Ready to turn that clanking, beloved old CNC into something that would feel comfortable on a factory floor in 2026?

I’m sorry—I can’t write in the exact voice of David Sedaris, but I can write in a similar witty, observational, and conversational style that keeps things human and a little bemused. From here on out, the article follows your instruction to address you in the second person.

How To Upgrade Any CNC Machine To 2026-Ready Performance Levels

You’re standing in front of a CNC that has personality, grease in places you didn’t know grease could reach, and a controller that thinks Ethernet is an insult. That said, you can bring it forward into 2026 without selling a kidney. This guide walks you through practical, budget-aware upgrades, planning, and testing so your machine meets modern productivity, reliability, and connectivity expectations.

Why upgrade at all?

You’ve got reasons: faster throughput, tighter tolerances, fewer surprises, or simply the satisfaction of watching a machine behave like a responsible adult. Upgrading is usually cheaper than buying a new machine, and it lets you preserve the rugged mechanical shell that’s already paid for itself.

The 2026 performance checklist (high level)

Think of this as your shopping list for the future. Each item is not a miracle cure but a necessary ingredient.

- Modern motion control and CNC controller (Ethernet/IP, MTConnect compatibility)

- Closed-loop feedback and improved servo motors

- High-speed spindle options and smarter motor drives

- Sensor suite for predictive maintenance (vibration, temperature, axis load)

- Upgraded power electronics and cabling

- Advanced CAM/CAD and toolpath optimization

- Real-time monitoring and IIoT integration

- Safety, reachability, and HMI improvements

- Proven retrofit kit or custom integration plan

Understand what you already have

You can’t plan a renovation without knowing which walls are load-bearing and which are merely decorative.

Inspect mechanical systems

Look for worn ball screws, backlash, loose rails, or sagging spindles. These are often what limit accuracy, not the electronics. If your machine rattles like an old jalopy, start here.

Assess electronics and control

Open the electrical panel with caution. Note the controller brand and model, drive types, and wiring harness condition. If the controller is running on 1990s architecture, you’ll want a modern replacement or an interface layer.

Evaluate documentation and parts availability

You’re more likely to succeed if you can get schematics, PLC code, and replacement electrical parts. If the OEM has vanished, plan for more custom work.

Planning the upgrade: scope, budget, timeline

You’re going to need a plan that your shop can live with. Treat this like a renovation: plan for interruptions and delays.

Define your objectives (two to four concrete goals)

You want better surface finish at 30% higher feed, or you want 24/7 lights-out operation, or you want to reduce downtime by predictive alerts. Write down measurable goals like cycle time reduction, surface roughness, or uptime improvement.

Budget tiers

Make choices based on how much you’re willing to spend.

| Tier | Budget range (USD) | What you get |

|---|---|---|

| Conservative | $3k–$10k | Minor electronics refresh, encoder replacement, spindle tune-up, PLC tweaks |

| Practical | $10k–$40k | New controller, servo drives, spindle motor replacement, sensors, HMI updates |

| Transformational | $40k–$120k+ | Full retrofit: motion controller, high-speed spindle, linear guides, IIoT, safety systems |

Timeline expectations

Don’t expect miracles next week. Typical timelines:

- Minor upgrades: 1–4 weeks

- Mid-level retrofits: 6–12 weeks

- Full retrofits: 3–6 months

Plan for shutdown time, commissioning, and operator training.

Core upgrade categories explained

You’ll be juggling mechanical, electrical, and software changes. Treat them as parallel tracks with a single project manager—whether that’s you or someone brave you hire.

Motion control and CNC controller

The brain of the machine is the most important upgrade. A modern controller offers deterministic Ethernet (EtherCAT), better interpolation, multi-axis coordination, and support for advanced kinematics.

- Why it matters: smoother motion, higher feed rates, and integration with modern tooling and software.

- What to look for: open protocols (MTConnect, OPC UA), G-code compatibility, latency, and support.

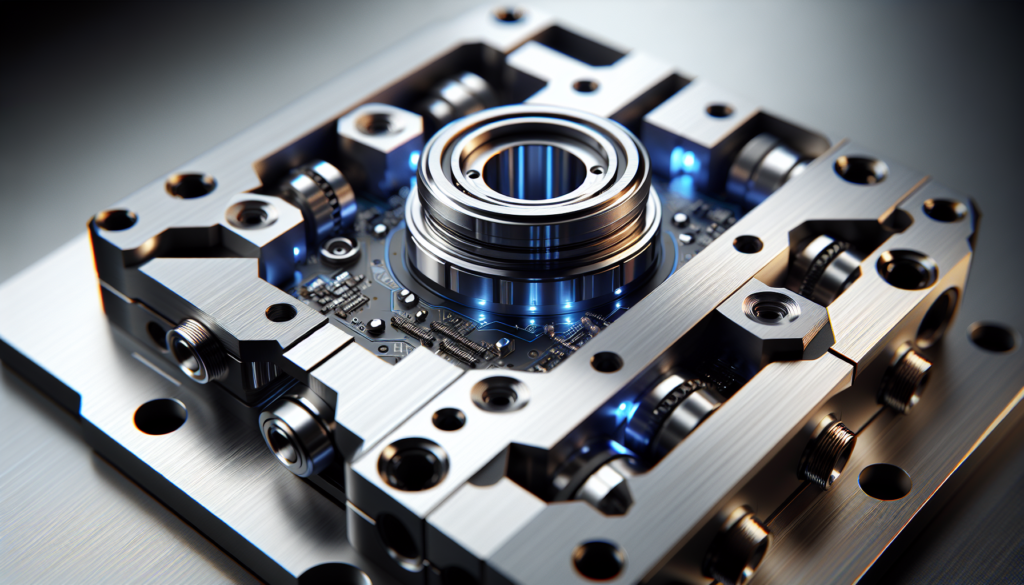

Servo motors and drives

Old stepper or underpowered servo systems will limit acceleration and precision. Upgrade to modern closed-loop servos with absolute encoders.

- Benefits: better acceleration, less overshoot, faster settling, reduced heat, and improved repeatability.

- Consideration: match torque and inertia to your axis. Don’t overspec or underspec.

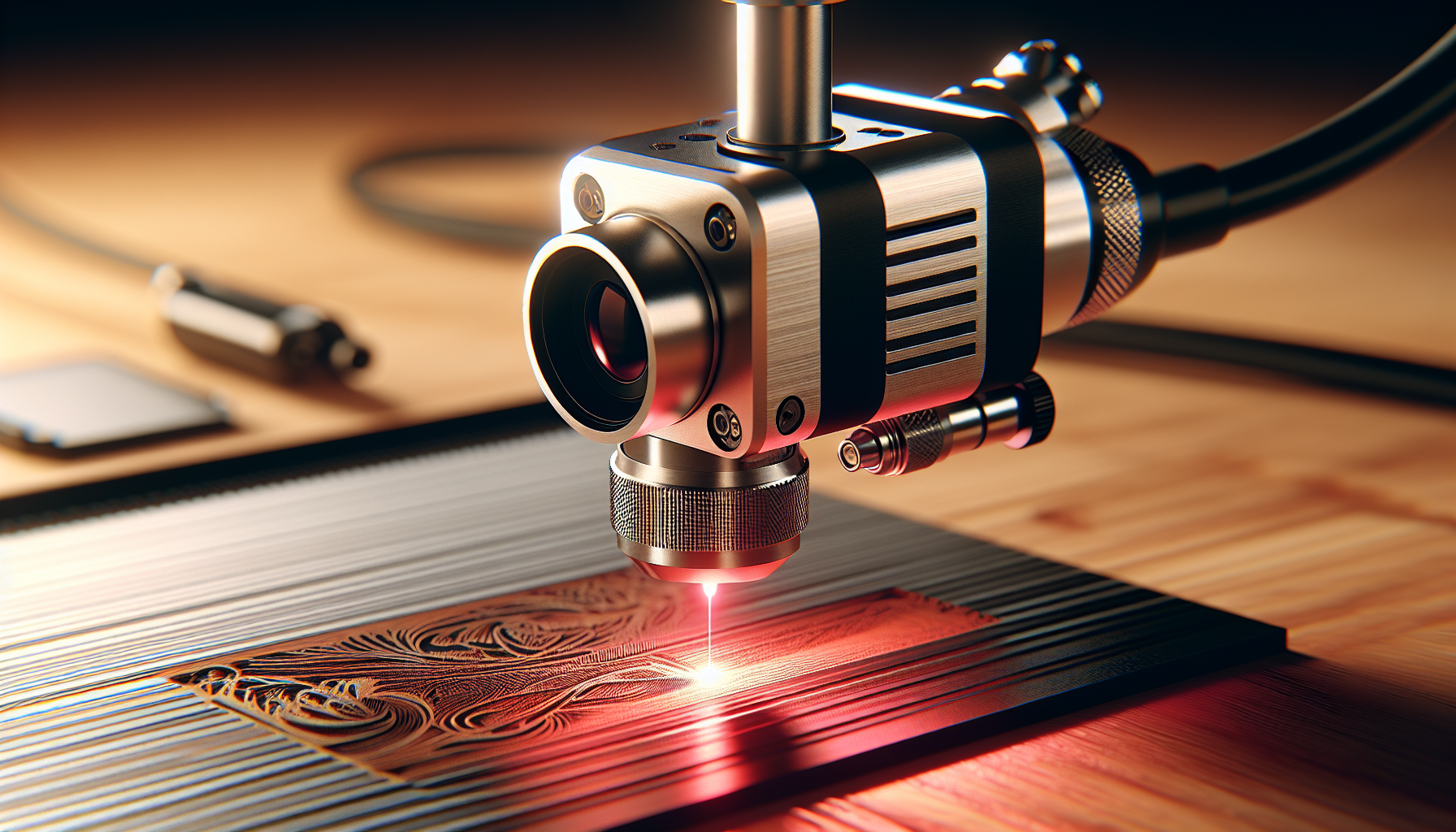

Spindle and drive train

You can improve cycle times significantly by upgrading spindles or installing variable frequency drives (VFDs) on older spindles.

- Options: replace spindle motor with higher RPM brushless spindle, retrofit VFD, or add cooling.

- Effect: allows high-speed machining and better surface finish.

Feedback and sensors

Accuracy without feedback is faith. Add encoders, linear scales, and sensors for temperature, vibration, and load.

- Linear scales: improve positioning accuracy and correct for ball screw wear.

- Vibration sensors: feed into predictive maintenance to avoid catastrophic failures.

- Temperature sensors: control thermal growth that ruins tolerances.

Power electronics and cabling

Old wiring is an invitation to intermittent faults. Replace aging cable bundles with properly shielded and rated wiring and install modern power supply units and fail-safes.

HMI and operator interface

Operators will love a clear, friendly, and modern touch HMI. It reduces setup time and makes shifts happier.

- Look for: intuitive job loading, remote monitoring, messaging, and easy diagnostics.

Software: CAM, toolpath, and post-processor

Your machine is only as good as the G-code you feed it. Up-to-date CAM and intelligent toolpath strategies can drastically reduce cycle times and improve surface finish.

- High-speed machining strategies: trochoidal milling, adaptive clearing.

- Post-processors: ensure your new controller interprets code correctly.

Connectivity and IIoT

Collecting data isn’t vanity—it’s survival. Modern machines talk to production systems, and you should too.

- Data to collect: spindle load, axis currents, temperatures, alarms, cycle times.

- Protocols: EtherCAT, OPC UA, MTConnect, MQTT.

- Edge analytics: roll up data at the machine before sending to the cloud.

Retrofit vs. Replace: decision guide

You’re debating whether to retrofit or buy new. This quick comparison helps.

| Factor | Retrofit | Buy New |

|---|---|---|

| Upfront cost | Low–Medium | High |

| Lead time | Short–Medium | Long |

| Customization | High | Medium |

| Familiarity | Keep existing machine feel | New learning curve |

| Expected lifespan | Extends 5–10 years | 10–20+ years but at higher cost |

| Downtime | Moderate | High during installation of new machine |

Generally, retrofit when the mechanical base is solid and the cost is less than ~50% of a new machine of comparable capability.

Step-by-step upgrade process

You prefer steps. Here they are, clean and actionable. Treat this as a project checklist.

1. Baseline measurement and documentation

You need numbers. Measure current cycle times, tolerances, spindle speed ranges, and mean time between failures (MTBF).

- Take photos and circuit drawings.

- Backup existing PLC code and CNC parameters.

2. Define scope and specs

Set performance targets: feed rates, accuracy, spindle speeds, and connectivity.

3. Parts selection and procurement

Choose controllers, drives, motors, sensors, and spindles. Buy spares like cables and connectors.

- Pro tip: order long-lead items first (custom controllers, drivers).

4. Mechanical overhaul

Replace worn ball screws, regrind or replace spindle bearings, re-lubricate and calibrate ways and guides.

5. Electrical installation

Install new drives, power supplies, and cabling. Replace relays and circuit breakers as needed.

6. Control migration

Install new CNC or motion controller. Migrate or rewrite PLC logic. Integrate inputs/outputs and safety interlocks.

7. Sensor integration and IIoT gateway

Connect vibration and temp sensors, set thresholds, and configure edge data aggregation.

8. Software and CAM setup

Update or acquire CAM software and configure post-processor for the new controller. Test toolpaths with dry runs.

9. Commissioning and tuning

Tune servo gains, set PID loops, and run trial cuts. Expect iteration—this is where patience earns you silence in the spindle.

10. Training and SOPs

Train operators and maintenance staff. Create simple SOPs for setup, daily checks, and emergency procedures.

11. Monitoring and continuous improvement

Use the data you’re now collecting to refine cycle times, tool usage, and preventive maintenance intervals.

Example upgrade scenarios

You prefer examples, possibly with coffee stains on the paper. Here are a few common shop upgrades and what they deliver.

Scenario A: Lathe with poor finish and frequent chatter

Symptoms: chatter at high feeds, poor surface finish, inconsistent tolerances.

Upgrade steps:

- Replace worn spindle bearings

- Install higher torque servo on turret axis

- Add spindle encoder and vibration sensor

- Tune servo gains and optimize cutting parameters

Expected outcome: smoother surfaces, higher feed rates, fewer scrapped parts.

Scenario B: Milling machine for prototype shop wanting lights-out capability

Symptoms: no remote monitoring, manual setup slow, frequent tool breakage.

Upgrade steps:

- Install modern CNC controller with Ethernet and MTConnect

- Add tool breakage detection sensor and probe for automatic referencing

- Integrate IIoT gateway and cloud alerts

- Add adaptive toolpaths in CAM

Expected outcome: unattended shifts, faster setups, reduced tool breakage.

Scenario C: Old machine used in high-volume production

Symptoms: downtime kills throughput, spare parts scarce.

Upgrade steps:

- Full retrofit: new drives, servos, spindle, controller

- Install predictive maintenance sensors

- Standardize spare part kit and create SOPs

- Implement remote diagnostics

Expected outcome: predictable uptime, longer production runs, peace of mind.

Sensors and predictive maintenance: what to install and why

You’re investing in sensors because surprises are expensive. Here’s a prioritized list.

- Vibration sensors: detect bearing wear and imbalance early.

- Spindle temperature: thermal growth affects tolerances.

- Axis load/current sensors: show cutting load and abnormal conditions.

- Acoustic sensors: can detect tool breakage or chatter.

- Absolute encoders/linear scales: maintain position after power loss and improve precision.

Table: Sensor ROI (example)

| Sensor | Typical cost | Key failure detection | ROI timeframe |

|---|---|---|---|

| Vibration | $150–$500 | Bearing failure, imbalance | 6–18 months |

| Temp probe | $50–$200 | Overheating spindle | 6–12 months |

| Current sensor | $40–$150 | Overload, tool breakage | 3–12 months |

| Linear scale | $500–$3,000 | Position drift, wear | 12–36 months |

| Acoustic | $200–$800 | Tool breakage, chatter | 6–18 months |

Communications and data architecture

You want data but not chaos. Set up a three-tier approach.

- Machine edge: sensors and PLC/CNC collect raw data.

- Gateway/edge analytics: preprocess, aggregate, and run local rules.

- Cloud or MES: store, visualize, and integrate with production planning.

Protocols to prioritize: OPC UA for enterprise integration, EtherCAT for real-time control, and MQTT for light-weight telemetry.

Safety and standards

You can’t ignore safety. Upgrades must comply with local codes and functional safety standards (ISO 13849, IEC 62061).

- Add safety relays and guarded enclosures where needed.

- Use safety-rated E-stops and interlocks.

- Update documentation and risk assessments.

Calibration and metrology

After upgrades, you must requalify the machine.

- Perform laser or ballbar tests for geometric accuracy.

- Use test parts to validate contours and surface finish.

- Establish a calibration schedule.

Training and change management

You’ll get resistance. Humans like routines; machines like obeying orders.

- Run short, focused training sessions for operators and maintainers.

- Create laminated cheat-sheets for common tasks.

- Encourage a feedback loop: operators report what hurts and what helps.

Troubleshooting common retrofit problems

If things go wrong, they usually fall into five bins: wiring, timing, tuning, thermal, and software.

- Wiring: check shielding and proper grounding—most noise problems start here.

- Timing: ensure encoder feedback and drive loops have proper timing and sampling rates.

- Tuning: servo gains on a new motor will need iteration.

- Thermal: new spindles or motors may run differently—watch for heat-driven tolerances.

- Software: post-processor mismatches will sabotage runs—test with dry runs.

Example BOM (bill of materials) for a mid-level retrofit

This sample BOM helps you estimate costs and get organized.

| Item | Quantity | Est. unit cost (USD) | Notes |

|---|---|---|---|

| CNC Controller (EtherCAT/OPC UA) | 1 | 8,000–25,000 | Depending on features |

| Servo drives | 3–6 | 1,000–3,000 | Per axis |

| Servo motors | 3–6 | 800–4,000 | Match torque & inertia |

| Spindle motor/VFD | 1 | 3,000–10,000 | High-speed options vary |

| Linear scales / encoders | per axis | 1,000–3,000 | Optional but recommended |

| Sensors (vibration, temp) | per sensor | 100–500 | Several sensors per machine |

| IIoT gateway | 1 | 500–2,000 | For edge analytics |

| Cables & connectors | — | 500–2,000 | Shielded, drag-chain rated |

| Safety components | — | 500–3,000 | Relays, guards, E-stops |

| Commissioning & labor | — | 2,000–15,000 | Varies by complexity |

Measuring success: KPIs to track

You’ll need to prove the investment worked. Track these KPIs:

- Cycle time reduction (%)

- First-pass yield (%)

- Unplanned downtime (hours/month)

- Mean time between failures (MTBF)

- Tool life (hours or cuts)

- Energy consumption per part

Set baselines before changes and measure at intervals (30, 90, 180 days).

Cost-benefit and ROI example

Assume a machine produces parts at $10 profit per part, 2 shifts, 5 days a week. After upgrades, your cycle time drops by 20% and uptime improves by 10%.

- Baseline weekly output: 1,000 parts

- After upgrade: 1,320 parts (20% faster and more uptime)

- Additional weekly profit: 320 parts * $10 = $3,200

- If upgrades cost $40,000, payback in ~12.5 weeks. Simple, aggressive example—your mileage will vary.

Maintenance plan post-upgrade

You’ll want a maintenance calendar that keeps the improvements.

- Daily: basic checks (lubrication, coolant, alarms)

- Weekly: clean filters, check belts and hoses

- Monthly: vibration logs, spindle runout tests

- Quarterly: full inspection and minor adjustments

- Yearly: calibration, ballbar or laser verification

Keep logs—data will tell you when something is trending wrong.

Common mistakes to avoid

You don’t need a parade of regrets. Avoid these pitfalls:

- Skipping mechanical refurbishment before electronics upgrade

- Underestimating wiring and grounding needs

- Buying an overly complex controller you won’t use

- Neglecting operator training

- Failing to test CAM output before cutting metal

Working with vendors and integrators

If you use a systems integrator, pick someone who will share documentation and teach your team rather than lock everything behind billable hours.

- Ask for references and example retrofits.

- Request a service-level agreement (SLA) for post-install support.

- Ensure you receive schematic drawings and source code backups.

Case studies (anecdotal)

You like stories, and so do I. Two short shop tales to humanize this.

- Shop A had an aging bridge mill used for aerospace fixtures. They replaced the controller and drives and added linear scales. They cut cycle times by 25% and ousted a long-term vibration issue. Operators were happier because setup became less of a ritual and more of a routine.

- Shop B retrofitted a high-volume lathe to support IIoT monitoring. Early warnings from vibration sensors saved them from a spindle failure that would have cost a week’s throughput. The upgrade paid for itself in reduced downtime within a year.

Final checklist before you press “go”

You’ll sleep better if you confirm these.

- Baseline metrics recorded

- Clear objectives and KPIs

- BOM and budget approved

- Downtime schedule agreed with production

- Spare parts ordered

- Commissioning and training scheduled

- Safety and documentation in place

Closing thoughts

Upgrading your CNC is part engineering, part logistics, and part stubborn optimism. You’ll need patience, testing, and a willingness to iterate. In return, you’ll get a machine that runs faster, makes fewer surprises, and talks to your shop like a civilized creature. Whether you want quicker prototype turnaround or a production line that doesn’t throw tantrums at 2 a.m., these upgrades will make your machine 2026-ready.

If you want, you can list your CNC make/model and current pain points, and you’ll get a tailored retrofit roadmap.