Can we write in any single living author’s exact style? We can’t, but we’ll bring a friendly, witty, and self-aware voice that aims for the same charm.

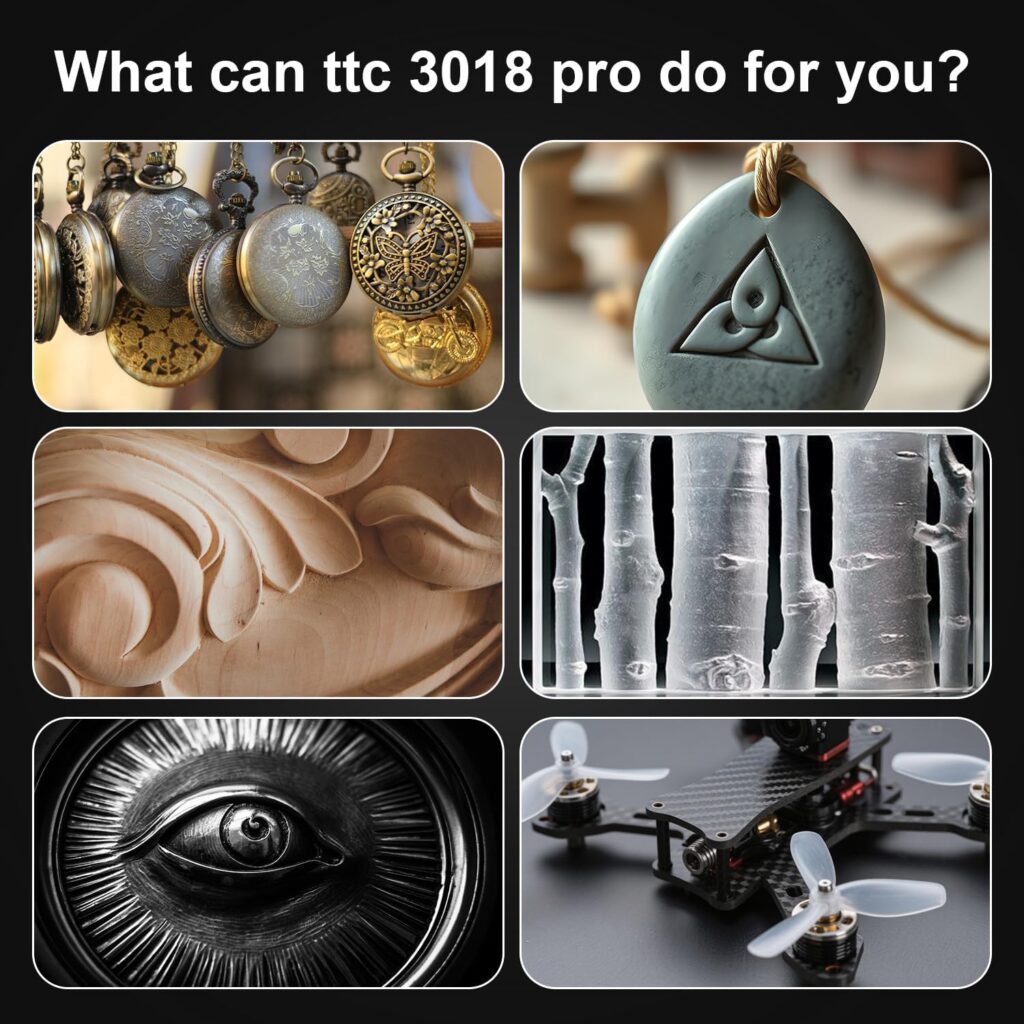

Why this compact CNC grabbed our attention

We love gear that doesn’t demand a two-car garage, a second mortgage, and a degree in mechanical engineering. The Twotrees TTC 3018 Pro CNC Router Machine, Desktop CNC Engraving Machine Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon, 300mm x 180mm x 40mm Working Area promises a compact footprint with serious upgrades where it counts. We see it as a gateway tool for anyone who wants the precision and repeatability of CNC without jumping straight into industrial territory.

What really nudged us closer was the metal Z-axis module and anti-backlash T8 lead screws—two features that move this CNC out of toy land and into “starter professional” territory. The kit is also meant to be completely hands-on during assembly, which means we get to learn the machine inside and out while we build it. That alone scores points with us.

Twotrees TTC 3018 Pro CNC Router Machine,Desktop CNC Engraving Machine Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon,300mmX180mmX40mm Working Area

What’s in the box and what’s not

A CNC kit should never feel like a scavenger hunt. With this package, the essentials are right there: a 775 brushed spindle motor (7000–9000 RPM), an ER11 chuck that supports 0.5–7 mm tools, and a set of 10 flat-bottomed pointed cutters to help us start cutting right away. We also get the power supply, full cable set, and control board (MKS DLC32) with built-in 2.4G Wi‑Fi.

We appreciate that the manufacturers didn’t skimp on tools either. Screwdrivers and hex keys are included, along with over 40 parts in a fully disassembled kit. That sounds like work—and it is—but it’s the kind of work that results in a deeper understanding of the machine’s structure and motion systems.

Quick breakdown of what we’ll find

It’s easier to breathe when we can see the essentials at a glance. Here’s how the kit shakes out.

| Category | Included | Not Included |

|---|---|---|

| Motion System | Metal Z-axis module, T8 anti-backlash lead screws, aluminum profiles, linear shafts | Limit switches (check your variant), bed spoilboard extras |

| Spindle & Tools | 775 brushed spindle (7000–9000 RPM), ER11 chuck (0.5–7 mm), 10 cutters | Upgraded spindles, specialty end mills, probe |

| Control | MKS DLC32 board with 2.4G Wi‑Fi, USB, TF card support | Computer, design software licenses (free options exist) |

| Power & Wiring | Dedicated power supply, cables | Surge protector, cable management accessories |

| Assembly | Screwdrivers, hex keys, fasteners, brackets | Thread locker, torque wrench, calipers |

| Safety & Setup | Basic instructions | Eye/ear protection, dust collection, workholding clamps beyond the basics |

We always recommend adding: safety glasses, ear protection, a dust mask, a vacuum or dust collection option, and decent workholding clamps. If this is our first CNC, we’ll also want a small set of end mills in a few diameters and profiles to expand what we can do.

The footprint and form factor we can live with

A desktop CNC shouldn’t demand the desk. This unit measures roughly 420 x 355 x 280 mm, which means it fits on a sturdy workbench or a corner desk without turning our workspace into a garage annex. The working area is 300 x 180 x 40 mm—enough for nameplates, small signs, PCB prototypes, custom stamps, inlays, and even aluminum or brass sheet projects.

We also appreciate the solidity of the all-metal and reinforced components. Aluminum profiles and the upgraded metal Z-axis help fight deflection and chatter. For a machine at this size and price bracket, that’s a real perk.

Assembly: part puzzle, part apprenticeship

We like a kit that teaches. With over 40 parts and a step-by-step build, we end up learning exactly how our CNC moves along X, Y, and Z. That makes later troubleshooting more manageable and turns calibration into something we do with confidence rather than dread. It even scratches that quiet, Saturday-morning satisfaction itch.

While the kit includes tools, we still keep a decent set of metric hex keys and a digital caliper nearby. Thread locker is helpful for motor mount screws and moving assemblies. During assembly, we check linear shafts for smooth travel and lead screw couplings for alignment. A few minutes spent aligning and squaring the frame saves hours of headaches down the line.

Tips that save time and sanity

We never want to reassemble the whole Z-axis because one coupler wasn’t tightened. Here are a few tricks we keep in mind:

- Hand-tighten first, then torque gradually in a crisscross pattern on frames and mounts.

- Square the gantry to the bed using a reliable square or calipers; measure twice, tighten once.

- Confirm the Z-axis carriage moves smoothly by hand before powering anything.

- Keep the lead screws clean; avoid over-greasing—light lubrication is better than paste.

- Label cables as we go, especially stepper motor leads, to avoid swapping axes.

We expect the total assembly to take a few focused hours. It’s not a race, and we’ll learn more if we treat it like a careful build rather than an obstacle to the “first cut” moment.

The metal Z-axis: a small upgrade with a big effect

CNC work lives or dies on rigidity. The upgraded metal Z-axis module and the T8 anti-backlash lead screws combine to reduce flex and slop, especially under changing loads. When the spindle encounters denser material or takes a deeper pass, a stiffer Z-axis helps maintain consistent depth of cut.

Anti-backlash lead screws matter because they limit the tiny reversals that cause milling marks and fuzzy edges. On a small machine, those incremental savings add up across a longer job. Even engraving projects benefit, producing cleaner lines and better detail.

Specs that actually matter for our projects

Plenty of numbers look good on paper but don’t show up in our projects. The specs here translate nicely to everyday making:

- Work area: 300 x 180 x 40 mm (enough for plaques, small molds, PCB boards, and gift items)

- Positioning accuracy: around 0.1 mm (typical for 3018-class prosumer machines)

- Spindle: 775 brushed motor, 7000–9000 RPM

- Controller: MKS DLC32, Wi‑Fi built-in, GRBL-compatible

- Operation: USB connection or TF card offline use

- Materials: wood, MDF, acrylic, nylon, PCB copper board, and aluminum/brass sheets

We should treat aluminum and brass as careful projects with conservative feeds and multiple passes. For hardwoods, the key is modest depth per pass and sharp bits. Acrylic demands a bit of finesse to avoid melting; we rely on higher RPM and lower feed with two-flute or single-flute bits designed for plastics.

The open-source control system we like to live with

We’re big fans of open ecosystems because they don’t lock us into a specific software flow. The MKS DLC32 controller with GRBL compatibility keeps everything flexible. Wi‑Fi support is a nice touch for moving files around without a cable, and we can also run jobs offline using a TF card.

Compatible software we actually use

Picking software can feel like picking a favorite coffee spot. Here are good options that play nicely with this machine:

- Fusion 360: parametric modeling and CAM, great for precise parts and detailed toolpaths.

- Easel: beginner-friendly and ideal for sign-making, inlays, and straightforward workflows.

- ArtCAM (legacy), Carveco: artistic reliefs, signs, and more organic modeling.

- Candle, UGS: GRBL senders for jogging, zeroing, and job execution.

- FlatCAM: for PCB generation from Gerber files.

We tend to start with Easel or Candle for early projects and graduate to Fusion 360 for parts that need tight tolerances. We keep a simple GRBL sender installed so we can jog, set zero, and monitor progress without extra friction.

Materials and what we can reasonably make

One reason we keep coming back to 3018-class machines is their ability to handle a broad range of small projects. Is it a production powerhouse? No. Is it a charmingly capable daily driver for desktop-scale parts and personalized gifts? Absolutely.

Wood, MDF, and plywood projects

For wood and MDF, this machine is in its happy place. We can create:

- Nameplates and signs

- Guitar headstock inlays

- Jewelry boxes and small trays

- Coasters and plaques

- Simple 2.5D relief carvings with ball-nose bits

We stick to small stepdowns and moderate feeds, and we use sharp upcut or downcut bits depending on whether we want crisp top edges or a clean underside.

Acrylic and plastics

For acrylic and nylon, we prioritize sharp bits and high RPM to avoid melting. This is a great tool for:

- LED edge-lit signs

- Control panels and custom faceplates

- Enclosures for electronics projects

- Lightweight brackets and fixtures

We experiment with single-flute bits for softer plastics to maintain chip evacuation. A little compressed air directed at the cut line helps keep chips clear.

PCBs and electronics

Once we try milling a PCB, we understand why many hobbyists adore desktop CNCs. With a V-bit or a small end mill and careful leveling, we can produce:

- Single-sided prototype boards

- Breakout boards for sensors

- Quick test circuits without waiting for a fab service

Getting a flat bed and good Z calibration is critical here. We always check runout and test with a tiny engraving pass before committing.

Aluminum and brass sheets

This category is where expectations matter. Thin aluminum or brass sheets can be cut and engraved, and we can even do pocketing if we accept very shallow passes and conservative feeds. Good workholding is essential—double-sided tape or strong clamps—and lubrication helps (a bit of light oil applied sparingly).

What we routinely make:

- Front panels and tags

- Nameplates and decorative inlays

- Simple brackets in thin stock

- Engraved badges

What we shouldn’t expect

We shouldn’t assume this machine sands hardwood floors, mills steel, or bores deep pockets in dense hardwood at high feed rates. It’s not built for thick metal machining or heavy-duty industrial loads. If we want fast clearing in aluminum blocks, we’ll outgrow the 775 spindle and the 3018 format quickly.

Materials table for quick planning

We find it helpful to think in terms of what tool, pass depth, and pacing we might use.

| Material | Typical Bits | Job Types | Notes |

|---|---|---|---|

| Softwood/MDF | 1/8″ upcut/downcut, 1/16″ ball-nose | Signs, inlays, pockets, profiles | Shallow passes; dust collection recommended |

| Hardwood | 1/8″ upcut, 1/8″ downcut, ball-nose | Plaques, small furniture parts, inlays | Reduce depth per pass; keep bits sharp |

| Acrylic | Single-flute upcut, O-flute | Edge-lit signs, panels, enclosures | High RPM, slow feed to avoid melting |

| Nylon/Plastics | Single- or two-flute | Brackets, fixtures, panels | Watch heat; compress chips with air |

| PCB Copper | V-bit (20–60°), small flat end mills | Traces, isolation routing, drill holes | Bed leveling very important |

| Aluminum/Brass Sheets | Single-flute or two-flute | Engraving, tags, thin brackets | Very shallow passes; secure work firmly |

Spindle performance: what the 775 motor does well

The included 775 brushed motor (7000–9000 RPM) fits the goals of an entry-level CNC: it’s compact, light, and forgiving. It’s happiest with woods, plastics, and engraving tasks, with aluminum or brass work done slowly and patiently. Brush motors aren’t the marathon runners of spindles, but they’re widely used in this class because they’re accessible and easy to replace.

We keep a couple of practical habits:

- Use sharp bits and keep pass depths modest.

- Pause between long jobs to avoid overheating.

- Consider a small fan or airflow around the spindle during extended runs.

If we decide later that our work demands more spindle torque, upgrade paths exist, but the stock setup is a sensible baseline.

Feeds, passes, and the art of not snapping bits

Settings depend on our exact bit, stock, and expectations. Since this machine is compact, we stick with gentle stepdowns (especially in harder materials). We’d rather take four clean passes than one chattering mess. It’s also easier on the spindle and extends tool life.

A few rules of thumb we adopt:

- Start conservative; we can always speed up later.

- For plastics, keep chips moving; if the material melts, we slow the feed and check our bit geometry.

- In aluminum/brass sheets, shallow passes and firm clamping are non-negotiable.

Noise, dust, and basic safety

CNC machines aren’t quiet. The 775 spindle produces a steady hum that can climb with certain bits or materials. We wear hearing protection for longer sessions. Dust from MDF is particularly nasty, so a shop vac, dust shoe, or at least a hose near the toolpath is worth setting up.

We never run this unattended. A machine this compact can still fling a bit or launch a workpiece if clamping fails. We keep clear eye protection on and position ourselves to the side of the spin-up path when testing.

Accuracy and repeatability we can count on

With a claimed positioning accuracy around 0.1 mm and anti-backlash lead screws, we can achieve neat edges and clean geometry for desktop projects. The upgraded Z-axis contributes to more consistent depth of cut, which we notice most in V-carving and PCB traces.

We also pay attention to:

- Rigidity of the frame: recheck frame tightness occasionally.

- Runout: the ER11 collet is standard; good-quality collets and bits matter.

- Squareness: a square gantry and a flat bed help everything from engraving to pocketing.

Bed flatness, spoilboards, and workholding

We use a spoilboard that we can surface lightly with a fly cutter or a large flat bit. Even small variations across the bed can ruin PCB milling and delicate engravings. Workholding is as important as any spec; a part that shifts by a fraction might as well shift a mile in CNC terms.

Clamping methods we keep handy:

- Toe clamps with low profiles

- Double-sided Nitto or carpet tape for thin sheets

- Small cam clamps for wood projects

- A custom MDF spoilboard with threaded inserts for flexible hold-downs

Open-source control: Wi‑Fi plus offline equals convenience

The MKS DLC32 controller hits a sweet spot for us. We can jog and set zero using a PC connection, send files over Wi‑Fi, or load a G-code file directly from a TF card and run jobs offline. This flexibility is more than a gimmick; it means we don’t have to rearrange a laptop setup every time we make a small part.

GRBL compatibility is the real hero here. It’s a mature ecosystem with tons of tutorials, community wisdom, and software support. That reduces friction when we’re first learning and gives us room to grow without switching tools.

Workflow that won’t make us re-learn everything

Our typical flow:

- Design the part in Fusion 360, Easel, or similar.

- Generate toolpaths (CAM) and export G-code.

- Load G-code to the controller via USB, Wi‑Fi, or TF card.

- Secure the workpiece and set XY zero and Z zero (with a paper method or probe if we have one).

- Run the job while monitoring spindle sound, chips, and clamping.

- Pause as needed to clear chips or change tools.

We keep notes on what worked, what didn’t, and which bits deliver the cleanest results on each material. After a few projects, those notes are gold.

An education in a box: why the kit format helps us learn

Assembly kits occupy a rare middle ground between hobby and curriculum. With over 40 parts, we learn how lead screws translate rotational motion, how linear shafts guide the axes, and why couplers and bearings matter. When something goes wrong months later—and it will—we have the confidence to diagnose rather than panic.

We’ve also found that kits spark curiosity about the math and physics behind CNC. Suddenly feed rates and chip loads aren’t just numbers; they’re cause-and-effect. As a bonus, this is a solid pick for STEM programs, makerspaces, and family projects where we want hands-on mechanical literacy.

Practical table: key features at a glance

Sometimes we just want a clear snapshot to check whether a machine fits our needs. Here it is.

| Feature | What it means for us | Why it matters |

|---|---|---|

| Work Area: 300 x 180 x 40 mm | Small-to-medium desktop projects | Fits signs, PCB boards, small panels |

| Positioning: ~0.1 mm | Decent detail and repeatability | Clean text, accurate fit for small parts |

| Z-Axis: Metal module | Stiffer, more reliable depth control | Fewer wavy cuts and cleaner engravings |

| Lead Screws: T8 anti-backlash | Reduced play during direction changes | Better pockets, less chatter at reversals |

| Spindle: 775 brushed, 7000–9000 RPM | Works well on wood, plastics, thin metals | Good starter spindle for beginners |

| Controller: MKS DLC32 | Wi‑Fi, TF card, GRBL | Flexible connection and wide software support |

| Kit: Fully disassembled w/tools | Hands-on learning during build | Easier troubleshooting later |

| Included bits: 10 cutters | Start making on day one | Experiment with basic profiles |

Where this CNC shines

We imagine two groups who will be particularly happy:

- Beginners who want a proudly assembled machine that actually cuts well and teaches them what’s going on.

- Hobbyists who want a compact, open-source platform for small runs of signs, panels, PCB prototypes, and occasional soft metal sheet work.

The upgraded mechanics—especially the Z-axis—put it ahead of older 3018 models that rely on more flexible assemblies. It’s not a mill for deep aluminum hogging, but it’s a very capable printer-sized CNC.

Where we’d be honest about limits

No machine is perfect, and even great starter CNCs have edges we can bump into:

- The 775 spindle is fine for what it is, but heavy milling in aluminum or hardwood may feel slow.

- The bed area is modest; larger projects will require tiling or segmenting our designs.

- Workholding on small beds can be a puzzle; we often make or buy accessory clamps and spoilboards.

These aren’t dealbreakers—just part of the realistic expectations that keep us happy.

Accessories and upgrades we’d consider

We don’t need to buy everything at once, but gradual improvements go a long way.

- Bits: Quality end mills and V-bits in a few sizes; single-flute bits for plastics.

- Collets: A reliable ER11 collet set improves runout and bit grip.

- Workholding: Low-profile clamps, cam clamps, and a spoilboard with threaded inserts.

- Dust control: A lightweight dust shoe or a directed vacuum nozzle for MDF and plastics.

- Probing: A Z-probe puck makes zeroing less guessy, especially for repetitive work.

- Cooling/air assist: A gentle air blast keeps chips out of the cut for plastics and metals.

- Enclosure: Helps with dust, noise, and safety if our workspace doubles as a living area.

If we later push into harder projects, a spindle upgrade might make sense, but we should confirm compatibility and power requirements before ordering anything. Many 3018-format machines can accept third-party spindles, but we keep an eye on mount dimensions and controller limits.

Project ideas that make this machine earn its keep

We want tools that pay us back in joy and usefulness. Here are ideas that keep this CNC busy:

- Personalized cutting boards, coasters, and phone stands

- Custom nameplates for gifts or workshops

- PCB breakout boards for sensors and microcontrollers

- Acrylic LED edge-lit signs for events or home decor

- Brass or aluminum tags for toolboxes and gear

- Wooden inlays for small boxes and instrument accents

- Engraved stamps for wax seals or leather work

Once we have a few bits and a reliable clamping strategy, the creativity snowballs. We end up with a steady stream of quick wins that build skill and confidence.

Troubleshooting habits we swear by

It’s tempting to assume software is the culprit when a cut goes sideways. Often, it’s something simpler. Here’s the checklist we run:

- Check clamping: Did the workpiece move or bow?

- Inspect the bit: Is it dull, chipped, or clogged with melted plastic?

- Confirm the collet: Is the bit seated and tightened correctly?

- Verify zero: Did we reset Z after a tool change?

- Listen for chatter: Reduce stepdown or feed rate.

- Inspect the couplers: Any set screws loose on the lead screws?

- Check parallelism: Is the gantry still square and the bed still flat?

- Re-run a test pattern: A small 20 x 20 mm square tells us a lot quickly.

We also keep a “known good” test project ready, like a small sign or pattern, to verify machine health after changes.

Maintenance that keeps things humming

Routine maintenance is the unsung hero of consistent cuts. We set reminders and do the following:

- Wipe down linear rods and leadscrews; apply light lube, avoid heavy grease.

- Vacuum dust from the electronics and controller area.

- Check belt tension—if applicable on accessory axes—and ensure couplers are tight.

- Re-square the frame if we see drift in accuracy.

- Inspect cables and connectors; strain relief is a kindness here.

- Surface the spoilboard lightly after several projects to restore flatness.

Five minutes of prevention now beats a Saturday spent chasing mystery errors later.

The learning curve and how to flatten it

CNC isn’t magic, but it is methodical. The first few projects teach us feeds and speeds, how different woods behave, and why acrylic needs a specific touch. If we’re new to CAD/CAM, Easel is a welcoming entrance. If we’re hungry for detail and precision, Fusion 360 rewards our effort with total control over toolpaths.

We take advantage of the broader GRBL community. There are countless tutorials, feeds-and-speeds calculators, and troubleshooting guides written for newcomers. Because this machine is open-source friendly, we’re never stuck solving problems alone.

Safety culture we won’t skip

We treat every project with respect:

- Eye protection is non-negotiable.

- Ear protection pays off, especially with long runs.

- Dust control is essential for MDF and plastics.

- No loose sleeves or hair near the spindle.

- We never leave the machine unwatched.

A steady, careful approach gets us better results and a workspace our future selves will thank us for.

Who we think will love this

This machine is for makers who want to build something real—both the machine and the projects that follow. It’s tailor-made for:

- Beginners who value learn-by-building kits with a clear upgrade path.

- Hobbyists who want reliable results on a desk-friendly footprint.

- STEM programs and classrooms introducing CNC fundamentals.

- Electronics enthusiasts who want rapid PCB prototypes.

If we know we’ll be machining thick aluminum blocks or want to produce in volume, we’ll need to step up to a stiffer frame and a more powerful spindle. For everything else in the “small workshop, big ideas” category, this unit is an excellent start.

A quick comparison with similar classes

It’s helpful to frame this unit against other options:

- Older 3018 kits without a metal Z-axis tend to flex more, show more chatter, and produce less consistent Z-depth in engraved work.

- Larger hobbyist CNCs (e.g., 4030/4040 class) offer bigger work areas, stronger spindles, and stiffer frames, but they cost more, require more space, and can be more intimidating to assemble and maintain.

- Laser engravers excel at engraving and cutting thin materials fast, but they don’t mill plastic, wood, or metal, and they require careful safety and ventilation protocols.

The Twotrees TTC 3018 Pro sits in a sweet spot: enough rigidity and features to feel like a serious tool, small and approachable enough to actually use.

Pros and cons, laid out plainly

We like to see the trade-offs without squinting.

| Pros | Cons |

|---|---|

| Metal Z-axis for better rigidity | 775 spindle limits heavy milling |

| T8 anti-backlash lead screws | Small work area by workshop standards |

| GRBL-compatible, open ecosystem | Workholding can be tricky on small beds |

| Wi‑Fi plus offline TF card | Noise and dust require a plan |

| Comes with cutters and ER11 collet | Requires patient feeds/passes in metals |

| Compact size fits most desks | Assembly may intimidate total non-tinkerers |

| Great for learning and STEM | Upgrade path requires research and care |

These aren’t surprises; they’re the honest envelope of a desktop CNC meant for learning and small projects.

Real-world pacing: going from idea to finished part

We measure a CNC not just by specs but by how quickly we can go from “what if” to “finished part.” With this kit, that cycle feels approachable:

- Start with a handwritten sketch, switch to Easel or Fusion 360.

- Generate G-code and send it by Wi‑Fi or load via TF card.

- Clamp carefully, zero axes, and run a short air-cut to confirm path and clearance.

- Make light first passes, listen to the spindle, and watch chips.

That rhythm becomes second nature. The machine becomes a trusted collaborator rather than an unpredictable contraption.

Thoughtful touches we appreciate

A few details lift this machine:

- The included cutters get us moving immediately.

- The ER11 collet supports a decent range of tools.

- The MKS DLC32 board keeps our setup flexible across software and connection modes.

- The all-metal and reinforced components increase confidence during cuts.

Small features add up to a smoother first month—the time when many people either become CNC people or tuck the tool away.

A note on community and resources

Because this machine lives in the GRBL world, we inherit a generous library of guides, videos, forums, and troubleshooting charts. It’s far easier to learn a new skill when the answers are already out there. We also find more third-party accessories and ideas to borrow from when the platform is standardized.

That said, we keep our expectations grounded. A vibrant community doesn’t replace steady setup and careful practice. Both are essential partners.

Lessons we’ve learned the slow way

We’ll save someone a headache with these:

- Set Z zero with a consistent method; a paper trick works if we’re careful and repeat it exactly.

- For PCBs, surface the spoilboard lightly and check level across multiple points.

- Acrylic loves sharp bits and hates friction; if it smells like a campfire, adjust.

- Don’t chase speed at the expense of accuracy; let the machine be what it is.

- Clean chips often. Chips are tiny saboteurs waiting to cause heat and chatter.

We also keep a “first pass” depth shallower than we think necessary. If the first pass is perfect, future passes stay consistent.

Value and where this fits in our tool lineup

CNC can be a rabbit hole. Before we know it, we’re pricing 2.2 kW spindles and cast-iron frames. There’s wisdom in starting with a machine that invites success and encourages learning. This model gives us real capability with a gentler learning curve and a manageable footprint.

We value tools that unlock creativity right away. The included cutters, flexible control options, and robust mechanics mean more making and less fiddling. Over time, we know exactly what upgrades might matter, because we learn by doing.

The bottom-line use cases we’d recommend

- Personalized gifts and small-run craft items

- Control panels and custom faceplates in acrylic/aluminum

- PCB prototypes for electronics projects

- Decorative inlays and detailed engravings in wood

- Classroom demonstrations of CNC principles

If these live in our project list, the Twotrees TTC 3018 Pro makes sense. If our endgame is heavy metal machining or large furniture panels, it’s the wrong tool; better to move up a class.

Final verdict

We love what this machine represents: a compact, upgraded 3018-class CNC that balances education with real capability. The Twotrees TTC 3018 Pro’s metal Z-axis, anti-backlash lead screws, and open-source, Wi‑Fi-enabled control board pull it above the typical entry-level kit. It’s easy to recommend to makers who want to assemble their own tool, understand it, and use it for a wide range of small projects.

We’d be honest about its limits. The 775 spindle asks for patience in hardwoods and thin metals. The work area might feel tight if we’re thinking bigger. But for everyday desktop CNC work—signs, panels, PCB boards, decorative pieces—it performs with a confidence that belies its size.

Most of all, we appreciate that it invites us to make things. From unboxing to first engraving, we feel supported rather than tested. And as we improve, the machine rewards us—cleaner cuts, sharper details, and a workflow that fits neatly into our lives. If our bench has room for one compact CNC that punches above its weight, this is a smart and satisfying pick.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.