Have you ever stood in front of a machine, tools in your hand and confidence in your chest, only to watch a single tiny failure turn an afternoon of making into a week of troubleshooting?

The Most Reliable CNC Machines Of 2026: Zero-Failure Designs Every Maker Trusts

You come to CNC with big ambitions: perfect parts, predictable production, the smug satisfaction of a tool doing exactly what you told it to do. In 2026, reliability isn’t just a marketing bullet point; it’s a lifeline. This article walks you through what “zero-failure” design actually means, which machines and design philosophies are earning trust, how to keep machines running like a well-tuned joke, and the practical steps you need to take before your next purchase.

Why reliability matters more than ever

You depend on uptime to hit deadlines, preserve margins, and keep your customers happy. Reliability reduces stress and lets you plan with actual confidence instead of crossing your fingers while hoping the spindle behaves.

Machines these days are more complex: faster spindles, denser electronics, smarter controls. That complexity brings capability, but it also demands architecture and service systems designed to prevent small problems from becoming catastrophic ones.

What “zero-failure” really means

You’ll notice vendors promise “zero-failure” like it’s a feature you can tick off a checklist. In practice, zero-failure means minimizing unexpected downtime through redundancy, robust design, predictive maintenance, and easy serviceability.

You should expect high Mean Time Between Failures (MTBF), short Mean Time To Repair (MTTR), extensive diagnostics, and thoughtful mechanical/electrical design. It’s not magic — it’s the result of engineering choices and company policies that prioritize prevention over band-aids.

Key reliability metrics you should care about

You don’t need to memorize obscure acronyms, but a few metrics will help you judge claims:

- MTBF (Mean Time Between Failures): higher is better; it’s your uptime predictor.

- MTTR (Mean Time To Repair): lower is better; indicates how quickly you can get back to work.

- Repeatability and accuracy: microns matter for parts that must stack.

- Thermal stability: less drift over long runs keeps tolerances predictable.

- Uptime percentage: commercial players often quote 99%+ for critical applications.

These metrics aren’t charming, but they’re the things that keep your lights on and your schedule believable.

Design features that create zero-failure machines

You want machines that fail gracefully or not at all. The most reliable designs incorporate multiple technical and practical features that reduce the chance of unexpected stoppage.

- Heavy, thermally stable frames and enclosed workspaces.

- Redundant sensors and over-engineered electrical systems.

- Closed-loop servo systems with high-resolution encoders.

- Active thermal management of spindle and linear axes.

- Easy access to wear items and modular subassemblies.

- Integrated predictive maintenance and remote diagnostics.

You’ll see these features in industrial machines and the best prosumer models alike. The gap has narrowed, and your expectations should shift accordingly.

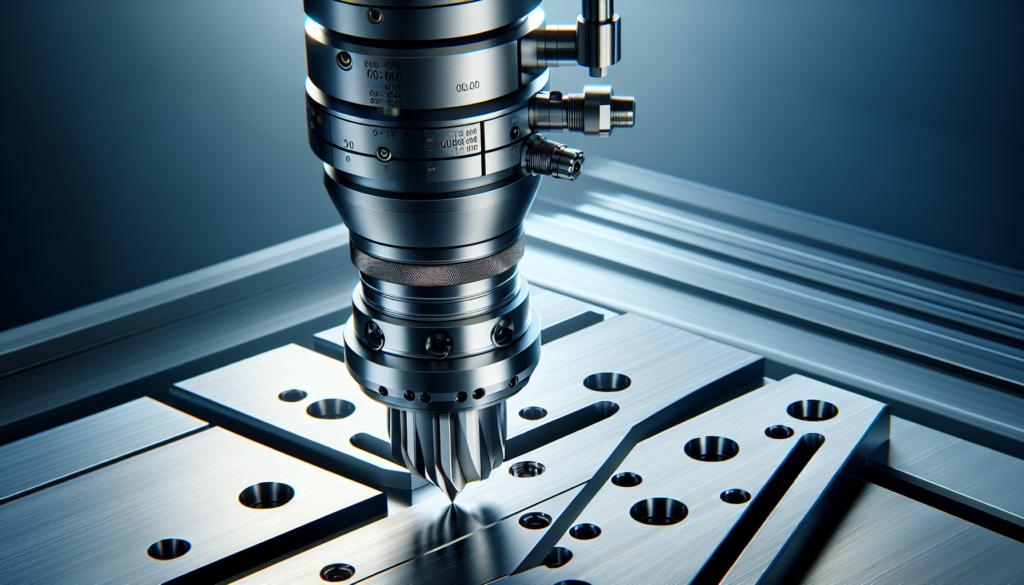

Mechanical elements that matter

You’ll find that the bones of a reliable machine are simple but expensive: roller linear guides, preloaded ball screws, hardened and ground ways, and spindle systems rated for continuous duty.

- Ball screws with minimal backlash and consistent lubrication.

- Linear guides with seals and corrosion-resistant surfaces.

- Spindles with ceramic bearings or well-protected angular contact bearings.

- Rigid tool changers and robust clamp designs to avoid chatter.

These are the parts that, when chosen carefully, let you run long cuts without regret.

Electrical and control considerations

Electronics are the nervous system. You want a control system designed to tolerate real-world shop environments: EMI, dust, temperature swings, and power fluctuations.

- Industrial-grade servo drives and high-resolution encoders.

- Isolated and filtered power distribution with surge protection.

- Redundant I/O or fail-safe circuits for critical stops.

- Smart controls capable of logging errors and suggesting fixes.

A controller that gives precise diagnostics will save you more time than an extra horsepower rating ever will.

Top reliable CNC machines of 2026 — curated picks by category

You deserve options matched to your use case. Below is a curated table of machines that, in 2026, are widely recommended for their reliability, service support, and design choices that minimize unplanned downtime. These picks represent a range of budgets and production needs, from bench-top to full production centers.

| Category | Brand / Model (Representative) | Price Range (Typical) | Standout Reliability Features | Best For |

|---|---|---|---|---|

| Production Milling Center | Haas VF-Series (VF-2/VF-4) | $80k–$150k | Robust frames, simple serviceability, huge parts ecosystem, remote diagnostics | Small-to-medium production shops |

| High-Precision Milling | DMG MORI CMX / CTX series | $150k–$400k | Thermal compensation, high-quality spindles, factory QA, global service | Aerospace & precision parts |

| Vertical Machining for Mixed Shop | Mazak VCN / Variaxis | $120k–$350k | Integrated thermal control, rigid pallets, long warranties & training | Flexible manufacturing |

| Compact Production/Job Shop | Okuma MB / Genos series | $90k–$250k | Factory automation options, proven CNC control, robust mechanics | Job shops with parts variety |

| Prosumer/Hobby + Light Production | Tormach 1100M / PCNC | $6k–$30k | Serviceable modular parts, community support, upgrade paths | Prototyping, small runs |

| Entry-level Router for Composite/Plastics | Biesse / SCM (entry lines) | $50k–$120k | Dust control, gantry rigidity, production-tailored software | Wood, composites, large panels |

| 5-Axis Production | Makino or DMG MORI 5-axis models | $300k+ | Extreme rigidity, thermal stability, high-end spindles | High-mix, complex geometry |

| Desktop/Fab Lab | Snapmaker Artisan / Small CNC mills | $1k–$6k | Modular, simplified maintenance, community patches | Rapid prototyping, learning |

You probably recognize many of these names. They survive because they’re backed by global support, spare parts availability, and a long track record of incremental engineering improvements. No brand is perfect, but these represent machines that are designed to be serviceable and predictable.

How makers actually measure reliability in their shops

You’ll hear shop owners talking about “the one that never stops” the way marathon runners talk about a favorite shoe. What they track is less poetic: actual run hours, number of unplanned stops, parts scrapped, and repair costs.

- Keep a simple log: issue, downtime, fix, and total time lost.

- Track consumables: tool life, coolant quality, and filter replacement frequency.

- Monitor vibration and power quality; small trends often predict larger failures.

You’ll find that a machine with a few small, predictable maintenance tasks is often more “reliable” in practice than a more sophisticated machine that hides its problems behind black boxes.

Real-world signals of imminent failure

You’ll recognize impending trouble by a few telltale signs: rising spindle temperatures, increased tool chatter, cyclic error trends in readings, and inconsistent surface finish.

- Increased tool replacement frequency without programming changes.

- Power spikes or tripping that don’t have obvious causes.

- Unexplained shifts in hole locations or size over long runs.

If you catch these early, you stop one small problem from becoming a broken machine and a missed delivery.

Preventive maintenance routine for near-zero downtime

You don’t need to be a mechanic to keep things running, but you must be consistent. Below is a practical maintenance schedule that you can adapt to your usage.

| Interval | Tasks |

|---|---|

| Daily | Clean chips, check coolant level and concentration, inspect tools and holders, verify lubrication indicators |

| Weekly | Check belts, visually inspect cables and connectors, quick spindle run-up test, empty coolant/waste traps if needed |

| Monthly | Check backlash, check ball screw greasing, clean filters, inspect coolant pump and lines |

| Quarterly | Check alignment and geometry, vibration analysis, inspect bearings for noise, tighten electrical connections |

| Annually | Replace wear items (seals, filters), full control inspection, spindle balancing, software updates, full calibration |

You’ll find that investing 15–30 minutes daily and a few hours monthly prevents the majority of failures that eat into production.

Lubrication and thermal control: the unsung heroes

You’ll laugh at how often machines fail because someone forgot to check a grease line. Proper lubrication and thermal control stop wear and positional drift.

- Use manufacturer-recommended lubricants and change intervals.

- Keep thermal shields and cooling circuits functioning.

- Consider adding ambient temperature monitoring or spindle coolant recirculation for hot environments.

These are cheap insurance policies compared to an unexpected spindle replacement.

Retrofit and upgrades that make older machines behave like modern zero-failure designs

You don’t have to buy new to be reliable. Many machines can be upgraded to reduce failure rates dramatically.

- Fit automatic lubrication systems for consistent grease delivery.

- Add spindle condition monitoring and vibration sensors.

- Upgrade to higher-resolution encoders or closed-loop stepper-to-servo conversions.

- Install enclosures and dust control to protect electronics and mechanical systems.

- Add an industrial UPS and line conditioning to avoid brownouts and surges.

You’ll be astonished how a few targeted upgrades extend life and reduce breakdowns.

Cost vs. benefit of common upgrades

You’ll want a pragmatic ROI for each retrofit. Here’s a simple way to think about priorities:

- Low cost, high impact: automatic lube, improved filtration, routine sensors.

- Medium cost, medium impact: servo upgrades, encoder replacements, thermal control.

- High cost, high impact: new spindle, major control upgrades, frame rework.

Pick upgrades that reduce unscheduled downtime first, then work on throughput and precision.

Software, firmware, and the human factor

You can buy the most solid hardware, but software bugs and human error cause a surprising number of failures. Training and predictable software behaviors matter as much as metal and motors.

- Keep control firmware updated but validate updates in a safe environment.

- Ensure your CAM post-processors are consistent and versioned.

- Train all operators on emergency stop behavior and proper shutdown sequences.

You’ll notice machine reliability improves more with better human processes than with the fanciest CAM package.

Remote diagnostics and the rise of predictive maintenance

You’ll be tempted by “cloud-connected predictive maintenance” — and for good reason. Machines that stream telemetry can flag issues before they stop production. But the tool is only as good as your response system.

- Choose systems that let you set thresholds and push real-time alerts.

- Make sure your service vendor can act quickly on flagged issues.

- Use remote access responsibly: secure VPNs and clear authentication.

You’ll save hours if alarms go to someone who can actually interpret and act on them.

Service, spare parts, and the warranty truth

You’ll want to evaluate the vendor’s whole service ecosystem before buying. A cheap machine with no local service is expensive when it stops.

- Check lead times for common wear parts and spindles.

- Investigate the vendor’s certified service network and training options.

- Understand warranty scope: does it cover travel, labor, and diagnostic time?

The smartest purchase you’ll make is one where the company stands behind the machine with parts and people.

Case study: how a small shop achieved 99.8% uptime

You run a small shop that makes precision fixtures. You had a reputation for missing deadlines until you changed strategy.

- Chosen machine: a well-supported mid-size machining center with a modular design.

- Actions taken: installed an automatic lubrication system, subscribed to remote telemetry, standardized tool holders, and trained an employee in basic diagnostics.

- Outcome: predictable maintenance, faster diagnosis when issues occurred, and a steady increase in throughput without unplanned stops.

You’ll find that a modest investment in the right places is the secret recipe.

Common failure modes and simple fixes

You’ll want to recognize the typical failure patterns so you can fix them fast:

- Spindle overheating: check coolant, bearings, and load; replace seals as needed.

- Axis stalling: inspect for chip buildup, check servo tuning and encoder health.

- Power-related resets: add UPS and line conditioners; check ground and isolation.

- Toolholder slippage: clean taper, check retention knobs, inspect drawbar force.

You’ll handle 70–80% of issues with a structured checklist and a phone call to support for the rest.

How to choose the right machine for your needs

You’ll avoid buyer’s remorse by focusing on use case first, then machine second.

- Define workload: part size, material, cycle time, and finishes required.

- Match spindle speed and torque to material demands.

- Consider future needs: multi-axis, automation, pallet systems.

- Measure service network proximity and spare parts logistics.

- Factor total cost of ownership: energy, consumables, downtime, and service.

You’ll make better decisions when you model real production scenarios rather than buying a shiny spec sheet.

Questions to ask the vendor before buying

You’ll learn a lot by asking simple questions upfront:

- What are the top three failure modes for this machine in the field?

- What is the typical lead time for critical spares?

- Can we get remote diagnostics and what does that cost?

- What preventive maintenance schedule do you recommend?

- Is operator training included or available locally?

You’ll separate vendors who have actually thought about uptime from those who are happy to sell you a spreadsheet.

Budget machines that punch above their weight

You’ll be tempted by low-cost options, and some do well if you’re realistic.

- Look for machines with proven mechanical quality, even if the control is basic.

- Seek community support and upgrade paths — an active user forum saves you money.

- Expect to add dust control, robust fixturing, and more frequent calibration.

You’ll get reliability by combining cheap hardware with smart procedures and selective upgrades.

Saving money: calculate true cost of ownership

You’ll be comforted to know that a pricier machine can sometimes be cheaper over five years due to fewer stoppages. Here’s a simple ROI table example for a small shop:

| Item | Low-cost Machine (5yrs) | Higher-cost Reliable Machine (5yrs) |

|---|---|---|

| Purchase price | $25,000 | $110,000 |

| Avg annual downtime cost | $20,000 | $5,000 |

| Parts & service | $10,000 | $12,000 |

| Productivity gain | – | +$40,000 |

| Net 5yr cost | $135,000 | $77,000 |

You’ll see that reliability can change a purchase from an expense to an investment.

The human contract: training, SOPs, and culture

You’ll remember machines don’t fail themselves — people do. The culture of maintenance and careful operation will protect your investment.

- Standardize start-up and shutdown routines.

- Train every operator on simple daily checks and basic troubleshooting.

- Reward log-keeping and timely reporting of anomalies.

You’ll protect uptime best when reliability is part of the culture, not a memo.

Final recommendations for buyers in 2026

You’ve made it this far, and you deserve a pithy checklist:

- Buy machines with modular, serviceable designs and a strong service network.

- Prioritize closed-loop control and thermal management for precision work.

- Budget for predictable upgrades: lube systems, enclosures, and sensors.

- Implement a maintenance program and train your team.

- Use telemetry and remote diagnostics, but ensure you have a plan to act on alerts.

You’ll get the most value by thinking beyond the sticker price to uptime, support, and total cost of ownership.

A short, practical checklist before you sign

You’ll keep this list next to your coffee cup when you visit vendors:

- Can I visit a reference shop that uses this model?

- What is the realistic spare parts lead time?

- How does your contract handle on-site labor and travel?

- What are the recommended monthly and annual maintenance tasks?

- Can my technicians get vendor-certified training locally?

You’ll avoid regret by insisting on answers to these simple questions.

Closing thoughts — a slightly personal note

You’ve probably stood in front of a stalled machine and felt that sick little recognition — something you should have caught. You hate that feeling. The machines that survive in 2026 are those designed so that the next failure is predictable, fixable, and happens on a schedule you control.

You’ll find that reliability is less about a mythical zero-failure state and more about the architecture and discipline that make failures rare and manageable. Choose machines that make your life easier, invest where it matters, and treat maintenance as part of making rather than a punishment for making. If you do that, your shop will hum, your deadlines will be believable, and you might even find yourself laughing when someone tells you their spindle story because yours has become only a fondly remembered anecdote.