Have you ever stood behind a machine, watching metal or plastic surrender to a spinning tool, and wondered how someone figured out the choreography that makes that cut look effortless?

The Science Of Toolpath Optimization In 2026: Faster, Cleaner, Smarter Cuts

This is where the choreography meets mathematics, software, and a stubborn quest for perfection. You’re about to get a practical, slightly opinionated tour of how toolpath optimization in 2026 is changing what you can expect from machining — faster cycles, cleaner finishes, and smarter processes that act like they’ve been reading your notes.

Why toolpath optimization matters to you

You care about cutting time, material waste, and the number of times you have to run back and fix a part. Toolpath optimization is the invisible hand that nudges those metrics in your favor. Beyond saving minutes on the clock, optimized toolpaths affect quality, cost, sustainability, and even your afternoon mood when a job finishes without drama.

The business case in a sentence

Optimized toolpaths reduce cycle time, improve surface finish, extend tool life, and lower energy consumption — which means fewer headaches and better margins. If you treat machining as an expense rather than an investment, you’ll miss how much optimization pays back.

What is toolpath optimization?

Toolpath optimization is the process of improving the route and behavior of cutting tools to achieve specific goals: minimize time, reduce tool wear, improve surface finish, or lower energy. It’s not magic; it’s applied math, sensor input, and software heuristics working together.

The difference between a toolpath and an optimized toolpath

A toolpath is a sequence of moves for the tool; an optimized toolpath is a sequence that has been tuned for performance and constraints. Think of one as a map, and the other as a clever taxi driver who knows the shortcuts and which roads to avoid on a rainy Tuesday.

Key benefits you’ll notice

You’ll see shorter cycle times, fewer tool changes, less manual rework, and improved consistency across batches. These benefits compound: savings in tool life and energy add up to significant cost reductions.

Quantifying benefits

You can track improvements with clear KPIs: cycle time, tool life, Ra (surface roughness), burr count, scrap rate, and energy per part. If you like charts, your spreadsheet is about to get more satisfying.

Core technologies enabling 2026 toolpath optimization

Multiple technological advances converged to make 2026 a turning point. Machine controllers are faster, sensors are smarter, and software uses more advanced models to plan motion.

Machine control and real-time feedback

Controllers can now accept high-frequency feedback and adjust feeds and speeds on the fly. You’ll see adaptive feed rate control that reacts to cutting forces, tool condition, and material heterogeneity in real time.

Artificial intelligence and machine learning

ML models predict tool wear, find patterns in chatter, and suggest optimal strategies based on historical data. You don’t have to understand every model — you just have to trust that the system learns from your shop floor and improves over time.

Simulation and digital twins

Simulations are faster and more accurate, and digital twins let you validate toolpaths before they touch the workpiece. You can iterate virtually until the strategy looks flawless, saving material and time.

Edge computing and cloud integration

Edge devices handle fast, local control loops while cloud services aggregate data and run heavy analytics. This split gives you both low-latency reactions and large-scale learning across multiple machines.

Popular optimization techniques and algorithms

There are many approaches, each with strengths and trade-offs. Knowing the tools helps you pick the right one for your needs.

Common algorithm categories

- Heuristic methods (e.g., genetic algorithms, simulated annealing): good for complex multi-objective problems.

- Rule-based strategies: rely on proven best practices and shop knowledge.

- Model-based control: use physics and dynamic models for precise predictions.

- Data-driven methods (ML-driven): learn from historical outcomes and sensor data.

Practical techniques you’ll encounter

- Trochoidal milling: reduces tool load and heat buildup for deep pockets.

- High-efficiency milling (HEM): favors higher speeds and shallower depths of cut to boost material removal rates.

- Contour-parallel and adaptive passes: adjust stepovers to maintain constant engagement and consistent cutting conditions.

- Rest machining: targets remaining material after roughing to reduce total tool time.

How adaptive and predictive systems work together

You’ll see adaptive systems that react instantly to the cutter’s condition and predictive systems that plan ahead based on trends. The combination keeps your processes robust: prediction gives you a plan, adaptation keeps you alive when reality misbehaves.

Example workflow

You run a roughing program informed by ML-predicted tool life; during cutting, force sensors detect a spike and the controller momentarily reduces feed to avoid a premature failure. Afterwards, analytics update the tool life model. That loop is the whole point — learn, act, adjust, learn.

Sensors and data sources that matter in 2026

Good optimization needs good inputs. You’ll pick from a buffet of sensors: force, torque, spindle current, acoustic emission, vibration, temperature, vision systems, and sometimes simple encoders.

Common sensor roles

- Force/torque sensors: give direct feedback on cutting load.

- Acoustic emission: sensitive to micro-fractures or chatter.

- Spindle current: a proxy for cutting power.

- Vision: detect surface defects and burrs.

- Temperature: helps with tool life and workpiece distortion estimates.

Data quality and preprocessing

Data must be cleaned, filtered, and synchronized. Poor data yields poor models; good instruments and thoughtful preprocessing make your analytics reliable.

Software features to look for in 2026

You want CAM that understands materials, tools, and machines; simulation that’s fast and accurate; and MES/analytics that convert data into actionable insights.

Must-have CAM capabilities

- Adaptive toolpaths that keep tool engagement constant.

- Material-aware feeds and speeds.

- Integrated simulation with collision and deflection checks.

- Parameter optimization loops for feeds, speeds, and stepover.

Post-processing and machine integration

Your post-processor must speak your controller’s language precisely. If it doesn’t, you’ll end up with unnecessary dwell times, misinterpreted macros, or worse — banks of swearing on the floor.

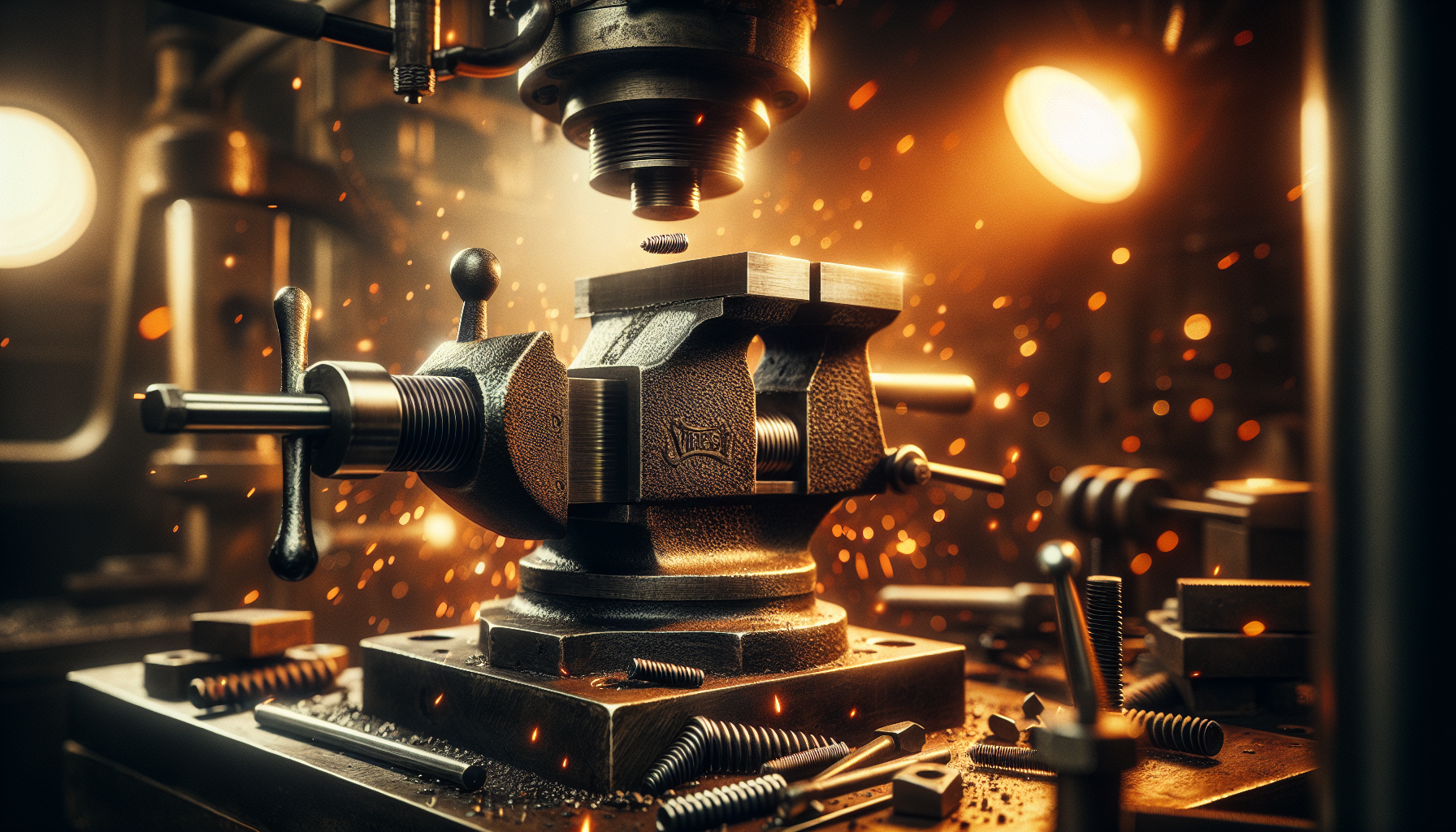

Hardware improvements supporting smarter cuts

Spindles, drives, and toolholding systems have improved, enabling more aggressive and precise strategies. You’ll see higher rpm spindles, better dynamic response, and hybrid machines that combine additive and subtractive workflows.

How hardware boosts software

Better hardware lets software push the envelope: higher accelerations mean shorter rapid times; stiffer spindles handle higher speeds; improved chatter damping yields smoother finishes. The software is only as capable as the machine allows.

Case studies: real-world comparisons

Below is a simplified table illustrating typical improvements you might expect when moving from a conventional toolpath to an optimized strategy in a production shop.

| Metric | Conventional toolpath | Optimized toolpath (2026) | Typical improvement |

|---|---|---|---|

| Cycle time (part A) | 45 min | 28 min | 38% reduction |

| Tool life (avg) | 6 hours | 9.5 hours | 58% increase |

| Surface roughness Ra | 1.2 µm | 0.6 µm | 50% improvement |

| Energy per part | 12 kWh | 8 kWh | 33% reduction |

| Scrap rate | 3.5% | 1.1% | 69% reduction |

You may not hit these numbers immediately, but the table shows what’s possible with integrated tools and disciplined implementation.

A short story about a stubborn bracket

You bring a bracket that always needs a finishing pass and a second inspection. With an optimized trochoidal roughing step, adaptive finishing, and in-process force monitoring, the shop that used to run that bracket three times now runs it once and writes home about it. You’ll like that feeling.

Practical steps to implement toolpath optimization in your shop

You don’t need a miracle or a six-figure overhaul. You need a plan, some clean data, and the patience to iterate.

Step-by-step checklist

- Audit your current process and collect baseline KPIs.

- Standardize tooling and holders to reduce variability.

- Add critical sensors (spindle current, force, vibration) to key machines.

- Update or validate your CAM/post-processor chain.

- Pilot a single part family with controlled changes.

- Measure, analyze, and tune parameters.

- Roll out changes slowly and keep stakeholders informed.

Quick wins you can try first

- Reduce or eliminate air cuts by optimizing entry/exit moves.

- Use constant tool engagement strategies to flatten cutting forces.

- Adjust step-over and step-down for better chip evacuation.

- Implement simple adaptive feeds on troublesome operations.

Cost and ROI considerations

You’ll face upfront costs for software, sensors, and training, but these are often recovered quickly through cycle time savings and longer tool life. ROI depends on volume, complexity, and how aggressively you pursue automation.

Simple ROI model

Use this lightweight calculation to estimate payback:

- Annual parts produced × time saved per part × labor cost = labor savings.

- Add tool and energy savings.

- Subtract implementation and subscription costs.

If the payback period is under 12–18 months, it’s usually a reasonable investment.

Metrics and KPIs you must track

You’ll be best served by a small, focused set of metrics that reflect both performance and quality.

Core KPIs

- Cycle time per part (min)

- Tool life (hours or parts per tool)

- Surface roughness Ra (µm)

- Scrap/rework rate (%)

- Energy consumption per part (kWh)

- Machine uptime/availability (%)

Track these before and after any change, and be honest — optimism won’t beat data.

Common pitfalls and how to avoid them

Optimizing toolpaths is not a silver bullet. You’ll encounter issues like overfitting models to one part, ignoring machine variability, or skipping safety checks.

Pitfall checklist

- Don’t rely solely on simulation without real-world validation.

- Avoid one-off optimizations that can’t be replicated on other machines.

- Don’t ignore clamps, fixtures, or workholding when tuning parameters.

- Keep human oversight; autonomous modes should have safety interlocks and manual overrides.

Training and change management

People are the most important part of any optimization program. You’ll need buy-in from operators, programmers, and management. Training should be hands-on and tied to real shop problems.

How to get operators on board

- Show them time- and comfort-saving wins.

- Teach tools that reduce firefighting, not add bureaucracy.

- Celebrate small victories, like fewer tool breakages or cleaner first-offs.

Safety and compliance considerations

Faster and more aggressive cuts can introduce hazards if not managed properly. You must validate new strategies safely and comply with relevant standards in aerospace, medical, or automotive work.

Safety steps

- Run simulations and dry-runs before full-speed execution.

- Use protective limits in the controller and set clear emergency stop procedures.

- Document parameter changes and approvals for traceability.

Sustainability and waste reduction

Optimized toolpaths reduce scrap and energy use, making your shop greener and cheaper. You’ll see less material dumped into bins and a smaller electricity bill.

Concrete sustainability impacts

- Lower scrap rates mean fewer virgin materials consumed.

- Fewer tool changes reduce packaging waste and tool production impacts.

- Energy reductions per part add up across thousands of parts.

Future trends to watch beyond 2026

The next frontier includes more autonomous systems, multimodal manufacturing, and stronger integration across supply chains. You’ll see machines that coordinate with planning systems to prioritize urgent jobs and self-heal from minor errors.

Promising directions

- Autonomous process control that reduces human supervision for routine tasks.

- Hybrid additive-subtractive sequences with continuous toolpath transitions.

- Federated learning across multiple shops to share anonymized lessons without exposing IP.

Example toolpath strategies and when to use them

This short table helps you decide which strategy to try based on your problem.

| Problem | Strategy to try | Why it helps |

|---|---|---|

| Long rough cycles, high tool wear | Trochoidal milling / HEM | Keeps engagement consistent and reduces load spikes |

| Poor surface finish | Adaptive finishing, optimized entry/exit | Minimizes tool deflection and vibration |

| Excessive tool changes | Multi-stage tooling and rest machining | Maximizes tool utilization across operations |

| Variable material behavior | In-process force/adaptive feed control | Adjusts cutting in real time to prevent failures |

Tools and vendors — what to evaluate

You’ll want software that’s flexible, supports your machine controllers, and has an active roadmap. Hardware vendors should provide open APIs for sensor integration and robust support.

Selection criteria

- Compatibility with existing machines and controllers.

- Availability of local support and training.

- Ease of integration into your MES and ERP systems.

- Demonstrated success in similar industries or applications.

A small shop’s path to sophistication

You don’t need hundreds of machines to benefit. Start with the most problematic part or the highest-volume family and iterate. Even modest automation and modest sensor upgrades can make a big difference.

Minimum viable implementation

- One CAM license with adaptive toolpath modules.

- Basic spindle current monitoring and one force sensor.

- A simple PLC or edge device for real-time adjustments.

This setup gets you most of the way without a complete overhaul.

What you’ll tell your boss (or yourself) after implementation

You’ll be able to point to numbers: less time per part, lower tooling costs, fewer rejects. You’ll also have the less quantifiable wins: cleaner shops, more predictable schedules, and fewer late-night firefights.

A short victory script

“After pilot optimization, cycle time dropped X%, tool life increased Y%, and we reduced scrap by Z%. Scaling this across our production lines will save [estimate] annually.” Say that, then pause for applause, petitions for raises, or at least a quiet nod of approval.

Final checklist before you press play on a new optimized program

You should be ready if you can answer yes to the following:

- Have you validated the post-processor for your controller?

- Have you instrumented the machine sufficient to detect anomalies?

- Have you run virtual simulations with collision checks?

- Is operator training complete and documented?

- Are rollback procedures and emergency stops tested?

If you can say yes, go ahead and start the run. If you can’t, fix the weakest link before risking a costly crash.

Closing thoughts — what to remember

Toolpath optimization in 2026 is less about flashy features and more about rigorous engineering, good data, and pragmatic implementation. You don’t need mysticism; you need an organized plan, quality sensors, and a willingness to iterate. If you treat this like continuous improvement rather than a product purchase, you’ll reap steady gains.

Parting image

Imagine your machine as a musician and the optimized toolpath as the sheet music that finally makes sense of the musician’s talent. When they play together, you get a performance that’s both efficient and beautiful. Your job is to keep the score readable, the instruments tuned, and the audience (your customers) pleasantly surprised.