Have you ever felt like you’re being judged by a stopwatch while a micrometer glares at you from across the bench?

How Smart Fabricators Balance Speed, Precision, And Cost

You can think of fabrication as a three-act play where speed, precision, and cost share the stage. You want the audience to applaud, not to notice the seams. The trick is learning when to let one character lead and when to quiet another without spoiling the plot. This article gives you practical tools, mental frameworks, and a few wry observations so you can manage those trade-offs without losing sleep or your sense of humor.

The classic conflict: speed vs. precision vs. cost

You probably know the phrase “fast, good, cheap—pick two.” It’s a bit of a fabrication nursery rhyme, spoken in break rooms and procurement meetings. That rhyme is true, but not useful unless you know how to bend it intelligently. Here you’ll get an understanding of the tensions and practical ways to make them work for you.

Why the triangle matters

When your customer demands a rapid turnaround, the temptation is to push machines to their limits, shorten setup times, or reduce inspection. That often raises scrap rates or hidden rework costs. On the other hand, hyper-precision can inflate costs and slow output. You need a balanced plan that reduces surprises and keeps everyone—customers, operators, and accountants—reasonably happy.

How to think about trade-offs

Think of trade-offs as adjustable dials, not binary switches. You can nudge precision up a hair and recover speed elsewhere. You can cut cost in one area and invest savings into something that preserves both speed and precision. This section is about learning which knobs to turn and in what order.

Define your priorities and constraints

You should never optimize without a clear objective. Is your primary goal lead-time reduction for an aerospace client, or cost minimization for a commodity part? Your choices will differ by application.

Clarify customer requirements

Ask your customer for tolerances, finish, lifecycle expectations, and regulatory needs. You’ll be amazed how many debates end with a simple question: “What happens if the part is off by 0.05 mm?” When you have specifics, you can engineer solutions that meet expectations without overpaying for unnecessary precision.

Set internal constraints

Document your raw material budgets, available machine hours, staff skill levels, and lead time windows. These constraints form the boundary conditions for any optimization you attempt. Treat them like the edges of a sandbox: you can build sandcastles, but don’t expect to play soccer.

Process mapping: where time and error hide

You can’t fix what you don’t measure. Process mapping reveals bottlenecks, redundant steps, and quality risks. It’s the equivalent of putting the production line under a microscope—and sometimes that’s literal, when you get to inspection.

Create a value-stream map

A value-stream map shows every step from order intake to shipping. You’ll see cycle times, wait times, inventory piles, and rework loops. This visualization helps you decide whether to invest in faster machines, additional fixtures, better tooling, or process standardization.

Identify non-value-added activities

You should ruthlessly list activities that don’t add value—excess handling, duplicated inspection, waiting for fixtures. Eliminating even small waste items can yield outsized improvements in both speed and cost.

Lean principles and continuous improvement

If you’re not practicing continuous improvement, you’re leaving money and time on the floor. Lean thinking is a practical toolbox for reducing waste and uncoupling cost from speed and precision.

Implement a Plan-Do-Check-Act (PDCA) cycle

You can test a change quickly and measure its effect. Start small with a pilot, measure cycle time and scrap, then expand. PDCA keeps you from making expensive, company-wide mistakes based on a gut feeling.

Use poka-yoke and standard work

Mistake-proofing, or poka-yoke, reduces rework. Standard work stabilizes processes so you can focus on continuous gains rather than firefighting. You should build standard checklists, visual cues, and jigs that make the correct action the easiest one.

Automation and robotics: when speed and precision need a friend

Automation can feel like a luxury when budgets are tight, but smart automation often pays for itself in reduced cycle time, consistent precision, and lower labor variability.

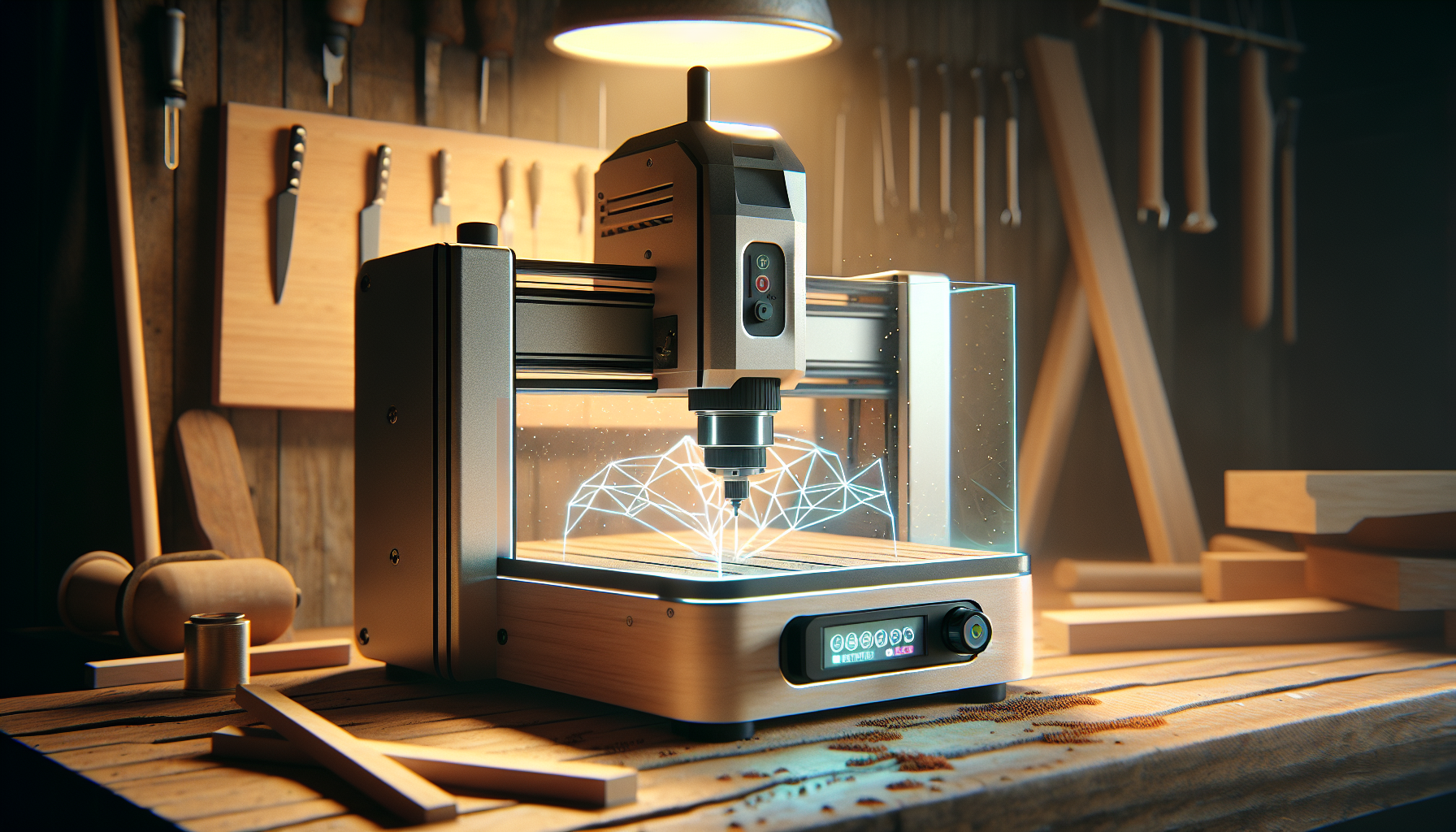

Types of automation to consider

- CNC machining centers for repeatable precision and reduced operator variability.

- Robotic load/unload stations to cut non-value labor and improve throughput.

- Automated material handling (AGVs, conveyors) to remove internal logistics bottlenecks.

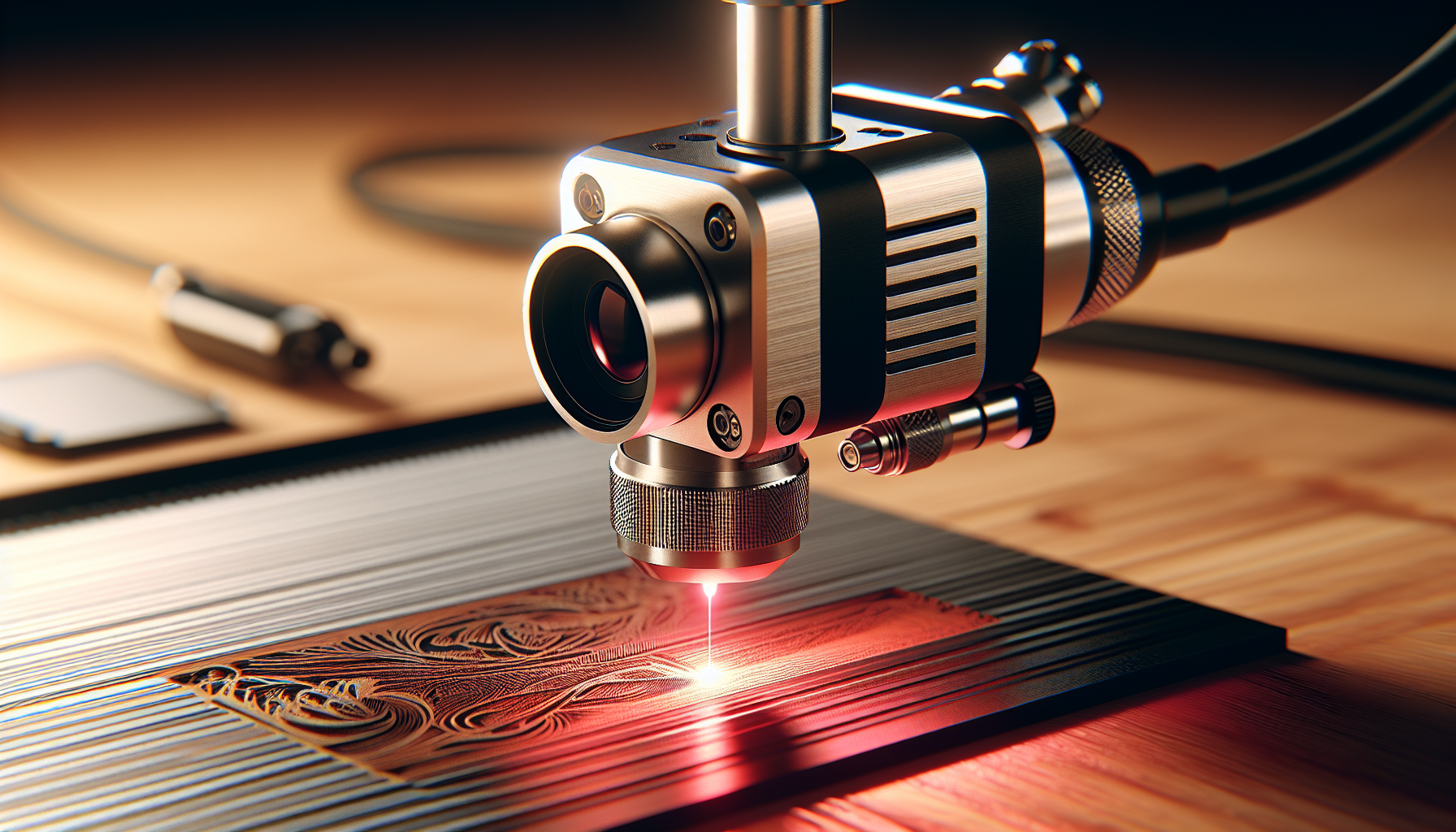

- Laser cutting and waterjet systems for high-speed, accurate cutting of complex shapes.

Evaluate ROI before you buy

Don’t adopt automation because it’s shiny. Calculate ROI based on cycle time reduction, lower scrap, and labor redeployment benefits. Factor in maintenance, training, and integration costs. A thorough cost model helps you avoid the “automate everything” trap.

Tooling, fixtures, and jigs: little things, big effects

If a machine is the pianist, tooling and fixtures are the sheet music. Good tooling reduces setup time, increases repeatability, and protects parts from damage.

Design fixtures for repeatability

A well-designed fixture minimizes alignment time and secures parts so tolerances are achieved without constant adjustment. Fixtures should be built with modularity in mind, so you can quickly adapt to new jobs.

Optimize tooling selection and maintenance

Use the right cutting tool geometry, coatings, and edge prep for the material. Hold preventive maintenance schedules for cutters and fixtures. A dull tool ruins finish and increases force, which affects both precision and machine life.

Material selection and sourcing

Material choice affects machining time, tolerances, and overall cost. You should weigh machinability against performance requirements and lifecycle costs.

Balance material properties with practicality

Stainless steel may be required for corrosion resistance, but it often costs more to machine than aluminum. If functional requirements allow, pick materials that machine easily and don’t demand exotic tooling.

Use strategic sourcing to control cost

Establish relationships with suppliers, consolidate purchasing, and consider vendor-managed inventory for high-turn materials. Buying smarter reduces costs and shortens lead time.

Programming and CAM strategies

Your CAM (Computer-Aided Manufacturing) strategies can shave minutes—or hours—off cycle times while maintaining precision. You want toolpaths that are efficient and robust.

Optimize toolpaths and feeds/speeds

Reduce air cuts, use trochoidal milling for hard materials, and adjust feed rates for consistent chip load. Simulation software can predict tool loads and detect collisions before the first cut.

Standardize post-processes and tool libraries

A shared library of optimized toolpaths, tools, and post-processors saves programmer time and yields consistent parts. Standardization also makes it easier to scale capacity across machines or sites.

Quality control and inspection: early detection saves money

You need inspection routines that are proportionate to the risk. Excess inspection slows production, but insufficient inspection costs more in rework and returns.

Layered inspection strategy

- In-process checks: quick gauge checks or probing mid-cycle to detect drift.

- First-off inspection: confirm setups before full production runs.

- Statistical sampling: use AQL or statistical process control for high-volume parts.

- Final inspection: comprehensive checks where risk demands it.

This layered approach reduces over-inspection while catching defects early.

Invest in metrology where it matters

Coordinate measuring machines (CMMs), laser scanners, and optical inspection systems reduce human error and provide traceable measurements. Use metrology selectively—where tolerances or regulatory demands require it.

Scheduling, batching, and batch size optimization

Batching decisions impact lead time, cost, and quality. You should tailor batch sizes to part geometry, setup time, and customer urgency.

Economic lot size versus flow

Large batches reduce setup frequency but increase work-in-progress and lead time. Smaller batches improve flow and reduce inventory, but setup time erosion can hurt throughput. Use total cost models to find the sweet spot for each part family.

Dynamic scheduling and capacity planning

Use real-time scheduling tools or an MES to react to urgent orders without wrecking the schedule. A disciplined approach to order prioritization helps maintain both lead time and quality.

Workforce and skills: your secret weapon

Machines are only as good as the people who program, set up, and maintain them. You should invest in training and create a workplace culture that rewards problem-solving.

Cross-skilling and operator empowerment

Cross-train operators to run multiple machines and troubleshoot basic issues. Empower them to suggest process improvements and stop the line for quality problems. When operators own part of the process, quality improves and so does morale.

Use training matrices and apprenticeships

Document required competencies and track training. Apprenticeship programs keep critical skills in-house and help you avoid dependence on scarce talent.

Data, metrics, and KPIs: measure what matters

You can’t improve what you don’t measure. Pick a few KPIs that align with your goals and track them obsessively.

Useful KPIs for fabricators

| KPI | What it measures | Why it matters |

|---|---|---|

| Cycle time (per part) | Time to make one part | Speed and throughput |

| First Pass Yield (FPY) | Percentage of parts that meet spec without rework | Quality and cost of rework |

| Scrap rate | % of material scrapped | Material cost and process stability |

| OEE (Overall Equipment Effectiveness) | Availability x Performance x Quality | Machine utilization and efficiency |

| Setup time | Time to changeover | Impacts batch size and responsiveness |

| Lead time | Time from order to delivery | Customer satisfaction and cash flow |

Track these metrics over time and look for trends rather than one-off spikes.

Use dashboards and visual management

A simple visual dashboard in the shop keeps everyone aligned. Use color-coded boards or an electronic display to show realtime status of KPIs, current work orders, and machine health. Visual management helps you act quickly.

Cost modeling: reveal hidden costs

It’s easy to focus on obvious costs like raw material and wages. hidden costs—like rework, expedited shipping, or warranty claims—are often larger. Build a comprehensive cost model.

Components of a good cost model

- Direct material cost

- Direct labor cost (including setup)

- Machine operating costs (energy, maintenance, amortization)

- Overhead allocation

- Rework and scrap

- Logistics and expedited fees

- Compliance and certification costs

A robust model helps you make decisions that truly reduce total cost, not just apparent cost.

Case examples: practical trade-offs in action

If you like stories (and who doesn’t, other than auditors), here are condensed examples of how these trade-offs play out.

Case 1: Aerospace precision, long lead-time pressure

You’re fabricating a landing gear component with tight tolerances. Customer wants a faster delivery than your normal cycle. Options:

- Rush with overtime: faster but increases labor cost and fatigue-related errors.

- Add a second shift: longer-term capacity boost, moderate cost.

- Introduce a dedicated fixture and a second CNC: capital expenditure, lower cycle time, improved precision.

Smart path: run a pilot using the dedicated fixture and a subcontractor for overflow. Demonstrate reduced setups and scrap before investing capital.

Case 2: Automotive supplier chasing cost targets

You need to drop unit cost without sacrificing acceptable quality for a volume part. Options:

- Switch to a cheaper alloy: risk of reduced wear life.

- Optimize tooling and CAM: upfront programming cost but lower cycle time.

- Batch larger runs: economies of scale but higher inventory.

Smart path: optimize tooling and processing first, then evaluate material change with accelerated life testing. This preserves quality while lowering per-unit cost.

Technology stack and integration

Integrating ERP, MES, and CAD/CAM systems reduces manual handoffs and errors. The aim is data flow that supports decision-making in near real-time.

Key software components

- CAD/CAM for seamless part design to program transfer.

- MES for shop floor execution and traceability.

- ERP for order, purchasing, and financials.

- SPC or quality management software for statistical monitoring.

Integration reduces lead-time and cost associated with administrative overhead and manual transcription errors.

Risk management and contingency planning

You will have disruptions—machine breakdowns, supplier delays, or sudden spec changes. Plan for them.

Build redundancy and contingency plans

Identify critical machines and materials. Maintain alternate suppliers for critical raw materials and spare parts for key machines. Keep a small safety stock for high-turn components.

Use failure mode and effects analysis (FMEA)

FMEA helps you quantify risk and prioritize mitigation. You should document the severity, occurrence, and detectability of failure modes and target the highest risks with preventive actions.

Implementation roadmap: how to start

Big transformations are scary. Here’s a practical roadmap to implement balanced improvements.

- Baseline: measure cycle time, FPY, scrap, and OEE for a representative product family.

- Prioritize: identify top problems with the biggest impact on speed, precision, or cost.

- Pilot: run small, timeboxed experiments (PDCA) to test solutions.

- Standardize: document successful changes as standard work and update training.

- Scale: roll out across similar processes and refine.

- Sustain: assign ownership, maintain metrics, and continue PDCA.

This phased approach minimizes disruption while delivering measurable gains.

Common pitfalls and how to avoid them

You could make choices that feel reasonable at the moment but cost more later. Here are traps you should watch out for.

Pitfall: over-specifying requirements

Specifying tolerances tighter than necessary increases cost without adding value. Always ask what function the tolerance supports. Reduce unnecessary constraints.

Pitfall: automating poor processes

Automation simply accelerates your current process. If your process is flawed, automation will accelerate defects. Fix the process first, then automate.

Pitfall: ignoring human factors

People resist change. If you exclude operators from decisions, you’ll get workarounds and resentment. Include them early and often.

Practical checklists you can use today

Here are quick, actionable checklists that you can apply immediately.

Pre-production checklist (for each new part)

- Confirm tolerances and finishes with the customer.

- Validate material selection and supplier lead times.

- Create a process plan and value-stream map.

- Identify required fixturing and tooling.

- Estimate cycle time and setup time.

- Set inspection points and acceptance criteria.

Pre-shift operator checklist

- Verify machine calibration and tool wear.

- Confirm fixture alignment and clamps.

- Check material batch and heat number (if required).

- Load job with correct program and verify first-off dimensions.

- Log any deviations immediately.

Final thoughts: balancing with nuance

You’re not choosing among three immutable forces; you’re orchestrating them. The most effective approach is iterative: measure, change one variable, and observe. Keep the conversation between engineering, production, and purchasing open—those conversations will save you scrap, money, and sleepless nights.

You’ll find that small, disciplined changes—like reduced setup times, smarter tooling, and better inspection placement—often deliver the most value. Those things require thought, patience, and occasional humility: you’ll admit that a process you swore by could be improved.

If you treat speed, precision, and cost as levers rather than binary choices, you’ll rarely be surprised. You’ll learn how to make conscious trade-offs, and you’ll sleep a little better knowing your fabricator’s stage is set for applause, not a hasty curtain call.