? Have you ever held something so small that it felt like a secret, and wondered how it was made?

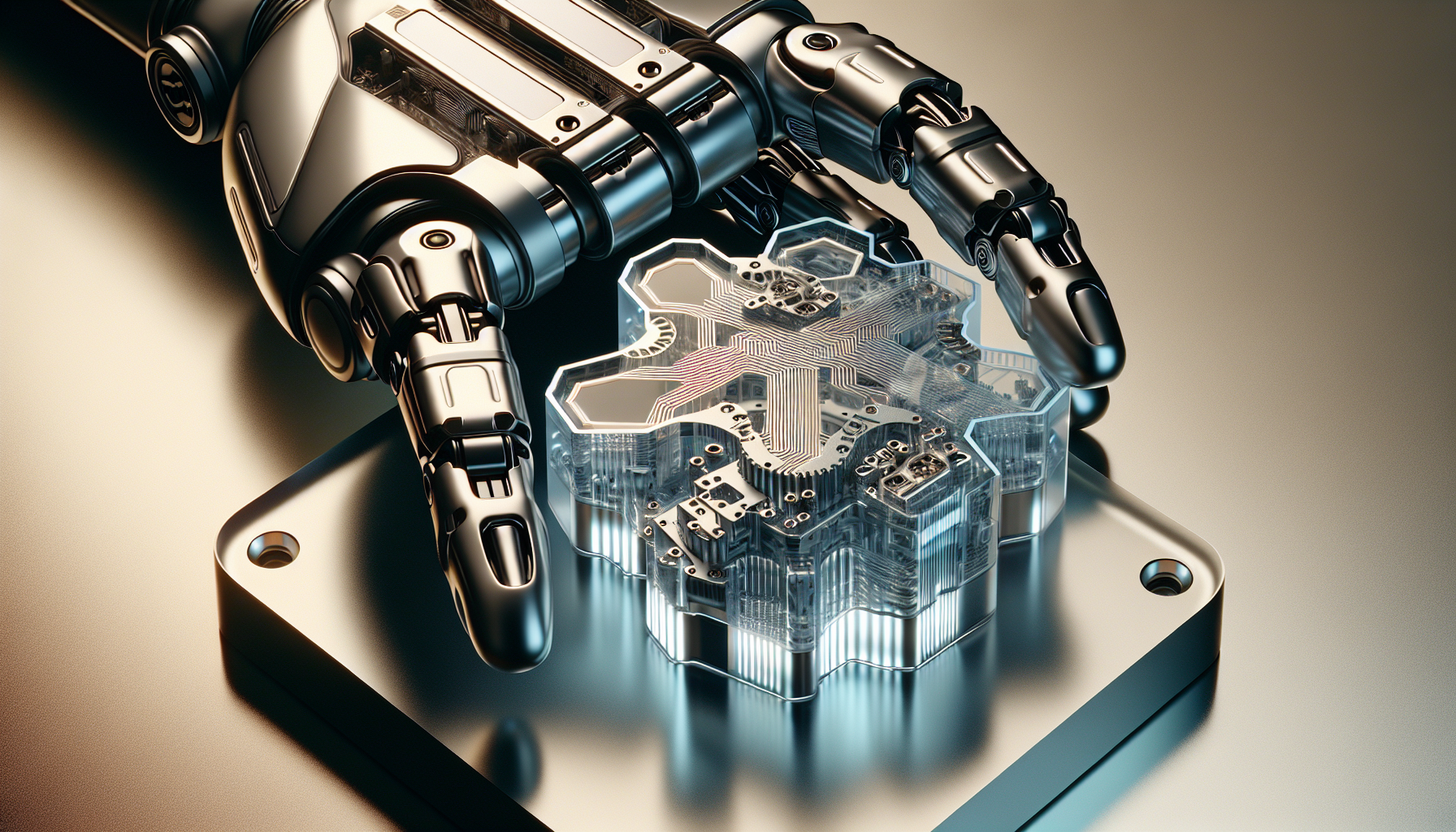

Why 2026 Is The Year Of Micro-Manufacturing: CNC Miniaturization At Scale

You might think the phrase “manufacturing revolution” is reserved for flashy headlines and venture capital decks, but 2026 has a quieter, sharper kind of revolution arriving — the kind you can hold between your thumb and forefinger. This article explains why CNC miniaturization reaches a tipping point in 2026, what that means for you, and how you can prepare to take advantage of micro-manufacturing at scale.

A short primer: why this matters to you

If you design, buy, or make parts — or if you’re simply curious about how tiny things get made — the miniaturization of CNC machining changes timelines, costs, and possibilities. You’ll find new product shapes, faster iterations, and localized production that make your projects nimbler and sometimes more profitable.

What is micro-manufacturing?

You already know manufacturing at a basic level: remove material, shape, assemble. Micro-manufacturing is the same idea but on a much smaller scale, producing parts measured in fractions of a millimeter to a few millimeters with tolerances in microns.

The scale and precision you need to picture

Think of watch components, micro-valves, MEMS housings, or medical stents. These are parts where surface finish, geometric accuracy, and feature fidelity determine whether a device works or fails. You’ll be working with tolerances that laugh in the face of conventional machining.

CNC Miniaturization: what actually changed?

You might imagine that smaller machines are just shrunk versions of bigger ones, but the real story involves specialized spindles, ultra-rigid micro-frames, micro-tooling, control software tuned for tiny engaged chip loads, and metrology folded into the machine.

Key innovations enabling the shift

- High-speed micro-spindles that run at 60k–200k RPM without sacrificing runout.

- Piezo and voice-coil actuators for sub-micron positioning and rapid small moves.

- Micro-tools made with advanced coatings and geometry for predictable wear.

- Integrated thermal control and environmental enclosures to remove thermal drift.

- CAM and control algorithms optimized for small chip loads and micro-tool deflection compensation.

Market drivers pushing 2026 as the inflection year

You already see micro-components appearing more often; what’s changed is scale and demand. Several converging forces push miniaturized CNC into mainstream production in 2026.

Major demand drivers

- Medical devices shifting to minimally invasive and implantable designs.

- Consumer electronics focusing on smaller sensors, haptics, and wearables.

- Aerospace and defense seeking weight and size reductions for micro-drones and avionics.

- Automotive electrification requiring precision small components in EV power electronics.

- Research sectors (quantum, photonics, micro-robotics) moving from prototypes to production.

Table: Sector drivers and how they affect micro-manufacturing

| Sector | Primary Driver | Production Requirement | Why micro-CNC matters |

|---|---|---|---|

| Medical | Minimally invasive implants | Biocompatible micro-features, tight tolerances | Enables patient-specific designs with short lead times |

| Consumer Electronics | Miniaturization and battery constraints | Thin-wall structures, weight control | High throughput for tiny components at scale |

| Aerospace | Weight & performance | High-strength, precise small parts | Reduces component mass and improves system integration |

| Automotive | Power-density & reliability | Fine-feature connectors, seals | Supports compact, modular EV subsystems |

| Research & Optics | Prototyping to production | Complex micro-geometries | Bridges lab work to marketable devices |

Technology enablers in detail

You’ll want to know what technologies combine to make micro-manufacturing scalable. Each contributor reduces a technical bottleneck so you can produce more, faster, and with higher quality.

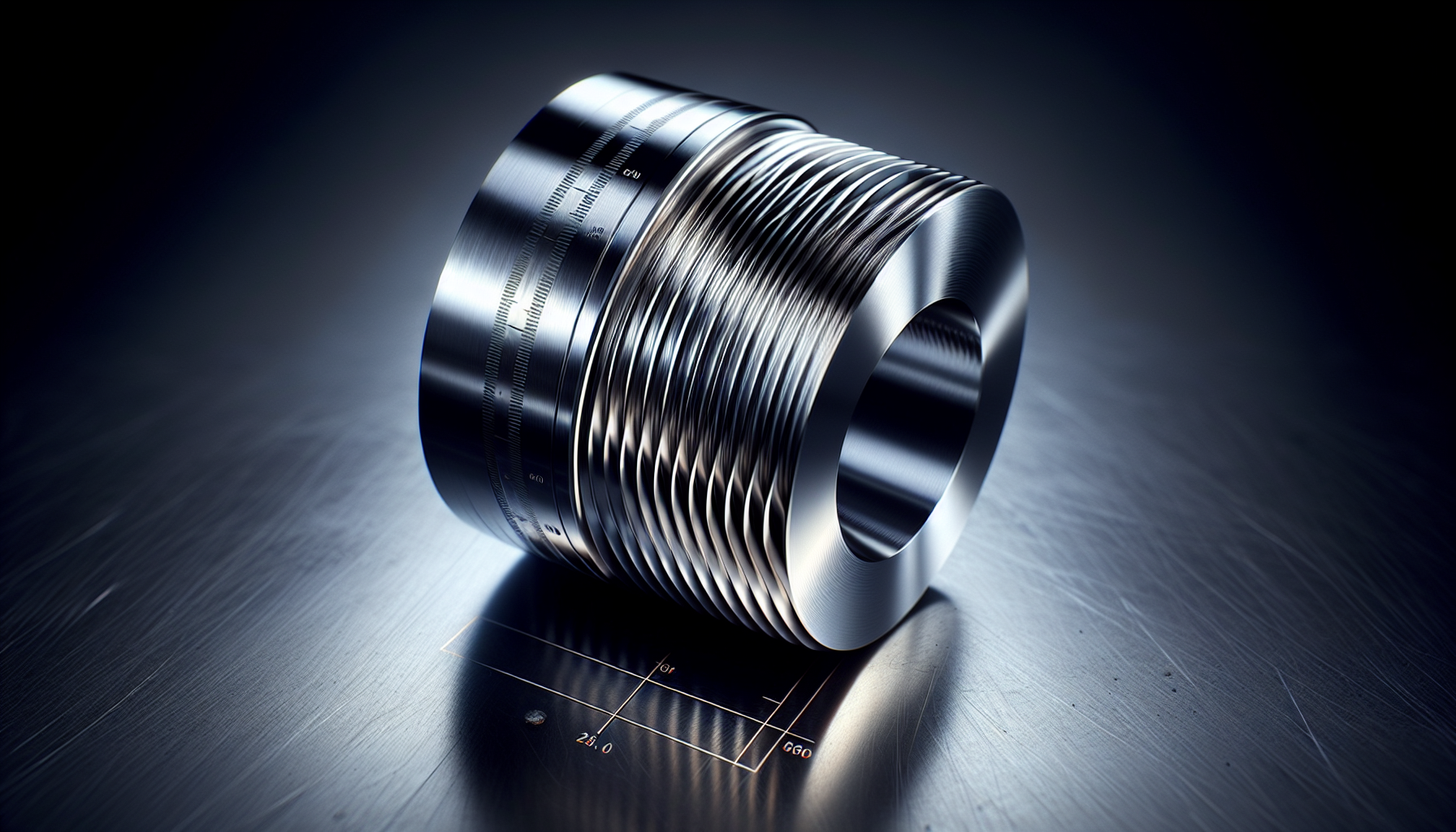

Spindle and tool tech

Micro-spindles are smaller but must maintain axial rigidity and low runout. You’ll see hybrid ceramic bearings, active balancing, and air-bearing spindles in higher-end machines. Micro-tools use ground flutes, special coatings, and advanced substrate materials.

Machine structures and actuation

Miniature machines aren’t just smaller; they need thermal symmetry and ultra-stiff frames that don’t resonate at spindle speeds. Piezoelectric and voice-coil actuators let you control motion at the sub-micron level with high-bandwidth response.

CAM, control systems, and software

Control algorithms now compensate for tool deflection, spindle-induced thermal effects, and micro-burr formation. Path planning emphasizes smaller stepover, constant chip load, and micro-helical interpolation to reduce cutting forces.

Metrology and in-process inspection

Inline optical profilers, laser interferometry, and micro-CT integrated into production cells help you catch defects early. Closed-loop corrections minimize scrap and improve first-pass yield.

Materials and coatings

You’ll work with super-tough alloys, bio-compatible materials, and polymer-metal hybrids. Coatings such as nano-composite DLC reduce wear and provide predictable cutting behavior on the micro-scale.

Table: Technology element vs. role and impact

| Technology | Role in Micro-CNC | Impact on Production |

|---|---|---|

| High-speed spindles | Reduce cutting forces, enable small tools | Faster feeds, smaller tool diameters |

| Piezo actuators | Sub-micron positioning & rapid response | Higher precision, better surface finish |

| Micro-tools | Cutting geometry for tiny features | Enables fine details and thin walls |

| Integrated metrology | Inline measurement & feedback | Lower scrap, higher yield |

| AI-driven CAM | Predictive toolpath optimization | Reduced programming time, fewer errors |

Economics: cost curves and scaling

You’ll want to know whether micro-manufacturing is a premium hobby or a pragmatic business move. The economics hinge on tooling cost, machine utilization, setup time, and yield.

Unit economics explained

- Tooling cost per part drops as tool life increases and you adopt batch processing.

- Machine cost per part depends on throughput — higher spindle speeds and multiple micro-operations reduce cycle time.

- Setup and fixturing are proportionally more important; a smart fixturing strategy turns small-batch manufacturing into profitable production.

Table: Cost factors and how they scale

| Cost Factor | Impact for Prototypes | Impact for Mass Micro-production |

|---|---|---|

| Tooling | High per-part cost | Lower per-part via tool life & reuse |

| Fixturing | High relative cost | Automation amortizes fixturing investment |

| Programming | Per-part overhead | Standardized CAM templates reduce cost |

| Inspection | Manual inspection costly | Inline metrology lowers marginal cost |

| Yield | Scrap hurts small runs | Process control improves yield over runs |

Manufacturing systems: cell architectures and production models

You can run a tiny part on a single benchtop micro-CNC, but for scale you need cells that think like ants: many small units working collectively.

Production approaches you’ll use

- Single-machine prototyping for rapid iterations.

- Micro-cell arrays (tandem machines with shared automation) for micro-batches.

- Distributed microfactories for local production and on-demand parts.

Table: Production models compared

| Model | Best for | Pros | Cons |

|---|---|---|---|

| Single-machine | Design validation | Low capital, flexible | Low throughput |

| Micro-cell array | Small-series production | Scalable, modular | Requires coordination & automation |

| Distributed microfactory | Localized supply | Reduced lead times, resilient | Higher management complexity |

Supply chain impacts and reshoring

Imagine ordering a custom micro-valve and receiving it from the other side of the country in days rather than weeks. You’ll see supply chains shorten, because micro-manufacturing is more adaptable to local demand.

How supply chains change for you

- Lower inventory: make-to-order becomes feasible for small high-value parts.

- Fewer long lead items: localized production reduces dependency on far-flung suppliers.

- Vendor consolidation: you’ll work with micro-specialists rather than large generalists.

Design for Micro-Manufacturing (DfMM)

Design rules change when your parts are measured in microns. You’ll need to adopt new DfMM habits to maximize success and minimize iterations.

Practical DfMM rules you should follow

- Avoid thin unsupported walls unless you have validated fixturing strategies.

- Specify tolerances only where function demands it — overconstraining increases cost.

- Design for single-setup machining where possible to reduce handling and alignment errors.

- Consolidate parts into single micro-machined components to reduce assembly complexity.

Example checklist for your part designs

- Are all tolerances necessary? If not, relax them.

- Can features be made on a single side or in one setup?

- Have you considered fixturing and micro-clamps in the design?

- What surface finish is functional vs aesthetic?

Quality control & metrology at micro scale

If your feature is 0.2 mm across, a regular caliper is laughably useless. You’ll rely on optical systems and clever algorithms to keep quality high.

Inspection technologies you’ll adopt

- Optical profilometry for surface texture and small feature geometry.

- Laser interferometry for axis verification and precision positioning.

- Micro-CT for internal feature inspection and assembly verification.

- AI-based vision systems for rapid pass/fail on repetitive features.

Table: Metrology methods and typical uses

| Method | Typical Use | Precision | Strength |

|---|---|---|---|

| Optical profilometry | Surface roughness & geometry | nm–µm | Non-contact, fast |

| Laser interferometry | Axis calibration & positioning | sub-µm | High accuracy |

| Micro-CT | Internal geometry | µm | Non-destructive internal views |

| AI vision | Visual inspection | µm resolution | Fast automated decisions |

Workforce and skills you’ll need

You might think micro-manufacturing means less human involvement, but the reality is that your team’s skills shift toward higher complexity.

Roles and skills that matter to you

- Micro-CNC programmers who understand small-tool physics and chatter avoidance.

- Fixturing and automation engineers who can design tiny clamps and part-handling systems.

- Metrology technicians trained in optical systems and micro-CT operation.

- Material scientists and process engineers who can tune cutting parameters for micro-tools.

- Maintenance technicians comfortable with precision spindles and piezo systems.

Training approaches to get your team ready

- Short, focused certification programs on micro-CAM and spindle care.

- On-the-job apprenticeships where junior staff learn from experienced micro-machinists.

- Simulation-based toolpath verification to reduce trial-and-error on expensive parts.

Regulatory and standards landscape

You can’t ignore standards when micro-parts live inside medical devices or aircraft — regulators consider scale and complexity.

Standards you’ll encounter

- ISO standards for dimensional metrology and quality management.

- AS9100 for aerospace-related micro-components.

- FDA and CE requirements for medical implants and devices with micro-features.

- Emerging standards around traceability, serialization, and digital twins.

What you must do for compliance

- Maintain traceability of materials, tools, and lot runs.

- Implement validated processes and document first-article inspections.

- Incorporate traceable, calibrated metrology and retain inspection records.

Case studies and early adopters you can learn from

You’ll find successful examples already showing how micro-CNC reshapes production. These cases highlight how design changes, process control, and automation come together.

Example: medical stent holder

A surgical toolmaker replaced EDM and laborious manual finishing with micro-CNC for a stent deployment mechanism. The result: shorter lead times, consistent feature geometry, and lower rejection rates — and surgeons appreciated the higher reliability.

Example: haptic actuator for a wearable

A small electronics firm needed tiny metal housings with precision slots for a haptic motor. By shifting to micro-CNC with inline optical inspection, they reduced cycle time and could iterate new designs in days instead of weeks.

Example: micro-gear for a watchmaker

A boutique watch company used hybrid micro-CNC and additive steps to produce complex gear profiles. You’ll appreciate how micro-machining enabled surface finish and tooth profile control that additive-only methods couldn’t match.

Environmental impact and sustainability

You might assume smaller parts equal less waste, but sustainability requires nuance. Micro-manufacturing can be greener if you consider energy usage, material efficiency, and lifecycle.

Sustainability advantages

- Lower raw material usage per part, especially with consolidated components.

- Reduced transportation emissions when production is localized.

- Less packaging and lower inventory waste due to make-on-demand practices.

Environmental caveats

- Tooling and machining oil use can be proportionally higher per kilogram of material removed; you’ll need efficient coolant recovery and disposal strategies.

- Energy usage for high-speed spindles and thermal control can be significant; consider renewable sources or energy-recovery strategies.

Risks and challenges you should watch

This isn’t all sunshine and tiny bearings. Several pitfalls could trip you up if you’re not careful.

Common risks

- Tool breakage and variation: micro-tools break unpredictably and often without obvious signals.

- Thermal drift: even small temperature shifts ruin micron tolerances.

- Contamination: microscopic chips and debris can clog tiny features or damage spindles.

- Scale-up complexity: fixing single-part issues doesn’t guarantee batch performance.

Risk mitigation strategies

- Implement tool-health monitoring and predictive maintenance.

- Use temperature-controlled environments and machine thermal compensation.

- Adopt cleanroom-like practices for critical processes.

- Standardize process parameters and validate across batches before ramping volume.

Roadmap to 2030: how the timeline looks for you

You’ll want a realistic timeline to plan investments and product launches. The next five years will follow a progression of capability and adoption.

Table: Roadmap milestones (2024–2030)

| Year | Technology & Market Milestone | What it means for you |

|---|---|---|

| 2024 | Early pilot cells & R&D adoption | Prototyping and niche production; high per-part costs |

| 2025 | Improved tool materials & inline metrology | Higher yields and more reliable small-series runs |

| 2026 | Economies of scale in micro-CNC modules | Lower per-part costs, microfactories viable |

| 2027 | Standardized automation & CAM libraries | Faster new-product introductions |

| 2028 | Distributed microfactories become common | Local production and shorter lead times |

| 2030 | Mature ecosystem and regulatory clarity | Micro-manufacturing mainstream for many sectors |

How you can prepare: practical steps

If you want to take advantage of 2026’s micro-manufacturing moment, don’t wait until everyone else is experimenting. Start building the capabilities now.

Checklist for you to act on

- Audit your design portfolio for parts that could benefit from miniaturization.

- Invest in small-scale prototyping capacity — even a single micro-CNC with good fixturing.

- Train a small team in micro-tooling, CAM strategies, and metrology.

- Develop supplier partnerships for micro-tools and micro-fixturing systems.

- Pilot a micro-cell with inline inspection to validate yields before scaling.

What to prioritize in your budget

- Tooling and metrology initially beat raw machine count for ROI.

- Fixturing and part-handling automation reduce labor errors and save time.

- Software licenses and CAM templates pay off quickly once you standardize part families.

Business models you can adopt

You’ll find several business models that let you capitalize on micro-manufacturing without massive upfront commitments.

Models that work well

- Microfabrication-as-a-service: offer small-batch, high-precision runs to other firms.

- Distributed production network: deploy small cells in multiple regions for local demand.

- Co-development partnership: share development costs with customers who need custom micro-components.

Pros and cons to weigh

- Service models need excellent QC to build trust quickly.

- Distributed networks require robust digital coordination and traceability.

- Co-development reduces product risk but requires contractual clarity on IP and volume pricing.

Cultural and organizational shifts you’ll lead

You’ll need to change more than machines. Micro-manufacturing asks you to rethink engineering timelines, procurement habits, and value chains.

Organizational changes to consider

- Shorter design cycles with more frequent iterations.

- Stronger collaboration between designers, process engineers, and metrology teams.

- Metrics focused on yield, time-to-market, and per-part total cost rather than only machine utilization.

Final thoughts: why 2026 is the pivot year for you

By 2026, the combination of technology readiness, market demand, and improved economics makes micro-manufacturing a practical choice for serious producers. You’ll move from the realm of boutique craftsmanry into scalable, reliable production that still delivers the charm of a hand-made part.

A parting observation in a tone you might like

If you begin now, you’ll be one of the people who can say you were making tiny miracles before they were fashionable. Your parts will be small, your margins might be surprisingly sane, and your lead times will be something you can confess at dinner without sounding apologetic. You’ll also gain the peculiar pleasure that comes from mastering a craft so detailed that a grain of dust becomes a villain in your story — and you’ll like that because it means you care.

If you want, you can use the checklist above as a start. You don’t have to overhaul everything overnight; a single micro-CNC cell and a disciplined DfMM process will tell you more than months of speculation.