?Have you ever stood at the edge of a factory floor and felt the same quiet, small panic you get when you open your inbox and find three thousand unread emails?

Why Fabrication Intelligence Will Define Manufacturing After 2026

You’re about to read about a phrase that sounds like it was invented by a management consultant on a long train ride: Fabrication Intelligence. It’s not a buzzword dressed up for a PowerPoint; it’s the cumulative force of data, sensors, robotics, and machine learning making manufacturing behave less like a cranky machine and more like a lucid, opinionated person who knows how things should be done. After 2026, this will be the way most factories think and act — or they’ll be the ones you pass on the highway, windows dark, like antique diners that never quite modernized.

Why you should care

You probably care because your job, your company, or your livelihood is connected to making things. You might be a plant manager who sleeps with a tablet under your pillow. Or you might be someone who pays attention to manufacturing because it decides what gets made, when, and how much it costs. Fabrication Intelligence, or FI, changes those answers in ways you’ll notice and ways you won’t. It affects quality, speed, sustainability, and the kind of work people do.

What Fabrication Intelligence actually means

You want a definition that’s practical, not preachy. Fabrication Intelligence is the orchestration of real-time production data, advanced analytics, automation, and human expertise to enable manufacturing systems that learn, adapt, and optimize their own processes. It’s where digital twins, edge computing, and adaptive control strategies hang out together and argue about tolerances.

The simplest breakdown

You need to keep things simple to implement them. FI has three core pillars:

- Data acquisition: sensors, cameras, PLCs, and operator inputs that feed the system.

- Analytical intelligence: models and algorithms that turn raw data into decisions.

- Action and feedback: robots, CNCs, MES commands, and human interventions that execute and give results back to the system.

You’ll want all three working, otherwise you have an expensive dashboard that makes you feel busy while nothing improves.

A brief history you can use at parties

You may not bring this up at a holiday dinner, but it helps to know the arc. Manufacturing was once human skill plus machine. Then automation replaced repetitive motions, deterministic PLCs ruled, ERP centralized information, and Industry 4.0 promised connected everything. Fabrication Intelligence is the next turn: not just connected, but context-aware and prescriptive.

Why now, not before?

You might ask why FI arrives now instead of a decade ago. The short answer: sensor affordability, compute at the edge, mature ML models, and pressure from supply chains and sustainability goals forced the timeline. In other words, technology finally caught up to the dreams, and the business need stopped being optional.

Key drivers shaping Fabrication Intelligence after 2026

You’ll encounter multiple pressures that push FI from pilot projects into factory-wide practice. These are not hypothetical: they are measurable and often painful.

Economic pressures

When margins get tight, you look for yield, uptime, and scrap reduction. FI reduces value leakage by predicting failures and optimizing throughput.

Supply chain complexity

Your suppliers are global, your lead times are volatile, and demand is fickle. FI helps you respond faster, by adjusting production schedules using real-time data instead of optimistic Excel spreadsheets.

Environmental and regulatory demands

You care about emissions, waste, and compliance. FI gives you the visibility to measure and reduce energy use and material waste, which regulators will increasingly require.

Workforce transformation

You will face workforce shortages and the need to upskill. FI shifts routine tasks to machines and cognitive work to people who now interpret results, not tighten bolts. You’ll either reskill your workforce or watch them leave for jobs that don’t rely on being photocopied.

Core components of Fabrication Intelligence

You deserve a clear view of the architecture. Below is a table that lays out the major components and what they do.

| Component | Purpose | Typical Technologies |

|---|---|---|

| Sensors & Edge Devices | Capture real-time signals (temperature, vibration, vision) | IoT sensors, cameras, PLCs, edge gateways |

| Connectivity | Move data reliably and securely | 5G, Ethernet, OPC-UA, MQTT |

| Data Fabric & Storage | Aggregate and normalize data | Time-series DBs, data lakes, data mesh patterns |

| Digital Twins | Virtual replicas of processes or machines | Simulation engines, real-time models |

| Analytics & ML Models | Predict, classify, and prescribe actions | Supervised/unsupervised ML, reinforcement learning |

| Control & Execution | Implement decisions on the floor | MES, SCADA, PLCs, robot controllers |

| Human Interface | Inform operators and decision-makers | Dashboards, AR/VR, alerts, mobile apps |

| Security & Governance | Protect assets and ensure compliance | IAM, network segmentation, encryption |

| Integration Layer | Connect legacy systems to modern tools | APIs, middleware, adapters |

You’ll want to pay particular attention to the integration layer; it’s where grand dreams meet old hardware and stubborn legacy systems that think they invented manufacturing.

How FI improves outcomes (with examples)

You like results more than theory. FI improves manufacturing in predictable ways.

Improved yield and quality

You’ll reduce defects by catching root causes earlier. Imagine a production line where a camera spots a subtle discoloration and a model traces it to a knob that is slightly out of spec — the system adjusts the machine and flags the batch. This reduces rework and warranty costs.

Higher uptime

Predictive maintenance means you no longer wait for the dramatic clank at 4 AM. FI forecasts component wear and schedules maintenance proactively. Production lines stop less often, and when they do, the repair kit arrives with the exact part.

Faster throughput and flexibility

You’ll be able to reconfigure lines for smaller batches without manual rework. FI orchestrates robots and human tasks to meet changing demand without the usual chaos.

Energy and materials savings

You can minimize energy spikes and waste. FI adjusts heating, cooling, and material feeds so the factory uses only what’s needed.

A comparison: Traditional vs Fabrication Intelligence-driven manufacturing

You’ll find this helpful when discussing strategy with finance or the CEO.

| Aspect | Traditional | FI-driven |

|---|---|---|

| Decision basis | Human rules, fixed schedules | Data-driven, adaptive |

| Error detection | Post-production inspection | Real-time anomaly detection |

| Maintenance | Reactive or scheduled | Predictive and condition-based |

| Changeover time | Manual and lengthy | Automated and fast |

| Sustainability | Limited visibility | Continuous measurement and optimization |

| Human role | Manual tasks, repetitive | Supervision, analysis, exception handling |

You’ll notice the human role becomes higher-level, which is both an opportunity and a responsibility.

Technologies enabling Fabrication Intelligence

You want to know which technologies to prioritize. Not every shiny tool is necessary at first, but certain capabilities are non-negotiable.

Edge computing and real-time processing

You don’t want round-trip latency to the cloud deciding whether a weld is acceptable. Edge compute enables decisions at the machine level, where milliseconds matter.

Machine learning and adaptive control

You’ll use supervised learning for defect detection, unsupervised learning for anomaly discovery, and reinforcement learning to optimize complex sequences. These models are practical tools, not magic.

Digital twins and simulation

You’ll create a virtual copy of a process to test changes before you deploy them. This saves time and material and reduces risk.

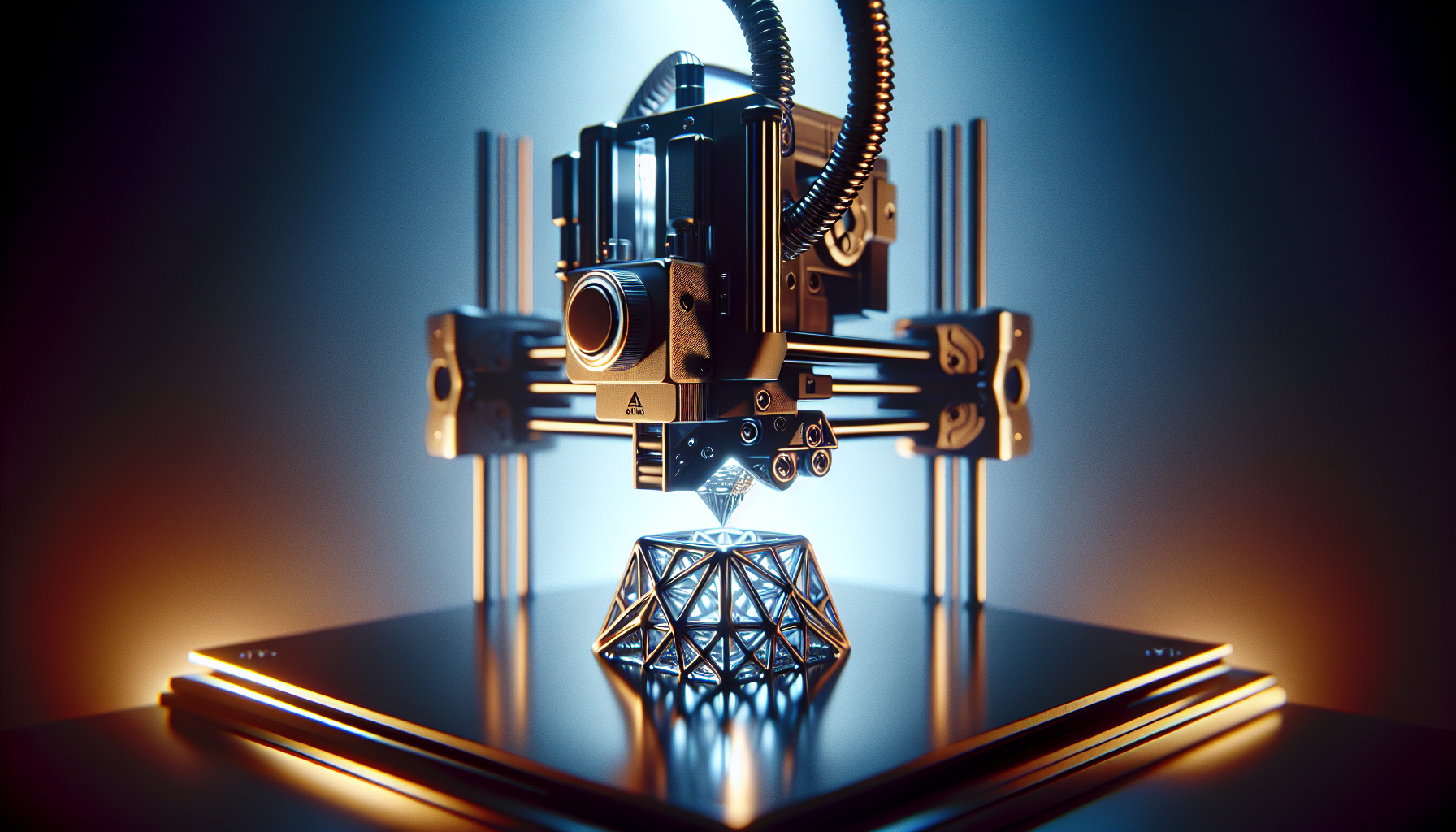

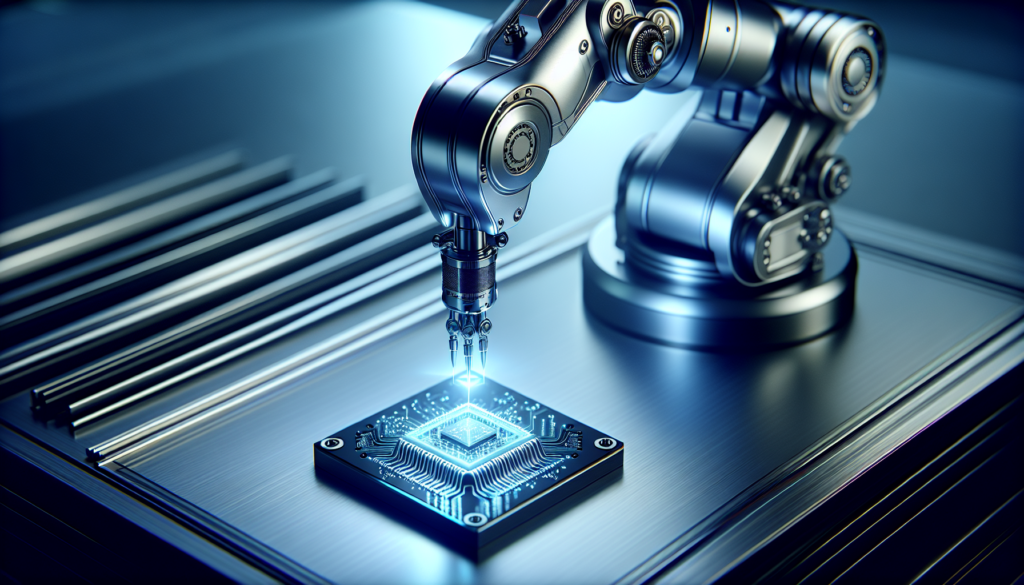

Advanced robotics and collaborative robots

Cobots let you keep human dexterity while adding machine repeatability. You’ll design workflows where robots handle hazardous or monotonous work and people handle judgment calls.

Connectivity standards and interoperability

You’ll insist on open protocols so systems can interoperate without high consulting fees. OPC-UA and MQTT are your friends.

Organizational changes you’ll need to make

You can’t just drop a system into old contracts and expect enlightenment. Change management matters.

Skills and roles

You’ll need data engineers, ML engineers, and “production translators” — operators who understand data. Reskilling is not a choice; it’s a survival tactic.

Governance and decision rights

You’ll define what the system can change automatically and what still needs human sign-off. You’ll set thresholds and exception policies with clear accountability.

Procurement and vendor management

You’ll prefer vendors that offer modular, interoperable components. Be wary of single-vendor lock-in; it’s like owning a dog that also eats your socks.

Cultural shifts

Your team will need to trust automated decisions and accept that machines will sometimes be right in ways people find annoying. This trust is built with transparency, not with slogans.

Implementation roadmap for manufacturers

You want practical steps. Here’s a phased approach you can follow.

- Assess readiness: Map assets, data sources, and pain points. Establish KPIs.

- Pilot with high-impact use cases: Start with predictive maintenance or quality inspection.

- Scale incrementally: Expand to adjacent lines, integrating learnings.

- Institutionalize: Embed FI into standard operating procedures and training.

- Optimize and evolve: Use continuous improvement cycles driven by FI metrics.

You’ll keep the pilots short and measurable. Nothing kills momentum like a multi-year experiment that produces only slides.

Key performance indicators to measure success

You’ll be judged on metrics. Make sure they tell the true story.

- Overall Equipment Effectiveness (OEE)

- First Pass Yield (FPY)

- Mean Time Between Failures (MTBF)

- Cycle Time and Changeover Time

- Energy Consumption per Unit Produced

- Scrap Rate and Material Utilization

- Time to Detect and Respond to Anomalies

You’ll also track softer metrics: worker satisfaction, training hours, and the number of issues resolved autonomously.

Security, privacy, and governance

You must treat data like currency. When your machines talk, they publish secrets.

Cybersecurity

You’ll segment networks, enforce multi-factor authentication, and encrypt data in motion and at rest. You’ll also regularly test systems with red teams and vulnerability scans.

Data governance

You’ll classify data types, set retention policies, and ensure provenance. Who owns the data your factory produces? That matters when you’re negotiating contracts.

Regulatory compliance

You’ll ensure traceability for regulated industries (medical devices, aerospace). FI can automate traceability, but only if you maintain auditable logs and access controls.

Risks and limitations you should expect

You won’t have a fairy tale. Expect friction.

Integration complexity

Legacy equipment resists being modernized. You’ll spend time and money creating adapters and teaching old machines new tricks.

Model drift and maintenance

You’ll need to retrain ML models as processes or materials change. Treat models like production assets: they require monitoring and version control.

Organizational resistance

People will fear job loss or view FI as surveillance. You’ll address concerns with transparency and retraining, not corporate slogans.

Upfront costs

You’ll invest in sensors, edge compute, and software. The ROI is real but not always immediate; you’ll need to prioritize.

Post-2026 scenarios: what you can reasonably expect

You want scenarios you can plan against. Here are three plausible outcomes for manufacturing ecosystems after 2026.

Scenario 1 — Widespread adoption and productivity gains

Many manufacturers adopt FI aggressively. You’ll see significant improvements in uptime, quality, and sustainability. Supply chains become more responsive, and smaller batch production becomes economical. If this happens, you’ll work in systems that assume composability and continuous improvement.

Scenario 2 — Uneven adoption and dominant platform vendors

A few large vendors consolidate the market, offering end-to-end FI platforms. You’ll get integrated experiences but face vendor lock-in and pricing pressure. Smaller manufacturers may be left choosing modular, open-source alternatives.

Scenario 3 — Regulatory and geopolitical friction

Export controls, data localization laws, and cybersecurity incidents force fragmentation. You’ll need region-specific FI architectures and more stringent governance. This slows progress but increases resilience.

You may experience a mix of these scenarios, which is why flexibility in technology choices is crucial.

Case studies: realistic examples you can model

You like examples you can emulate. These are archetypal, based on common industry patterns.

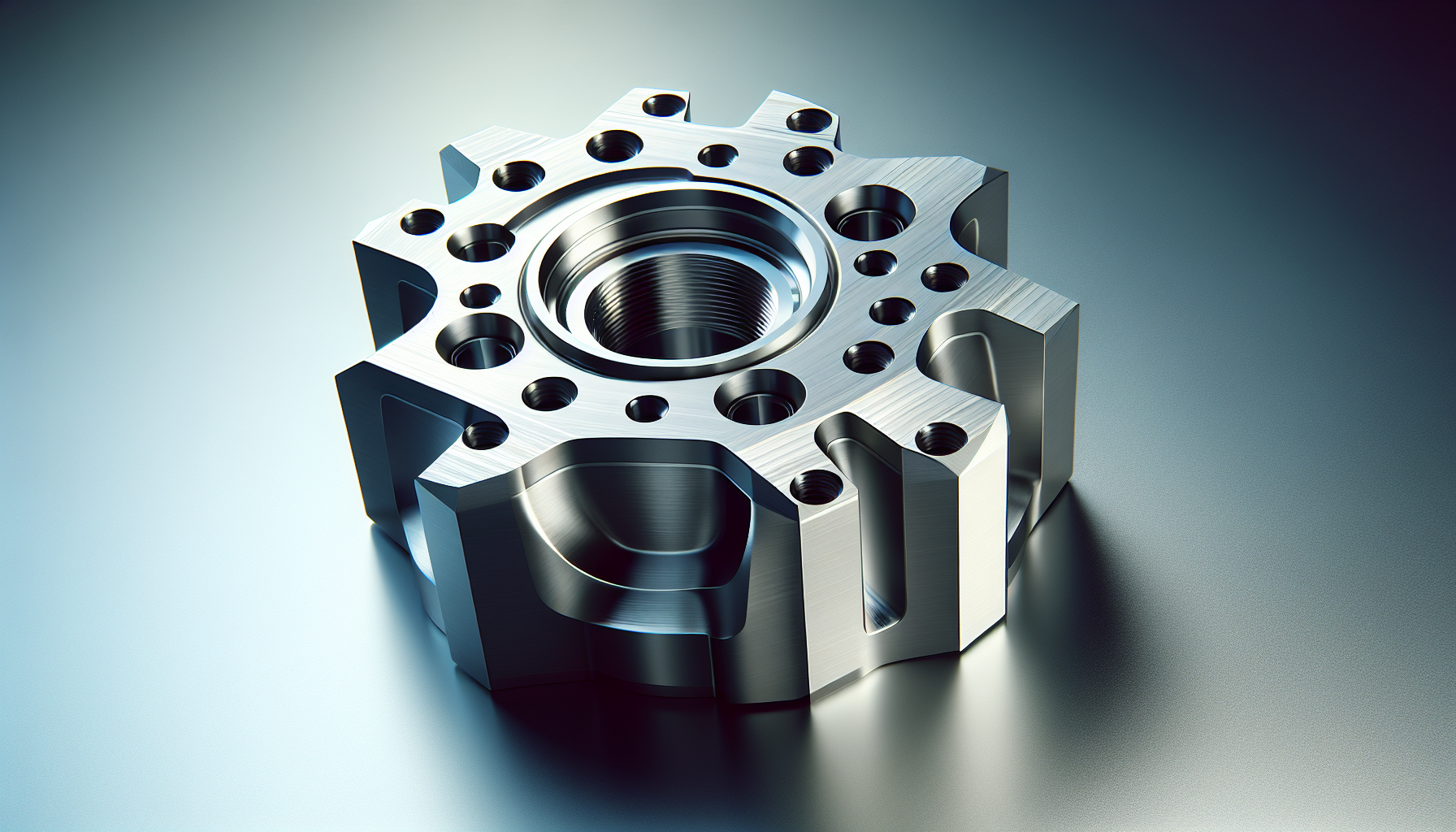

Automotive supplier — defect reduction

An automotive parts supplier implemented FI to detect micro-cracks in injection-molded parts. Vision systems with ML models flagged anomalies, and the FI system adjusted mold temperature profiles in real time. Results: FPY improved by 12%, scrap decreased by 18%, and customer complaints dropped.

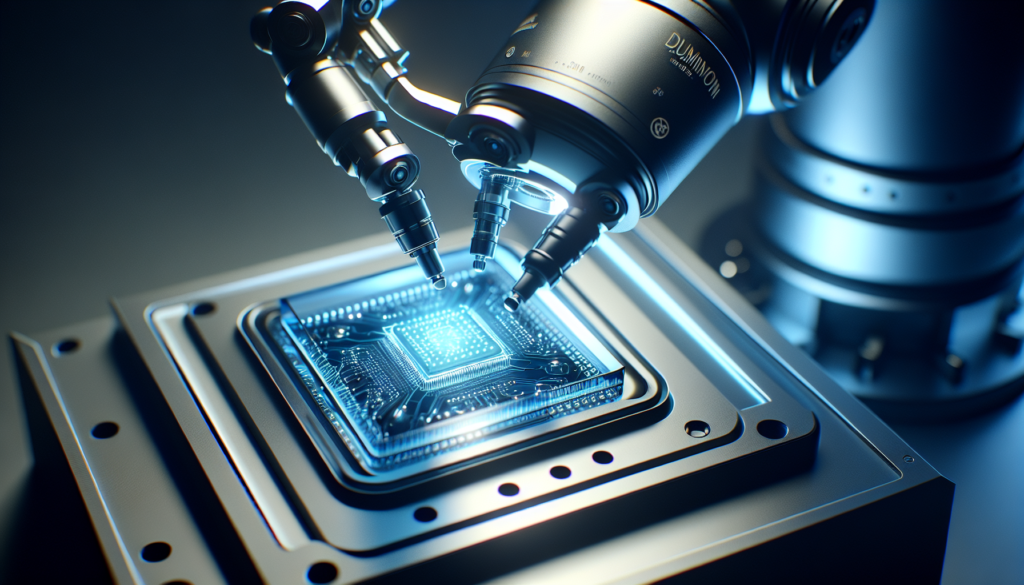

Electronics manufacturer — throughput optimization

A contract manufacturer used FI to balance assembly and test lines dynamically. The system predicted bottlenecks based on equipment health and incoming orders, enabling automated re-routing and prioritized scheduling. Results: Cycle time reduced by 22%, and on-time delivery rates increased.

Metal fabrication shop — energy and material savings

A metalworking plant integrated power monitoring and machine telemetry. FI algorithms adjusted idle settings and consolidation plans, reducing energy spikes and optimizing material nesting for laser cutting. Results: Energy use per part fell 14%, and material yield improved by 6%.

You’ll pick a use case that aligns with your biggest pain point, because success breeds confidence.

Vendor landscape and procurement tips

You’ll be choosing partners. Here’s how to avoid common mistakes.

What to look for

- Interoperability and open standards

- Proven case studies in your industry

- Clear service-level agreements (SLAs)

- Support for incremental deployment

- Transparent pricing models

Common red flags

- Closed ecosystems that require rip-and-replace

- Overpromises without measurable outcomes

- Lack of domain expertise in manufacturing

- Hidden data ownership clauses

You’ll insist on proof-of-value pilots before committing to multi-year contracts.

The human element: skills, training, and new career paths

You’ll need to think about people as the system’s variable that matters most. FI won’t replace humans; it will change what humans do.

New roles you’ll hire for

- Industrial data scientists

- Edge systems engineers

- Process automation architects

- Operator-analyst hybrids

Training strategies

You’ll deploy modular training programs, pair coaches with operators, and use simulated environments with digital twins. You’ll reward curiosity, not just compliance.

Worker experience

You’ll make FI systems that reduce drudgery and increase autonomy. Treat change as mutual; the system should support workers, and workers should provide feedback into the system.

Standards, interoperability, and the open-source opportunity

You’ll benefit from standards that make integration cheaper and safer. Where possible, favor solutions that implement open protocols and contribute back to communities.

Standards to watch

- OPC-UA for industrial data exchange

- MQTT for lightweight messaging

- ISA standards for automation

- Open-source ML toolkits adapted for manufacturing

You’ll find that a hybrid of proprietary tools and open integrations often gives the best outcomes.

Financial considerations and ROI

You’ll need to make the business case. The ROI varies by use case but follows a predictable structure.

- Upfront investment: sensors, compute, software licenses, integration

- Recurring costs: model maintenance, cloud/edge compute, support

- Returns: reduced scrap, higher uptime, lower energy, faster throughput

You’ll build scenarios: conservative, expected, and aggressive. Use near-term wins (quality and maintenance) to fund longer-term projects.

How to start tomorrow

You want checklist-level actions you can take immediately.

- Map your top three pain points and their metrics.

- Inventory data sources and connectivity gaps.

- Run a 90-day pilot for a single line with clear KPIs.

- Assign an executive sponsor and a cross-functional team.

- Start training a small group in data literacy and ML basics.

You’ll move fast, but not so fast that you trip over legacy systems.

Frequently asked questions (short and useful)

You want quick answers to common doubts.

- Will FI replace operators? No, it changes their tasks toward supervision and exception handling.

- Is cloud mandatory? No — edge computing is often essential for real-time control.

- How long until benefits show? Some pilots show improvements in 3–6 months; full rollouts take longer.

- Is FI secure? It can be, but you’ll need active cybersecurity measures and governance.

You’ll keep answers pragmatic and evidence-based when presenting to skeptical stakeholders.

Conclusion: what you’ll remember in 2028

You’ll probably remember these three facts: FI is practical, not just theoretical; it’s driven by real business needs; and it will reshape what manufacturing work is. If you treat it as a continuous journey — small pilots, clear KPIs, transparent governance, and a human-centered approach — you’ll find FI elevates your factory from a set of machines to a nervous system that senses, thinks, and reacts.

You’ll also accept that progress will have awkward moments: models that misidentify, sensors that need recalibration, and managers who long for simpler dashboards. That’s normal. Manufacturing has always been a bit of a comedy of errors, and FI just hands you a better script.

If you lean into the technology and the people equally, by 2028 you’ll be working in a facility that feels less like a relic and more like a responsive organism — and you’ll wonder how you ever tolerated the clank and the checklist-driven tragedies of the past.