Have you ever watched a robot pause mid-task while you stood there feeling both indignant and oddly maternal?

The Role Of Calibration And Maintenance In Intelligent Fabrication

You’re stepping into a workshop that looks less like a factory and more like a nervous brain with arms: CNC mills that smell faintly of metal and coffee, 3D printers clicking like an old typewriter, articulated robots with grippers that could double as chopsticks, and sensors that never stop gossiping about temperature and torque. In intelligent fabrication, calibration and maintenance aren’t bureaucratic chores — they’re the quiet rituals that keep the machinery civilized, accurate, and safe. You’ll find that a machine’s personality often depends on how well you attend to those rituals.

What Calibration Means in Intelligent Fabrication

Calibration is the act of aligning a machine’s measurements or behavior with a known standard. You’re not coaxing personality out of steel; you’re ensuring a sensor reads what it should and a motor moves where it’s told. Calibration creates traceability — a documented chain that proves the measurements are trustworthy. Without it, your so-called “precision” parts become a lottery.

Calibration is about reproducibility and confidence. When you calibrate, you reduce measurement uncertainty and make sure your processes can be audited, certified, and repeated.

Types of Calibration

There are many flavors of calibration, depending on whether you’re dealing with length, force, temperature, or the invisible quirks of a robot arm.

| Calibration Type | What it checks | Typical tools/methods |

|---|---|---|

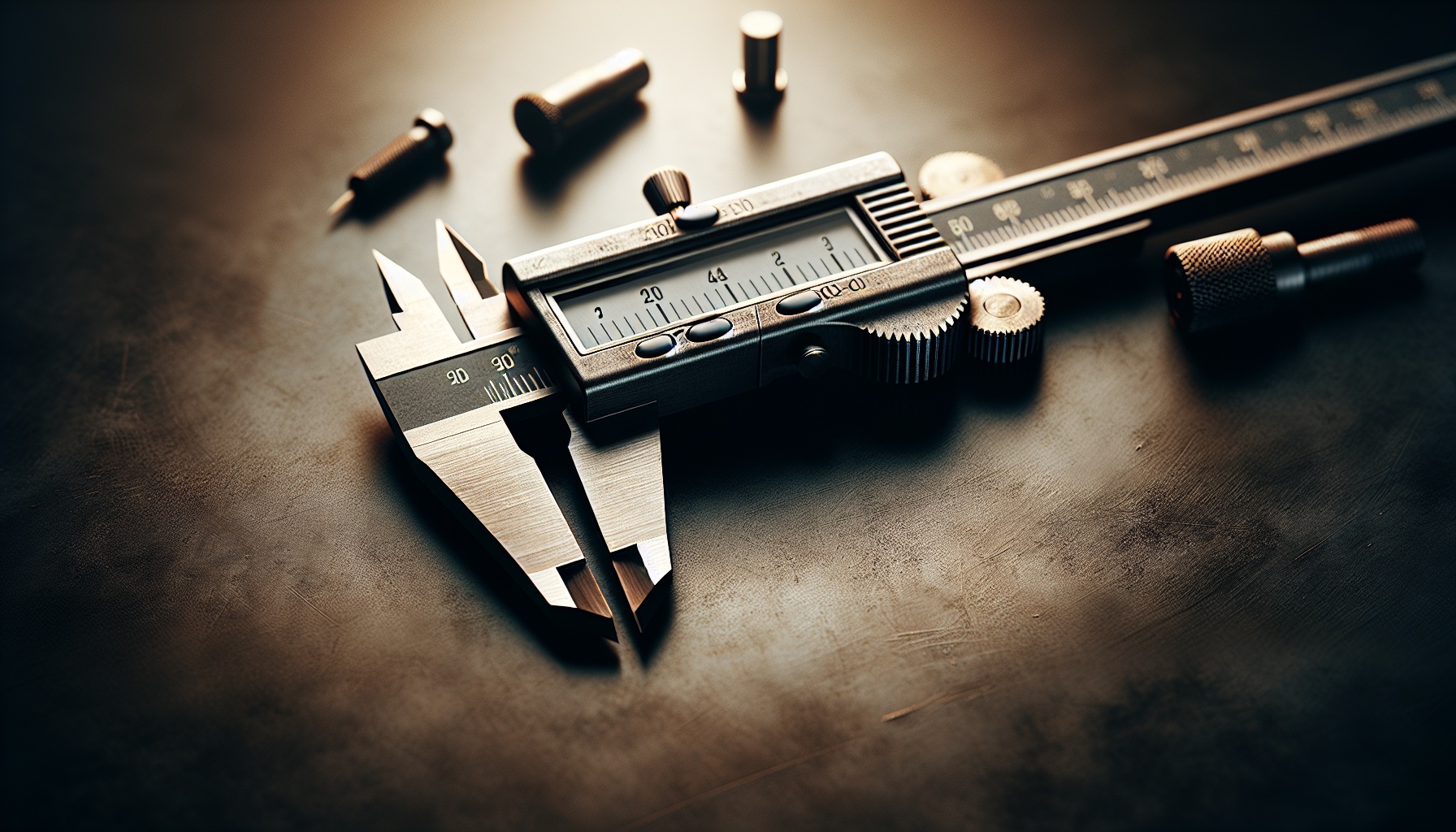

| Dimensional / Geometric | Accuracy of lengths, angles, flatness, runout | CMMs, gauges, laser trackers |

| Thermal | Temperature sensors, heat profiles, oven uniformity | Calibrated thermometers, baths |

| Electrical | Voltage, current, signal fidelity | Multimeters, calibrators, oscilloscopes |

| Sensor calibration | Accuracy and linearity of sensors | Reference sensors, injection signals |

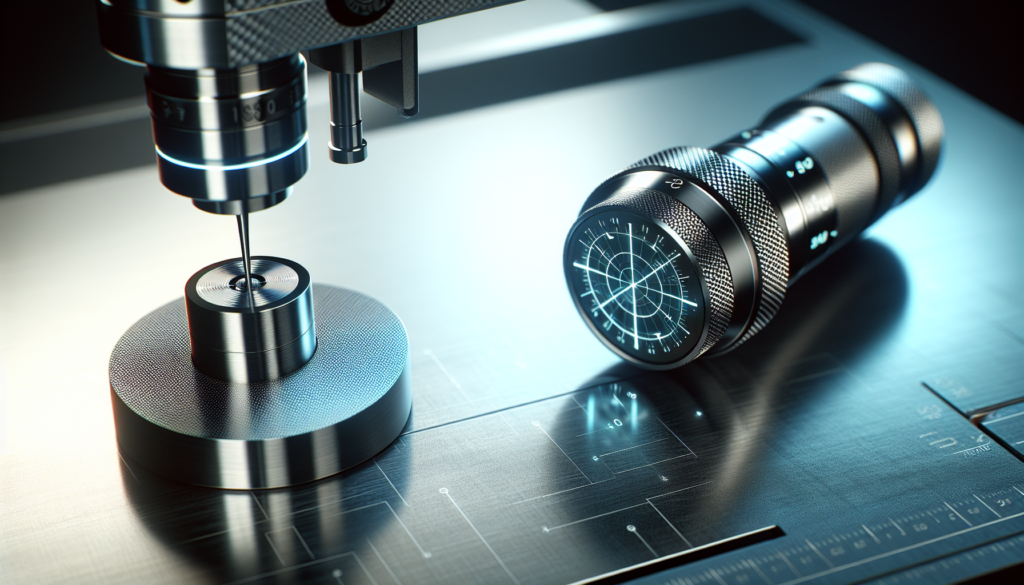

| Kinematic / Positional | Robot joint offsets, axis alignment | Laser interferometer, ball-bar tests |

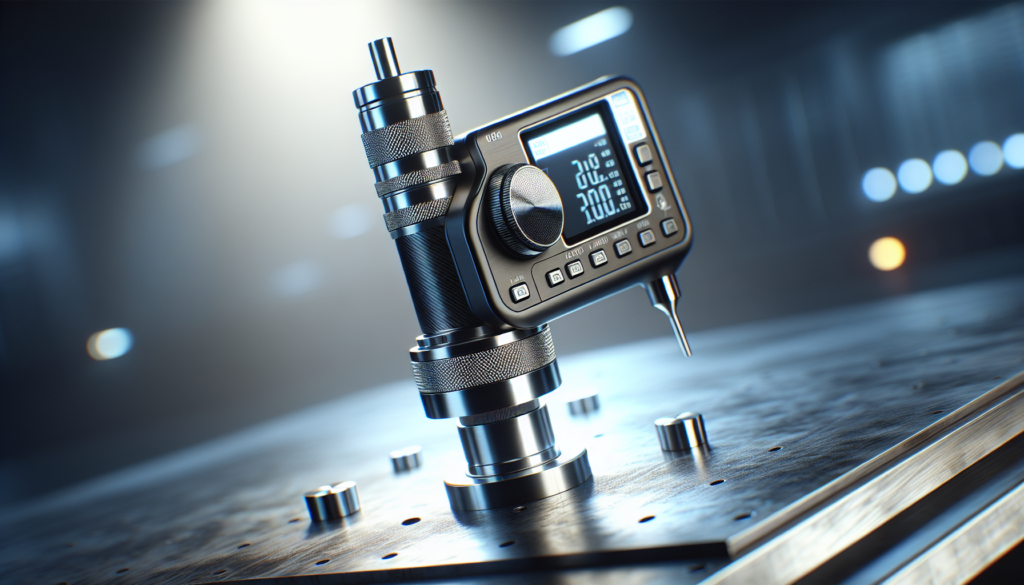

| Force / Torque | Load cell and torque sensor validation | Dead weights, torque meters |

| Optical / Laser | Power, beam alignment, focus | Power meters, beam profilers |

Calibration Standards and Traceability

You’ll want your calibrations to be traceable to national or international standards (NIST, EURAMET, ILAC-accredited labs). That means your reference instruments themselves have been compared to higher-level standards, and there’s documentation at every step. Without traceability, the word “calibrated” is just a fashion accessory.

- ISO/IEC 17025 governs testing and calibration laboratory competence.

- ISO 9001 supports quality management systems and often references calibration.

- Industry-specific standards (e.g., ISO 230 for machine tools) may dictate testing protocols.

Document uncertainty budgets and acceptance criteria. If you can’t quantify how uncertain a measurement is, you can’t decide whether a part is good or bad with confidence.

What Maintenance Means in Intelligent Fabrication

Maintenance keeps equipment functioning as intended through repair, replacement, and preventative action. In intelligent fabrication, maintenance is no longer just greasing a bearing; it’s interpreting streams of sensor data and making decisions that balance uptime and longevity.

Maintenance reduces unexpected downtime, safety incidents, and production variability. For you, good maintenance is the difference between a humming production line and a week-long argument with a PLC.

Maintenance Strategies

There are several strategies you can adopt, each with pros and cons. Your choice depends on risk tolerance, cost, and the criticality of the equipment.

| Strategy | Description | Pros | Cons |

|---|---|---|---|

| Reactive (Run-to-failure) | Fix things only after they break | Low routine cost | High downtime, unpredictable costs |

| Preventive | Scheduled inspections and replacements | Reduces unplanned failure | May replace parts prematurely |

| Predictive | Use data to predict failures and act just-in-time | Optimizes part life, minimizes downtime | Requires sensors, analytics, and data maturity |

| Prescriptive | Automated actions prescribed by analytics | Can automate fixes or adjust processes | Complex, needs high trust and integration |

You’ll want to mix strategies depending on the asset. Critical, high-cost machinery often benefits most from predictive and prescriptive maintenance, whereas non-critical tools might be fine with routine preventive checks.

Integration with Intelligent Systems

Intelligent fabrication thrives on connectivity. Calibration and maintenance systems integrate with:

- CMMS (Computerized Maintenance Management Systems)

- Digital twins that simulate machine behavior

- IoT platforms for sensor telemetry

- MES (Manufacturing Execution Systems) and ERP for traceability

- AI models for anomaly detection and predictive scheduling

When your logs and sensors talk to each other, you can move from cleaning up after surprises to pre-empting them.

Why Calibration and Maintenance Matter (Beyond the Obvious)

Your parts can be tiny works of art or scrap metal, depending on how well your machines are adjusted. Calibration ensures the measurement instruments are telling the truth. Maintenance ensures the machines behave consistently over time. Together they ensure product quality, worker safety, regulatory compliance, and lower total cost of ownership.

There’s a poetic cruelty to neglect: a well-calibrated sensor can still mislead if the cable has a fatigue fracture and the connector is more interested in falling out than transmitting data. You’ll save money, but more importantly, you’ll save your professional dignity.

Building a Calibration Program

A calibration program is a living system. It maps instruments to standards, sets frequencies, documents procedures, and assigns responsibility.

Key steps:

- Inventory instrumentation and assets.

- Classify by criticality and risk.

- Establish calibration intervals based on manufacturer recommendations, experience, and process capability.

- Create written procedures and acceptance criteria.

- Select accredited labs or in-house metrology.

- Maintain records and audit trails.

- Train personnel and perform periodic reviews.

Calibration Schedule and Checklist

Below is a practical schedule template you can adapt to your shop. Adjust intervals based on usage and criticality.

| Item | Typical Frequency | Responsible | Tools Needed | Acceptance Criteria |

|---|---|---|---|---|

| CMM | 6–12 months | Metrology Tech | Calibration artifact, certified gauge | Dimensional tolerances per spec |

| Laser interferometer | 12 months | Metrology Tech | Reference interferometer | Positional accuracy within μm |

| Thermocouples | 3–12 months | Process Engineer | Calibrated bath, reference probe | ± specified °C |

| Load cells | 6–12 months | Maintenance Tech | Dead weights | Within ± specified % |

| Force/Torque sensors | 6–12 months | Robot Specialist | Torque standard | Specified error tolerance |

| Machine tool axis (ballbar) | Daily/Weekly checks (run) and 6–12 months (full) | Operator / Tech | Ballbar kit | Roundness and backlash thresholds |

| Vision system cameras | 3–6 months | QA Tech | Calibration target | Image fidelity and scale accuracy |

Typical On-site Calibration Procedure (Simplified)

| Step | Action |

|---|---|

| 1 | Verify the asset is clean, stable, and warmed up to operational temperature |

| 2 | Inspect connections and mechanical condition |

| 3 | Use traceable reference standard to apply known stimulus |

| 4 | Record measurement vs reference and calculate error |

| 5 | Apply correction factors or adjust instrument as per procedure |

| 6 | Re-check and document results, including uncertainty |

| 7 | Label the instrument with calibration date and next due date |

| 8 | Enter data into CMMS or calibration management software |

Calibration isn’t mystical. It’s repetitious and solemn, like combing a friend’s hair after he’s been in a hedgerow.

Measurement Uncertainty and Acceptance Criteria

Your instruments are not gods. They have uncertainties. Be explicit about them.

- Build an uncertainty budget that includes instrument resolution, reference standard uncertainty, environmental influences, and operator variability.

- Compare measurement uncertainty with process tolerances. If uncertainty approaches the tolerance range, tighten calibration procedures or improve instrumentation.

- Use statistical tools (Gage R&R, Cpk) to understand whether variability comes from the measurement system or the process itself.

If your measurement uncertainty is large compared to the allowed tolerance, you’ll be making bad decisions with confidence.

Building a Maintenance Program

Maintenance should be strategic and fit into your broader operations. You’ll need policies, teams, spare part strategies, and metrics.

Key components:

- Asset registry and criticality ranking

- Preventive maintenance schedules and SOPs

- Predictive monitoring for key assets

- Spare parts inventory and reorder rules

- Maintenance KPIs and dashboards

- Root cause analysis procedures (FMEA, 5 Whys)

Maintenance KPI Table

| KPI | What it measures | Target | Why it matters |

|---|---|---|---|

| MTBF (Mean Time Between Failures) | Average operational time between failures | Increasing | Indicates improving reliability |

| MTTR (Mean Time To Repair) | Average time to restore service | Decreasing | Affects downtime and responsiveness |

| Availability (%) | Uptime / Total scheduled time | >95% (varies) | Direct impact on production capability |

| Planned Maintenance Percentage | Ratio of planned work to total | >70% | Reduces reactive fixes |

| Maintenance Cost per Unit | Total maintenance cost / production volume | Context-dependent | Financial efficiency |

| Calibration Compliance | % of instruments within calibration date | 100% | Regulatory and quality assurance |

Condition Monitoring Technologies

You can use a toolbox of monitoring techniques to detect early signs of failure.

- Vibration analysis: bearings, imbalance, misalignment

- Thermography: hotspots in motors, bearings, electrical panels

- Ultrasound: leaks, electrical arcing, bearing issues

- Oil analysis: contamination, wear particles

- Acoustic emission: crack initiation, friction events

- Electrical signature analysis: rotor bar faults, insulation degradation

Each method catches different failure modes. If you treat these as exotic toys, they’ll underperform; treat them as reliable informants and you’ll learn to read the language of machines.

Calibration and Maintenance for Specific Processes

Different fabrication processes demand different attention. Here are targeted considerations.

Additive Manufacturing (AM)

You love AM for its creativity, but printers are fussy.

- Calibrate extrusion rates, nozzle diameters, and filament diameter for material extrusion (FFF).

- For powder-bed fusion, monitor laser power, beam alignment, and powder characteristics.

- Ensure bed leveling, build-plate flatness, and recoater alignment.

- Monitor chamber atmosphere (O2, humidity) and temperature uniformity.

- Implement in-situ monitoring (thermal cameras, melt-pool sensors) for closed-loop control.

You’ll find that a small misalignment today becomes a phantom layer tomorrow.

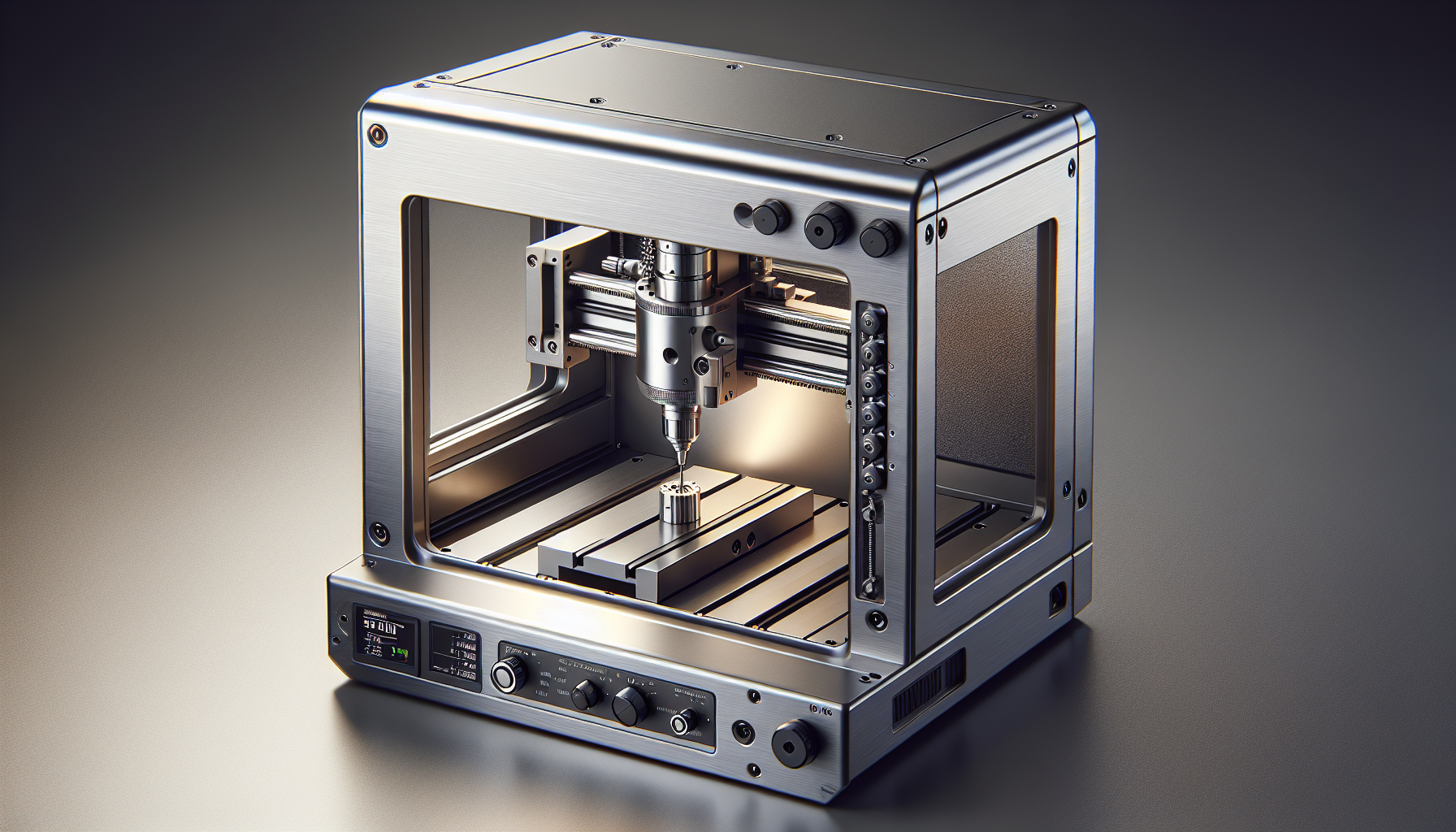

CNC Machining

Precision machining depends on geometry and thermal behavior.

- Regularly check spindle runout, spindle bearing condition, and tool-holder clamping.

- Calibrate tool offsets and lengths; use tool presetters where possible.

- Monitor coolant concentration and filtration to avoid corrosion and overheating.

- Compensate for thermal growth in long runs; use temperature sensors near critical axes.

- Measure backlash, squareness, and axis straightness during maintenance windows.

Machines don’t simply “get tired” — they shift, warp, and develop opinions about your tooling choices.

Robotics and Automation

Robots must know where they are in the world.

- Perform joint and kinematic calibration (encoder checks, zeroing).

- Calibrate force-torque sensors and vision systems for pick-and-place accuracy.

- Ensure gripper repeatability and payload balancing.

- Keep the robot controller firmware updated and verify safety interlocks.

- Establish robot reach and singularity checks; test for path deviations.

Robots will forgive a lot, but not hubris.

Laser Cutting and Welding

Lasers need alignment and beam quality checks.

- Calibrate laser power and focus position; use beam profilers.

- Check lens cleanliness and alignment; replace optics based on performance indicators.

- Monitor assist gas quality and pressures.

- For welding, maintain wire feed systems and check current/voltage sensing calibration.

An unapologetically misaligned laser will produce artless cuts and wobbly confidence.

Implementing Predictive Maintenance with AI

Predictive maintenance isn’t magic. It’s data, engineering, and careful modeling.

- Instrument your assets with relevant sensors: vibration, temp, current, acoustic.

- Collect labeled failure data where possible; else use anomaly detection.

- Feature engineering: RMS vibration, spectral peaks, temperature trends, kurtosis.

- Choose models: supervised (if you have labeled failures) or unsupervised (for anomalies).

- Validate models with cross-validation and hold-out datasets.

- Implement explainability: you must justify actions to engineers and auditors.

- Integrate with CMMS to schedule work automatically based on risk.

AI will help you catch subtle drifts before they become catastrophic failures. You’ll still need domain expertise to interpret model outputs, not unlike pairing a sommelier with a barista.

Common Pitfalls and How to Avoid Them

You’ve made a checklist for everything except the obvious mistakes. Here’s where people trip.

- Pitfall: Calibrations performed but not recorded. Fix: Centralize records in calibration management software.

- Pitfall: Relying solely on manufacturer recommended intervals. Fix: Use data to adjust intervals.

- Pitfall: Poor environmental control during measurement. Fix: Stabilize temperature/humidity in metrology areas.

- Pitfall: Using non-traceable reference standards. Fix: Use accredited labs or NIST-traceable equipment.

- Pitfall: Overconfidence in AI predictions. Fix: Pair AI with human review and implement staged automation.

- Pitfall: Spare parts shortages. Fix: Implement critical spares lists and reorder thresholds.

If you treat maintenance like an afterthought, your equipment will treat you like an absentee landlord.

Cost-Benefit and ROI of Calibration & Maintenance

You’ll often need to justify expenditures with numbers. Consider:

- Cost to maintain: labor, parts, calibration services.

- Cost of downtime: lost production, expedited shipping, reputational damage.

- Quality costs: scrap, rework, returns, customer complaints.

- Safety and compliance costs: fines, corrective actions.

Simple ROI example:

- Annual downtime reduction from predictive maintenance: 200 hours

- Production value per hour: $1,000

- Savings: $200,000

- Annual maintenance program cost: $50,000

- Net benefit: $150,000 (300% ROI)

Numbers like that make stakeholders more receptive than metaphors about obedient machines.

Stories from the Shop Floor (With Permission to Laugh)

You’ll recognize these scenes: a new engineer is proud of a shiny, expensive sensor and mounts it with the subtlety of a child with stickers. Three months later, readings are nonsensical because the sensor is oriented wrong. That same engineer learned to check wiring and orientation before commissioning, like someone learning to put shoes on the correct feet.

In another shop, a laser cutter’s beam alignment drifted by fractions of a millimeter. For two weeks, parts passed visual inspection but failed fit-up at assembly. The culprit? A loose mirror mount that two technicians had “touched” during maintenance without re-verification. The lesson: if you adjust, verify.

These anecdotes underscore a gentle truth: machines won’t judge you for being forgetful, but your customers will.

Checklist: Getting Started Today

If you want immediate, measurable improvement in your shop, do these things in order.

- Inventory all measurement instruments and critical assets.

- Prioritize by criticality (safety, quality, production impact).

- Create a calibration calendar and label instruments with due dates.

- Implement basic preventive maintenance routines for critical assets.

- Instrument one asset for condition monitoring and run a pilot predictive model.

- Centralize records in a CMMS or calibration management tool.

- Train operators on simple checks (visual, cleanliness, connectors).

- Review spare parts for critical assets and set reorder points.

- Establish KPIs and a reporting cadence for maintenance and calibration.

- Audit the program quarterly and adjust intervals with data.

You’ll be surprised how much confidence you reclaim after taking these small steps.

Conclusion

You’ll find that good calibration and maintenance are less about heroics and more about rituals: consistent, documented, and respectful of the machines and people involved. By treating instruments as precious informants and maintenance as an investment instead of a cost center, you’ll produce more reliable parts, reduce stress, and maybe — just maybe — make the robots a little happier.

If you leave with one notion, let it be simple: measurement without trust is gossip, and machines will forgive gossip only so long. Keep standards tight, records tighter, and your patience just long enough to teach the next technician how to listen to the shop’s true language: data.