Is this the moment we finally give our garage the job title “creative studio” and mean it?

What This CNC Router Promises—and Why We Were Curious

We were drawn to the VEVOR CNC Router Machine with the same resignation-tinged excitement we reserve for new kitchen gadgets: it claims to be simple, precise, and durable, and we just wanted it to make us look more competent than we feel. With a 100W spindle, a sturdy aluminum alloy frame, and a 15.75 x 15.75 x 3.74 in working area, it has the stats of a capable shop companion. It’s set up for wood, acrylic, MDF, leather, and even soft metals, and it’s built on a 32-bit control board running GRBL 1.1-compatible software. On paper, it checks a lot of boxes. We wanted to see if it would check them in our shop, too.

VEVOR CNC Router Machine, 100W Spindle, 3-Axis Wood Engraving Milling Machine, with 15.75 x 15.75 x 3.74 in Working Area, Linear Rail, Aluminum Alloy Structure, for Wood Acrylic Carving Cutting

First Impressions: Build and Design

We unboxed the machine and immediately appreciated the aluminum alloy structure. It’s not just shiny hardware—it’s a frame that shrugs off twist and wobble. The Z-axis rides on a linear rail, which, in the CNC world, is like swapping flip-flops for hiking boots. Things track straighter, tolerate loads better, and generally behave like they’ve had a good night’s sleep.

Aluminum Alloy Structure and Linear Rail: Why It Matters

We’ve met machines at this price point that go wobbly when you sneeze near them. This one doesn’t. The linear rail on the Z-axis keeps the spindle moving like it’s on a guided tour—no sagging, no guessing. It helps with clean vertical passes and crisp edges, which is where accuracy lives. The aluminum frame ties it together with decent rigidity for woodworking and light metal work.

100W Spindle and 32-Bit Control Board: Quiet Confidence

The 100W spindle is not a bulldozer, and we never pretended it was. But paired with smart feeds and sharp bits, it can carve woods, plastics, and soft metals with surprising finesse. The 32-bit control board keeps motion snappy and smooth. We liked that the machine supports GRBL 1.1-compatible software, which means we weren’t trapped in a proprietary labyrinth. It feels modern, open, and practical.

Safety and Sanity: Dust Guard and Control Box

We noticed the dust guard right away, and our vacuum noticed the reduction in airborne debris. The control box features an emergency stop and a home button—two little comforts that make every test cut feel less like a leap of faith. We used them often; not because of issues, but because we like a reset button in woodworking and in life.

Assembly: Easier Than We Expected

We’ve had flat-pack furniture fights that lasted longer than this setup. The key components came pre-assembled and pre-wired, which trimmed our setup time to a level that felt almost indulgent. The included hardware was labeled, the wiring wasn’t a spaghetti situation, and the instructions didn’t read like poetry in a language we don’t speak.

What Comes in the Box

Out of the box we found the pre-assembled gantry sections, control box, spindle, mounts, wiring, and the basic tools to put the pieces together. We kept our own hex drivers nearby because that’s our way, but we could have done it with the included tools.

Step-by-Step Highlights

- We squared the frame carefully during assembly. A square machine cuts square parts—this is the hill we will die on.

- Wiring was straightforward, with connectors that only fit where they belonged.

- Gantry alignment took a little patience, as it should; we tightened incrementally and checked travel for smoothness on all axes.

- The LED lighting under the Z-axis made it easier to see our bit touch-off. It feels small until you use it in a dim shop, and then it feels essential.

Software Setup

Candle (also called CNC Candle) was included and installed without drama. We appreciated that the machine is compatible with Mac, Windows, and Linux, and supports common tools like Candle, Easel, LaserGRBL, and LightBurn. GRBL 1.1 compatibility means we used the tools we already liked without re-learning everything. We loaded drivers, connected via USB, and were jogging the machine within minutes.

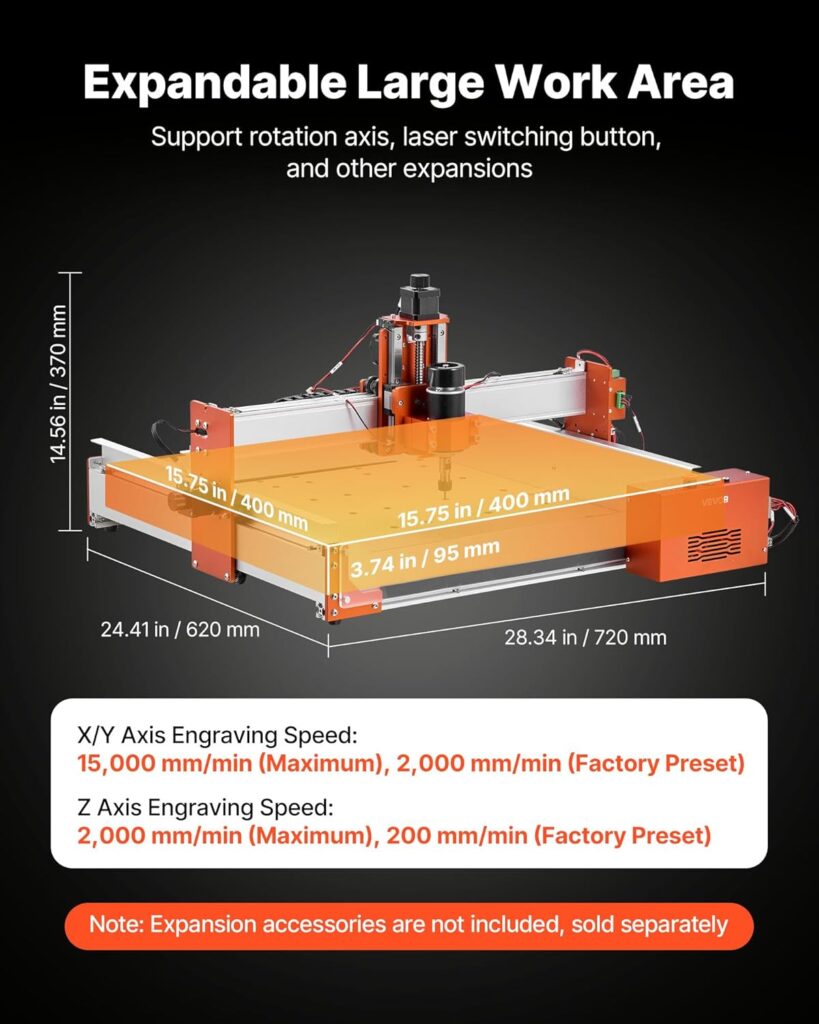

Working Area and Expandability

The working area is where we spend our time, and at 15.75 x 15.75 x 3.74 inches (400 x 400 x 95 mm), we felt like we had room to breathe. It’s plenty for signs, inlays, coasters, plaques, faceplates, small furniture accents, and trays. We don’t need to mill dining tables every week; if you do, we admire your ambition and recommend a larger machine.

Collets and Spindle Compatibility: 52 mm and 65 mm

The router supports 52 mm and 65 mm collets, which gives us flexibility in the type of spindle upgrades or accessories we might add later. Out of the box, the 100W spindle handles all the basics, but knowing we could switch to a different style spindle later felt like permission to grow.

Laser Module and Rotary Axis (Sold Separately)

We like that it supports a laser module and a rotary axis with expansion accessories (Note: those are not included and must be purchased separately). A rotary can turn gift projects into heirlooms—think custom rolling pins, engraved tumblers (with the right material), and decorative columns. A laser adds crisp graphics with low material stress. We didn’t test those here, but we appreciate the platform’s openness to upgrades.

Specifications and Essentials at a Glance

We found it helpful to keep the core specs in one place while we learned the machine’s rhythm.

| Feature | Details |

|---|---|

| Model | VEVOR CNC Router Machine |

| Axes | 3-axis |

| Spindle | 100W |

| Working Area | 15.75 x 15.75 x 3.74 in (400 x 400 x 95 mm) |

| Frame | Aluminum alloy |

| Z-Axis | Linear rail |

| Controller | 32-bit, GRBL 1.1 compatible |

| Software | Candle included; works with Easel, LaserGRBL, LightBurn |

| OS Compatibility | Mac / Windows / Linux |

| Accuracy | Repeat positioning ≤ 0.05 mm |

| Safety | Emergency stop, home button, current detection protection |

| Extras | Dust guard, LED lighting, rotary knob for spindle control |

| Expandability | Supports laser module and rotary axis (sold separately) |

| Spindle Life | Up to 5,000 hours with current detection protection |

Performance and Precision

This machine is rated for repeat positioning accuracy of 0.05 mm or better, which in human terms means it returns to where it started with a consistency we can trust. We checked with a dial indicator and test cuts across the working area. It’s not a metrology lab, but we were impressed. Our pockets aligned, our inlays fit, and our patience stayed intact.

Real-World Cutting on Woods and Plastics

On wood and acrylic, the results were consistently crisp. MDF cut like a cooperative sponge cake—clean edges, minimal fuzz. Acrylic, with a sharp O-flute bit and the right chip load, came off the machine with polishable edges. We kept passes light and feeds sensible, and the machine rewarded us with confidence.

Soft Metals With a Gentle Touch

We worked aluminum with gentle step-downs and good lubrication. This isn’t a heavy metal shop machine, so success depends on conservative parameters:

- Use sharp single-flute or 2-flute carbide bits designed for aluminum.

- Keep chip loads in the safe range by lowering RPM and steadying your feed.

- Consider a light mist coolant or periodic manual lubrication.

- Keep step-downs shallow to respect the machine’s stiffness.

Results? Clean badges, faceplates, and small brackets with tidy edges and predictable dimensions. If you try to hog material like a millwright, it will complain. Treated with kindness, it behaves beautifully.

Workholding: Don’t Skip This

We used a spoilboard with threaded inserts and a variety of clamps. Blue tape and CA glue worked well for thin acrylic and delicate veneers. The machine’s accuracy means little if the work shifts mid-pass, so we overdo it on clamping and don’t feel guilty.

User Experience: The Little Things That Matter

The LED lighting is the kind of feature we don’t know we need until it’s there. It cuts shadows on the Z-axis and helps with zeroing. The rotary knob gives us tactile control over spindle speed adjustments, which we liked more than we expected.

Noise, Vibration, and Dust

Noise is modest compared to trim routers. We could hold a normal conversation near it with hearing protection on. Vibration felt controlled thanks to the aluminum structure and Z-axis rail. The dust guard helps contain chips, but we still used a shop vacuum or dust shoe for serious cleanup. Nothing kills romance faster than MDF dust in every corner of the garage.

Safety and Reliability: Building Trust

There’s comfort in knowing a machine is paying attention to itself. The spindle’s current detection protection is one of those unobtrusive features that may save a motor from a tragic end. VEVOR rates the service life up to 5,000 hours under protection, which isn’t a contract with destiny but does suggest longevity when used sensibly.

Emergency Stop and Homing: Our Favorite Button Combo

We used the home button at the start of every session. Repeatable homing is the backbone of repeatable jobs, and it means we can run multi-step setups without re-inventing zero every time. The emergency stop? It’s like a seatbelt: we hope not to use it, we’re glad it’s there, and we like to know exactly where it is without thinking.

Maintenance We Actually Did

- We wiped the rails and leadscrews after dusty sessions.

- We checked belts, couplers, and fasteners weekly for snugness.

- We vacuumed the control box ventilation to keep it breathing.

- We swapped bits before they dulled into heat generators. This isn’t a high-maintenance machine, but a few minutes of attention go a long way.

Software Workflow: Smooth and Flexible

We tried multiple software tools to see how the machine behaved with different workflows.

Candle: A Friendly Starting Point

Candle is straightforward for jogging, zeroing, and sending G-code. It connects cleanly, displays the toolpath, and gives us confidence without clutter. For many users, Candle plus their preferred CAM software is enough.

Easel: Gentle Learning Curve

Easel remains a favorite for users who want to design and cut in one place. We made signs and simple 2.5D projects quickly, and the post-processor generated GRBL-friendly code that ran without fuss.

LaserGRBL and LightBurn: For Laser Expansion

If you add a compatible laser module later (sold separately), LaserGRBL and LightBurn are excellent. The machine’s GRBL foundation means the transition is natural. We appreciated that this platform can grow into laser workflows without starting from scratch.

Mac, Windows, and Linux

We tested on Windows and macOS, and both were reliable. Linux users will feel at home too. USB connectivity was stable, and the machine reconnected smoothly after restarts.

Projects We Actually Built

We like to measure a machine not just by specs, but by the objects it brings into the world without emotional harm.

A Walnut House Sign with V-Carving

We surfaced a walnut blank, sealed it, and ran a V-carve job for house numbers and a surname. The corners were razor-sharp, and the depths consistent. We finished with black epoxy fill and a satin clear coat. The machine didn’t flinch.

Acrylic LED Edge-Lit Panel

We used a single-flute O bit to engrave an acrylic panel for a gift lamp. Clean lines, minimal melting, and a gratifying glow once lit. The LED lighting on the Z helped with bit alignment for that first scratch pass.

Leather Stamp Die

We engraved a brass stamp for leather embossing. Light passes, patient step-downs, and frequent brush-offs kept edges crisp. The soft metal setting made the detail pop without chatter.

MDF Organizer with Pockets

We pocketed MDF to organize measuring cups, hardware, and other things we lose weekly. The machine worked quickly and cleanly in MDF. We sealed the MDF afterward to keep the dust from living on our shelves.

Aluminum Badge Plate

We cut a small badge with simple text and a beveled edge. With lubricant and conservative feeds, it came out clean and more professional than we deserved. We felt like we should hang it on the wall and deny all mistakes.

Strengths and Limitations: Honest Observations

We like to name the boundaries, because boundaries keep things tidy.

-

Strengths:

- Rigid-for-class aluminum structure with Z-axis linear rail.

- Repeatable accuracy for tight-fitting inlays and fixtures.

- Large working area (400 x 400 x 95 mm) for this price tier.

- GRBL 1.1 compatibility and broad software support.

- Safety features that actually matter: E-stop, homing, current protection.

- LED lighting and dust guard—small improvements that add up.

-

Limitations:

- The 100W spindle asks for finesse on metals and hard woods; hogging is not its style.

- No included laser or rotary (sold separately), though it supports both.

- Workholding hardware variety is up to us; plan for clamps, tape, and a spoilboard.

Comparison: Where This CNC Sits in the Landscape

We all have that friend who tells us their “starter machine” can mill a car engine. We love them and nod and change the topic. Here’s where this machine actually fits.

Versus A 3018-Style Mini CNC

- The VEVOR gives us a bigger area, a stiffer frame, and linear rail on Z.

- Better repeatability and smoother motion.

- More forgiving with real-world projects like signs, trays, and acrylic panels.

- The 3018 is fine for learning; this is a step into truly useful territory.

Versus Mid-Range Hobby CNCs with Larger Spindles

- Heftier machines with 500W–1.5 kW spindles can remove material faster, especially in hardwoods and aluminum.

- They often cost more, weigh more, and take longer to assemble.

- If speed is your priority, those machines win. If precision per dollar and friendly setup matter more, this VEVOR shines.

Who Should Choose What

- Choose this VEVOR if your projects are wood, acrylic, MDF, leather, and occasional soft metals, and you value accuracy and a generous work envelope without committing to a shop-crushing machine.

- Consider a higher-power spindle platform if you plan to cut thick hardwoods or aluminum daily, at aggressive rates.

Practical Tips and Best Practices

We learned a few lessons the gentle way and a few the other way. We’re passing on the gentle ones.

Squaring, Tramming, and Calibration

- Square the frame during assembly; measure corner-to-corner diagonals.

- Tram the spindle if you can—ensure the bit is perpendicular to the spoilboard. A trammed spindle means smoother faces and less cleanup.

- Surface your spoilboard once the machine is assembled to ensure a true work plane.

Bits, Feeds, and Speeds

- Keep bits sharp. Dull bits cause heat, chatter, and regrets.

- Use single-flute O bits for acrylic, two-flute upcut or downcut for wood depending on edge quality needs.

- For aluminum, single-flute bits, shallow step-downs, and a lubricant are your friends. Respect the machine’s stiffness.

Workholding

- Invest in a spoilboard with threaded inserts or a t-track system.

- Use blue tape and CA glue for delicate or small stock.

- Always check clamp clearance in your CAM to avoid a dramatic encounter.

CAM Strategies We Like

- Use ramped entries to reduce tool shock.

- Leave a spring pass for finishing on tight pockets and contours.

- For pockets, rough with a bigger bit, then finish with a smaller one to sharpen corners.

Materials and Settings Cheat Sheet (Guideline)

We don’t claim these are universal, but they gave us clean results. Adjust for your bit and material.

| Material | Typical Bit | Strategy | Notes |

|---|---|---|---|

| MDF | 1/4″ 2-flute downcut | Moderate feed, shallow step-downs | Clean pockets, minimal fuzz |

| Birch Ply | 1/8″ compression | Slower feed to protect veneer | Painter’s tape helps prevent tear-out |

| Walnut | 1/4″ upcut | Moderate passes, finish pass | Oil finish brings out crisp edges |

| Acrylic | 1/8″ single-flute O | Lower RPM, steady feed | Avoid melting; consider air blast |

| Aluminum (6061) | 1/8″ single-flute | Very shallow passes, lubricant | Prioritize chip evacuation |

| Leather (for cutting) | Drag knife or small upcut | Multiple light passes | Backer board prevents stretch |

Comfort Features We Loved

- LED lighting under the Z-axis reduces guesswork while zeroing.

- The spindle rotary knob invites quick speed tweaks mid-job.

- The home button saved time between repetitive tasks.

- The dust guard means less cleanup and fewer excuses to postpone projects.

Reliability and Longevity

The spindle’s current detection protection contributes to a rated service life of up to 5,000 hours. We can’t fast-forward time, but we can say the machine ran consistently over our test windows. The frame remained square, the motion didn’t loosen, and the rails stayed smooth with basic care. It feels like a machine designed to work, not just to impress on day one.

Who This Machine Is For

- Makers moving beyond a 3018 who want a bigger, more capable platform without spending like a corporate lab.

- Woodworkers and sign makers who favor clean inlays, carved lettering, and repeatable pocketing.

- Tinkerers who want to add a laser or rotary later without changing ecosystems.

- Small shops that need consistent parts and jigs within a compact footprint.

- Educators who want a reliable, approachable CNC for classroom or lab use.

Who Should Consider Something Else

- Metal-focused users planning heavy aluminum or steel jobs every week.

- Production environments requiring aggressive removal rates and all-day duty cycles.

- Those who need an out-of-the-box rotary or laser included rather than optional.

The Learning Curve: Kinder Than You Think

CNC can feel like flying a small plane through a spreadsheet. This machine, with Candle and GRBL 1.1 support, makes the routine parts easy enough. We jogged, zeroed, and ran toolpaths without needing to recite incantations. If you can measure wood and read a G-code file name, you can work this machine.

Troubleshooting Moments We Had—and Solved

- We noticed a faint ripple on pocket walls early on; tramming the spindle and slowing our finishing pass fixed it.

- Acrylic edges dulled until we lowered RPM and used a single-flute bit.

- Our first aluminum pass squealed like a kettle; a light mist of lubricant and a shallower step-down calmed everything down.

Longevity Habits Worth Keeping

- Dust the leadscrews, wipe the rails, and keep the control box vents clear.

- Check tightness of bolts monthly; movement loosens things over time.

- Replace bits before you’re tempted to push harder to compensate for dullness.

- Keep firmware and software versions consistent; stable setups make stable cuts.

Value for Money

For the price, the VEVOR CNC Router Machine delivers a rare combination: a large working area, a rigid frame with a Z-axis linear rail, GRBL 1.1 compatibility, and thoughtful quality-of-life features like LED lighting, dust guard, and a proper control box with emergency stop and homing. It feels like the sweet spot for serious hobbyists and small shops that want consistent results more than brute-force speed.

Frequently Asked Questions

Can we cut aluminum with this machine?

Yes, with conservative parameters. Use a single-flute bit, take shallow passes, use lubricants or air for chip evacuation, and avoid aggressive removal rates. It’s great for badges, panels, and small parts, not heavy metal hogging.

How accurate is it really?

VEVOR states repeat positioning accuracy of ≤ 0.05 mm. In our tests, it returned to zero reliably, and our multi-pass inlays fit snugly without gaps. Real-world accuracy depends on setup, tramming, and workholding, but the platform is capable.

Which software do we need?

Candle is included and works well for sending G-code and basic control. For design and CAM, Easel is a friendly option. If you add a laser (sold separately), LaserGRBL and LightBurn are excellent. It supports Mac, Windows, and Linux.

Is assembly difficult?

Not at all. Many parts are pre-assembled and pre-wired. We squared the frame, attached the gantry, connected cables, and were jogging within a short session. Take your time tramming and surfacing the spoilboard for best results.

Does it support a rotary axis or laser module?

Yes, the platform supports both—but they’re not included and must be purchased separately. We like that we can add them later without changing the control ecosystem.

How loud is it?

Quieter than trim-router-based machines, especially at modest RPMs. We still use hearing protection because we enjoy our hearing.

How do we manage dust?

The dust guard helps, but we recommend a dust shoe and shop vacuum for MDF and similar materials. Keeping the work area clean preserves accuracy and our mood.

A Few Project Ideas to Get Started

- Personalized family signs with V-carved lettering.

- Inlay cheese boards and cutting boards.

- LED edge-lit acrylic nightlights.

- Leather embossing stamps and branding dies.

- Drawer organizers and tool trays in MDF or plywood.

- Custom electronics faceplates and small aluminum badges.

- Coasters with logos or geometric patterns.

Pros and Cons

Pros

- Rigid aluminum structure with Z-axis linear rail for stable, accurate cuts.

- Large 400 x 400 x 95 mm work area in a compact footprint.

- GRBL 1.1-compatible, with Candle included; works across Mac/Windows/Linux.

- Emergency stop, homing button, current detection protection.

- LED lighting and dust guard reduce frustration and mess.

- Expandable with laser and rotary (sold separately).

- Repeat positioning accuracy ≤ 0.05 mm for confident fits.

Cons

- 100W spindle is precise but not powerful; requires gentle parameters on metals and harder woods.

- Rotary and laser accessories not included.

- Expect to invest in clamps, spoilboard, and a few quality bits for best results.

What We’d Upgrade First

- A quality set of carbide bits: 1/4″ and 1/8″ upcuts, a 1/4″ downcut, a 60°/90° V-bit, and a single-flute O for plastics.

- A dust shoe paired with a quiet shop vacuum.

- A solid spoilboard with threaded inserts or T-tracks.

- Coolant/lubricant for aluminum jobs, even if it’s just a light mist system or manual application.

Safety Habits That Make Us Sleep Better

- Always home the machine at the start of a session.

- Keep hands clear and tools tidy; clamps deserve their own space.

- Preview G-code in your sender; if a move looks weird, it probably is.

- Use the emergency stop without hesitation. It’s there for a reason.

Why the Design Choices Work Together

We think the machine’s success stems from a simple recipe:

- A strong frame keeps motion true.

- A linear rail on Z preserves vertical accuracy where it counts.

- A 32-bit GRBL-compatible controller keeps motion smooth and software flexible.

- Usability touches like LED lighting, dust guard, and real buttons reduce friction. None of this reinvents CNC; it just respects the parts that matter and doesn’t skimp.

When Precision Meets Modesty

We like that this machine doesn’t posture. It won’t pretend to be a 2 kW spindle on hardened steel, but it will cut clean walnut lettering, shim-tight inlays, acrylic edges that catch the light, and aluminum nameplates that make us look professional. It’s the kind of tool that improves our projects by removing uncertainty, not by promising wizardry.

The Bottom Line on Value

We judged this machine on three things: how quickly we went from box to results, how reliably it held zero and returned to it, and whether we felt constrained or empowered. On all three, it did well. The learning curve was gentle, the results were repeatable, and the platform gives us room to grow with expansion options. The price-to-capability ratio is strong, and that’s before we counted the LED light that saved us from hunching under the gantry with a flashlight.

Final Verdict

We think the VEVOR CNC Router Machine—with its 100W spindle, aluminum alloy structure, Z-axis linear rail, and 400 x 400 x 95 mm work area—earns a spot on the shortlist for serious beginners and seasoned hobbyists alike. It trades brute force for precision and consistency, pairs easily with common software, and respects our time with straightforward assembly and smart usability touches. If we measure it by the projects we completed and the patience we retained, this machine is a fine partner. For wood, acrylic, MDF, leather, and carefully handled soft metals, it’s more than capable. Add the possibility of laser or rotary down the road, and we have a platform that grows with us.

If our garage is getting a new job title, this is the kind of machine that justifies updating the business cards.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.