Have we ever wished a machine would turn our coffee-fueled sketches into clean, repeatable parts without staging a tiny revolution on our desktop?

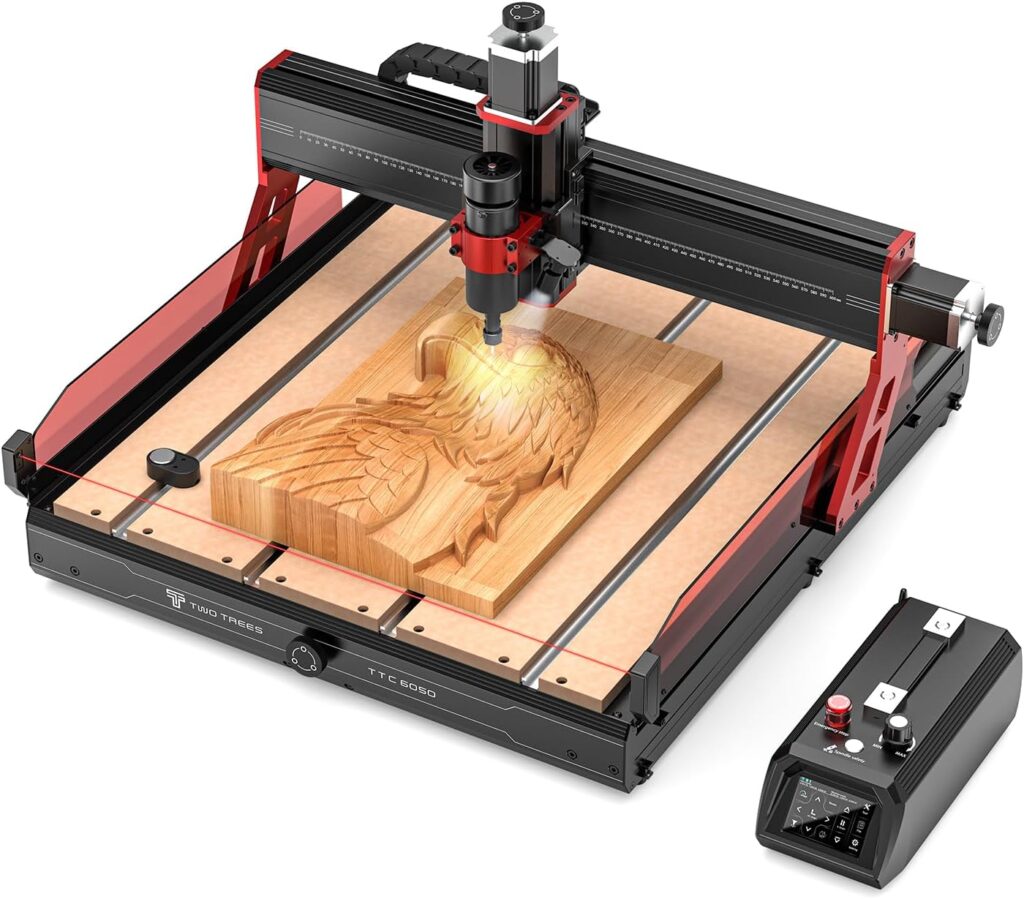

Our Hands-On Review of the TTC6050 CNC Router Machine

We spent time living with the TTC6050 CNC Router Machine, Desktop Engraving Machine 600x500mm Working Area, 500W Spindle, 3-Axis CNC Engraving & Laser Cutting for Wood, Metal, Acry. It’s a long name for a machine that turned out to be surprisingly considerate—like a houseguest who wipes their shoes without being asked and doesn’t drink all the oat milk. We cut wood, shaped acrylic, flirted with aluminum, and negotiated cautiously with stainless steel. Along the way, we learned which settings kept parts crisp and which ones made us regret not reading the manual first.

TTC6050 CNC Router Machine, Desktop Engraving Machine 600x500mm Working Area, 500W Spindle, 3-Axis CNC Engraving & Laser Cutting for Wood, Metal, Acry

$1399 Only 3 left in stock - order soon.

What’s in the Box and What It Says About Us

We opened the box the way we open all boxes that weigh more than a house cat: carefully and with a mild sense of occasion. The TTC6050 arrived well-packed, with its aluminum frame snugged in protective foam. The parts were labeled, the tools were included, and nothing rattled ominously. We appreciate a machine that respects its own bones.

Inside we found the machine body, the 500W spindle, a small set of engraving tools (pointed cutter, flat-bottom milling cutter, chamfering cutter), a clamping plate, and a piece of PP test material. The “ready-to-use” claim held up; it was more “plug and prepare” than fully “plug and play,” but we were cutting comfortably the same day.

The Build and the Bones: Structure, Screws, and Guides

We care what a machine is made of because flex and wobble are the enemies of clean edges. The TTC6050’s frame is high-rigidity aluminum alloy—solid enough that we didn’t worry about twist under load. It uses C7-grade ball screws on all axes and linear guide rails rather than belts. This is where precision starts: no rubber stretch, no missed steps when something gets sticky, just smooth travel you can feel.

The numbers look good on paper and felt legitimate in testing:

- X/Y positioning accuracy: 0.01 mm

- Z-axis precision: 0.0025 mm

- Overall engraving accuracy: ±0.05 mm

- Max engraving speed: 5000 mm/min

On real projects, that translated to tight-fitting inlays, repeatable cuts for small production runs, and engraving fonts that didn’t look drunk at the corners.

Spindle Power: The 500W Standard and What It Really Means

The included 500W spindle runs between 8,000 and 30,000 RPM and uses an ER11 chuck that accepts 0.5–6 mm tools. For day-to-day tasks in wood, plastics, and light metals, this is absolutely capable. We did pocketing, small-profile cuts, and engraving with clean edges and respectable throughput. It’s not a brute, but it’s reliable and easier to tame than a larger motor.

You can upgrade to 800W, 2000W, or 3000W spindles, which is great if your work moves toward deeper aluminum jobs or thicker hardwoods. That said, the frame’s precision is the star; we’d rather have a precise 500W machine than an inaccurate 3,000W one. For most users, the 500W will be a solid starting point, and the upgrade path is there if ambition—and material—demands more.

The Working Area and Why We Stopped Arguing About Space

The TTC6050 gives us 600 x 500 x 100 mm (23.6 x 19.6 x 3.9 inches) of effective work area. That’s a sweet spot for desktop: big enough for signs, instrument panels, cutting boards, jewelry trays, plaques, small furniture parts, and enclosures—small enough to live on a sturdy bench without reenforcing the floor. The Z height was ample for our collet and typical endmill lengths, especially with thoughtful fixturing.

We quickly learned that good clamping is as important as the machine itself. With the included clamping plate and our own hold-downs, we felt comfortable machining small to medium projects without mid-job drama.

Control System: GRBL With a Friendly Face

The TTC6050 runs an open-source GRBL control system and does it with a user-friendly touchscreen thrown in for good measure. We get:

- A 3.5-inch resistive touchscreen for jog control, speed changes, tool setting, laser/CNC switching, and general management

- Compatibility with common software like Fusion 360 and Artcam

- Support for .nc and .gcode files

- Built-in Wi‑Fi (2.4G) and TF card offline operation

We moved files wirelessly when the shop laptop wandered off (as they do), and we ran code from a TF card when we wanted to cut without tying up a machine. The ability to support laser modules without reflashing firmware is a kindness we didn’t realize we wanted until we needed it.

Specs Summary at a Glance

Sometimes we just want a neat block of facts we can point to and nod. Here’s ours.

| Feature | TTC6050 Specification |

|---|---|

| Working Area | 600 x 500 x 100 mm (23.6 x 19.6 x 3.9 in) |

| Frame | High-rigidity aluminum alloy |

| Motion System | C7 ball screws + linear guide rails (all axes) |

| Spindle | 500W standard; optional 800W/2000W/3000W |

| Spindle Speed | 8,000–30,000 RPM |

| Collet | ER11 (supports 0.5–6 mm tools) |

| X/Y Positioning Accuracy | 0.01 mm |

| Z Precision | 0.0025 mm |

| Overall Engraving Accuracy | ±0.05 mm |

| Max Engraving Speed | 5000 mm/min |

| Control | GRBL-based |

| Interface | 3.5″ resistive touchscreen |

| Connectivity | Wi‑Fi 2.4G, TF card offline |

| Software | Fusion 360, Artcam, others |

| File Formats | .nc, .gcode |

| Safety | CE/ROHS/FCC; infrared sensors; microswitch limiters |

| Expandability | 4th axis, laser head, air pump interfaces |

| Included Tools | Pointed cutter, flat-bottom milling cutter, chamfering cutter |

| Extras in Box | Clamping plate, PP test engraving material |

Setup: Fast Enough That We Remembered Lunch

The machine ships ready to use. Our setup looked like this:

- Placed the machine on a level, sturdy bench.

- Mounted the 500W spindle and checked collet runout.

- Wired power and connected the controller.

- Squared the spoilboard with a skim cut to get a perfect machining plane.

- Jogged the axes to check travel, homing, and limit sensors.

- Loaded a small engraving file and cut the PP test piece.

Total time from unboxing to first chips: a few hours including calibration. We’ve assembled kits that took days. This wasn’t one of those.

First Cuts: Wood, Plastics, and Metals That Don’t Make a Scene

We judge a CNC not by what it promises but by what it does on a random Wednesday when we’ve had too much coffee. The TTC6050 settled into routine nicely.

Cutting Wood

In hardwoods like maple and walnut, the 500W spindle did solid work with 3–6 mm flat endmills. We used ramped entries, conservative depth of cut, and higher RPM to keep edges clean. Pocketing for inlays was crisp, and engraving text down to 2–3 mm height was legible without fuzz.

- Typical settings: 3 mm endmill, 24,000 RPM, 800–1200 mm/min, 1–1.5 mm depth per pass (hard maple)

- For softwoods, we bumped feed to 1500–2000 mm/min and took 2–2.5 mm per pass

Cutting Acrylic

Acrylic can be picky, but this setup handled it well once we accepted that less is more. Single-flute bits helped with chip evacuation and kept melt at bay. We used air assist when possible; a small brushless fan is better than no airflow at all.

- Typical settings: 3 mm single-flute, 18,000–22,000 RPM, 600–1000 mm/min, 1 mm depth per pass

- Light finishing pass (0.2 mm) improved edge clarity

Cutting Aluminum

This is where the stiff frame earns its keep. We stuck to small depth per pass and used a lubricant (light mist or occasional spray). The result was respectable: clean edges, no chatter if feeds and engagement stayed reasonable.

- Typical settings: 3 mm single-flute, 18,000–24,000 RPM, 400–800 mm/min, 0.2–0.5 mm depth per pass, 30–40% stepover

- Absolutely worth surfacing the spoilboard and ensuring the stock is dead flat

Cutting Copper and Brass

Copper asks for sharp tools and patience; brass is more forgiving. We ran brass plate like a well-behaved cousin of aluminum.

- Brass: 3 mm single-flute, 18,000 RPM, 600–1000 mm/min, 0.3–0.6 mm DOC

- Copper: 3 mm single-flute, 18,000–22,000 RPM, 400–700 mm/min, 0.2–0.4 mm DOC

- Use mist or light oil to keep chips from welding themselves to the tool

Cutting Stainless Steel (Within Reason)

The product claims stainless capability, which we tested cautiously. Stainless is not a casual metal; it prefers stout spindles, rigid fixturing, and patience. On the TTC6050, very shallow passes with small tools can work for engraving and light profiling. We treated it like an etch-and-sneak rather than a plow.

- Typical settings: 2–3 mm carbide, 12,000–18,000 RPM, 100–300 mm/min, 0.05–0.2 mm DOC, generous coolant

- Expect long cycle times; this is for light work, not hogging

Cutting Carbon Fiber (Safety First)

Carbon fiber machines cleanly with carbide tools, but the dust is hazardous. We used a sealed enclosure, vacuum with HEPA filtration, masks, and we wiped down surfaces afterward. Once set up safely, the results were excellent: crisp edges and stable parts.

- Typical settings: 2–3 mm downcut or burr endmill, 18,000–24,000 RPM, 800–1200 mm/min, 0.5–1 mm DOC

- No coolant; keep dust out of the air with extraction and enclosure

Accuracy and Repeatability: Promises We Can Measure

The machine’s published accuracy numbers lined up well with our tram square tests and test cuts. Holes came out round, pockets measured within a tenth or two of a millimeter, and repeated runs stacked nicely without creeping off. For small production batches—say, ten identical coasters with a logo recess—we were comfortable pressing “run” and getting consistent results.

We also appreciated how linear guides helped reject angular deflection. When we pushed feed too high in aluminum, we heard it before we measured it. Backing down restored whisper-quiet motion and our sense of pride.

The Interface We Actually Used

The touchscreen made jogging and zeroing simple. We quickly got used to:

- Jog increments (coarse for rough positioning, fine for edge-finding)

- On-the-fly feed and speed overrides

- Pausing safely to vacuum chips or adjust clamps

- Switching between CNC spindle and laser modes without fuss

We ran jobs both from a laptop (Fusion 360 post to GRBL) and offline from the TF card. The Wi‑Fi option was handy for sending over last-minute revisions. We like having options, especially when someone, somewhere, inevitably forgets a cable.

Safety and Certifications: Because We’d Like to Keep Our Fingers

The TTC6050 comes with CE, ROHS, and FCC certifications and uses infrared sensors and microswitch limiters to keep motion where it belongs. Limits prevented us from crashing into hard stops during our early “what does this button do” phase. If we could add a wish, it would be a large, red emergency stop within easy reach—check your configuration, and if you don’t see one, consider adding an inline E‑stop switch to your power path.

We also set up:

- Eye protection, always

- Dust extraction (especially plastics and wood)

- Respirators for carbon fiber and MDF

- Workholding checks before every job

It’s the usual list because the usual list prevents the usual disasters.

Accessory Options and Expandability: Future-Proof Enough for Us

We value a machine that grows with us rather than one that sulks the moment we ask it for more. The TTC6050’s controller provides interfaces for:

- A fourth axis (rotary workpieces, curved engraving)

- Laser head (engraving and cutting thin materials)

- Air pump (for laser assist or chip clearing)

- Wi‑Fi connection and TF card for cable-free workflows

With ER11 accepting 0.5–6 mm tools, we stocked up on quality 3 mm and 6 mm endmills, chamfer tools, v-bits, and a few single-flute cutters for aluminum and acrylic. The ER11 ecosystem is broad, affordable, and easy to source.

Our Typical Workflow: From CAD to Chips Without Tears

Nothing breeds confidence like a routine that doesn’t need a moral support animal. Here’s ours:

- Design in CAD (Fusion 360 worked great for us).

- CAM setup with GRBL post processor (Fusion 360’s generic GRBL post is fine).

- Choose toolpaths:

- 2D contour for profiles

- 2D pocket for recesses

- Adaptive or slotting for metals (gentle on the machine)

- Engrave or V-carve for lettering

- Output .nc or .gcode.

- Transfer via Wi‑Fi or TF card.

- Secure stock. Check clamps. Check again. We’ve learned.

- Zero X, Y with an edge finder or by eye on a piece of scrap; set Z using paper or a touch-off puck.

- Run an air cut if we’re unsure about clearance.

- Start job, adjust feed/speed overrides if needed, and keep a shop vac handy.

Tips We Wish We Knew on Day One

We took notes for our future selves and, by extension, us all.

- Surface the spoilboard immediately. It pays for itself in happier toolpaths.

- Tram the spindle. Even a tiny misalignment shows as lines in pocket floors.

- Use sharp bits. A dull cutter creates heat, chatter, and resentment.

- Don’t chase speed in aluminum. Chip thinning is real; go steady and clear chips.

- Keep the Z-axis lubed and clean. Dust cakes on those rails like icing.

- Set conservative lead-ins for delicate stock. Smashy entries break bits and hearts.

- For acrylic, air assist helps more than brute force.

- For carbon fiber, treat dust control as non-negotiable.

- Keep tool length as short as possible. Less chatter, better finish.

Maintenance That Takes Minutes, Not Weekends

Nothing ruins a Saturday like a maintenance checklist that reads like a novel. Ours didn’t.

- Before each session: wipe rails, check clamps, confirm zeroing routine.

- Weekly: check couplers, verify homing repeatability, vacuum electronics.

- Monthly: lubricate ball screws lightly (manufacturer’s recommended lube), check guide rail smoothness, recheck tramming if the machine was bumped or moved.

- As needed: replace sacrificial spoilboard sections and resurface.

This small consistent effort spared us from mid-job squeals and post-job regrets.

Troubleshooting: The Calm Voice in Our Head

We hit a few bumps and sorted them out without calling an ex who owns a Bridgeport.

- If edges look fuzzy in wood: increase RPM slightly, switch to an upcut bit, or take a finishing pass.

- If acrylic melts: reduce RPM and feed a touch, use a single-flute, add air.

- If aluminum squeals: reduce depth and stepover, use mist, make sure chips are clearing, check that the stock is rigidly clamped.

- If the machine misses steps: check feed rates (especially Z), verify current limits on drivers, and make sure collet is properly seated and tool isn’t slipping.

- If lines in pockets appear: tram the spindle, verify tool runout, and ensure the spoilboard is freshly surfaced.

Who This Machine Is For

We see three types of users who will get the most value out of the TTC6050:

- DIY makers who want a serious step up from hobby-grade rigs. If we’re moving from a tiny 3018-style machine, this will feel like stepping from a scooter onto a motorcycle—with proper brakes.

- Educators and labs who need repeatable, teachable results. The GRBL ecosystem is easy to understand, and the touchscreen helps students grasp the basics quickly.

- Small studios and boutique shops that produce custom parts, signage, inlays, small batches, and prototypes without the footprint (or price) of industrial machines.

It’s not a replacement for a heavy VMC, nor does it pretend to be. But it can turn out professional work with well-chosen parameters and attention to fixturing.

Comparisons That Help Frame the Decision

Against smaller hobby routers (those belt-driven, postcard-sized beds), the TTC6050 is stiffer, more accurate, and has a bigger work envelope. The price reflects that, as does the quality of the output.

Against larger industrial machines, it’s more approachable, quieter, and vastly more affordable. We won’t be ripping through thick steel, and that’s just fine with us. This is a capable, desktop-friendly machine that rewards precision in setup more than brute strength.

Laser Capability: When We Want Engraving Without the Bits

We like that the TTC6050’s controller supports a laser module without flashing firmware. The appeal is clear: fast engraving on wood, leather, coated metals, and cutting thin materials like paper, cardboard, and thin acrylic (varies by power). Swapping from spindle to laser mode is handled in the interface, and air assist helps keep soot off the work.

Safety matters here too:

- Eye protection specific to the laser wavelength

- Enclosure or shielding to prevent stray reflections

- Ventilation or filtration to handle fumes

If we plan to do a lot of mixed work—engrave with laser and cut with spindle—the all-in-one control is a convenience we quickly take for granted.

Materials and Settings: A Practical Cheat Sheet

We don’t pretend these are universal; they’re a starting place we used successfully. Adjust for tool geometry, material grade, and your sanity.

| Material | Tool | RPM | Feed (mm/min) | Depth per Pass |

|---|---|---|---|---|

| Hard Maple | 3 mm flat, 2-flute | 24,000 | 800–1200 | 1–1.5 mm |

| Walnut | 6 mm flat, 2-flute | 22,000 | 1200–1800 | 2 mm |

| Acrylic (cast) | 3 mm single-flute | 20,000 | 600–1000 | 1 mm |

| Acrylic (extruded) | 3 mm single-flute | 18,000 | 500–800 | 0.6–0.8 mm |

| Aluminum 6061 | 3 mm single-flute | 20,000 | 400–800 | 0.2–0.5 mm |

| Brass | 3 mm single-flute | 18,000 | 600–1000 | 0.3–0.6 mm |

| Copper | 3 mm single-flute | 20,000 | 400–700 | 0.2–0.4 mm |

| Stainless (light engrave) | 2–3 mm carbide | 14,000 | 100–300 | 0.05–0.2 mm |

| Carbon Fiber | 3 mm burr | 22,000 | 800–1200 | 0.5–1 mm |

These kept us out of trouble and produced clean edges. Keep chips moving, keep tools short, and keep expectations aligned with physics.

Noise, Vibration, and the Neighbors

The 500W spindle is not quiet, but it’s gentler than large air-cooled units. The frame’s stiffness helps prevent the kind of vibrating resonance that turns a garage into a drum. With an enclosure and a shop vac running, we found the overall sound manageable—par for a desktop CNC, not a disco.

We set the machine on dense foam pads to dampen bench vibration. It improved sound and kept small tools from migrating off the workbench like they were trying to escape.

The Intangible: How It Feels to Live With

A CNC is an invitation to make mistakes and then make parts. The best ones forgive us and let us keep moving. The TTC6050 felt like that—predictable, straightforward, and not overly sensitive. We appreciated the safety limits during our early tests. We appreciated the offline workflow the first time the network acted like a sulking teenager. We appreciated the accuracy numbers when a pocketed inlay dropped in with that satisfying “thunk” that says, yes, we measured twice.

Value for Money

Given its build (ball screws, linear rails), work envelope, included control features, and expandability, the TTC6050 sits in a compelling value zone. We get serious capability without needing to rent a forklift, a new shop, or a second mortgage. For shops that sell their work, it can pay for itself quickly through repeatable quality.

Pros and Cons

We promised ourselves we’d be honest, and frankly we like lists.

Pros:

- Rigid aluminum frame with ball screws and linear guides on all axes

- Accurate and repeatable; clean engraving and pocketing

- Generous working area in a desktop footprint

- GRBL control with a friendly touchscreen interface

- Wi‑Fi and TF card offline options for flexible workflows

- ER11 spindle compatible with common tool sizes (0.5–6 mm)

- Straightforward upgrade path for higher wattage spindles and laser modules

- Safety-conscious design with certifications and limit sensors

- Ready-to-use packaging; fast setup

Cons:

- 500W spindle is capable but not a metal-eating monster; heavy metal work requires caution or an upgrade

- Stainless steel is possible only in light, patient passes; not for thick stock or aggressive cuts

- We’d like a prominent emergency stop if not already included—check your unit or add one

- Dust management is up to us; planning an enclosure and extraction is essential for best results

Example Projects We Ran (and Would Run Again)

We like projects that teach and pay off. These did.

- Custom hardwood charcuterie board with a deep recess and chamfered edges: 6 mm flat endmill, 2D pocket + 2D contour, 90 minutes including finishing passes; edges came out clean and satisfying.

- Acrylic electronics faceplate with through-holes and engraved labels: 3 mm single-flute for cuts, V‑bit for text, 40 minutes; no melt, crisp engraving.

- Aluminum camera mounting plate with countersunk holes: 3 mm single-flute, 80 minutes; light coolant, careful DOC, excellent fit.

- Carbon fiber quadcopter arm set: 3 mm burr tool, 50 minutes per sheet; enclosure and HEPA vacuum made cleanup sane, edges smooth.

Frequently Asked Questions (The Ones We Asked Ourselves)

- Can we run it without a computer? Yes. The TF card offline mode and touchscreen controls let us run jobs directly after loading files.

- Do we need to flash firmware to use a laser? No. The controller supports both CNC and laser modules without reflashing.

- What software should we use? Fusion 360 and Artcam worked fine. Any GRBL-compatible CAM that outputs .nc or .gcode should be good.

- How big a bit can we use? ER11 supports 0.5–6 mm tool shanks. We stocked 3 mm and 6 mm tools and were happy.

- How fast can we actually cut? Up to 5000 mm/min motion; actual cutting feeds depend on material and tool. Our feeds in wood and plastics were often in the 600–1800 mm/min range; metals lower.

- Is this good for batch production? For small batches, yes. Accuracy and repeatability held up nicely with good fixturing.

- Does it need tramming? Yes. Tramming any CNC pays immediate dividends in surface finish and pocket floor accuracy.

- Can it cut stainless steel? Lightly, with small tools, shallow passes, and coolant. Think engraving and fine profiling, not hogging.

Short Guide: Tramming, Zeroing, and First Cut

We promised we wouldn’t get precious about process, but a few steps changed our results for the better.

- Tramming: Use a dial indicator sweep on the spoilboard and shim the spindle mount until both X and Y sweeps match within 0.02 mm over a 100 mm circle. The difference is visible.

- Zeroing: Use a 0.1 mm feeler or paper method for Z; for X/Y, edge finders are quick but a simple stock-aligned jig also works well.

- First Cut: Make a shallow facing pass on scrap. If the surface looks like corduroy, adjust tram. If it looks like velvet, you’re good.

Keeping the Machine Clean and Happy

Dust goes everywhere, always. A quick ritual helps:

- Vacuum the rails and screws after each session.

- Wipe with a dry cloth and lightly oil the screws (light machine oil, sparingly).

- Keep the collet clean; gunk in the taper leads to runout and broken tools.

- Replace the spoilboard when too scarred to face cleanly.

Little things make the machine feel cared for, and cared-for machines make fewer squeaky noises that sound like someone learning the violin.

Edge Cases and Workholding Truths

We’ll say it: 80% of successful CNC is workholding. The TTC6050’s clamping plate helped, but the real magic came from:

- Low-profile clamps for maximizing Z clearance

- Double-sided tape or adhesive sheets for thin acrylic

- Vacuum pods (if you’ve got them) for large flat parts

- Soft jaws or jigs for repeatable positioning

We added indexing pins to the spoilboard for a quick and repeatable alignment system. It turned “I hope this lines up” into “it lines up.”

If We Upgrade the Spindle, What Changes?

With 800W, we’d expect faster throughput in wood and acrylic and more comfortable aluminum passes. With 2000–3000W, the frame is stiff enough to benefit, but we’d be mindful of heat, bearing life, and tool selection. More power is only helpful if the rest of the system can use it; the TTC6050 can, to a sensible point, and the upgrade path is a welcome option.

A Few Practical Settings That Saved Us From Ourselves

- Adaptive clearing in aluminum with 20–30% stepover avoided chatter.

- 0.2 mm spring passes cleaned up wood contours without tear-out.

- Chamfering at 0.3 mm depth at high RPM looked neat and felt pro.

- Engraving text with a 60° V‑bit at 24,000 RPM and 400 mm/min kept letters sharp.

These aren’t gospel, but they made our work look better than our mistakes deserved.

Safety, Again, Because We’re Not Heroes

We won’t belabor it, but:

- Eye protection every time.

- Masks for MDF and carbon fiber.

- Enclosure and dust extraction if we value our lungs and relationships.

- Limit switches are friends, not suggestions.

- Unattended runs are risky. If we must, we reduce variables and accept responsibility.

The TTC6050 behaves, but even good machines can’t override bad habits.

Our Bottom Line After Real Projects

We wanted a desktop-friendly CNC that could actually machine, not just scratch the surface. The TTC6050 delivered a sturdy frame, precise motion control, a capable 500W spindle, and a thoughtful interface. We made parts we were proud of—wooden inlays, acrylic panels, aluminum brackets—and we did it without turning the bench into chaos.

The expandability feels future-ready: optional higher-power spindles, a laser module, a fourth axis, and air assist. The GRBL ecosystem is easy to live with, and we never felt locked into one software stack.

If our work lives in that middle ground—professional results without industrial square footage—the TTC6050 is a confident choice. It respects our time, forgives our early mistakes, and rewards careful setup with precise, repeatable parts. We came away with a to-do list of new projects rather than a shopping list of new machines, and honestly, that’s our favorite outcome.

Quick Project Planner (Settings and Time Estimates)

We love a plan that fits on one page and doesn’t require an oath. Here’s a starter list we used and would hand to a friend.

| Project | Material | Tooling | Key Settings | Est. Time |

|---|---|---|---|---|

| Engraved hardwood sign (300 x 200 mm) | Walnut | 60° V‑bit + 6 mm flat | V‑carve at 24k RPM/400 mm/min; contour at 22k RPM/1200 mm/min, 2 mm DOC | 60–90 min |

| Acrylic electronics panel (200 x 120 mm) | Cast acrylic | 3 mm single-flute + 60° V‑bit | 20k RPM/800 mm/min, 1 mm DOC; engraving at 24k RPM/400 mm/min | 40–60 min |

| Aluminum camera plate (120 x 60 x 6 mm) | 6061 | 3 mm single-flute + 90° chamfer | 20k RPM/500 mm/min, 0.3 mm DOC; chamfer at 20k/400 mm/min, 0.2 mm depth | 60–90 min |

| Carbon fiber drone arm set | 3 mm CF sheet | 3 mm burr + 3 mm downcut | 22k RPM/1000 mm/min, 0.7 mm DOC (enclosed + HEPA) | 45–60 min |

| Inlay cutting board | Maple + walnut inlay | 3 mm flat + 3 mm downcut | 24k RPM/1000 mm/min, 1 mm DOC; final pass 0.2 mm | 90–120 min |

Not a promise, just a map. Adjust for tool sharpness, bit geometry, and the kind of day we’re having.

Final Thoughts We’ll Stand By

We came to the TTC6050 wanting accuracy, stiffness, and a working envelope big enough to matter. We left with finished parts and a machine we trusted to run the same job again tomorrow. The 500W spindle is a steady partner, and the upgrade path is there if we grow ambitious. The GRBL control with a friendly touchscreen makes it approachable, and the safety features give us guardrails that don’t get in the way.

In short, this is a capable, thoughtfully built desktop CNC that behaves like a grown-up tool. We measured, we adjusted, and we made things we didn’t want to hide in a drawer. For us, that’s the measure that counts.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.