Can we admit that the smell of lightly toasted wood has become our new favorite room fragrance?

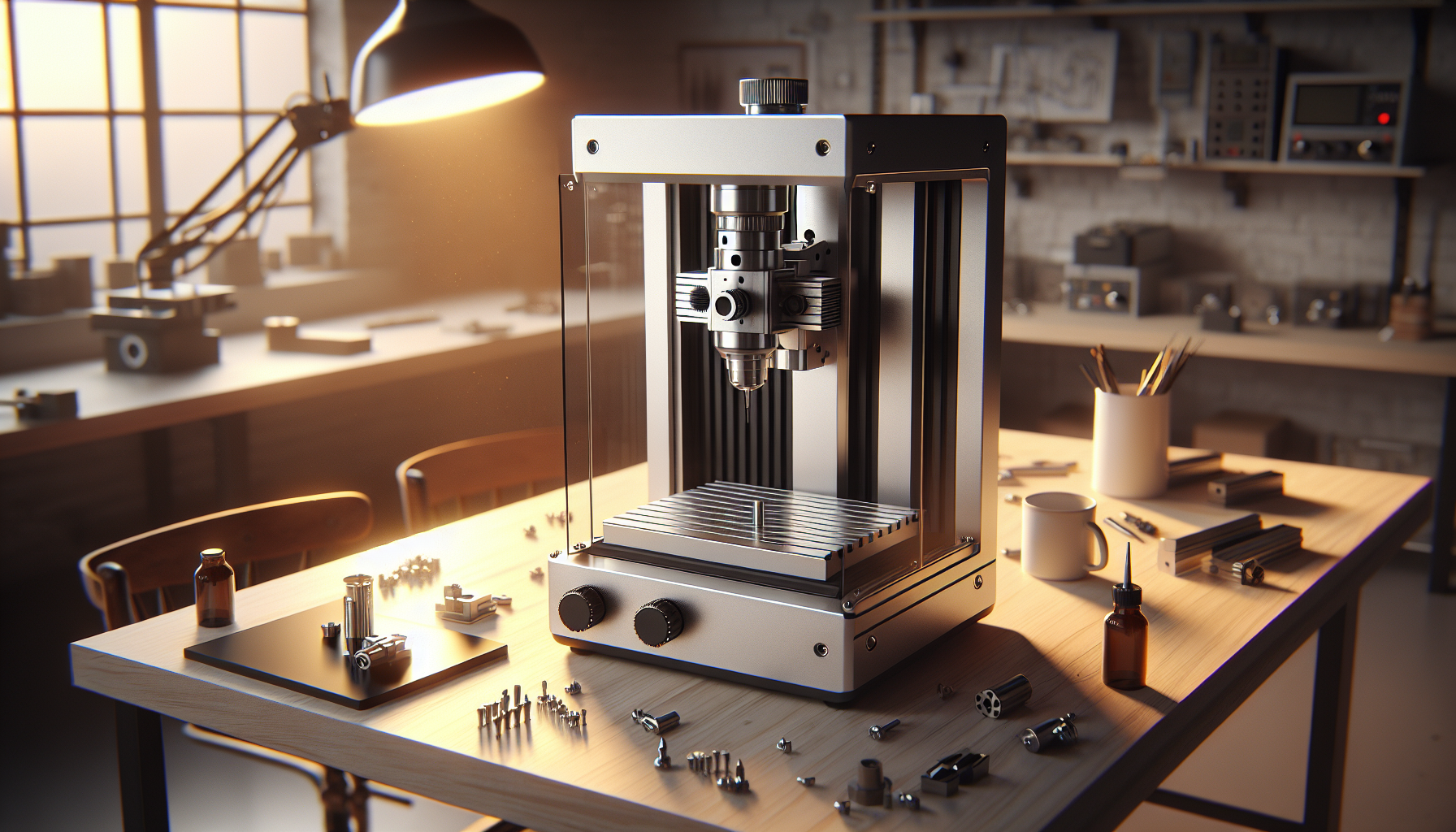

Why we chose the WAINLUXPRO K10 3000mW

We wanted a compact, safety-conscious laser engraver that doesn’t require us to reorganize our home or mortgage. The WAINLUXPRO K10 3000mW promised thoughtful safeguards, a small footprint, and the kind of precision that makes us feel more like artisans and less like people burning our initials into scrap plywood.

Quick summary in two lines

This is a 3W diode laser engraver with a fully enclosed, Laser Class 1 design and an easy app called Cutlabx. It connects by Wi‑Fi or USB, engraves common materials like wood, leather, acrylic, and coated glass, and it’s aimed squarely at hobbyists, families, and small craft setups.

WAINLUXPRO K10 3000mW Laser Engraving Machine,0.01mm Accuracy Laser Engraver, WiFi Connection,DIY Tools for Wood, Leather, Laser Class1,Offline Engraving,Grabadora Láser

At‑a‑glance features and what they mean for us

| Feature | What it means for us |

|---|---|

| Laser Class 1 enclosure with micro‑opening induction shield | Built-in safety: shield stops the machine when opened, and the window filters blue light (manufacturer states 99.7%). We still treat it like a real laser and keep good habits. |

| 3000mW (3W) diode laser at 455 nm ±5 nm | Suitable for engraving organic materials and certain coated surfaces. Not meant for bare metals or highly reflective surfaces. |

| 0.01 mm accuracy | Fine detail on logos, type, and line art when focus and settings are right. |

| Wi‑Fi connection for iOS/Android + USB for Windows/macOS | Simple setup with phones or computers. We can run jobs offline after transfer. |

| Cutlabx app and PC compatibility | The included app is beginner‑friendly; we can also use LaserGRBL (free) and LightBurn (paid) if we want more control. |

| Four modes listed; documentation names black & white, discrete, outline (the fourth is unspecified) | Mode options for different artwork styles; we mostly use black & white and outline for clean edges. |

| Supported image formats: JPEG/JPG/GIF/BMP/PNG | We can bring in artwork from almost anywhere. |

| Rotary roller support (add‑on) | Options for cylinders like tumblers or rolling pins. |

| FDA registration (Accession No. 2311241-004); IEC 60825‑1 tested | Regulatory compliance and a more established safety profile. |

| One‑year warranty and manufacturer support | A safety net if we run into trouble. |

Unboxing and first impressions

We opened the box braced for parts and panic, but what we found looked more like a polite appliance than a science project. The enclosure is compact and tidy, with a viewing window that keeps things civilized while still letting us keep an eye on the engraving progress.

Safety-first design that’s actually thoughtful

The “micro‑opening induction shield” is a mouthful, but what it does is dead simple: when the lid opens, the machine stops. It’s the kind of interlock that makes us exhale. The window has an anti‑laser tint that filters blue light, and the body uses fire‑resistant engineering plastic. We still never leave it unattended; a small laser plus flammable material is not a set‑and‑forget situation.

Build quality and footprint

Everything feels sturdy for a compact unit. The moving parts track smoothly, and the sealed design keeps smoke and dust somewhat contained. We fit it comfortably on a desk, and when we’re done, it looks like a gadget rather than a garage tool. That counts for something when the dining table doubles as a workshop.

Getting set up without drama

Setup is short and mercifully uneventful. We followed the quick‑start steps, powered it on, and connected via the app. For anyone who loses patience faster than a laser beam travels, this is a relief.

Wi‑Fi connection with phones and tablets

We connected our iPhone and Android devices through Cutlabx. Once paired, we loaded an image, chose a mode, and set power/time. The app walks us through the process, and for a first run, it’s reassuring to see something recognizable etch onto a bit of bamboo.

USB connection for Windows and macOS

We took the more “serious” route with USB on a Mac and a Windows laptop. Cutlabx runs there too, but we also tried LaserGRBL (Windows, free) and LightBurn (Windows/macOS/Linux, paid). USB gives us a sturdier connection, and with LightBurn we got more granular control over power, speed, and layering.

Offline engraving for the easily distracted

A nice feature: we can send a job and let the K10 run it without babysitting the computer or phone connection. If our Wi‑Fi hiccups or our cat decides to nap on the keyboard, our coaster monograms remain on schedule.

Software and workflow we can live with

The learning curve is manageable—even if we’re not the kind of people who relish manuals. We appreciate that we can start simple with Cutlabx and graduate to more advanced programs later.

The Cutlabx app: friendly, with training wheels

Cutlabx is clearly designed for beginners and casual makers. We import a PNG or JPG, size it, pick black & white or outline mode, and start. There’s also a library of project templates aimed at parent‑child activities, crafts, and education. It’s wholesome, and it actually helps with ideas when our brain is a blank slate.

LaserGRBL and LightBurn integration: for control enthusiasts

LaserGRBL is solid if we want a free desktop tool for Windows. LightBurn is the gold standard in laser hobby circles, and the K10 plays well with it. We got smoother motion planning and better path optimization in LightBurn, plus the option to vectorize artwork. If we plan on selling items or running batch jobs, LightBurn is worth it.

Image formats and engraving modes

We stuck with PNG for logos and transparent backgrounds, JPG for photos, and occasionally BMP for line art. The documentation mentions four engraving modes but names three: black & white, discrete, and outline. We used black & white for photos converted to threshold, discrete when we wanted a stippled feel, and outline for clean line drawings and signatures.

What we engraved and how it turned out

The 3W diode isn’t a metal carver, but for wood, leather, paper, and coated materials, it’s more capable than its size suggests.

Wood and bamboo: the sweet spot

We got consistent, high‑contrast results on birch ply, bamboo, basswood, and walnut. After focusing carefully and doing test swatches, line art came out crisp and small text remained legible down to a few millimeters. On darker hardwoods, we sometimes slowed down a touch to deepen the mark. When engraving cutting boards, we kept away from food‑contact areas or sealed them after, because char isn’t seasoning.

Leather and fabric: texture, meet laser

Vegetable‑tanned leather took marks beautifully, with a dark, permanent brand‑like finish. We used light passes on faux leather to avoid melting. On cotton canvas and denim, we got a controlled faded look; think custom patches and tote bag designs. As always, we ventilated—burning textiles comes with a certain aroma that our pets did not sign up for.

Paper and cardboard: delicate but delightful

We made custom cards, tags, and packaging accents. Low power and higher speed kept the edges from charring too much. Cardboard etched nicely for stamps and logos on shipping boxes—handy if we’re small‑batch sellers who like a personal touch on packaging.

Acrylic and plastics: engrave, don’t cut

On opaque and painted acrylic, marks show up clearly. Transparent acrylic and reflective plastics are a no‑go without coating; the manufacturer warns that reflections can damage the laser head. We used a matte black paint or a sacrificial black film when working with shiny plastics, then peeled or cleaned it off afterward. Cutting isn’t the K10’s thing—this is engraver territory.

Glass and ceramics: coat it first

The machine can mark glass and ceramic if we paint the surface black first or use a dedicated black engraving tape. The paint absorbs the energy; the glass itself does not. After engraving, we scrubbed off the coating with warm water or alcohol to reveal the frosted pattern underneath. It’s oddly satisfying to watch a wine glass transform from zero personality to monogrammed confidence.

What it can’t engrave: metals and mirrors

The K10 is not built for bare stainless steel or aluminum. Transparent or reflective materials are also off limits unless coated. The manufacturer is clear about this, and we appreciate that honesty. If we want deep metal engraving or fast cutting, we’d need a more powerful diode with specialized coatings or a different class of machine entirely.

Real‑world performance and precision

Do we get the promised 0.01 mm accuracy? Within the constraints of material and focus, yes—enough to make tiny details look intentional rather than accidental.

Focus and alignment: where the magic lives

We learned quickly that careful focusing is half the battle. A clean lens, a correctly set focal distance, and a flat, stable material surface made the difference between “nice” and “did we outsource this?” Once dialed in, fine lines and micro‑text were clear.

Speed and throughput: 3W expectations

A 3W diode is built for engraving, not cutting or turbo‑charged production. For bookmarks, coasters, phone‑case backs, leather tags, and small plaques, the pace felt reasonable. Larger photo‑style engravings take longer, especially at higher resolution or stipple settings. We queued multiple pieces in one bed and let the machine hum while we pretended this was passive income.

Noise, smoke, and smell

It’s not loud, but the fan and motion are audible. The bigger consideration is fumes; burning wood smells like a campfire, but leather and plastics are less romantic. We kept a window cracked and a small fan pointed outward. If we planned on daily use, we’d consider a compact air purifier or an external vent.

Safety practices we actually stick to

The K10 is Laser Class 1 with a smart shield and interlocks. That’s encouraging, not a license to be careless.

Interlocks, motion protection, and overheating monitors

We tested the lid interlock by accident the first week—we lifted it mid‑job to adjust a clamp, and the machine stopped instantly. Motion protection and overheating monitoring add extra layers of safety, which we appreciate on days when caffeine outruns our coordination. Still, we never leave the room during an engraving job.

About goggles and the viewing window

The manufacturer notes that the shield’s window filters blue light. We treat that as a helpful layer, not an invitation to stare into an active laser. We keep our gaze casual and brief during a job and avoid leaning in. If we ever run the machine with the shield open for maintenance or testing (not recommended), we use proper laser safety glasses rated for 455 nm.

Fire safety: we keep it boring

We keep a small fire extinguisher nearby and a clean workspace. We avoid stacking materials inside the enclosure and never engrave anything with unknown coatings that might catch fire or release nasty fumes. The sealed design helps, but our common sense does the heavy lifting.

Maintenance and longevity: tiny tasks, big dividends

We want this engraver to age gracefully, so we treat maintenance like a ritual. It’s not difficult, and it’s cheaper than replacing parts.

General cleaning: weekly wipe‑downs

The manufacturer suggests wiping internal smoke and dust weekly with a dry rag. We do that, paying attention to corners where soot likes to loiter. When we store the K10, we toss in desiccant bags and keep it dry. Moisture is not a friend.

Laser lens care: every 30 hours

A cotton swab and a little alcohol clean the laser head window lens. Dust can block the beam and cause energy to build up, which risks damaging the lens. We set a reminder: every 30 hours of operation, we give the lens a gentle spa day.

Screws and lubrication: smooth motion, smooth results

We check the transmission screw for dry lubricant and reapply when needed. Dust buildup can cause chattering or artifacts in engravings, so we keep those threads tidy. It’s satisfying in the way that folding laundry can be—tedious but undeniably effective.

Rotary engraving: when cylinders join the party

If we add a rotary roller, the K10 can engrave cylindrical objects. Think mugs (coated or painted), rolling pins, and tumblers. We tested with coated stainless tumblers after painting a band of removable black marking spray. The results looked crisp, and the setup wasn’t fussy once we got the height and alignment set.

Tips for rotary work

- Secure the object to prevent slip; a single wobble equals a warped logo.

- Use test markings on painter’s tape before committing to the real surface.

- Check that the design is mirrored if needed; our mugs do not benefit from upside‑down names unless we’re going for an inside joke.

A machine that plays well in family and classroom settings

The K10 leans into parent‑child projects, with materials and templates available in the Cutlabx library. That’s a nice touch, especially for makerspaces and classrooms that value guided activities. We keep a close eye if kids are present—this is still a laser, not a toy—and we prefer to be the ones loading and unloading material.

Simple projects that actually land

- Personalized wooden bookmarks for book fairs

- Leather key fobs with initials for party favors

- Classroom signs and labels on birch ply

- Etched designs on ceramic tiles using black paint as a coating

- Custom cardboard tags for student projects

Support, warranty, and compliance

We’re cautious with anything that emits energy and heat, so regulatory clarity and warranty coverage matter to us.

FDA registration and IEC testing

The K10 is registered with the FDA (Accession No. 2311241-004) and tested to IEC 60825‑1, with a Laser Class 1 designation. We take that as a baseline assurance that the product meets safety standards, with the usual caveat: safe operation is still on us.

One‑year warranty and manufacturer support

There’s a one‑year warranty, and the company states it’s the actual manufacturer. We reached out with a small software question and got a prompt, helpful reply. We kept our order details and serial handy, and that kept the conversation short and painless.

How it compares to other options

No engraver exists in a vacuum (except perhaps in our dreams of a sawdust‑free workshop). Here’s where the K10 fits.

Versus open‑frame 3W diode engravers

Open‑frame models often cost a bit less and have larger work areas. But they lack the K10’s enclosure, interlocks, and filtered window. If we’re engraving in a living room or shared space, the K10’s safety‑forward design feels better. If we have a dedicated, ventilated workshop and want a bigger bed, open frames can be appealing.

Versus higher‑power diodes and CO2 lasers

A 10–40W diode or a 40–60W CO2 machine will cut faster, mark deeper, and handle more materials. They also cost more, take more space, and often require external ventilation, water cooling, or more frequent maintenance. The K10 is the “small studio apartment” of lasers—cozy, tidy, and perfect if our ambitions lean toward engraving rather than cutting. If we need production‑level throughput or metal marking, we’d graduate to a different class.

Tips and best practices we wish we knew sooner

Little habits make a big difference, and our trash bin of test scraps has turned into a kind of wisdom archive.

Artwork preparation

- Convert photos to high‑contrast black & white before importing. We use curves and threshold to keep midtones from turning into mush.

- Use vector artwork (SVG) when possible; if we import as PNG, set it to a high resolution.

- Keep text bold and above 8–10 pt for best legibility on wood.

Material prep

- Sand lightly and wipe with a lint‑free cloth before engraving wood.

- Mask glossy surfaces with painter’s tape to reduce soot sticking; after engraving, peel for clean edges.

- For glass or ceramic, coat with black paint or use dedicated black engraving tape to protect the laser head and improve marking.

Test grids are our secret weapon

We make a small test grid on each new material with varying power and speed. It takes a few minutes and saves us from re‑making a gift that suddenly looks like it slept in the fireplace.

Common mistakes and how we fixed them

We made them so you don’t have to. Or, realistically, so you make them with less cursing.

Burn marks and over‑charred edges

- Problem: Dark halos around designs on soft wood.

- Fix: Lower power, increase speed, and clean the lens. Masking tape can help; peel after engraving.

Faint or patchy engravings

- Problem: The mark looks inconsistent or too light.

- Fix: Refocus the laser, slow down slightly, or increase power in small increments. Make sure the material is flat and clamped.

Banding or misalignment

- Problem: Lines don’t line up or there’s a repetitive stripe pattern.

- Fix: Clean and lubricate the transmission screw, check belt tension (if applicable), and secure the workpiece. Reduce acceleration settings in LightBurn if needed.

Connection hiccups

- Problem: Wi‑Fi drops mid‑job or app disconnects.

- Fix: Send the job for offline engraving, use USB for long runs, or move the machine closer to the router. Ensure the device isn’t going to sleep.

Lens damage fear

- Problem: We accidentally tried a shiny surface.

- Fix: Stop immediately. Paint the surface black or apply black engraving tape, refocus, and try a small test run. Inspect and clean the lens before resuming.

Living with the K10 day to day

We’ve settled into a pattern: design on a laptop, send to the machine, and let it etch while we line up the next idea. The sealed design keeps the workspace neat, the app is reassuringly simple, and the safety features help us relax without tempting us to be reckless. The best part might be the feeling of progress we get from small, beautiful objects leaving the machine—coasters, tags, tiles—like little trophies for our attention span.

Projects that made us unreasonably happy

- A set of bamboo coasters engraved with a local map—clean lines and lots of oohs from guests

- Leather luggage tags with initials—sturdy, readable, and very giftable

- Ceramic kitchen spoon rests with botanical outlines—paint, engrave, scrub, admire

- Custom notebook covers on kraft board—minimalist and easy to batch

- Classroom door sign on birch ply—clear lettering that looks store‑bought

Environmental and workspace considerations

We run the K10 in a well‑ventilated area. A small window fan helps push fumes outside, and we keep the machine elevated on rubber feet for stability. We put a silicone mat under it to catch any residue when cleaning. The enclosure keeps the worst of the mess contained, and our vacuum has never been more appreciated.

Frequently asked questions we asked ourselves

Does the window really mean no goggles?

The manufacturer says the window filters blue light and is part of a Laser Class 1 enclosure. We still avoid staring at the beam and treat it with care. If the shield is open for any reason, we wear proper laser safety glasses rated for the diode’s wavelength.

Can we engrave stainless steel or aluminum?

Not directly. The K10 is not designed for bare metals. We stick to wood, leather, acrylic (opaque or coated), paper, cardboard, and coated glass/ceramics.

Do we need the rotary roller?

Only if we plan to engrave cylindrical items regularly. For mugs, tumblers, and rolling pins, it’s great. Otherwise, flat work covers most hobby needs.

Is LightBurn worth it?

If we’re doing many projects, want layering, or need better path control and a polished workflow, yes. If we’re casual and happy with basic settings, Cutlabx is fine.

How big is the working area?

The manufacturer doesn’t focus on a large bed; this is a compact, enclosed engraver oriented to small projects. If we need a very large work area, we’d consider an open‑frame machine.

How often should we clean?

Weekly wipe‑downs inside the enclosure, lens cleaning every 30 hours of use, and periodic lubrication of the transmission screw. It’s quick and keeps engravings consistent.

Who this engraver is perfect for

- Hobbyists who want a safe, compact machine in a shared living space

- Parents and educators looking for structured, supervised craft and STEM projects

- Etsy or small craft sellers making small goods, personalization, and packaging accents

- Beginners who want an easy app and a short learning curve without sacrificing precision

Who should consider something else

- Makers who need to cut thick wood or acrylic regularly

- Anyone wanting to engrave bare metals without coatings

- Production shops that prioritize speed and large bed sizes

Pros and cons after real use

What we love

- Safety‑forward, Laser Class 1 enclosure with responsive interlock

- Compact footprint that fits a real home, not just a workshop

- Clean, sharp engraving on wood, leather, and coated materials

- Simple Cutlabx app plus compatibility with LaserGRBL and LightBurn

- Offline engraving and reliable USB connection

- Clear warnings about reflective materials and sensible documentation

- FDA registration and IEC 60825‑1 testing offer peace of mind

What we’d change

- Limited to engraving (not cutting) and not suitable for bare metals

- Transparent/reflective materials require coating, which adds a step

- The documentation mentions four engraving modes but names only three

- Work area is modest; larger projects require tiling or another machine

Final thoughts on the WAINLUXPRO K10 3000mW

We bought this machine for its safety and stayed for its results. The WAINLUXPRO K10 3000mW Laser Engraving Machine (Grabadora Láser, as the listing helpfully says) packages the essentials—precision, ease of use, and real‑world safeguards—into a tidy unit that doesn’t ask for much beyond a good cleaning routine and a little respect. It’s honest about its limits: it won’t carve thick wood, it won’t etch bare metals, and it’s not a production behemoth. But within its lane, it’s a pleasure.

We kept coming back to it on weeknights when we wanted to make something tangible without clearing the whole garage. It turned scraps into gifts, ideas into prototypes, and the smell of toasted bamboo into a punchline in our home. For a first laser engraver or a compact, family‑friendly unit with just enough sophistication to grow with us, the K10 makes a compelling case.

If our goals are small to medium engravings on wood, leather, cardboard, acrylic, and coated glass or ceramics—and we value an enclosure that’s serious about safety—the WAINLUXPRO K10 earns a spot on our desk. We clean it, we respect it, and in return it helps us put our name on the world, one crisp outline at a time.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.