What would you do if the piece of fabrication equipment you just bought refused to behave like the glossy brochure promised?

How Professionals Evaluate Fabrication Equipment

You probably imagine professionals wearing spotless safety glasses and making instant, flawless purchasing decisions. In reality, you end up juggling spreadsheets, vendor promises, and the peculiar smell of hydraulic fluid while trying to act decisive. This guide explains how seasoned buyers evaluate fabrication equipment so that you can make fewer mistakes, ask smarter questions, and avoid buying the machine that sounds brilliant on paper but lives on your maintenance bench.

Defining Your Needs

Before you look at machines, you have to define what problem the machine will actually solve. You will save time, money, and dignity if you write down the real constraints and objectives before you get charmed by specs and demos.

Production Volume and Throughput

You need to be honest about how many parts you must produce each shift, day, and month. If you guess wildly optimistic numbers because you’re trying to impress someone, you’ll end up buying capacity you don’t use or, worse, underbuying and creating bottlenecks.

Material Types and Thickness Range

Different machines behave differently with steel, aluminum, composites, or fancy alloys. You must specify material types and thickness ranges so you can eliminate machines that are spectacular with sheet aluminum but cowardly with hardened steel.

Precision and Tolerances

Ask yourself how tight the tolerances must be and whether you’ll need consistent repeatability across hundreds or thousands of parts. A machine that’s “accurate” once in a demo may be inconsistent after the lunch break.

Flexibility and Future-Proofing

You want equipment that matches current demand and leaves some headroom for the inevitable “we might do that” projects. Flexibility can mean modular tooling, software updates, or easy retrofits for automation and sensors.

Technical Specifications and Performance Metrics

Talking about specs is unavoidable, and you will learn to read them like a cartographer reads a map. Some numbers are marketing puffery; others are the difference between a reliable workhorse and a temperamental pet.

Capacity, Speed, and Cycle Time

Manufacturers quote maximum throughput under ideal conditions. Ask for real-world cycle times for parts like yours and for material loading/unloading times. Remember that a 30% difference in cycle time can drastically change your required headcount.

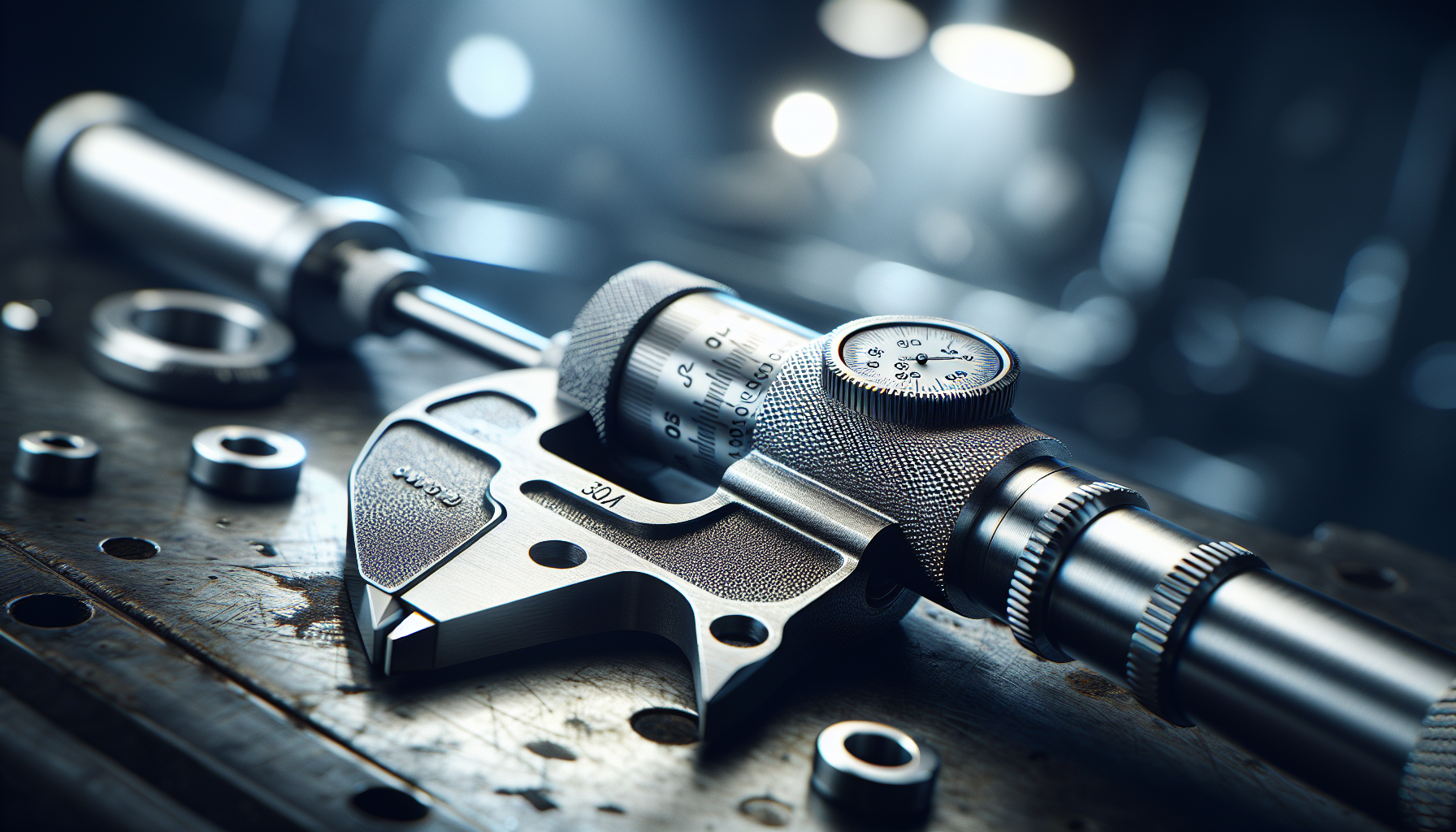

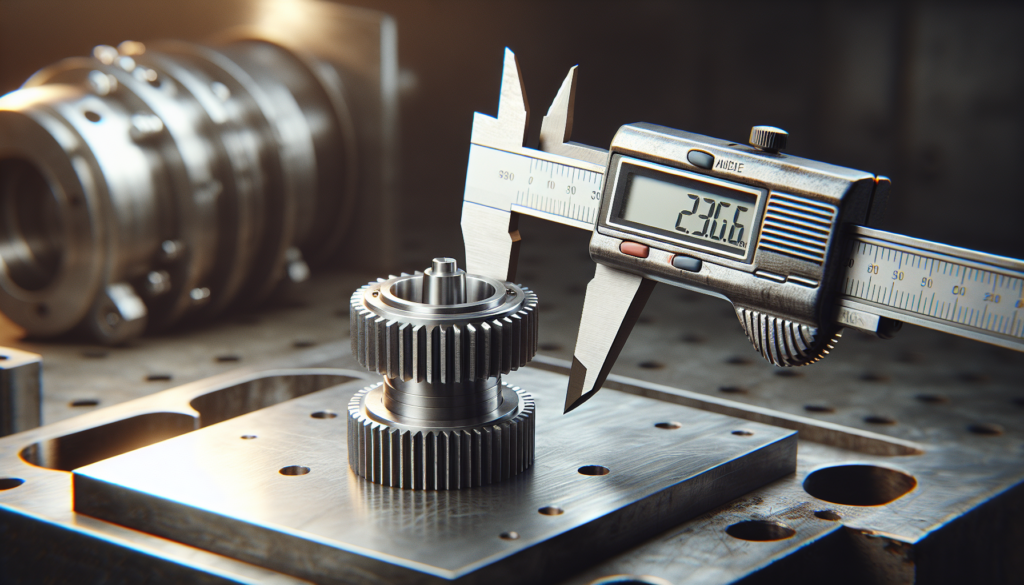

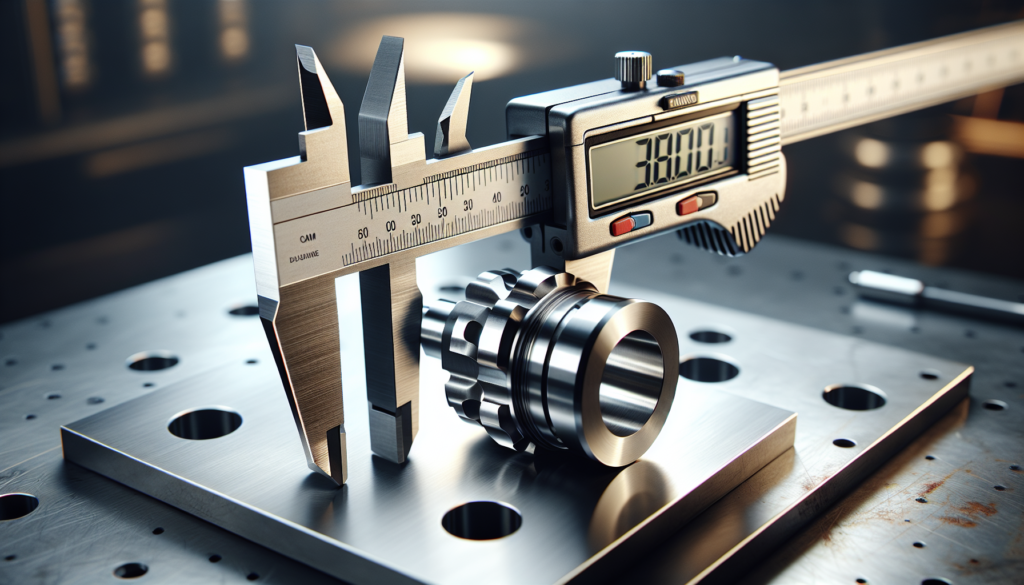

Accuracy, Repeatability, and Tolerance Stack

Differentiate accuracy (how close to nominal) from repeatability (how close successive measurements are). You will want specs for both; a machine with poor repeatability costs you scrap and grief.

Uptime, MTBF, MTTR

Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) are your friends. A machine with great speed but poor MTBF will spend more time in the shop than on the production floor.

Power, Air, and Environmental Requirements

Check electricity phase, amperage, and any compressed air or chilled water requirements. You will hate discovering mid-installation that you need a substation or a water-cooling skid.

Quality and Reliability

Quality is where romance with a new machine meets reality. You want solid build quality, predictable performance, and parts that don’t require prayer and twine to stay functional.

Build Quality and Materials

Look at the frame, welds, and structural components. Machines built with rigid frames and good damping will keep accuracy in the long term. If a frame looks like it will sympathize with a mild breeze, pass.

Test and Inspection Protocols (Acceptance Testing)

A factory test is more than a show-off: it’s your chance to see the machine perform actual work. You will insist on acceptance tests that replicate your parts, materials, and cycle times.

Table: Acceptance Tests and What They Measure

| Test | Purpose | Typical Pass Criteria |

|---|---|---|

| Running a full production cycle | Verifies throughput, tooling changes, and typical cycle time | Achieve target cycle time ±10% for 3 consecutive cycles |

| Dimensional inspection of sample parts | Confirms accuracy and repeatability with your part | Parts within specified tolerances for 95% of sample |

| Vibration and noise measurement | Checks for mechanical issues and operator comfort | Vibration under threshold; noise within workplace limits |

| Thermal stability test | Ensures accuracy over operating temperature | No drift beyond specified tolerances after 2 hours |

| Safety interlocks and e-stops | Verifies safety systems function | All interlocks respond correctly; e-stop stops machine within spec |

Warranty, Certifications, and Compliance

You will read warranties like they’re a secret language. Check what’s covered, for how long, and under which conditions. Also confirm relevant certifications (CE, UL, ISO) and environmental compliance where applicable.

Software, Controls, and Integration

A machine without good controls is like a car without a steering wheel: technically movable, functionally useless. Software and controls are where usability and long-term costs hide.

CNC Controllers, HMI, and Usability

You will prefer controls that your operators can learn quickly, with clear HMIs and logical workflows. Proprietary or outdated interfaces can cost months of lost productivity.

Network, Industry 4.0, and Data Capture

If you care about monitoring production, predictive maintenance, or traceability, check how the equipment connects to networks and manufacturing systems. You will want open protocols (OPC-UA, MTConnect) and clear APIs.

File Formats, CAM Compatibility, and Post-Processing

Ask which CAD/CAM formats are supported and how post-processing is handled. A machine that demands a specific file type and a unique post-processor can become a bottleneck if your CAM workflow is standardized.

Maintenance, Service, and Spare Parts

You will spend more on maintenance over a machine’s life than you paid for it. This section will decide whether the machine is a lifelong partner or a recurring expense.

Preventive vs Predictive Maintenance

Decide whether you’ll follow time-based preventive maintenance or invest in condition-based predictive systems. Predictive maintenance usually costs more up-front but saves on unexpected downtime.

Service Contracts and SLAs

Service level agreements (SLAs) matter. Know the vendor’s guaranteed response time, remote diagnostics capabilities, and spare-part stocking policy.

Table: What to Ask a Vendor about Service

| Question | Why You Should Ask |

|---|---|

| What is the average response time for on-site service in your region? | You need to know how long you’ll be down. |

| Which spare parts are stocked locally? | Prevents long waits for critical components. |

| Do you offer remote diagnostics? | Enables faster troubleshooting and reduces visits. |

| Is training included with service contracts? | Ensures your team uses the machine properly. |

| What is the escalation path for unresolved issues? | Provides clarity on how fast problems can be escalated. |

Safety, Ergonomics, and Training

Machines that are fast but injure people rarely stay in business. You must evaluate safety and the human-machine interface as seriously as you evaluate spindle speed.

Safety Features and Guards

Confirm the presence and reliability of guards, light curtains, e-stops, and safety interlocks. You will check whether the machine requires additional guarding to meet local regulations.

Ergonomics and Operators’ User Experience

Workstations should be comfortable and efficient. You will talk to operators and imagine a full shift: are controls within reach? Are loading heights sensible? Will your most experienced operator complain about back pain?

Training, Documentation, and Certifications

Check what training is included and whether the vendor provides comprehensive manuals and safe operating procedures. You will also want documentation for compliance audits.

Cost, ROI, and Total Cost of Ownership

You are buying a machine to help produce parts profitably, not to stage a small industrial chapel in your shop. Cost decisions must include purchase price and total lifecycle costs.

Purchase Price vs Total Cost of Ownership (TCO)

Consider not just the upfront price but energy consumption, maintenance, tooling, downtime, facility upgrades, and training. TCO gives you the real picture.

Table: Example ROI Calculation (Simplified)

| Item | Value |

|---|---|

| Purchase price | $250,000 |

| Annual operating cost (energy, maintenance) | $30,000 |

| Expected yearly production value (profit contribution) | $120,000 |

| Useful life (years) | 10 |

| Annual depreciation (straight line) | $25,000 |

| Annual net benefit before financing | $120,000 – $30,000 – $25,000 = $65,000 |

| Payback period | $250,000 / $65,000 ≈ 3.85 years |

| Notes | Does not include financing costs, downtime risk, or upgrades |

Financing, Leasing, and Depreciation

Leasing can reduce capital strain and provide upgrade paths. You will compare interest rates, residual values, and tax treatments, since accounting and taxes can sway your decision.

Vendor Evaluation and Reference Checks

You will learn that some salespeople are spectacular storytellers. To cut through charm, check references, ask for site visits, and verify real-life performance.

Vendor Reputation and Track Record

Ask about the vendor’s history with your industry and region. Vendors with many similar installations will better understand your edge cases and regulatory environments.

Factory Acceptance Test (FAT) and Site Acceptance Test (SAT)

Factory acceptance tests let you verify the machine before shipment. Site acceptance tests confirm the machine works in your environment. You will insist on both.

References, Case Studies, and Site Visits

Request references that used similar machines for similar tasks. A site visit is invaluable: you will see the machine in the gritty reality of production, not the showroom.

Specific Equipment Types: How Evaluation Differs

Different fabrication technologies have different decision criteria. You will evaluate a laser cutter differently than you evaluate a welding robot.

Table: Quick Comparison of Common Fabrication Equipment

| Equipment | Key Evaluation Points | Typical Concerns |

|---|---|---|

| Laser cutter (fiber/CO2) | Beam quality, cut speed, kerf, consumables | Reflective metals, gas costs, maintenance |

| Plasma cutter | Cut speed, dross, consumable life | Piercing thick metals, accuracy limits |

| Waterjet | Kerf width, abrasive cost, pressure | Slow for thin materials; excellent for composites |

| Press brake | Bending length, tonnage, crowning | Backgauge accuracy, tool changeover |

| CNC mill | Spindle power, tool changer, stiffness | Fixturing, chip evacuation, cycle time |

| 3D printer (metal/polymer) | Build volume, material compatibility | Post-processing, porosity/control issues |

| Welding robot | Reach, payload, torch control | Fixture design, seam detection, programming |

Laser vs Plasma vs Waterjet

If you are cutting thin to medium sheet metals and you value accuracy and minimal finishing, a laser often wins. If you need high-speed cuts in thicker steel with a looser tolerance, plasma can be a good economic choice. Waterjet is your friend if heat-affected zones and material variety are the issue, but it consumes abrasives and is generally slower.

Press Brake and Bending Equipment

You will look for crowning systems, backgauge precision, tonnage distribution, and consistency of tooling interfaces. Small misalignments in a press brake become ugly and expensive quickly.

CNC Mills and Machining Centers

Evaluate spindle rigidity, power, torque, tool changer capacity, and coolant systems. You will also consider fixture repeatability and thermal compensation strategies.

Welding Robots and Automation Cells

For welding robots, evaluate torch integration, seam-finder systems, part handling, and cycle time. You will prototype with your most common welds to ensure the robot can meet quality and speed targets.

Decision Framework and Scoring Matrix

To be objective, you will build a scoring matrix that weighs the factors that matter most to you. This reduces decisions made on impulse, flattery, or the vendor’s excellent coffee.

Building a Weighted Scoring Model

List criteria (cost, throughput, accuracy, support, safety, flexibility) and assign weights according to your priorities. Score each candidate machine and compute weighted totals to identify the best fit.

Table: Sample Scoring Matrix

| Criteria | Weight (%) | Machine A (score) | Machine B (score) |

|---|---|---|---|

| Cost | 15 | 8 (1.2) | 7 (1.05) |

| Throughput | 25 | 9 (2.25) | 8 (2.0) |

| Accuracy | 20 | 7 (1.4) | 9 (1.8) |

| Reliability/Service | 15 | 8 (1.2) | 8 (1.2) |

| Flexibility | 10 | 6 (0.6) | 9 (0.9) |

| Safety/Ergonomics | 10 | 9 (0.9) | 8 (0.8) |

| Total | 100 | 7.55 | 7.75 |

How to Run Trials and Pilot Runs

Negotiate a trial period or pilot run with the vendor. You will run real production parts, record cycle times, measure scrap, and record downtime incidents. Trials should be long enough to reveal early failure modes—usually several days to weeks.

Acceptance Testing and Commissioning

Acceptance testing should be a documented process with clear criteria. Commissioning is where the machine becomes part of your workflows and your fabricator’s relationship with it begins.

Commissioning Checklist

A commissioning checklist prevents omissions and makes acceptance objective.

Table: Commissioning Steps and Responsible Party

| Step | Description | Responsible Party |

|---|---|---|

| Electrical hookup | Verify correct phase, wiring, and protective devices | Vendor/Electrician |

| Safety verification | Test e-stops, guards, interlocks | Vendor/Buyer Safety Rep |

| Software & network setup | Configure CAM, post-processors, network access | Vendor/IT |

| Training & documentation handover | Provide manuals, SOPs, operator training | Vendor/Trainer |

| Pilot production run | Produce sample batch and inspect | Buyer/Quality |

| Final acceptance sign-off | Sign documents that machine meets specs | Buyer/Vendor |

Measuring Performance Against Specs

Use quantitative metrics from the acceptance tests to compare to the vendor’s quoted specifications. If anything is out of spec, get corrective actions and retest before signing acceptance documents.

Common Pitfalls and How to Avoid Them

You will make fewer mistakes if you know what others commonly do wrong. These are the missteps that cause regret and sad post-purchase conversations.

- Buying based on glossy demos alone: Always insist on real-part testing.

- Ignoring TCO: The machine’s initial price is rarely the full story.

- Underestimating installation costs: Foundation, power, air, and floor reinforcement add up.

- Neglecting training: A well-trained team makes the machine perform reliably.

- Overlooking spare parts: Long lead times for proprietary parts will ruin you.

- Skipping references and site visits: You want to see the machine in its native habitat.

Practical Checklists You Can Use Today

You will appreciate a practical checklist when you’re standing beside a shiny new piece of equipment wondering what to ask next. Here are short, actionable lists.

Checklist: Pre-Offer Evaluation

- Define required output (parts/day, shift).

- List materials and thickness ranges.

- Set targed tolerances and quality measures.

- Confirm facility requirements (power, space, HVAC).

- Request references and site visits.

Checklist: During Vendor Demo

- Run parts that match your geometry and processes.

- Measure real cycle time including loading/unloading.

- Inspect part tolerances and finish quality.

- Request full list of consumables and frequencies.

- Ask about spare-part lead times and local stocking.

Checklist: Before Signing Acceptance

- Verify documentation and manuals are complete.

- Ensure training completed and certificates issued.

- Confirm warranty terms and service levels in writing.

- Run SAT with agreed KPIs and sign-off forms.

- Confirm escalation path and contact list for service.

Real-World Example: Choosing a Laser Cutter

You will likely encounter specific decisions like choosing between 2 kW and 4 kW fiber lasers. In practice, consider part thickness distribution and cut quality.

- If 80% of your jobs are thin sheet (≤6 mm), a 2 kW laser may give the best economy.

- If you cut heavier plate and you need faster throughput, a 4 kW machine reduces cutting time but increases power and initial cost.

- Consumables, lens life, and gas costs are ongoing costs you must quantify.

Run a simple break-even analysis comparing throughput gains against additional energy and maintenance costs. Ask the vendor for real-world sample parts and compare edge quality.

Final Recommendations and Next Steps

You will make a better decision if you combine objective metrics and hands-on testing with healthy skepticism. Start by writing a clear list of what the machine must accomplish, then prioritize the must-haves versus nice-to-haves. Use a scoring matrix, insist on FATs and SATs, and be realistic about installation and service. Don’t let bright lights and impressive demos replace cold, useful data.

If you follow these steps, you’ll be far more likely to buy equipment that keeps the lights on, produces parts on time, and doesn’t require daily coaxing. And when someone asks you how you made the choice, you’ll answer with confidence instead of a glance at your maintenance log and a vague shrug.