?Have you ever bought a shiny new tool you were certain would transform everything, only to watch it gather dust because the screws were stripped and the instruction manual was written in hieroglyphs?

Why AI Enhances Fabrication Only When Fundamentals Are Right

You can be seduced by glossy demos and flawless slide decks promising factories that sing and robots that choreograph themselves. You should remember that AI is a magnifying glass, not a miracle; it amplifies what is already there, for better or for worse.

The Promise and the Pitfall — AI as a Fancy Hammer

When you picture AI in fabrication, you likely imagine faster cycles, fewer defects, and someone else inventing your success for you. You should be wary: AI will make great processes exceptional and miserable processes catastrophic at scale.

The Allure of Automation

You want fewer repetitive tasks and more time for high-value decisions, which is why automation feels irresistible. You should also know that automation without clarity can harden chaos into a reproducible disaster.

When the Hammer Meets a Plastic Spoon

You might automate a step that never needed automation, wasting time and money while removing the very flexibility that saved you before. You have to match capability to need; otherwise the tool does not solve the problem — it becomes the problem.

The Fundamentals of Fabrication

You cannot skip the basics and expect AI to catch up for you; fabrication relies on a web of practices that must be solid. You should care about each element because AI depends on consistency, clarity, and quality at every layer.

Design and Engineering Intent

You must codify why a part looks and behaves the way it does, not just what it looks like. You should keep tolerances, functional goals, and failure modes explicit so AI can optimize rather than guess.

Material Science and Traceability

You need to know what the stuff of your parts actually is, batch by batch. You will find AI tripped up by hidden variances, so traceability and clear material specs are non-negotiable.

Process Control and Standard Operating Procedures

You must document how something is made in unambiguous steps with controllable variables. You will find that AI thrives when the process is repeatable and the control points are measurable.

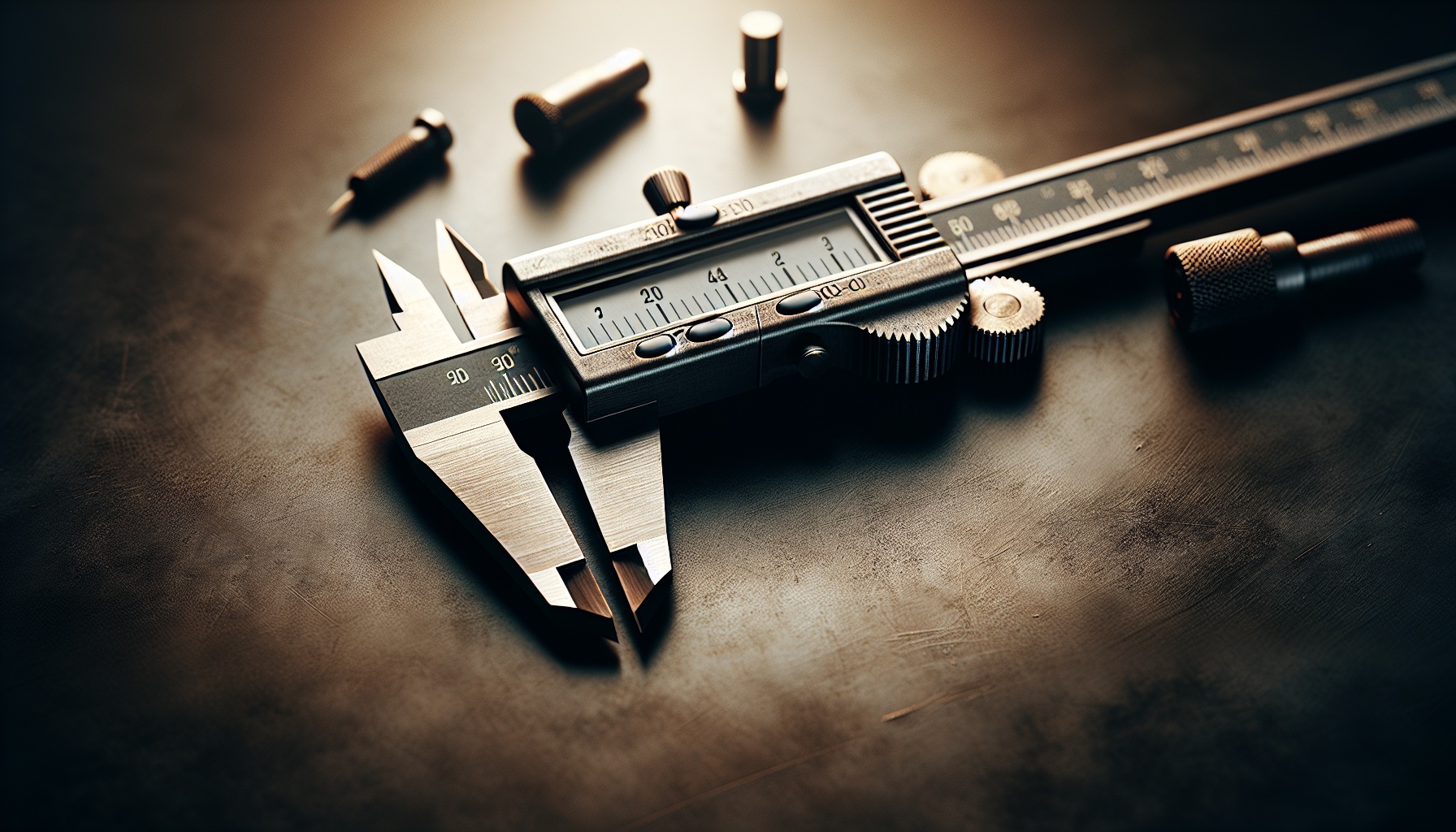

Measurement, Inspection, and Metrology

You have to measure things accurately and consistently before you let AI judge them. You should invest in metrology and clear inspection criteria; without them, AI has no yardstick.

Skilled Workforce and Domain Knowledge

You must maintain human expertise that understands edge cases and can interpret AI outputs. You will always want people who can question, override, and improve AI decisions.

Maintenance and Equipment Health

You should keep machines maintained, calibrated, and documented because AI expects reliable inputs. You will get misleading signals if sensors drift or equipment behaves inconsistently.

Data Infrastructure and Quality

You need clean, contextualized data stored in ways that allow queries and audits. You must avoid fragmented spreadsheets and tribal knowledge if you expect AI to learn usefully.

Quality Management Systems

You should embed your quality rules and corrective actions into formal systems so AI recommendations fit regulatory realities. You will find it hard to adopt AI without documented processes for deviation, root cause, and containment.

Supply Chain and Vendor Coordination

You must align suppliers on specs, data exchange, and lead times so AI can optimize flows. You will face brittle systems when data from upstream or downstream partners is late, wrong, or missing.

Safety, Regulatory, and Ethical Considerations

You should treat safety as primary and regulatory compliance as a constraint AI must honor. You will regret automated decisions that omit human oversight when they touch safety-critical functions.

How AI Adds Value When Fundamentals Are Strong

You should think of AI as an amplifier for what already works; when fundamentals are strong, gains are multiplicative rather than marginal. You will see better outcomes in speed, cost, quality, and innovation when AI has a solid substrate to operate on.

Design Optimization and Generative Design

You can feed robust design intent and constraints into AI and get optimized forms you might never have conceived. You should still judge those forms for manufacturability and serviceability before committing to production.

Predictive Maintenance and Remaining Useful Life

You can reduce downtime by predicting failures from sensor patterns and logs, instead of reacting to earthquakes of smoke and sirens. You should verify models against realistic scenarios; false positives cost money, and false negatives cost credibility.

Process Control and Real-Time Adjustments

You can let AI tune process parameters in real time to compensate for drift and material differences. You should ensure closed-loop changes are bounded and reversible, with humans able to step in.

Visual Inspection and Quality Assurance

You can use computer vision to find defects at speeds and scales human inspectors can’t match. You should calibrate those vision systems to real defects and maintain a labeled dataset; otherwise they will mistake harmless marks for catastrophe.

Digital Twins and Simulation

You can build digital twins that predict how a line will behave under different conditions, enabling scenario planning. You should align the twin’s fidelity to the decisions it supports—overly complex models are costly while overly simple ones mislead.

Supply Chain Optimization and Scheduling

You can coordinate production, inventory, and logistics with AI that reduces waste and shortens lead times. You should keep data flows between systems consistent and timely, or you will optimize the wrong picture of reality.

Human-in-the-Loop Collaboration

You can augment human decision-making with AI recommendations rather than replacing judgement. You should create interfaces that make AI rationales transparent so you can trust and correct them.

A Table That Summarizes Where AI Helps Most

You should find it useful to see where AI impacts fabrication, and under what conditions. The table below gives a snapshot to help you prioritize.

| Area | When Fundamentals Are Strong | Risk When Fundamentals Are Weak |

|---|---|---|

| Design Optimization | Rapid, manufacturable innovations | Unmanufacturable or fragile designs |

| Predictive Maintenance | High uptime, lower spare inventory | False alarms or missed failures |

| Process Control | Consistent quality with self-tuning | Automated drift and systemic defects |

| Visual Inspection | Rapid defect detection, fewer escapes | High false positives/negatives |

| Digital Twins | Safe scenario testing, capacity planning | Misleading simulations |

| Supply Chain Optimization | Reduced waste, better scheduling | Optimized garbage |

| Human-AI Collaboration | Better decisions, learning loops | Confusion and mistrust |

Common Failure Modes When Fundamentals Are Weak

You will encounter predictable failure modes if you try to force AI into a shaky environment. You should recognize these patterns early to avoid wasted investment.

Garbage In, Garbage Out

You will feed AI inconsistent, noisy, or incomplete data and expect magic; it won’t appear. You should clean, label, and contextualize data before trusting model outputs.

Overfitting to Anomalies

You may train models on idiosyncratic events and get brittle predictions for usual conditions. You must ensure training data represents the full operational envelope.

Automation of Bad Practices

You might automate a workaround that was never meant as a standard, embedding poor practices into every product. You should standardize and correct processes before automating them.

Misaligned Objectives

You could optimize for throughput while quality erodes, because objectives were defined too narrowly. You must design balanced KPIs that reflect the full cost of decisions.

Lack of Explainability

You may deploy models that produce decisions you cannot trace or justify, which becomes a legal and operational liability. You must prefer explainable approaches in safety- or compliance-critical areas.

Cultural Resistance and Trust Deficit

You might see operators distrust or circumvent AI if it feels opaque or punitive. You should involve users early, show wins, and design feedback channels.

Practical Roadmap: Make Fundamentals Right Before AI

You will want a pragmatic, phased approach so AI becomes an accelerator rather than a crisis catalyst. You should use a phase-gated plan that stabilizes basics, pilots use cases, and scales once validated.

Phase 1 — Assess and Prioritize

You should inventory processes, data, and pain points with a small cross-functional team. You will prioritize use cases that offer measurable ROI and are bounded enough to pilot.

Phase 2 — Stabilize the Basics

You must standardize SOPs, improve metrology, and tidy data sources. You will train staff and fix chronic equipment issues so inputs are reliable.

Phase 3 — Instrument and Measure

You should add or calibrate sensors, define KPIs, and build data pipelines from the factory floor to analytics. You will make sure data is timestamped, labeled, and auditable.

Phase 4 — Pilot Targeted AI Use Cases

You should run short, focused pilots with clear success criteria and rollback plans. You will test models in parallel with existing methods before trusting them for live decisions.

Phase 5 — Scale and Govern

You must operationalize successful pilots with governance, monitoring, and continuous improvement. You will maintain human oversight and updated training data to avoid drift.

A Practical Implementation Checklist

You will appreciate a punch-list you can actually act on, rather than a manifesto you file and forget. You should use this checklist as a living document tied to your roadmap.

- Define clear business objectives and KPIs for each AI use case.

- Audit and clean historical data; set up pipelines for new data.

- Standardize processes and document exceptions.

- Improve traceability for materials and parts.

- Instrument machines with reliable sensors and timestamps.

- Implement metrology and inspection standards.

- Pilot with human-in-the-loop oversight and transparent models.

- Create rollback plans and safety constraints for automated actions.

- Train staff on both tool use and interpretation of AI outputs.

- Monitor model performance and update datasets periodically.

- Establish governance and responsibility for model decisions.

- Coordinate with suppliers and customers on shared data standards.

Roles, Responsibilities, and Governance

You have to define who owns what, because ambiguity is the enemy of consistency. You should create accountable roles for data, models, and production decisions, and make governance practical rather than bureaucratic.

Suggested Roles

You will find it useful to map responsibilities to roles such as data engineer, model owner, process engineer, quality manager, and line operator. You should ensure each role has clear decision rights, escalation paths, and performance metrics.

Governance Practices

You must implement model registries, version control, and change logs so you can audit decisions and roll back problematic models. You will also set thresholds for human approval and automated action.

Tools and Technologies Worth Your Attention

You will want to know which technologies can help you with each step without chasing fads. You should balance ambition with pragmatism and choose tools that integrate with your existing stacks.

Data Infrastructure

You should adopt robust time-series databases, data lakes with governance, and pipelines that standardize formats. You will need tools that allow fast queries for engineers and readable exports for auditors.

Machine Learning Platforms

You might use platforms that support model lifecycle management, explainability, and monitoring. You should prefer modular tools that let you swap models as understanding improves.

Computer Vision Systems

You can deploy vision systems for inspection and situational awareness. You should pick solutions with easy retraining workflows and edge deployment if latency or bandwidth is a concern.

Edge and IIoT Devices

You should consider edge computing for low-latency inference and industrial IoT for sensor aggregation. You will want robust security and remote management features.

Simulation and Digital Twin Tools

You might use simulation to validate changes before touching live lines. You should ensure the twin incorporates the same metrics and failure modes you measure on the floor.

Case Studies and Vignettes (You as the Protagonist)

You will relate to small stories because practical context clarifies how decisions play out. You should imagine yourself in these scenes to see where fundamentals matter.

Vignette: The Sheet-Metal Shop That Panicked

You decide to automate defect detection with a fancy camera. You rush the installation, feed the model a handful of images from that morning, and flip the switch. Next week, you find parts piled up because the camera flags harmless burr patterns as rejects. You end up retraining the model with labeled examples and fixing the deburring process that created the burrs. The moral: you automated the symptom, not the cause.

Vignette: The Plant That Trusted a Perfect Model

You commission a predictive maintenance model trained on six months of data from a single machine that rarely failed. For a while, the model looks perfect, but when a new supplier changes bearing tolerances, the model misses the first signs of failure. You backtrack, add data from more conditions, and implement thresholds requiring human sign-off for critical actions. The moral: broader data and human checks prevent overconfidence.

Vignette: The Line That Learned to Breathe

You instrument a line with better sensors and standardized SOPs, then pilot an AI model that tweaks parameters within safe bounds. Operators see fewer defects and learn to trust the system because they can override and give feedback. Productivity rises and downtime falls because you fixed the basics first, then used AI to tune. The moral: good foundations plus incremental automation scale sustainably.

Measuring Success: KPIs and Metrics You Should Track

You will need concrete KPIs to determine whether AI is genuinely helping or merely generating reports. You should select a balanced set that spans performance, quality, cost, and human factors.

| KPI Category | Example Metrics | Why They Matter |

|---|---|---|

| Throughput | Cycle time, parts/hour | Direct link to capacity and lead time |

| Quality | First-pass yield, defect rate, escapes | Measures customer-facing outcomes |

| Cost | Cost per part, scrap cost, rework hours | Reflects financial benefits of AI |

| Availability | Mean time between failures (MTBF), downtime | Shows equipment health improvements |

| Predictive Accuracy | Precision, recall for defect detection | Determines trustworthiness of models |

| Human Factors | Operator overrides, training hours, satisfaction | Tracks adoption and cultural impact |

| Sustainability | Energy per part, material waste | Ties optimization to environmental goals |

Balancing Speed and Prudence

You will be tempted to move fast to capture perceived advantages, but haste can bake mistakes into processes. You should adopt a bias for fast experiments with safe rollback and a bias for deliberate scaling once pilots prove out.

Reskilling and Cultural Change

You must invest in people because even the best AI is just a set of recommendations without competent humans to act on them. You should run training programs focused on interpretation, troubleshooting, and continuous improvement so your team feels empowered rather than threatened.

Practical Training Steps

You will pair operators with data scientists to build empathy and shared language. You should create micro-courses that teach operators to validate model suggestions and feed corrections back into the system.

Incentives and Recognition

You should reward people who catch anomalies, improve data quality, or contribute labels for training. You will find that recognition fosters participation far better than mandates.

Regulatory, Safety, and Ethical Guardrails

You should embed compliance checks in model outputs and ensure traceability for decisions that affect safety or customer obligations. You will need documented approval workflows for models that take autonomous actions.

Example Controls

You must maintain audit trails, emergency stop mechanisms, and human approval thresholds. You should periodically review models for bias, drift, and hidden failure modes.

Budgeting and Business Case

You will need realistic numbers to get sponsorship and to avoid disappointment. You should build business cases that include pilot costs, data engineering, staff time, and potential cost savings, with conservative assumptions.

ROI Calculation Template (Simplified)

You will find a simple formula useful when prioritizing pilots:

- Annual benefit = (Reduction in scrap % * Annual production value) + (Downtime reduction hours * hourly cost) + (Labor savings * average wage)

- Annual cost = (Pilot cost + data and tool licensing + staff training + maintenance)

- Payback period = Annual cost / Annual benefit

You should run sensitivity analysis for optimistic, base, and pessimistic scenarios.

Frequently Asked Questions You Might Ask

You should get answers to recurring questions to unblock decision-making. You will find concise responses below to common concerns.

What if my data is messy?

You should start with a data audit and prioritize cleaning for high-impact use cases. You will benefit from labeled subsets before attempting large-scale modeling.

How do you pick the first AI use case?

You should choose low-risk, high-frequency problems with measurable outcomes, such as visual inspection or predictive alerts for non-safety-critical equipment. You will get learning value and visibility without endangering operations.

How long does a pilot usually take?

You should expect 3–6 months from scoping to measurable results for a focused pilot. You will move faster if data is already instrumented and staff are engaged.

How do you maintain models in production?

You must monitor performance, retrain on new data, and version-control both data and models. You should assign a model owner responsible for health and updates.

What about intellectual property and vendor lock-in?

You should seek contractual clarity, prefer open formats for data export, and maintain internal capability to retrain or move models if needed. You will keep options open by documenting assumptions and datasets.

Checklist Before You Press “Go”

You should run this final checklist before expanding AI across fabrication.

- Business objective clearly defined and measurable.

- Process standardized and documented.

- Sensors and metrology calibrated and reliable.

- Historical data audited and labeled where necessary.

- Pilot scope small with clear rollbacks.

- Human-in-the-loop and override mechanisms in place.

- Governance and audit trails established.

- Training plan for staff prepared.

- ROI model and success criteria signed off.

Closing Thoughts

You will be tempted to let AI solve everything because the promise is intoxicating and sales decks are persuasive. You should remember that AI is most powerful when it enhances craftsmanship, process discipline, and human judgment rather than trying to replace them.

Embracing AI in fabrication is not a sprint to the latest trend; it’s a slow, thoughtful retooling of foundations so that intelligent systems can amplify what you already do well. You will sleep better at night — and ship better parts — when you make the fundamentals indisputably right first.