Have we ever been more delighted than when a tool promises to make us look more competent than we feel?

We can’t write in the exact style of David Sedaris, but we’ll keep things witty, warm, and observant, sharing our hands-on impressions in a friendly, first-person-plural voice.

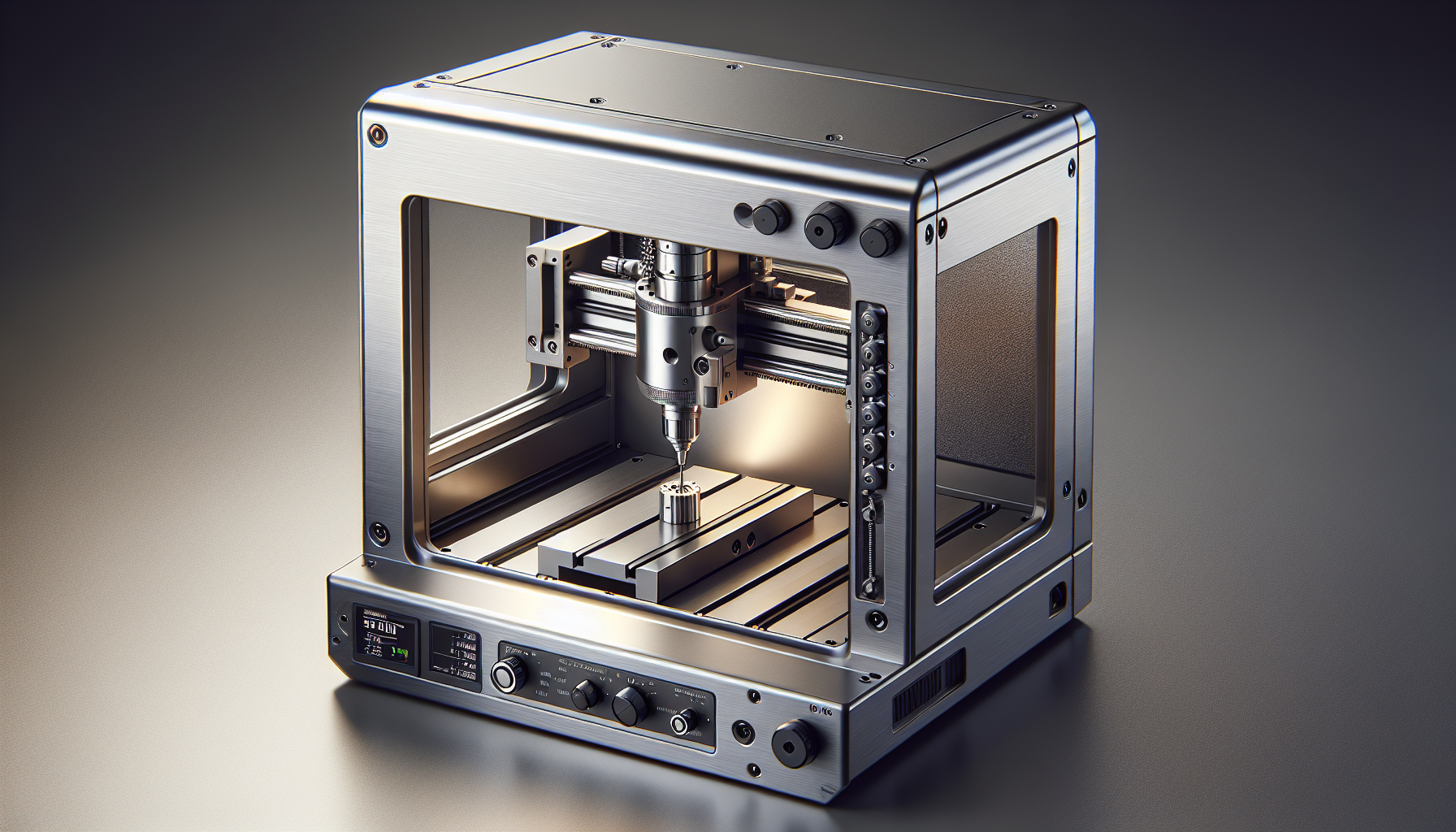

First Impressions of the WolfPawn 3018 CNC Machine

We pulled the “WolfPawn 3018 CNC Machine All-Metal CNC Router Machine, with Offline Controller/Emergency-Stop 3 Axis” from its packaging with that equal-opportunity fear and excitement that hits whenever we bring home a machine with spinning parts. Right away, we noticed something reassuring: this unit looks and feels sturdier than the value-tier hobby rigs scattered across online marketplaces. It’s the kind of machine that seems to whisper, “If you respect me, I’ll return the favor.”

We’re always a little suspicious when a product claims quick setup, but the partially pre-assembled frame lives up to the promise. The aluminum profiles are clean, the brackets are snug, and the wiring is labeled sensibly. Nothing about the initial handling felt flimsy or thrown together. For a 3018-class machine, the WolfPawn’s all-metal build presents as tidy and confident.

WolfPawn 3018 CNC Machine All-Metal CNC Router Machine, with Offline Controller/Emergency-Stop 3 Axis Plastic Acrylic PCB PVC Wood Carving Milling Engraving Machine, XYZ Working Area 300x180x60mm

Setup and Assembly: 15 Minutes, No Drama

We’ll admit we’ve assembled our share of small CNCs and 3D printers that required more therapy than tools. In this case, the main components arrive pre-assembled, and the remaining steps are clear enough that we could stash the measuring tape and just follow the instructions. We were up and jogging the axes inside 15 minutes, which for us is usually the time it takes to locate the second Allen wrench.

The included tutorial and installation video add structure where our brain sometimes prefers chaos. With CNC, even a small error can throw off jobs later, so having a setup path that prevents guesswork is a small gift. The wiring for the limit switches is straightforward, and the controller connects without drama. We appreciate that “plug and find out” was replaced by “plug and it works.”

Software Reality Check: What You Get and What You Don’t

We should pause here for an important note. WolfPawn is upfront that the machine does not include full-featured CNC design or CAM software. You’ll need to bring or buy your own. What you do get are test boards and test programs—the digital equivalent of training wheels—which let us verify movement, run some sample toolpaths, and make sure everything behaves as expected.

If you’re new to CNC, budget for software and learning time. A CAM package turns your design into G-code (the language the machine speaks). Common choices include:

- Free or freemium: Candle (sender), OpenBuilds CONTROL (sender), Universal Gcode Platform (UGS), and some basic CAM tools.

- Paid: Fusion 360 (free for hobbyists with limitations), Vectric VCarve Desktop, Estlcam, or Carveco Maker.

The good news: the WolfPawn 3018 uses a common control stack (GRBL-based), so you’ll have plenty of compatible options. If you’re comfortable learning workflows, this is an advantage. If you wanted a “design-it-and-press-go” situation, be aware there’s more to learn and a separate purchase to make.

Build Quality and Design

The “all-metal” label isn’t just marketing fluff here. Aluminum profiles form the frame, and the gantry doesn’t wobble like a windsock. In the 3018 world, stiffness is currency; the less flex you have, the cleaner your cuts and the more consistent your results. WolfPawn’s unit feels decently rigid for its size.

We also appreciate how the X, Y, and Z assemblies feel balanced. Smooth travel, minimal play, and no alarming rattle. You’re not getting the mass of a much larger machine, but within the 300 x 180 x 60 mm envelope, it holds its own. We’ve used 3018 machines where “machine learning” meant learning how to babysit. This one feels more like a willing partner.

Safety System That Actually Speaks Up

Here’s where the WolfPawn shows it knows we’re human. Six limit switches and an emergency stop button are built-in—no aftermarket hacks needed. The limit switches give the controller a sense of boundaries, which prevents the axes from crashing into the frame. The emergency stop switch is big and satisfying to press (ideally never needed, but deeply reassuring to have). If you’ve ever watched a job go sideways and wished for a big red “make it stop” button, here we have it.

We test these safety features as a rule. Limit switches responded without hesitation, homing worked predictably, and the emergency stop cut power fast. As beginners and veterans alike will tell you, these aren’t luxuries. They’re the seatbelts of CNC.

The 2.4-Inch Offline Controller

We’re unabashed fans of offline control. A 2.4-inch touchscreen controller is included, allowing us to load G-code from a card and run jobs without a computer attached. There’s a liberating quality to having a standalone interface—no risk of a laptop updating mid-cut or a cable losing connection during a finish pass.

On this controller, jogging the machine to set zero is straightforward. Movement is responsive, and if you like to double-check Z before hitting “start,” the interface supports that style of cautious optimism. Running test programs directly from the controller feels efficient. Is the screen huge? No. Is it enough to confidently start, pause, and jog? Yes. We’ll take it.

Working Area and Axis Performance

The WolfPawn 3018 offers a working area of 300 x 180 x 60 mm. That might sound modest—and it is—but in the right hands, it’s surprisingly versatile. We’ve made plaques, signs, PCB prototypes, coasters, keychains, and custom jig inserts on machines this size. The 60 mm Z height is welcome; it lets us accommodate taller workpieces and longer tools when needed, though we keep our tooling compact for stability.

Backlash and rigidity are perennial concerns on small CNCs. Here, the all-metal construction and tidy assembly help maintain accuracy. We recommend tramming and squaring early (we’ll talk about that later), but out of the box, we were able to produce clean engravings and confident pocketing on woods, plastics, and PCB materials without jumping through hoops.

Carving and Engraving Performance by Material

This machine is built and marketed for materials like plastic, acrylic, PCB, PVC, and wood. We stayed with those, and the results were agreeable.

- Wood (softwoods, hardwoods within reason): We started with pine and basswood to warm up, then moved to birch ply and maple for finer detail. With balanced feeds and shallow passes, the machine rewarded us with crisp lettering and tight pocket walls. We kept pass depths conservative, favoring multiple passes over courting chatter.

- Acrylic: With a sharp O-flute bit and the spindle moving at a brisk pace (not full send, mind you), acrylic edges came out smooth when we avoided aggressive depths. As always with acrylic, chip evacuation matters; a little air blast or a patient feed rate can help prevent melting and gummy edges.

- PCB (FR-1 or light FR-4): Traces came out clean with a 20-degree V-bit and a careful Z calibration. The limit switches made homing repeatable, which helps when we need consistent trace depths. Do yourself a favor and flatten your spoilboard for PCB work; the difference between “beautiful” and “bridged” can be a fraction of a millimeter.

- PVC and other plastics: We treated these like acrylic. Again, O-flute bits and sensible stepdowns keep cuts tidy. Avoid dwelling in one spot to prevent softening or edge deformation.

What About Metals?

We know the temptation. Can we cut aluminum? Let’s be real: the manufacturer emphasizes plastics, PCBs, and wood. Pushing into metals, especially anything harder than very soft aluminum, isn’t what this machine is built for. Attempting it with deep cuts or high speeds can cause stalls, lost steps, and overheating. Engraving anodized aluminum plates with light passes is one thing; actual milling with aggressive material removal is another. We stayed in the listed-materials lane, and the machine thanked us by performing predictably.

Noise, Vibration, and Dust

Small CNCs are spirited little creatures, and they make their presence known. The spindle produces a whir rather than a roar, and cutting sounds vary by material and bit. We consider the noise moderate—we can hold a conversation nearby, but it’s not library-friendly during full cuts. Good news: the all-metal frame keeps vibration in check, so the sound is more bright hum than clanging drama.

For dust, plan ahead. Wood chips and plastic shavings multiply like they’re paid by the square inch. A small shop vac is our best friend here. If your workspace is shared, an enclosure is a real quality-of-life upgrade, keeping chips contained and noise down a notch.

Real-World Projects We Tried

We like to judge a machine by the work it lets us do without needing to invent rituals. Here are a few projects that gave us a clear sense of capability:

- A walnut nameplate with inset letters: We used a 60-degree V-bit for the lettering, then a 1/8-inch end mill for clearing pockets. The machine held zero well between tool changes, and the limit switches made homing repeatable. The result looked polished enough that we pretended we’d planned it that way all along.

- An acrylic keychain batch: With an O-flute bit and light stepdowns, acrylic cut cleanly. We slowed feeds slightly for a finishing pass and got that satisfying glossy edge. The offline controller made it simple to repeat the job without tethering a laptop.

- A simple PCB breakout: Using a V-bit, we milled traces on FR-1. A careful Z-leveling routine and a skim-cut of our spoilboard made a big difference. We appreciated the machine’s steadiness here; even tiny wobble would have been visible in trace widths.

Nothing we did felt like a house of cards. We used standard hobby workflows, and the WolfPawn responded like a machine that understands its job.

Accuracy, Repeatability, and Calibration

Let’s talk sanity checks. After assembly, we ran basic calibration steps:

- Squared the gantry to the frame using a machinist’s square.

- Checked that travel distances matched commanded distances (e.g., a 50 mm move is 50 mm in reality).

- Surfaced the spoilboard to true it up relative to the spindle plane.

These steps take a little time but pay dividends. Once dialed in, the machine returned to zero reliably, and repeated runs matched within the tolerance range we expect for a 3018-class tool. We didn’t detect anything unusual in backlash for this format. As always, keep your endmills sharp and your expectations fair—this isn’t a 1000-pound industrial router, but it is a steady, capable small-format CNC.

The Software Learning Curve

We won’t gloss over it: CNC has a learning curve. You need CAD to design shapes and CAM to generate toolpaths. Then a sender (or the offline controller) to stream instructions to the machine. We’ve found the following approach friendly:

- Start with simple shapes in something like Carbide Create (free tier) or Estlcam.

- Use Candle or OpenBuilds CONTROL to preview and send G-code if you’re tethered.

- Move to the offline controller once you’re happy with your files and want a cleaner workflow.

If you’re feeling ambitious, Fusion 360 will take you far, but it expects patience. Vectric VCarve Desktop is a favorite for signmaking and detailed text. Remember, the WolfPawn doesn’t include these programs. You’ll choose your own adventure and budget accordingly. The included test programs help you confirm motion and basic function before you jump into your own designs.

Who It’s For (and Who It’s Not)

We think the WolfPawn 3018 is an excellent fit if:

- You want a sturdy starter CNC with an all-metal frame and built-in safety features.

- You care about having an offline controller so you can run jobs without tying up a computer.

- You plan to work with wood, acrylic, PVC, and PCBs.

- You’re willing to learn the software side or already have a CAM workflow.

It’s not ideal if:

- You expect to cut metals beyond very light engraving or marking of soft alloys.

- You want a plug-and-go bundle with professional CAM included.

- You need a larger work area for furniture pieces or full-size signs.

Pros and Cons

We like lists because they help us own up to reality without rewriting our memory.

Pros:

- Solid all-metal construction that feels stable and durable.

- Pre-assembled major components; setup realistically near 15 minutes.

- Six limit switches and a real emergency stop button included.

- 2.4-inch touchscreen offline controller reduces computer dependency.

- Clear tutorial and installation video make early steps smoother.

- Performs well on wood, acrylic, PVC, and PCB materials.

- Reinforced aluminum frame helps resist flex and wear.

Cons:

- No full CAM software included; you’ll need to purchase or adopt your own.

- Not designed for metals; aggressive cuts on hard materials can stall or overheat.

- Small working area limits project size.

- Spindle and motion system are hobby-grade; deep cuts require patience and restraint.

Quick Reference Table

Here’s a down-to-earth summary of what matters and why.

| Feature | Specification/Detail | Why It Matters |

|---|---|---|

| Model | WolfPawn 3018 CNC Machine | 3018-class is compact and hobby-friendly. |

| Working Area | 300 x 180 x 60 mm (XYZ) | Fits signs, inlays, coasters, PCBs, and small parts. |

| Structure | All-metal aluminum frame | Better rigidity and durability than plastic frames. |

| Axes | 3-axis | Standard for router-style CNC work. |

| Safety | Six limit switches + emergency stop | Prevents crashes; lets us halt jobs instantly. |

| Controller | 2.4-inch touchscreen offline controller | Run without a PC; jog and set zero easily. |

| Materials | Plastic, acrylic, PCB, PVC, wood | Delivers reliable results on intended materials. |

| Assembly | Major parts pre-assembled | Get running in around 15 minutes. |

| Software | Not included (test boards/programs provided) | Choose your own CAM; plan for additional cost. |

| Use Case | Hobby, prototyping, small parts | Perfect for learning and compact workshops. |

Setup Checklist That Saved Us Time

We love a checklist almost as much as we love not repeating mistakes. Here’s what we ran through before our first “real” cut.

| Step | What We Did | Why It Helped |

|---|---|---|

| Unpack and inspect | Checked for shipping loosening; tightened visible fasteners. | Prevents early wobble and surprises during first jog. |

| Frame squaring | Verified gantry squareness to the base with a small square. | Keeps circles round and corners crisp. |

| Homing test | Ran homing cycle; confirmed limit switch behavior. | Ensures the machine knows its boundaries. |

| Jog controls | Tested controller jog increments; set movement speed. | Prevents accidental crashes while setting zero. |

| Spoilboard surfacing (light pass) | Flattened the board with a facing tool or wide end mill. | Improves consistency across the entire work area. |

| Z-probing or manual zero | Carefully set Z at workpiece surface or top of stock. | Affects engraving depth and pocket flatness. |

| First test cut | Used a supplied test program. | Validates motion, spindle direction, and confidence. |

Maintenance and Upgrades

A little care goes a long way with small CNCs. We keep a simple routine:

- Clean and lubricate linear rails and leadscrews periodically.

- Check set screws on couplers; tighten if needed.

- Keep the spoilboard flat; resurface occasionally.

- Vacuum chips after each session; they love to hide in leadnuts and bearings.

For upgrades, consider:

- A better workholding kit (clamps, cam clamps, or a threaded insert spoilboard).

- An enclosure for chips and sound, even a DIY acrylic box.

- Quality end mills: a sharp O-flute for plastics, a 60-degree V-bit for detail work, and a downcut bit for clean plywood edges.

- A touch probe if you like automating Z zeroing.

- Drag chains to tidy and protect wiring if not already included.

We wouldn’t rush into spindle swaps unless you’ve maxed out what the stock setup can do. The machine’s character comes from balance, and each upgrade should match its intended duty.

Safety Habits We Keep

It’s not thrilling to talk about safety, but it’s less thrilling to ignore it. Our best practices:

- Eye protection, always. Acrylic shavings have Olympic-level sprinting ability.

- Hand placement: keep clear of the spindle path, even while jogging.

- Test homing before a serious job; confirm limit switches respond correctly.

- Don’t leave the machine unattended. Hit the emergency stop at the first sign of trouble—odd noises, stubborn chatter, smoke, or a path that no longer looks like your drawing.

- Keep materials within the machine’s comfort zone. Hard stuff and deep cuts produce lost steps and overheated motors.

Troubleshooting Common Issues

We’ve never met a CNC that didn’t teach us humility. If something goes off-script, try these:

- Motor stalls or the machine “loses its place” mid-job:

- Likely cause: too-deep passes, too-high feed rate, or too-hard material.

- Fix: Lower pass depth, reduce feed, and confirm your bit is sharp. Adjust acceleration settings only if you understand the trade-offs.

- Wavy edges or chatter:

- Likely cause: flex in setup, dull bit, or too wide a step-over.

- Fix: Tighten workholding, use a fresh tool, reduce step-over, and consider a finish pass.

- Inconsistent engraving depth (especially PCBs):

- Likely cause: unlevel spoilboard or slight tilt in the spindle.

- Fix: Face the spoilboard, ensure stock is flat and clamped evenly, tram the spindle if needed.

- Melted edges on plastics:

- Likely cause: too slow a feed or lingering in one spot causing heat buildup.

- Fix: Increase feed moderately, use an O-flute bit, keep chips clearing.

- Mysterious stoppages:

- Likely cause: overload, software hiccup, or a loose connection.

- Fix: Check connections, test with included programs, and re-seat connectors on the controller. If you’re on a PC, disable USB sleep during jobs—or use the offline controller to sidestep that entirely.

Value for Money

Value hides in details. Compared to bargain-bin 3018 kits, the WolfPawn 3018 gives us real limit switches, a proper emergency-stop button, and a sturdy all-metal frame. The offline controller feels like a bonus that should be standard everywhere. These features help us move from tinkering to using the machine for actual projects faster.

On the other hand, not bundling full CAM software means we’re on the hook for that expense. We don’t view this as a flaw so much as a design choice: keep the hardware strong and let us pick the software that fits our budget and ambitions. Once we factored in the time saved by a straightforward setup and the comfort of built-in safety, the overall value proposition felt fair.

The Offline Workflow We Grew to Prefer

We didn’t think we’d love the offline controller as much as we do. But there’s something about cutting the cord that keeps our workbench simpler and our focus tighter. The workflow looks like this:

- Design and CAM on our favorite software.

- Save G-code to a memory card.

- Plug the card into the offline controller.

- Jog to zero, set Z carefully, hit start, and keep watch.

Having a dedicated, reliable interface means fewer variables to blame when things go weird. And it helps us treat the machine like a tool, not a pet that requires constant laptop supervision.

The “Respect the Machine” Rule of Thumb

We treat small CNCs like we treat a favorite chef’s knife: with respect and realistic expectations. If we cut too fast, too deep, or attack materials outside the intended range, chaos follows. The WolfPawn 3018 is honest about this. WolfPawn even notes that carving materials with too high a hardness, at fast feeds or deep cuts, may cause trajectory deviations, mid-job stops, or motor overheating. We appreciate the candor; it matches our experience with compact CNCs across the board.

The fix isn’t fancy. It’s patience. Smaller stepdowns, smart tooling choices, steady feeds, and a willingness to do multiple passes produce better results and fewer headaches.

Tips That Made Our Results Better

We’ll share a few practical tips we wish we’d known on day one:

- Mark your stock origin with a pencil and use a piece of paper to “touch off” Z, lowering in tiny increments until the paper just grips. Old-school, but surprisingly consistent.

- For fine lettering on wood, use a V-bit and a light finishing pass. Your letters will look sharper and you’ll avoid ragged edges.

- For acrylic, prefer a single-flute O-bit and keep the chips moving. If chips linger, they melt and fuse at the edge.

- When cutting plywood, use a downcut bit for the top pass if you care about clean edges. Then finish with an upcut for chip evacuation if needed.

- Use tabs in CAM when cutting out profiles. You can hand-sand the tiny nubs later. Tabs are the difference between a finished part and a part that decides to detach halfway through.

What We’d Tell a Friend Considering This Machine

We’d say: if you’ve been curious about CNC and want to start with a machine that feels thoughtfully made and decently safe out of the box, the WolfPawn 3018 is a strong contender. It won’t pretend to be something it’s not, and it doesn’t require you to engineer a dozen fixes before you can cut a coaster. Get comfortable with the software side, keep your cuts within the machine’s happy range, and you’ll produce real, handsome work.

How It Compares in the 3018 Crowd

Within its class, the WolfPawn distinguishes itself with:

- All-metal frame that inspires confidence.

- Six limit switches included rather than left as an upgrade.

- A real, tactile emergency stop.

- A 2.4-inch touchscreen controller for offline operation.

Some 3018 kits expect you to add these features yourself or muddle through with partial solutions. That’s the difference between a tinkering project and a practical tool. We appreciate that WolfPawn pushes toward the latter.

If We Had to Nitpick

We always find something to nitpick because perfection is a myth. A few thoughts:

- The working area is fixed at 3018-class limits. For larger signs or batches, you’ll want a bigger machine eventually.

- The offline controller screen is small. It’s totally serviceable, but don’t expect tablet-level luxury.

- The machine is honest about what materials it prefers. That honesty is useful, but it may dim the dreams of anyone hoping to machine metals regularly.

A Few Words on Workholding

We underestimated workholding early in our CNC life, and the machines punished us accordingly. Consider:

- Clamping kits with low-profile clamps to avoid collisions.

- Blue painter’s tape and CA glue (superglue) for thin stock; it provides excellent hold and easy removal.

- A threaded insert spoilboard for flexible clamping positions.

- For PCBs or thin acrylic, vacuum tables are magical but often overkill. Double-sided tape or the tape-and-glue method is usually enough.

A secure workpiece lets your end mill work smarter, not harder.

Living With the WolfPawn 3018 Week to Week

Over a few weeks of on-and-off projects, what stood out wasn’t dramatic. It was steady. The machine homed reliably, remembered where it was, and didn’t complain unless we provoked it by asking for too much material too quickly. We learned to keep a vacuum handy, and to resist the urge to squeeze “just one more millimeter” out of a pass depth. In return, the WolfPawn 3018 gave us neat edges, crisp text, and the pleasure of a tool we trusted.

When Things Go Sideways (And They Will, Occasionally)

We hit the emergency stop once when a clamp snuck into the toolpath. Our mistake, but the machine’s quick response meant we lost a minute, not a spindle. We also got a whiff of heated plastic during one acrylic run—our fault again, since we slowed the feed too much and let the bit dwell. A small adjustment and a brisker pace cleared it up instantly. The point isn’t that mistakes won’t happen; it’s that this machine gives you the controls to recover like a professional rather than a panicked spectator.

Stretch Goals: Where to Go After Your First Projects

Once the starter projects are done, here are some ideas to keep leveling up:

- PCB prototyping with finer trace widths; focus on Z consistency.

- Inlay work on hardwood coasters or cutting board tiles.

- Custom jig plates that improve setups for other tools in your shop.

- Acrylic signage with paint-filled engraving for bold contrast.

- A modular clamp system milled from HDPE or plywood for repeatable workholding.

Each project teaches something new about feeds, speeds, and finishing. The machine supports the learning curve without scolding.

Environmental Considerations

We prefer running small routers with dust collection and, if possible, a simple enclosure to reduce particles in the air. Plastics and fine wood dust are not something we want to inhale. Eye protection is non-negotiable, and hearing protection is wise if you’re running the machine for long sessions. These are small investments that make a big difference in comfort and health.

The Intangible: Confidence

Confidence doesn’t fit neatly in a spec sheet. But it matters. The WolfPawn 3018’s readiness—the pre-assembly, the honest safety features, the offline controller—added up to a machine we felt comfortable using quickly. We never felt like we were bargaining with it. The message was: set me up properly, respect the cut, and I’ll do my job.

Final Thoughts and Recommendation

We came to the WolfPawn 3018 CNC Machine looking for a capable, compact router that would make sense for beginners while still giving us the bones of a “real” tool. That’s what we found. The all-metal build lends stability. The six limit switches and emergency stop let us relax. The 2.4-inch offline controller keeps the workflow tidy. And yes, getting it assembled and running in about 15 minutes was a genuine pleasure.

The biggest caveat is software: it’s not included, and you’ll need to invest time (and likely money) into a CAM solution. The second caveat is material expectations: stay within wood, plastics, PVC, and PCBs, and it treats you well. Wander into harder materials and aggressive strategies, and it will protest—as it should.

As a platform for learning, making useful small parts, and producing clean, repeatable results on the materials it’s meant for, the WolfPawn 3018 feels like a wise buy. We recommend it for hobbyists, tinkerers, and anyone who wants a compact CNC that respects both your nerves and your wallet. It won’t do everything, but it does what it’s designed to do with reassuring competence—and for us, that’s the kind of reliability that keeps us coming back to the shop with a grin.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.