?Have you ever wondered what “fabrication intelligence” actually means, or have you watched a maker machine and concluded either that it is sorcery or that you should have paid more attention in that one night class on CAD?

What Is Fabrication Intelligence? A 2026 Framework For Modern Makers

You’re about to get a map for a territory that feels part workshop, part neural net, and part improv comedy act. Fabrication intelligence (FI) is the mash-up of digital smarts and physical making — the systems, practices, and behaviors that let machines and people fabricate with foresight, adaptability, and efficiency. By 2026 it’s less theoretical and more practical: a framework to guide makers, small manufacturers, designers, and hobbyists who want to be both precise and creative while navigating supply chain chaos, sustainability pressures, and AI that sometimes tells you your prototype is “aesthetic” in a way you didn’t ask for.

Why this matters to you

You probably care because you make things, or plan to, or supervise those who do. Maybe you want to reduce trial-and-error, cut material waste, speed up iteration, or hand off grunt work to an algorithm so you can argue about color. Fabrication intelligence helps you do those things with fewer burned prototypes and fewer nights spent swearing at a soldering iron.

Defining Fabrication Intelligence

You can think of FI as a layered system: sensors and machines at the base, algorithms and data in the middle, and human practices at the top. All three interact to create a feedback loop that’s smarter than a machine alone, because you’re still in the loop.

- At its core, FI is about data-driven making: using information to predict, control, and improve fabrication outcomes.

- It combines AI, automation, materials science, manufacturing hardware, and human judgment.

- It’s not just automation. If automation is a dishwasher that does the same cycle forever, FI is the dishwasher that senses your plates, adjusts detergent, predicts when you’ll need a new filter, and sends you a passive-aggressive email about your cookware choices.

Key elements in one sentence each

- Sensors and IoT: Collect real-time data on process conditions.

- AI and analytics: Model, predict, and optimize fabrication steps.

- Digital twins: Virtual replicas for simulation and testing.

- Automated fabrication hardware: CNC, 3D printers, laser cutters with feedback.

- Human-in-the-loop workflows: Designers and technicians guiding and validating AI decisions.

- Materials and supply intelligence: Data on materials behavior and availability.

A short history (so you don’t feel like this came from Mars)

It helps to remember that fabrication intelligence didn’t arrive fully formed. You don’t wake up one morning and suddenly have a smart factory; you evolve from hand tools to mechanization, then to computerized control, and finally to integrated, data-driven systems.

- Pre-20th century: Craft, apprenticeship, tacit knowledge.

- 20th century: Mass production, standardized processes, statistical quality control.

- Late 20th–early 21st century: CNC, CAD/CAM, initial automation.

- 2010s: IoT and additive manufacturing matured; data began to matter more.

- 2020s: AI models, digital twins, and accessible automation made FI practical for small shops and hobbyists.

Why call it “intelligence”?

You might object: “Machines are not intelligent, they just follow rules.” Fair. But intelligence here is functional: the ability to adapt, predict, and improve fabrication outcomes based on data. Like someone who fixes a toaster by listening to it pop and getting suspicious of burnt crumbs, FI systems infer patterns, learn from outcomes, and change behavior.

How Fabrication Intelligence Differs From Traditional Automation

You’ve seen automation: repeatable, rule-bound, great for factories making one widget a billion times. FI adds adaptation, learning, and context. Here’s a quick comparison:

| Feature | Traditional Automation | Fabrication Intelligence (FI) |

|---|---|---|

| Decision model | Preprogrammed rules | Data-driven models + human input |

| Adaptation | Low | High — learns and adjusts |

| Variability handling | Poor | Designed for variability |

| Feedback | Limited | Continuous, real-time |

| Target scale | High volume | From prototypes to small-batch production |

| Goal | Repeatability | Efficiency, flexibility, optimization |

Components of a 2026 FI Framework

You will find it useful to imagine FI as a stack: hardware, data, software, workflows, and governance. Each layer needs attention.

Hardware and sensing

You need accurate sensing and reliable actuators. This is where you stop wondering if the noisy thing is supposed to be noisy and start checking thermocouples.

- Sensors: temperature, force/torque, optical, acoustic emissions, vibration, humidity.

- Edge devices: local controllers that preprocess data and handle low-latency actions.

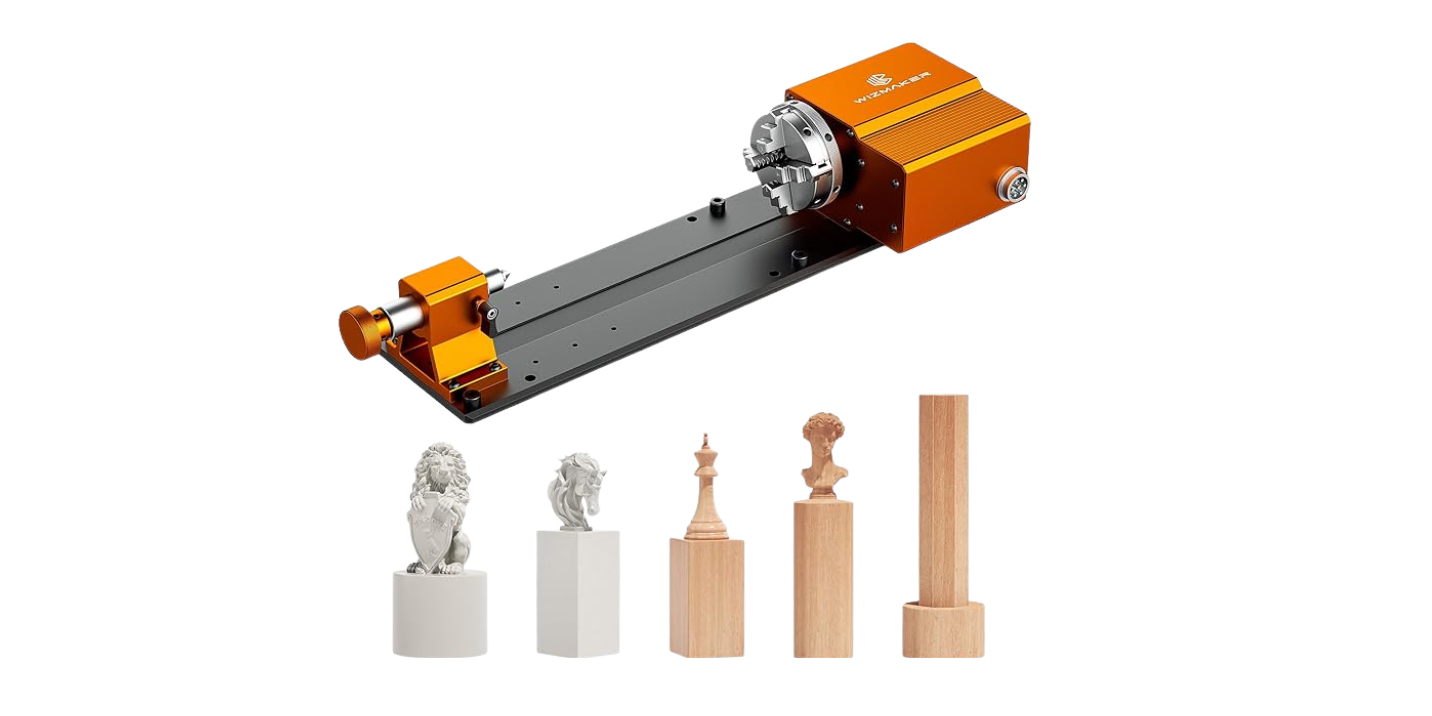

- Fabrication machines: 3D printers (FDM, SLA, SLS), CNC mills, cutters, pick-and-place machines, laser systems, robotic arms.

Data infrastructure

Data is messy. You will spend time cleaning it, labeling it, and sometimes crying quietly while it refuses to be useful.

- Data capture: structured logs, time-series, image and video streams.

- Storage: on-premise or cloud data lakes with secure access.

- Preprocessing: feature extraction, noise filtering, calibration correction.

- Metadata: versioning, build parameters, materials lot numbers.

Models and analytics

If sensors are ears, models are the sense you get when you realize the tea kettle is whistling because you forgot to turn off the stove.

- Predictive models: failure prediction, quality estimation, throughput forecasting.

- Control models: closed-loop control, reinforcement learning for process tuning.

- Optimization: nested simulations to minimize material use, cycle time, or cost.

- Visual analytics: dashboards and alerts that don’t require a PhD to interpret.

Digital twins and simulation

You use digital twins to try destructive things virtually before you do them physically. It’s like testing your stand-up routine in front of a sympathetic mirror.

- Virtual replicas of machines and processes for scenario testing.

- Material behavior models that simulate warping, curing, or stress.

- Integration with CAD and workflow tools for end-to-end planning.

Human-in-the-loop workflows

You remain crucial. FI amplifies your judgment and helps you focus on decisions that require creativity and ethics.

- Operator dashboards with prioritized actions.

- Explainable AI that gives you reasons, not just numbers.

- Collaborative interfaces connecting designers, fabricators, and QA.

Governance, safety, and compliance

You need rules and guardrails, because otherwise the machine might design a charming but structurally unsound garden gnome.

- Standards for process validation, traceability, and certification.

- Safety interlocks, emergency stop systems, and model validation.

- Documentation for auditability and liability management.

Practical tools and technologies to know in 2026

You don’t need to master everything, but knowing the landscape helps. Think of this as your travel guide to the fabrication technology bazaar.

- CAD/CAM: parametric design tools with generative design features.

- Slicing and toolpath generators: optimized for speed, strength, or surface finish.

- MES (Manufacturing Execution Systems): orchestration of jobs and tracking.

- Edge ML frameworks: TensorFlow Lite, ONNX Runtime for local inference.

- Digital twin platforms: simulation engines and physics-based solvers.

- Quality inspection tools: machine vision, laser scanners, CT scanning services.

- Supply intelligence: APIs that track material availability and lead times.

Use cases across maker profiles

You might be a hobbyist, a garage startup, a small manufacturer, or an R&D lab. FI serves them differently.

Hobbyists and prosumers

You want the best print without ornately crying over support structures.

- Guided slicing with material-aware presets.

- Small-scale sensors for print failure detection and pause-restart features.

- Community-shared models of process parameters.

Startups and small businesses

You need consistency without a team of PhDs.

- Process standards packaged as templates.

- Cloud-connected machines that report metrics for remote teams.

- Rapid quality checks to avoid shipping returns that ruin your week.

Contract manufacturers

You must balance many jobs and meet SLAs.

- Predictive maintenance to reduce downtime.

- Workload scheduling with dynamic routing across machines.

- Traceability and compliance data for audits.

Research and advanced fabrication labs

You push materials and geometry to extremes.

- High-fidelity simulations for novel materials.

- Automated experimental design with optimization loops.

- Close integration between data capture and scientific notebooks.

Implementation roadmap: from curiosity to FI in production

You might feel tempted to throw money at the brightest robot, but start with small wins.

- Inventory and measurement: instrument key machines and start logging.

- Baseline analytics: find your biggest pain points — scrap rates, downtime.

- Proof of concept: pick one use case (e.g., print failure detection), build a model.

- Integration: connect model outputs to operator interfaces or automated actions.

- Scale and standardize: create templates, document processes, train staff.

- Governance: define audit trails, safety standards, and model validation procedures.

Quick checklist (table)

| Phase | Action | Outcome |

|---|---|---|

| Inventory | Instrument critical machines | Data availability |

| Baseline | Analyze KPIs | Prioritized problems |

| PoC | Build one model | Proof of value |

| Integrate | Connect to workflows | Reduced manual steps |

| Scale | Standardize templates | Repeatable processes |

| Govern | Implement policies | Auditable operations |

Data strategy and quality: the often-ignored hero

You will succeed or fail based on data quality. Garbage in, ornate but useless graphs out.

- Provenance: track data sources and timestamps.

- Labeling: invest in consistent labeling for supervised learning.

- Sampling: get representative data across machine states and materials.

- Privacy and security: secure sensitive design files and telemetry.

Human factors and change management

Machines are not the only ones learning. Your team will need new skills and new habits.

- Training: practical sessions focused on using dashboards and interpreting model outputs.

- Roles: designate data stewards, model owners, and machine champions.

- Culture: reward experimentation, but with risk controls.

- Ergonomics: design operator interfaces for quick decisions under real conditions.

Quality control and inspection strategies

Quality has always been your enemy and ally. Use FI to make it less random.

- Inline inspection: non-destructive sensors that monitor part geometry and surface finish.

- Statistical process control (SPC): shift from manual sampling to continuous monitoring.

- Root-cause analysis: automated correlation of variabilities to machine parameters.

- Feedback loops: adjust process parameters automatically based on inspection results.

Materials and supply intelligence

Materials matter, and their availability will keep you humble.

- Material models: integrate vendor-supplied behavior and validated lab data.

- Lot traceability: correlate part performance to material lots.

- Supply forecasting: use market data to anticipate shortages or price spikes.

- Alternative sourcing: algorithms that suggest viable substitute materials and revalidate builds.

Safety, reliability, and legal considerations

You’re responsible for what you build and what your machines do. FI amplifies risks if you don’t manage them.

- Model risk: validate models against edge cases and failure modes.

- Fail-safe design: ensure human overrides and safe defaults.

- Documentation: maintain logs for legal compliance and liability clarity.

- Regulatory standards: align with ISO, ASTM, and industry-specific regulations.

Ethical and social implications

You’ll probably replace routine human tasks. People matter, even if they occasionally use a rivet gun like a personal vendetta.

- Job displacement: focus on retraining and higher-value roles.

- Transparency: explain how models decide, especially where safety is involved.

- Environmental impact: measure and minimize embodied energy, waste, and emissions.

- Accessibility: ensure FI tools don’t only reward those with deep pockets.

Case studies (short)

You appreciate real stories. Here are compressed anecdotes that show what FI looks like in practice.

Garage studio becomes product startup

A jewelry maker used sensor-equipped SLA printers and image-based defect detection to cut failed prints by 70%. That saved them nights of reprints and an embarrassing run of misshapen pendants that they blamed on Mercury retrograde.

Contract shop reduces downtime

A small CNC shop implemented vibration and temperature monitoring with edge ML. They moved from reactive maintenance to predictive alerts, reducing unscheduled stops by 40% and making their owner stop cursing when the spindle clunks.

University lab accelerates composites research

A materials lab integrated digital twins and automated experimental design. Instead of manually testing variants, they let the system propose experiments, run them, and reinterpret results — shortening iteration cycles by weeks.

Metrics that actually matter

You’ll be tempted to watch uptime like it’s a soap opera. Measure what aligns to your goals.

- Yield rate: first-pass success percentage.

- Time-to-prototype: from CAD to functional part.

- Scrap rate and material waste.

- Throughput per machine or cell.

- Predictive maintenance accuracy (false positives/negatives).

- Customer returns and field failures.

Common pitfalls and how to avoid them

You’ll read blogs predicting a robot will take over. Reality is messier.

- Pitfall: Starting with flashy tools, not data. Fix: instrument first, then model.

- Pitfall: Over-automation. Fix: keep human oversight and explainability.

- Pitfall: Treating models as permanent. Fix: continuous validation and retraining.

- Pitfall: Ignoring change management. Fix: involve operators from the start.

A practical example: setting up print-failure detection

This is a focused, slightly messy example. You can treat it as a practical starter kit.

- Sensors: install a small camera above the print bed and a thermistor on the nozzle and bed.

- Baseline dataset: collect 200+ prints labeled as pass/fail using consistent lighting and angles.

- Preprocessing: normalize images, extract motion patterns, timestamp sensor logs.

- Model: train a convolutional neural network for image classification plus an anomaly detection model on temperature traces.

- Deployment: run inference on an edge device; on failure flag, pause print and message the operator.

- Feedback: log the operator decision and the final outcome to retrain the model monthly.

The role of open source and communities

You don’t need to reinvent everything. Communities will save your hours and dignity.

- Shared parameter libraries: community-tested slicer and process settings.

- Open datasets: labeled failure cases that speed model training.

- Plugins and integrations: community-developed connectors to link devices and dashboards.

- Standards: community-driven formats that avoid lock-in.

Business models and monetization

If you’re reading this as someone charging for manufacturing, FI changes what you bill for.

- Outcome-based pricing: charge per successful part or function, not just per hour.

- Subscription services: continuous monitoring and model updates as a service.

- Platform monetization: selling templates and validated process packages.

Long-term outlook to 2030 and beyond

You want a sense of direction. By 2030, FI will be more integrated, more automated, and a little less dramatic than current hype implies.

- Standardization: common data formats and interfaces will reduce integration friction.

- Model marketplaces: validated process models and digital twin components will be traded.

- Democratization: affordable edge ML hardware and modular sensors will let more makers adopt FI.

- Sustainability focus: lifecycle intelligence will become a default requirement.

Final recommendations (for the pragmatic you)

You don’t need a full-bodied AI lab to start. Be practical.

- Start small: instrument one process and prove value.

- Prioritize safety and explainability.

- Invest in people: train operators and assign ownership.

- Use modular tools: choose systems that let you plug in better models later.

- Keep documentation: version everything from material lots to model checkpoints.

Conclusion

You’ve read a lot, and if you’re honest, you might be both optimistic and suspicious. Fabrication intelligence is not a magic wand, but it’s an honest toolkit to help you make better things, faster, and with less grief. It asks you to add sensors, collect data, and accept that sometimes a model will suggest something you didn’t think of — and sometimes you’ll ignore it because the human gut matters too.

If you want to start, pick the machine that annoys you most at 2 a.m., put a sensor on it, and build from there. You may not become a prophet of the smart factory overnight, but you’ll stop blaming the printer for your problems and start designing systems that improve — intelligently, humanely, and with slightly less cursing.