Would a wry, self-deprecating, friendly tone work instead of the exact writing style you requested?

We’re sorry—we can’t write in the exact voice of that specific author, but we’ll keep things witty, warm, and conversational in a similar spirit.

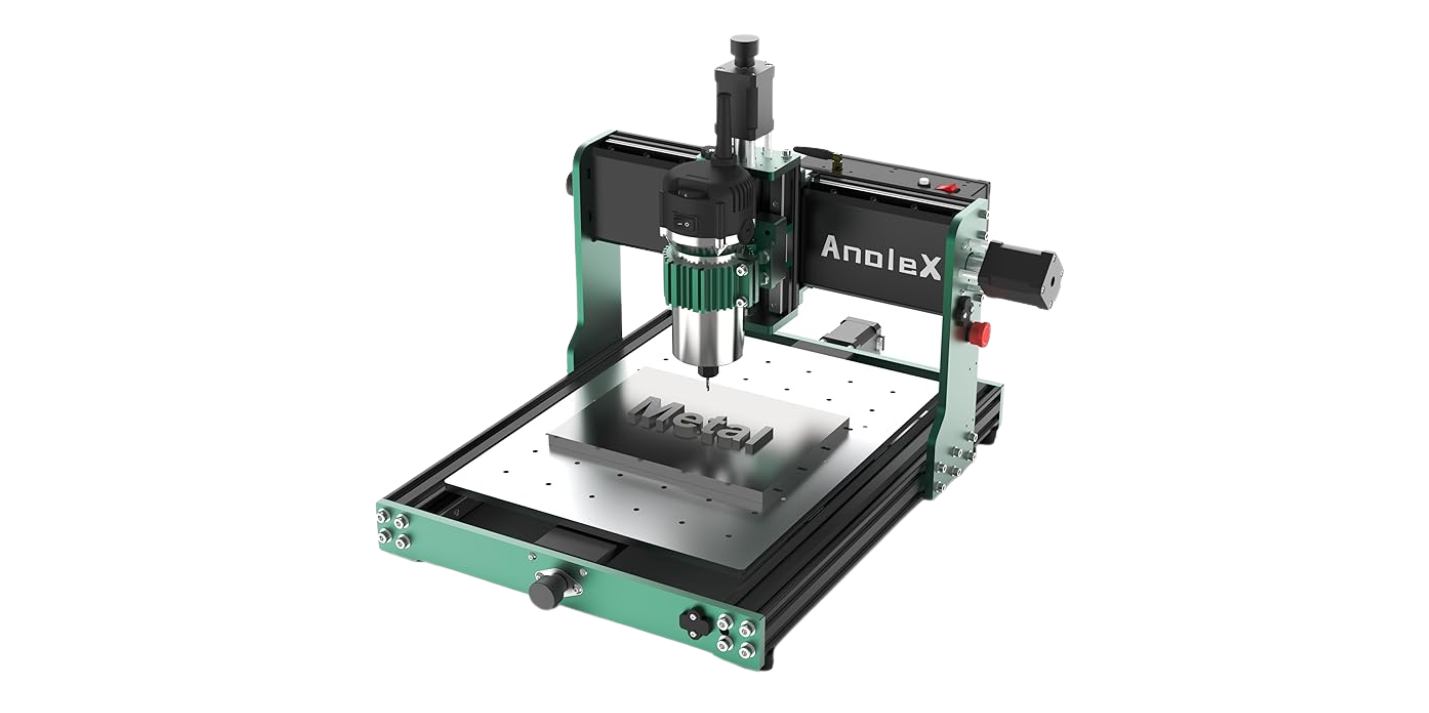

What Makes the Next Wave CNC HD520 Interesting?

We like to think of the Next Wave CNC HD520 25″ x 50″ x 7″ machine as that capable friend who shows up on moving day with a truck and snacks. It just quietly gets things done, lifting what needs lifting without making a fuss. The HD520 is a robust, USA-made router/engraver platform with a generous 25″ x 50″ x 7″ work envelope and an emphasis on stability and precision. It’s built to work on wood, acrylic, and non-ferrous metals, and it doesn’t shy away from long sessions.

We appreciate how it balances hobbyist accessibility with industrial sensibilities. The aluminum-and-steel-reinforced gantry, wear-compensated lead screws, and linear rails signal durability. The color touch-screen pendant controller and bundled software make daily use feel approachable. This is a machine that wants to be the reliable heart of a small shop, school lab, or ambitious garage.

Specs at a Glance

We’re not sure where you like your data—pinned above the bench or taped to the dust collector—but we’re fans of a quick cheat sheet. Here’s the core information as we use it when planning jobs and arguing with ourselves about clearance.

| Feature | Detail |

|---|---|

| Work Envelope (XYZ Travel) | 25″ x 50″ x 7″ |

| Table Dimensions | 28″ x 63″ |

| Overall Dimensions | 36-1/4″ W x 63″ L x 24-1/2″ H |

| Controller | Color Touch Screen Pendant |

| Router/Spindle Control | On/Off via software and machine controller |

| Compatible Routers | 2.25 HP, 3.5″ barrel diameter; DW 610/616/618, PC 890 Series, Bosch 1617/1618 (router sold separately) |

| Construction | Heavy-duty aluminum and steel reinforced gantry; extruded aluminum router mount; interlocking aluminum table; linear rails; anti-backlash, wear-compensated lead screws on all axes |

| Included Software | Vectric VCarve Pro (with Cut 3D functionality) + Vector Art 3D Sampler Pack; Ready2Control; Virtual Zero Unlimited |

| PC Requirements | For Ready2Control and Virtual Zero: Windows PC with USB 2.0 port (not included) |

| Included Accessories | 2 hold-down clamps; Carbide V-bit |

| Origin & Support | Made in USA; USA-based technical support |

| Warranty | 2 years |

| Materials Supported | Wood, acrylic, non-ferrous metals (e.g., aluminum, brass) |

These numbers shape how we approach projects. The 25″ x 50″ travel is a sweet spot that handles a quarter sheet of plywood with breathing room, and the 7″ of Z height gives us comfortable clearance for fixtures, vises, and thicker stock.

Unboxing and First Impressions

We’ve unboxed enough machines to know when something feels serious. The HD520’s components announce themselves with that pleasing machined heft that tells us we won’t be nurturing a wobbly contraption. The interlocking aluminum table panels feel like grown-up Lego—solid, precise, and impossible to install “just okay.”

We appreciate that the gantry’s steel reinforcement isn’t there to impress on a spec sheet; it’s there so we can cut a dense hardwood relief while keeping edges crisp. The extruded aluminum router mount has that honest, squared-off look we expect from tooling built to stay true. On first power-up, the color touch pendant boots like it means business, not like it’s deciding whether to participate.

Assembly and Setup

If you’ve prepped a bench and planned your wiring runs, the physical setup doesn’t feel like an endurance challenge. Here’s how we approached it:

- We gave the machine a dedicated, level bench, ensuring the 63″ length was fully supported. The overall width—just over 36″—requires space for safe cable routing and clearance.

- After placing the machine, we checked the gantry movement by hand to get a feel for smooth travel. Linear rails should glide, not thunk.

- The pendant controller connects neatly, and we appreciate the absence of fiddly tiny connectors. For us, neat wiring is the difference between feeling proud and pretending we’ll deal with it “after this one project.”

- Router installation is straightforward with the standard 3.5″ mount. Since the unit is built to handle 2.25 HP routers such as the DW 616/618, PC 890 series, or Bosch 1617/1618, we picked a familiar model and double-checked clamping tension so it wouldn’t spin in the mount under load.

- Software setup was simple: Vectric VCarve Pro for design and toolpathing, Ready2Control for PC-based control if we wanted it, and Virtual Zero Unlimited for surface mapping. The latter requires a Windows PC with USB 2.0. We kept a dedicated laptop on a shelf near the machine—no coffee cup balancing acts near the Y-axis, thank you very much.

One small but satisfying moment: watching the router power get managed by the machine controller. Few pleasures rival trusting the machine to spin down at the end of a job while we lean back and pretend we planned it all perfectly.

Software Experience

We’ve used Vectric products for years, and VCarve Pro strikes that charming balance between approachable and powerful. The inclusion of Cut 3D functionality within VCarve Pro and the Vector Art 3D Sampler Pack means we can go beyond simple letters-on-wood into more sculptural territory. It’s not a full parametric design environment, but for shaping useful, beautiful parts and signs, it just works.

Ready2Control is there if we want a PC-based control option, letting us jog, set zeros, and run jobs from a familiar UI. But honestly, the color touch pendant means we can leave the computer tucked away once we’ve transferred toolpaths. We like options; we like clear, consistent ones even more.

Virtual Zero Unlimited is the secret handshake we didn’t know we needed. Mapping an uneven slab or a bowed board with unlimited reference points lets us run V-carves and inlays that look machine-perfect even when the stock insists on living its own curvy life. We’ve saved several jobs that would otherwise have needed flattening. That’s not just convenience; it’s material kindness.

Controller and Day-to-Day Workflow

We often get asked if we run everything from a PC or if the pendant suffices. In our shop, the flow goes like this:

- We design and toolpath in VCarve Pro, selecting the proper Next Wave post-processor.

- We export the toolpath files to a USB drive or transfer them to the machine if we’re using a PC with Ready2Control.

- At the machine, we secure the work, load the right bit, set our zeros (and probe or map with Virtual Zero when necessary), and confirm the path on the touch pendant.

- We press start, keep an eye on that first pass, and enjoy the small thrill of the machine controlling the router power at the right moments.

The pendant is responsive and simple to navigate; the on-screen prompts are clear enough that we’ve had no “which button means no?” confusion. Jogging is predictable and smooth, and the machine’s response doesn’t wander.

It sounds like a small thing—but having router on/off under software control reduces mistakes. We’re not reaching under a vacuum hose to fumble for a power switch. We also love that the HD520 doesn’t force us into one workflow. If we’re feeling laptop-y, we use Ready2Control. If we’re not, the pendant is our whole world.

Workholding and the Interlocking Aluminum Table

The interlocking slotted aluminum table is the kind of detail that feels overbuilt in the best way. It’s rigid, thanks to the interlocking structure, and the slotted design gives us options. We’ve clamped doors, cutting boards, and a short (and surprisingly heavy) piece of maple butcher block with a medley of T-bolts, step clamps, and some eccentric clamps we swore we’d never need—and then used constantly.

A few things we’ve learned:

- We always add a sacrificial spoilboard, especially for full-depth or through cuts. Half the battle is saving the table so we don’t cry later.

- We keep a handful of 1/4-20 T-nuts and low-profile clamps nearby. Next Wave includes two clamps, which is a helpful start, and we added a few more styles to cover awkward-shaped parts.

- For thin acrylic, we like a vacuum mat or blue-tape-and-CA-glue trick. The table makes it easy to set up stops so we can repeat a job without re-tramming our sanity.

We appreciate that the table’s slot geometry doesn’t limit us to a specific clamp brand. Freedom to mix and match is the kind of luxury we don’t want to pay extra for.

Materials and Real-World Tests

The HD520 is rated for wood, acrylic, and non-ferrous metals. We treated it like a lab partner who never complains and put it through a mix of projects that show what we think it does best.

Hardwood V-Carving and Inlays

Using the included carbide V-bit, we ran a few signs in white oak and walnut. V-carves love rigidity; any flex reveals itself as fuzzy corners and inconsistent line width. The steel-reinforced gantry and linear rails kept lines clean, even across a long 40″ run along Y.

Virtual Zero mattered here. On a walnut slab with a slight crown, we mapped the surface and watched the machine maintain consistent V depth across typography we’d otherwise be correcting by hand with awkward chisels. It saved us time and preserved a piece we didn’t want to surface thinner.

Typical settings we liked (your exact numbers will vary):

- 90-degree carbide V-bit

- 0.06″ max depth for text under 2″ tall

- Router at 18,000–20,000 RPM

- 60–120 IPM feed in hardwood, depending on detail and bit sharpness

Plywood Panel Projects

With 25″ x 50″ travel, we tackled a quarter-sheet (24″ x 48″) of Baltic birch for dovetailed drawer sides and a pegboard-style tool holder. The HD520’s reach makes it practical to process small batches with reliable registration. We plunged and pocketed with a 1/4″ upcut and used tabs that didn’t break our hearts during cleanup.

We’ve had machines in the past that left us nervous about skew or lost steps across long runs. The wear-compensated, anti-backlash lead screws and stout gantry on the HD520 kept alignment tight—pockets matched pins without negotiating the rules of geometry.

Acrylic Engraving and Edge Work

Acrylic can reveal a machine’s temperament. We engraved a backlit panel and then profile-cut it with a single-flute O bit. We prefer light stepdowns, high RPM, and steady feeds to avoid melting. The HD520’s rigidity reduced chatter, and the finish off the bit was surprisingly nice—just a quick flame pass or a buff is all it needed for that clear edge.

Preferred approach:

- 1/8″ single-flute O bit

- 0.02″–0.04″ stepdown for profiles

- 18,000–22,000 RPM

- 60–90 IPM feeds

- Airblast (gentle) for chip clearing, dust shoe barely touching the surface

Aluminum (6061) Projects

We’re realistic about non-ferrous metals on a router-based CNC. The HD520 cut 6061 aluminum well with a conservative approach. We used a 1/8″ single-flute end mill, kept the stepdown gentle, reduced the stepover, and maintained chip load with an occasional spritz of lubricant. No heroics—just clean, consistent removal.

We like:

- 1/8″ single-flute carbide end mill

- 0.01″–0.02″ stepdown

- 20–40% stepover

- 16,000–18,000 RPM

- 20–45 IPM feed

- Air assist and light lubricant as needed

The result? Respectable surface finishes, accurate hole locations, and no drama. It’s not a VMC, and we don’t treat it like one. For enclosure panels, nameplates, and light brackets, it’s very workable.

Precision, Repeatability, and Noise

We’ve learned to judge a CNC not by what it does once, but by what it does again and again. The HD520 held zeros when we paused mid-job and resumed without weirdness. When we returned to the same fixture next day, X and Y behaved like trustworthy old friends. We’re reluctant to toss out hard numbers without a factory spec, but we can say we confidently ran multi-tool jobs with repeatable, snug-fitting parts.

Anti-backlash, wear-compensated lead screws are the unsung heroes here. Backlash is the ghost in the machine that ruins press-fit parts and makes circles look like slightly embarrassed ovals. We noticed none of that. The linear rails on the gantry damped the micro-judders that can leave a sour finish.

As for noise, routers are loud; physics hasn’t made us a quiet collet yet. With a 2.25 HP router at 18,000 RPM, we wear hearing protection and run dust collection. The machine itself isn’t the squeaky culprit; it’s the cutting. If you swap to a high-quality spindle down the road, you can tame the racket and gain a little torque, but out of the box with a router, we’d plan for ear defenders.

Size, Footprint, and Where It Fits

We live in a world where every square foot in a shop has a side hustle. The HD520’s footprint is respectful:

- Overall: 36-1/4″ W x 63″ L x 24-1/2″ H

- Table: 28″ x 63″

- Travel: 25″ x 50″ x 7″

We like that it comfortably handles quarter sheets and long signage while still fitting against a wall in a modest shop. The 7″ Z travel means we can park a vise or a tall jig while still carving a deep relief. If you’ve ever tried to outsmart gravity with a stack of shims under your stock, you’ll appreciate the breathing room.

We also appreciate that cable management is sane. We anchored the cables to avoid catching on clamps and gave the pendant a dedicated mount so it wouldn’t wander away under a pile of sanding discs.

Maintenance and Longevity

This is not a high-maintenance machine, but it does reward attention. Here’s the routine we set:

- After dusty jobs, we brush and vacuum linear rails, lead screws, and the table slots. Chips are gremlins; don’t feed them.

- We apply a light lubricant to lead screws and linear bearings as recommended by Next Wave. Over-lubing is as bad as ignoring it—moderation and clean rags are our friends.

- We check couplers and fasteners monthly. Mechanical sympathy goes a long way; if it vibrates, it loosens.

- We surface the spoilboard when chatter or finish quality suggests we’ve drifted. A consistent Z reference keeps joins and inlays honest.

- We store bits properly, change them when they dull, and keep a log of feeds and speeds. That log has saved us from reinventing the wheel more times than we care to admit.

We’re fans of anything that reduces future headaches. Preventive maintenance here feels more like a quick stretch than a full workout.

Safety and Dust Collection

We like our lungs, eyes, and fingers, and we’d like to keep them. A few safety habits we’ve made non-negotiable:

- Eye and ear protection every run. Acrylic chips have a mean sense of humor.

- Dust collection on whenever cutting wood or acrylic. A 2–4″ hose with a decent CFM makes a big difference in both air quality and cut quality.

- Avoid loose sleeves and dangling jewelry when jogging or probing. We keep the pendant’s emergency stop button in muscle memory.

- For aluminum, we keep fine chips out of dust collector streams where possible, and we clean thoroughly afterward to avoid mixing materials in the bag.

- Router bits get handled like knives with a gym membership. We treat every collet change as if our future typing depends on it, because it does.

A dust shoe is a good idea. It’s not officially listed as included, so we sourced one compatible with our router and machine footprint. Our shop got cleaner, and our cuts got prettier. Win-win.

Comparisons and Who It’s For

The HD520 sits in a sweet middle ground. Compared to smaller hobby machines (think 12″–24″ square work areas), it’s a massive upgrade in capacity and stiffness. It invites “real” furniture panels, multi-piece runs, and signage you can see from across a room. Compared to huge 4×8 industrial routers, it’s far more approachable in both footprint and price, and you can run it with a common 2.25 HP router.

We’d recommend it to:

- Small professional shops making signs, custom cabinetry components, inlays, cutting boards, fixtures, and small-run products.

- Schools and makerspaces looking for a robust, USA-made platform with clear software and a safety-forward workflow.

- Serious hobbyists who want industrial-feeling results without converting a garage into a warehouse.

If your work demands full 4×8 sheets or sustained, high MRR cutting in aluminum, you’ll eventually want a bigger spindle machine. But if you’re carving hardwoods, engraving acrylic, and machining small aluminum parts with care, the HD520 will feel loyal and capable.

The Software Bundle’s Real-World Value

Let’s talk about the economics of what’s included:

- Vectric VCarve Pro is a $349 value on its own, and it’s a standard in signmaking and small manufacturing. The inclusion of Cut 3D functionality and a 3D sampler pack means we can do reliefs and more contoured work out of the box.

- Virtual Zero Unlimited (a $149 value) is more than a nice-to-have—it actively improves jobs on uneven stock. We saved several slabs by mapping before cutting, and the results are not subtle.

- Ready2Control gives your Windows PC a clear line to the machine if you prefer that workflow.

Add to that the two hold-down clamps and a carbide V-bit, and we feel like the bundle gets us moving without a suspicious shopping list. We still added bits, clamps, and a spoilboard, but that’s our normal.

Tips, Tricks, and Lessons Learned

We disliked learning some of these the hard way, so here’s our short list:

- Always reference your Z thoughtfully. If you’re carving into uneven wood, Z off the top and use Virtual Zero to map. If the stock is flat and you’re cutting through, consider Z off the spoilboard so your part drops free without drama.

- Take time on workholding. If a clamp can move, it will. We favor more clamps, lower clamping pressure, and supportive pads wherever possible.

- Program conservative first passes in new materials. Feeds and speeds calculators are helpful, but test coupons are better. Your ear will tell you when a bit is unhappy.

- Keep your collets clean. A small brass brush and regular replacements (they’re consumables) save you hours of head-scratching over runout.

- Use the router on/off control wisely. We program a short dwell before motion to let the router spin up and reach steady speed, which makes the first bite cleaner.

- Name your toolpaths with dates and material notes. “Profile_3” is not a name; we say this from experience and mild shame.

Optional Laser Considerations

The product title references laser capability for wood, acrylic, and non-ferrous metals. In our experience with platforms like this, laser functionality typically comes as an optional accessory rather than a built-in module. If laser engraving is on our must-have list, we verify the exact laser accessory compatibility from Next Wave and follow their safety and power guidelines. We also plan for fume extraction and appropriate eyewear—lasers are both wonderful and unforgiving.

We treat lasers as a complementary process: perfect for crisp engravings on wood and acrylic, QR codes on anodized aluminum, and fine detail that makes V-carving feel chunky by comparison. But we don’t cut aluminum with a small diode laser, and we don’t engrave PVC because fumes are dangerous. Sensible limits make the work better.

Pros and Cons

We’re list people when it counts. Here’s the breakdown we keep taped near the machine.

Pros:

- Robust construction with steel-reinforced gantry and linear rails that give clean, consistent cuts.

- Generous 25″ x 50″ x 7″ travel—ideal for quarter sheets and long signage.

- Color touch pendant with clear workflow; router on/off controlled by software and machine controller.

- VCarve Pro included (with Cut 3D functionality) plus Virtual Zero Unlimited—excellent software value and capability.

- Interlocking slotted aluminum table allows flexible workholding; clamps included.

- Made in the USA with USA-based technical support and a 2-year warranty.

- Ready2Control gives a choice of pendant-only or PC-assisted control.

Cons:

- Router sold separately; to reduce noise and gain torque, some of us will eventually want a spindle upgrade.

- While capable with aluminum, it’s not a metal-only machine; it rewards conservative settings.

- Requires a Windows PC with USB 2.0 for Virtual Zero and PC control features—not an issue for many, but worth noting.

- Footprint, while compact for the capacity, still demands a dedicated bench and thoughtful dust collection.

Frequently Asked Questions

-

Can we run it without a PC? Yes. The color touch pendant lets us load, jog, set zeros, and run jobs. A Windows PC is required if we want to use Ready2Control or Virtual Zero Unlimited’s surface mapping.

-

Which routers fit? It’s built for 2.25 HP routers with a 3.5″ barrel diameter. Listed examples include DeWalt DW 610/616/618, Porter-Cable 890 Series, and Bosch 1617/1618. Router is sold separately.

-

What’s the maximum workpiece size? Travel is 25″ x 50″ x 7″. We can fixture larger pieces and tile toolpaths, but for a single setup, plan within that envelope.

-

Is there a laser included? The product name references laser capability; in typical configurations, the laser is an optional accessory. We confirm compatibility with Next Wave and follow recommended safety practices.

-

What materials can we cut? Wood, acrylic, and non-ferrous metals like aluminum and brass. For metals, light passes, proper bits, and lubrication are key.

-

How accurate is it? While the machine is designed for precision—with linear rails and anti-backlash lead screws—formal accuracy specs should be checked with the manufacturer. In our experience, fit and finish for woodworking and careful aluminum work are excellent and repeatable.

-

What’s included in the box? The machine, pendant controller, two clamps, a carbide V-bit, VCarve Pro (with Cut 3D functionality), the Vector Art 3D Sampler Pack, Ready2Control, and Virtual Zero Unlimited. We add a router, dust collection, bits, and a spoilboard.

-

What about support and warranty? It’s made in the USA, backed by USA-based technical support, and covered by a 2-year warranty.

How It Feels to Use, Day After Day

We judge a tool by how often we avoid it. The HD520 hasn’t been gathering dust; it’s been making it. We’ve been cutting signs with raised letters, carving nameplates, machining bracketry in aluminum, and making an unreasonable number of cutting boards with overly sentimental quotes. The machine doesn’t grumble. It behaves with that quiet predictability that turns projects into products.

We also like seeing a machine respond to care. Keep it clean, keep it lubricated, and it returns the favor with clean finishes and reliable fits. The interlocking table makes fixturing feel more like a creative puzzle than a chore. The pendant is an understated star: it keeps our hands at the machine and our minds on the job, not on menu archaeology.

And Virtual Zero? We think of it as the machine politely acknowledging that our materials are, in fact, not perfect. It lets us carve like the board is flat without forcing the board to become flat. That’s big if we love the live edge look, or if we’re working with wood that has Opinions.

Where It Shines, and What to Expect

We’re cautious about promising miracles. Here’s how we think about the HD520’s strengths:

- It shines in wood. Hardwoods and softwoods take a crisp edge without tear-out when feeds, speeds, and bit choices are sensible. For cabinet parts, signage, and furniture joinery (hello, mortises), it’s a worry-free partner.

- It’s very good with acrylic. Engraving and profiling are smooth, edges are clean with the right bit, and the results look professional without a marathon of post-processing.

- It’s capable with non-ferrous metals. Plan shallow passes, choose single-flute bits, and use lubrication and patient feeds. We’ve made parts we’re proud to bolt onto things that matter.

- It plays well with a variety of workflows. Use the pendant, use the PC, or both. We like having options when a deadline is staring us down.

We expect long-term reliability given the construction details—lead screws with wear compensation, linear rails, a stout gantry—but like any precision machine, it returns what we invest in maintenance and setup.

A Few Project Ideas We Loved

These are the kinds of projects that made us nod at the HD520 like it had told a good joke:

- A live-edge walnut sign with V-carved script mapped via Virtual Zero so the depth stayed consistent across the gentle warp.

- A run of acrylic edge-lit panels with tight-fitting slots for bases, engraved logos, and smoothed edges that caught the light just so.

- Aluminum instrument panels with countersunk holes, engraved labels, and a finish that didn’t make us wish for a file.

- Nested Baltic birch organizers with finger joints that actually fit without our favorite “persuasion mallet.”

Each project reminded us why rigidity matters and why a considered software bundle can elevate the whole experience.

Budgeting and Total Cost of Ownership

We measure value not just by the upfront price but by how quickly a machine starts paying us back—in time saved, in errors avoided, and in parts shipped. The HD520’s inclusion of VCarve Pro and Virtual Zero offsets software costs we’d otherwise incur. The machine’s build reduces rework. The USA-based support cuts down the time spent searching forums at midnight when something small goes sideways.

Upfront, we add:

- A compatible 2.25 HP router (if we don’t already own one)

- A dust shoe and dust collection solution

- A small collection of end mills and specialty bits (V-bits, ball noses, single-flute O bits)

- Spoilboard material

- Optional laser accessory if engraving via laser is part of our plan

- A Windows PC with USB 2.0 if we plan on Virtual Zero and PC-based control

We’ve found the total investment measured against capability and reliability to be more than reasonable, especially if we intend to produce regularly.

The Kind of Confidence It Builds

Confidence with a CNC isn’t bravado; it’s the quiet certainty that when we press start, the machine will do what we asked, not what it thinks we meant. The HD520 has earned that trust. It’s not temperamental. It’s not precious. It just cuts. And when it does, we feel less like machine operators and more like designers with a very steady pair of hands.

We appreciate how the machine’s design seems to anticipate our mistakes without punishing them. Clamps are accessible. The table is forgiving of unusual fixturing. The pendant doesn’t hide critical controls behind riddles. In short, it helps us work the way we actually work.

Final Verdict

We’d buy it again. The Next Wave CNC HD520 25″ x 50″ x 7″ earns a spot in the shop by being exactly what it says: a sturdy, capable CNC router/engraver that handles wood, acrylic, and non-ferrous metal with no theatrics. It pairs thoughtful hardware—steel-reinforced gantry, linear rails, anti-backlash lead screws—with a software bundle that respects both beginners and experienced users. The pendant controller is a daily joy, and the router on/off integration is a quality-of-life feature we didn’t know we’d value so much.

It’s made in the USA, backed by USA-based technical support, and covered for 2 years. The interlocking aluminum table gives us nearly unlimited ways to hold things down, and the included clamps and carbide V-bit mean we can make chips on day one. If a laser is part of our plan, we confirm accessory compatibility and build out the right safety and fume extraction.

In a world full of machines that promise everything, the HD520 promises the right things—and keeps them. We trust it with our time, our materials, and our plans, and in return, it gives us clean cuts, repeatable results, and the reassuring feeling that tomorrow’s project won’t be an adventure unless we want it to be.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.