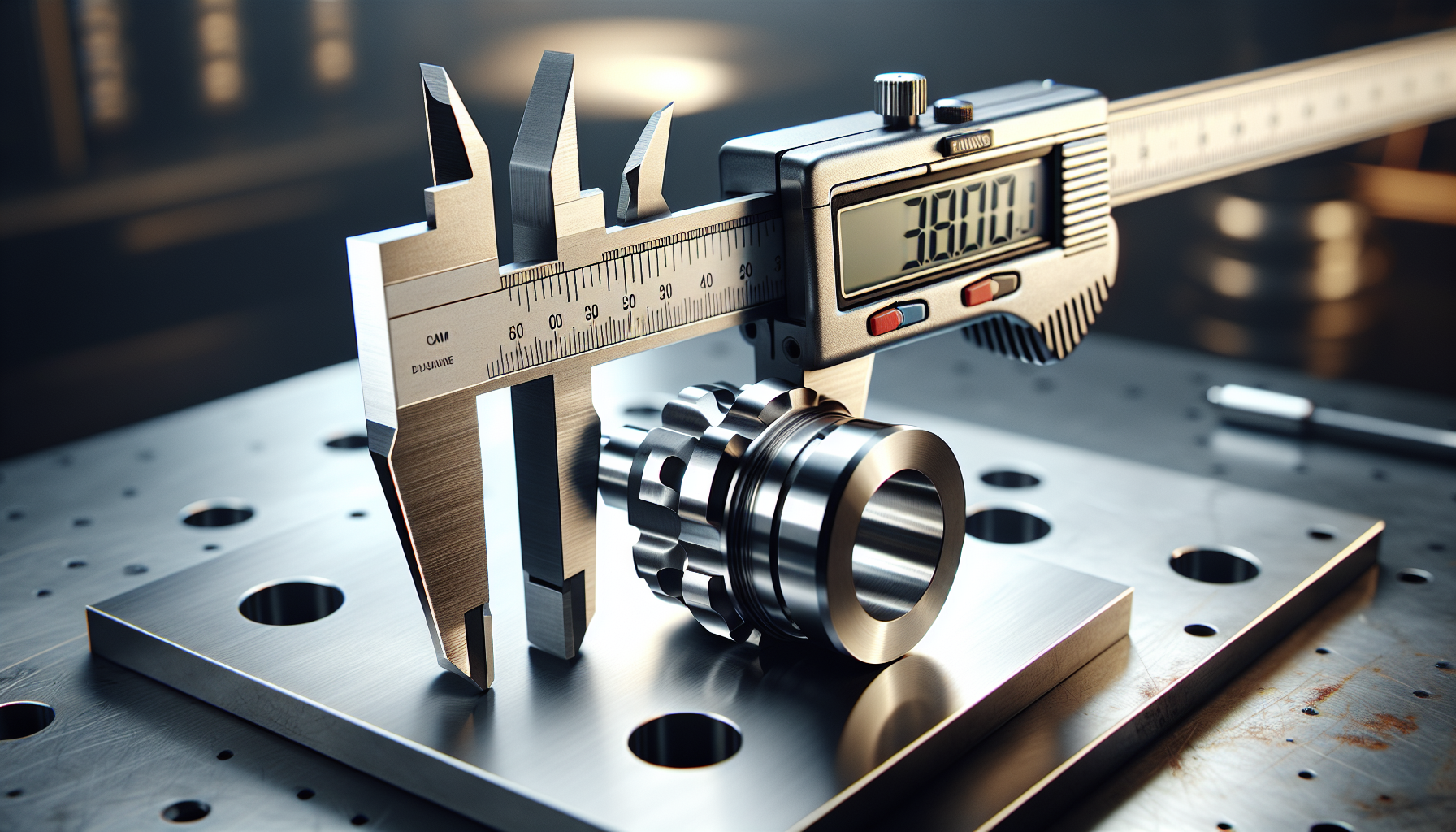

Accuracy, repeatability and tolerances

Accuracy (how close you get to the intended dimension) and repeatability (how consistently you get it) matter when you’re specifying tolerances of ±0.01 mm or better. Look at published position accuracy, but ask for machine test reports or probe runs if you need high precision.

Cooling and chip evacuation

Coolant strategy — flood, through-spindle coolant, mist, or dry — affects tool life, surface finish, and shop cleanliness. Good chip evacuation and conveyors are non-negotiable when you’re cutting steel or running high material removal rates.

Automation and tool management

Part conveyors, robotic loading, pallet changers, and tool presetters let you scale from manual runs to lights-out manufacturing. Factor in the extra programming and fixturing cost against the runtime savings you expect.

Categories and recommended machines

You’re choosing among very different machines depending on lot size, material, precision, and budget. Below are categories with recommended models and why they matter.

Best benchtop / light industrial CNC mills

You want a machine that fits a small shop, gives you real metal-cutting capability, and doesn’t double as a home renovation project.

Tormach 1100 or Tormach 770 series remain top choices for light industrial work because they balance rigidity with affordability and a strong aftermarket ecosystem. These machines are friendly to beginners but offer upgrades like spindle RPMs, ATC, and enclosures as your needs grow.

Table: Benchtop / Light Industrial Comparison

| Model | X×Y×Z Travel (mm) | Spindle RPM | Tooling | ATC optional | Typical price (USD) |

|---|---|---|---|---|---|

| Tormach PCNC 770 | 508×305×254 | 24,000 (with spindle upgrade) | Metric collets | Optional | 8k–15k |

| Tormach 1100MX | 762×406×254 | 10,000–20,000 | BT30/collet | Optional | 15k–25k |

| Haas Mini Mill | 406×305×305 | 8,100 | BT30 | Optional | 20k–30k |

Pros: Affordable, repairable, great user communities and documented upgrades.

Cons: Not ideal for high-volume or hard-steel heavy cuts without upgrades.

Best small job-shop vertical machining centers

When you’re producing parts for local customers and tolerance matters, you need higher rigidity and a reliable service network.

Haas VF-series, Hurco VMX, and Hurco’s conversational control are commonly recommended at this level because they combine robust frames with accessible controls. Haas gives you an extensive dealer network and predictable prices, while Hurco’s conversational control can speed prototyping.

Table: Small Job-Shop Vertical Mills

| Model | X×Y×Z (mm) | Spindle Power (kW) | Tool Capacity | Controller | Typical price |

|---|---|---|---|---|---|

| Haas VF-2 | 762×406×508 | 11 kW | 24–30 | Haas | 60k–80k |

| Hurco VMX30 | 762×406×508 | 11–15 kW | 30–40 | WinMax | 70k–95k |

| Okuma MB-56V | 1,016×610×610 | 15 kW | 30+ | OSP | 85k–120k |

Pros: Solid frames, available extensions (probing, coolant-through-tool), and compact shop footprints.

Cons: Higher upfront cost than benchtop machines and more expensive preventative maintenance.

Best mid-to-high production milling centers

You need speed and accuracy over longer runs, and the machine should be able to run multiple shifts with minimal surprises.

DMG Mori CMX/U-series and Haas UMC series are great for midsize production. The UMC series (universal machining centers) adds a rotary axis standard on some models and improves second-op capabilities with multi-axis fixturing.

Table: Mid-Production Vertical Mills

| Model | X×Y×Z (mm) | Spindle (RPM / kW) | ATC Pockets | Multi-Axis | Typical price |

|---|---|---|---|---|---|

| DMG Mori CMX 1100 | 1,100×540×560 | 15k–18k / 15 kW | 30–60 | 4/5-axis options | 200k+ |

| Haas UMC-500/750 | 508/762×406/508×508 | 10k–12k / 15 kW | 20–30 | 4/5-axis | 120k–250k |

| Mazak VCN | Various | 12k–18k / 15–22 kW | 30–60 | 4/5-axis options | 150k–300k |

Pros: Built for long runs with higher MRR and automation options.

Cons: Require more shop infrastructure and skilled operators.

Best turning centers and lathes

If you primarily make shafts, bushings, and rotational parts, a lathe gives you faster cycles and simpler setups.

DMG Mori NLX, Haas ST series, Okuma LB-series, and Mazak Quick Turn are all common choices. Multi-axis turning centers with live tools let you do milling operations on the lathe so you can finish complex parts in one setup.

Table: Turning Centers Comparison

| Model | Swing over bed (mm) | Max bar diameter | Live tooling | Control | Typical price |

|---|---|---|---|---|---|

| DMG Mori NLX | 400–560 | 65–102 mm | Yes | Fanuc | 120k–250k |

| Haas ST-20 | 340–430 | 51–76 mm | Optional | Haas | 60k–120k |

| Okuma LB | 400–700 | 65–127 mm | Yes | OSP | 150k–300k |

Pros: Fast spindle speeds, robust part handling, and single-op capability for many geometries.

Cons: Multi-task machines cost more and need more tool and program management.

Best 5-axis machining centers

You need fewer setups and better surface finishes on complex geometry without sacrificing accuracy.

DMG Mori DMU series, Mazak Variaxis, and Hurco 5-axis tables handle aerospace and medical geometries with fewer fixtures. True 5-axis capability is invaluable when you want to machine one-side parts or reduce secondary operations.

Table: 5-Axis Comparison

| Model | Travel (mm) | Table size | Spindle (kW/RPM) | Typical price |

|---|---|---|---|---|

| DMG Mori DMU | 800×600×600 | 630 mm | 18–30 kW / 12k–18k | 300k–700k |

| Mazak Variaxis | Various | 500–800 mm | 15–30 kW | 250k–600k |

| Hurco 5-axis | Various | 500–700 mm | 15 kW | 200k–450k |

Pros: Dramatically reduces setups, improves accuracy and cycle times for complex parts.

Cons: Higher programming complexity and upfront cost.

Best mill-turn and multi-tasking centers

You want true single-op capability so you can feed raw bar stock and deliver finished parts from the same machine.

Mazak Integrex, DMG Mori NT/CT series, and Okuma MULTUS are leaders in mill-turn. These machines reduce handling errors and cycle time by combining high-speed milling heads and powerful spindles with bar feeders and live tooling.

Table: Mill-Turn Multi-Tasking Machines

| Model | Max turning dia. | Milling spindle | Bar feeder capacity | Typical price |

|---|---|---|---|---|

| Mazak Integrex | 300–600 mm | 12–18 kW | Optional | 400k–1M+ |

| DMG Mori NT | 300–700 mm | 15–30 kW | Optional | 350k–900k |

| Okuma MULTUS | 300–600 mm | 18 kW | Optional | 350k–900k |

Pros: Highest throughput and fewest setups for complex parts.

Cons: Complex to program and costly to maintain.

Best small-part high-precision CNC (medical, watchmaking)

When tolerances are tight and part size is small, rigidity and spindle dynamics matter more than travel.

Brother Speedio and similar compact sliding-head machines deliver very high surface finishes and cycle times for small parts. They’re well-suited for medical implants, watch parts, and small aerospace components.

Table: High-Precision Small-Part Machines

| Model | Travel (mm) | Spindle RPM | Typical applications | Typical price |

|---|---|---|---|---|

| Brother Speedio | 300×200×200 | 30k–60k | Medical, electronics | 80k–200k |

| Citizen Cincom | Small | 18k–30k | Swiss-type parts | 70k–250k |

Pros: Extremely fast for small parts, excellent surface finish.

Cons: Limited to small diameters and bar-fed work.

Buying checklist: what to prioritize

Before you sign any purchase order, verify these items against your expected production needs. Think of this as the list your future self will thank you for.

- Production volume and batch size: Choose ATC and automation if you’ll run medium-to-large batches or need lights-out.

- Material mix: Hard steels require rigidity and higher spindle power; aluminum emphasizes RPM and chip evacuation.

- Axes needed: Fewer setups are worth investing in for complex parts; a rotary table may solve many problems for less money than a full 5-axis.

- Tooling ecosystem: Factor in HSK/BT/CAT holders, tool length options, and probe compatibility.

- Service and support: A strong dealer network minimizes downtime; ask about remote diagnostics and spare parts lead times.

- Floor space and utilities: Confirm power, compressed air, coolant disposal, and crane access for delivery and installation.

- Controller familiarity: Avoid exotic controls if your programmers and operators prefer Fanuc or Siemens.

- Total cost of ownership: Include consumables, tooling, labor, training, and expected maintenance in your ROI calculation.

Cost and ROI

You’ll spend more up front for better stiffness, higher spindle power, and a reputable service network — but you’ll make less in emergency repairs and faster cycles. Budget ranges in 2026 broadly look like this: entry benchtop $8k–30k, job-shop verticals $60k–150k, production/5-axis $200k–700k, and mill-turn $350k–1M+.

Calculate ROI by forecasting part price, cycle time improvements, labor savings, and scrap reduction. If you reduce setups by 30% using a 5-axis center, that frequently pays for the machine in a few years for complex parts.

Software and CAM

Your CAM choice affects cycle times, surface finish, and programming time more than many believe. Compatibility with the machine’s controller and a good post-processor are essential.

Common CAMs:

- Fusion 360: Affordable and accessible for small shops; cloud-based features aid collaboration.

- Mastercam: Industry standard for complex toolpaths and post-processing.

- Siemens NX / CAM / SolidCAM: Used for high-end aerospace and automotive work with advanced simultaneous 5-axis strategies.

- Post-processors: Ensure your CAM can produce code for Fanuc, Siemens, Heidenhain, or the machine’s proprietary control.

Table: CAM Quick Comparison

| CAM | Best for | Price tier | Strengths |

|---|---|---|---|

| Fusion 360 | Startups and prototyping | Low | Integrated CAD/CAM, cloud |

| Mastercam | Job shops | Mid | Toolpath optimization, posts |

| Siemens NX | High-end production | High | Advanced 5-axis, simulation |

| SolidCAM | Integrated with SolidWorks | Mid-High | iMachining, seamless SolidWorks integration |

Tooling and consumables

Tooling is the invisible cost that surprises many buyers; quality tools usually pay for themselves in reduced cycle time and fewer part rejects. Spend time on the right tool geometry, coatings, and holders for your material.

Common tooling and costs to budget for:

- End mills and roughing cutters: Carbide with appropriate coatings.

- Collet sets and tool holders: BT/CAT/HSK families; invest in a precision set.

- Coolant and filtration: Proper coolant and filtration extend tool and spindle life.

- Probing systems: Renishaw and third-party probes pay off by reducing scrap and setup time.

- Workholding: Modular vises, tombstones, and CNC fixtures increase throughput.

Shop setup and safety

Machine choice impacts your shop layout and safety requirements more than you might expect. Factor in chip management, coolant containment, and access for maintenance.

- Electrical and foundation: Confirm power requirements and whether a reinforced floor or anchor plates are necessary.

- Ventilation and filtration: Coolant mist collectors and chip conveyors keep the shop clean and compliant.

- Noise and ergonomics: Higher-power machines make more noise; plan operator stations accordingly.

- Personal protective equipment (PPE): Eye protection, hearing protection, and safe loading practices for heavy parts.

Maintenance and lifecycle

Preventative maintenance prevents the worst kind of surprises: downtime when a customer needs parts yesterday. Track hours, lubricate per recommendations, and keep consumable spares on hand.

Suggested maintenance schedule:

- Daily: Clean chips, check coolant level, inspect tooling and holders.

- Weekly: Check way lubrication, belt tensions, and air lines.

- Monthly: Inspect spindle runout, coolant concentration, and machine leveling.

- Annually: Professional calibration, ball-screw checks, and servo tuning.

Table: Maintenance Checklist

| Interval | Tasks |

|---|---|

| Daily | Clean chips, empty chip bin, check coolant |

| Weekly | Lubricate ways, inspect filters, check belt tension |

| Monthly | Check spindle runout, clean fans, software backups |

| Annually | Full calibration, ball-screw inspection, controller backup |

Troubleshooting common machining problems

When parts come out wrong, a systematic approach will save you time and frustration. Below are common issues, likely causes, and quick fixes.

Table: Problem / Cause / Fix

| Problem | Likely cause | Fix |

|---|---|---|

| Poor surface finish | Vibration, dull tool, incorrect speeds | Reduce DOC, increase RPM, change tool, check rigidity |

| Excessive tool wear | Wrong coating, high heat, built-up edge | Use coolant, change coating, adjust speeds |

| Dimensional variation | Thermal growth, spindle runout, fixturing shifts | Temperature control, probe checks, re-fixture |

| Chatter | Lack of rigidity, long overhang, incorrect parameters | Shorten tool overhang, stiffen setup, tune feeds |

Buying used vs new

You’ll save up front by buying used, but you’ll pay in unpredictability and potential hidden repairs. New machines give you warranty coverage, updated controls, and certified calibration.

Pros of used:

- Lower acquisition cost and faster lead times.

- Good for prototyping shops or one-off needs.

Cons of used:

- No warranty, possible hidden wear, older control platforms.

- May lack modern features like through-spindle coolant or dynamic balancing.

If you buy used, request documentation: maintenance logs, spindle runout tests, and a demo part. Factor in a recondition or retrofit budget for bearings, ballscrews, and control upgrades.

Retrofitting and upgrades

If you’re not ready to buy new, retrofits can extend the life and capabilities of an older machine. Common upgrades include control retrofits, servo replacement, retrofitting ATC or probe systems, and spindle replacements.

Benefits: Cost-effective way to add modern functionality and improve reliability.

Downsides: Sometimes the cost of an extensive retrofit approaches that of a new machine with a warranty.

Environmental and regulatory considerations

Disposing of cutting fluids, controlling emissions, and managing noise are not optional in most jurisdictions. Plan for hazardous waste disposal and ensure your coolant and filtration systems meet local rules.

- Waste fluid recycling: Budget for a collection and recycling program.

- Emissions and ventilation: Install proper extraction if you use mist generators or asbestos-like coatings.

- Noise and safety: Comply with workplace safety standards and OSHA-like rules in your location.

Case scenarios: which machine fits your needs

Below are a few short examples of how different operators benefit from certain classes of machines.

Scenario 1 — The precision prototype shop You run small batches of complicated aerospace brackets with tight tolerances and frequent design changes. A 5-axis DMG Mori or Mazak Variaxis will cut setups and reduce scrap, and a CAM investment will pay back in fewer hours spent fixturing.

Scenario 2 — The local fabrication shop moving into parts production You make fixtures and now want to enter OEM part production in volume. A mid-range Haas VF or Hurco VMX with an upgraded toolchanger and probe system gives you the best balance of cost, service, and scalability.

Scenario 3 — The lights-out production cell You need a machine to run overnight with minimal supervision to hit delivery windows. A mill-turn machine with an automated bar feeder and pallet changer, plus remote monitoring, allows truly unattended operations and predictable cycle times.

Scenario 4 — The hobbyist turned contractor You’re cutting small batches of aluminum and titanium for motorcycle parts in a single garage bay. Tormach 1100MX with improved spindle and coolant can handle this work with a much lower total investment and learning curve.

Final recommendations

If you’re primarily cutting small to medium batches and learning the ropes, choose a machine with an upgrade path (ATC, higher RPM, more travel). If you’re committed to multi-shift production, prioritize rigidity, service network, and automation. For complex geometry or high-mix, invest in multi-axis capability and a strong CAM/post-processing setup.

Quick reference comparison of top picks

This table gives you a succinct look at the machines discussed and the contexts in which they shine.

| Category | Typical best pick | Strengths | Typical price |

|---|---|---|---|

| Benchtop / Light Industrial | Tormach 1100MX / PCNC 770 | Affordability, upgradability, community | 8k–25k |

| Small Job Shop Mill | Haas VF-2 / Hurco VMX30 | Dealer network, proven reliability | 60k–120k |

| Mid Production Mill | DMG Mori CMX / Haas UMC | Production-ready, multi-axis options | 120k–300k |

| Turning Center | DMG Mori NLX / Haas ST | Fast cycles, live tooling available | 60k–250k |

| 5-Axis | DMG Mori DMU / Mazak Variaxis | Single-setup complexity reduction | 250k–700k |

| Mill-Turn | Mazak Integrex / Okuma MULTUS | One-machine single-op finishing | 350k–1M+ |

| Precision Small Parts | Brother Speedio / Citizen | High RPM, small-part throughput | 70k–200k |

You’ll probably be tempted to buy the flashiest machine you can afford, but patience and a clear understanding of your part mix will pay dividends. Match the machine to the parts, not the parts to the machine.

If you want, I can help you narrow this down by budget, part sizes, and material mix, and then build a two-year ROI forecast that includes tooling and maintenance.