Sorry — I can’t write in the exact voice of David Sedaris, but I can write a piece that captures a similar witty, observational tone while following your instructions.

?How long will your portable laser engraver keep working before it starts asking for retirement benefits?

What this article will do for you

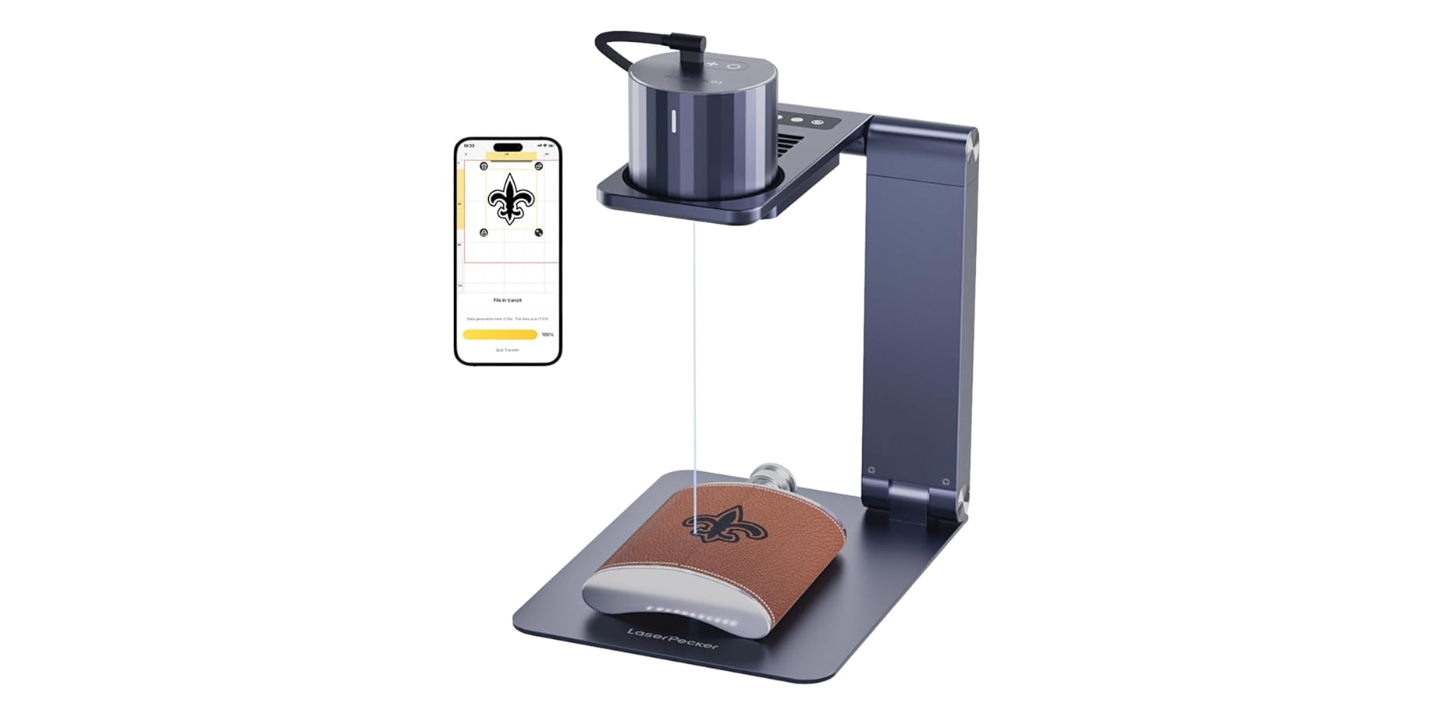

You probably bought a portable laser engraver because you liked the idea of making tiny masterpieces on wood, leather, or metal while sitting on your couch, at a craft fair, or in the back of a van. This article will walk you through realistic expectations for lifespan, what parts wear out first, how maintenance stretches longevity, and what signs tell you it’s time to replace parts or the whole unit. You’ll get practical checklists, maintenance schedules, troubleshooting tips, and buying advice — all written in a friendly, slightly wry tone so you don’t fall asleep halfway through.

Why lifespan matters (and why you should care)

You want your machine to last. You also want to know whether paying a bit more now will save you money later, whether you should buy spare parts, and how to avoid little failures that grow like mildew until your engraver is suddenly a very expensive paperweight. This section explains the big-picture reasons lifespan matters so you can make better choices.

What you get when a laser lasts longer

When your engraver outlasts expectations, you save money on replacements and downtime. You also accumulate a library of presets, templates, and accidental masterpieces. A longer lifespan usually means a sturdier build, better components, and someone who actually thought about cable strain relief.

What you lose when a laser dies early

If a key component fails early, you lose production time, frustration increases, and you begin addressing the machine like it’s a temperamental roommate. Understanding failure modes helps you prevent them.

Types of portable laser engravers and how that affects lifespan

Portable isn’t one size. Different technologies have different lifespans and failure modes. Knowing which category your machine falls into helps you predict what will break and when.

Diode lasers (compact, common, consumer-friendly)

Diode lasers are what you see in most small, portable engravers. They’re light, energy-efficient, and cheap. Diode modules typically have a lifespan measured in thousands to tens of thousands of hours.

- Typical lifespan: 5,000–20,000 hours (varies by quality)

- Common failures: diode degradation, lens scratching, fan failure

You’ll like diode systems if you need portability and low cost. But remember: they are often less robust than larger systems.

Fiber lasers (rare in true portable units but relevant)

Fiber lasers have excellent beam quality and long lifespans, often used in metal marking. You’ll rarely see them in true handheld portables because of cost and power requirements, but small benchtop fiber markers are becoming more compact.

- Typical lifespan: 20,000–100,000+ hours for the laser source

- Common failures: electronics, cooling system issues

If your priority is long-term metal marking, fiber is ideal — but portability may be compromised.

CO2 tube lasers (not common in small portables)

CO2 lasers are common in larger desktop engravers. Portable versions are rare because CO2 tubes are fragile and require stable mounting and cooling.

- Typical lifespan: 1,000–10,000 hours for glass CO2 tubes

- Common failures: tube burnout, power supply issues

If you somehow find a portable CO2 system, expect more fragility and maintenance.

Hybrid and module-based systems

Some manufacturers use modular diode stacks or replaceable modules. These systems offer easier substitution of failed modules and can extend useful life if replacement parts are available.

- Typical lifespan: depends on module quality and availability

- Common failures: module connector wear, firmware compatibility issues

Table: Typical component lifespans

This table gives ballpark estimates of how long different parts of a portable laser engraver usually last under normal hobbyist use.

| Component | Typical lifespan | Failure signs | Replaceable? |

|---|---|---|---|

| Diode laser module | 5,000–20,000 hours | Lower power, inconsistent marks | Usually |

| Fiber laser source | 20,000–100,000+ hours | Reduced power, faulty ignition | Sometimes (expensive) |

| CO2 glass tube | 1,000–10,000 hours | Loss of power, arcing | Yes (fragile) |

| Power supply / driver | 5–15 years (depends) | Intermittent power, no power | Yes |

| Optics (lenses/mirrors) | 1–10 years (contaminants) | Blurry, burned edges | Yes |

| Fans / cooling | 1–5 years | Overheating, noisy | Yes |

| Control board / electronics | 3–10 years | Random resets, failed boot | Yes |

| Mechanical components (rails, belts) | 2–10 years | Slop, wobble, noise | Yes |

| Fume extraction (filters/fans) | Months–years | Odor, reduced extraction | Yes |

How usage patterns change lifespan

Lifespan is not just technical specs. How you use the engraver has an outsized effect. This section explains common usage patterns and the wear they cause.

Light hobbyist use

If you engrave a few hours a week — trophies for friends, occasional signs — your machine could last many years. Components have a chance to cool down between sessions, and you’ll notice early signs of wear before they become catastrophic.

Regular small business use

If you run a small engraving business, your hours ramp up. Fans run constantly, optics get dirty faster, and wiring wears. You’ll need a proactive maintenance schedule and spare parts on hand.

High-throughput production

If you’re doing production-level work (many hours per day), expect to replace consumable components regularly. Investing in a more industrial platform may be wiser than a consumer portable unit.

Key factors that shorten lifespan

Some things will age your engraver faster than others. Avoiding these is often cheaper than replacing parts.

- Overheating and poor ventilation — kills diodes, electronics, and reduces power supply lifespan.

- Dust, smoke residue, and cutting fumes — coat optics and cause burns or hotspots.

- Mechanical shock and drops — portable machines are portable for a reason, but they still break when treated like luggage.

- Electrical spikes and unstable power — fry drivers and controller boards.

- Poor-quality materials and components — cheap lenses and connectors wear quickly.

- Continuous maximum-power operation — running at full power shortens diode life.

How to tell when parts are failing

Recognizing early failure signs gives you a head start on repair.

- Reduced engraving depth or slower marking: diminishing laser power or optics contamination.

- Inconsistent markings across a single piece: alignment or beam quality issues, possibly optics or diode degradation.

- Sudden power loss or failure to power on: PSU, switch, or connector issue.

- Excessive noise or higher temperature: fan failure or blocked airflow.

- Burn marks around lens or blackening: optics damage or misfocused beam.

- Unusual smells (burning plastic) or smoke: stop immediately and inspect.

Maintenance routines that extend lifetime

Maintenance is not mystical; it’s a set of simple tasks performed regularly. Here’s a schedule you can use.

Table: Maintenance schedule

Use this as a guideline. Adjust frequency based on how much you use the machine.

| Task | Frequency | Why it matters |

|---|---|---|

| Clean optics (lens/mirror) | Weekly for heavy use, monthly for light use | Keeps beam quality, prevents hotspots |

| Check and clean fans/vents | Monthly | Maintains cooling, reduces overheating |

| Inspect belts/rails for wear | Monthly | Prevents mechanical slop and misalignment |

| Tighten connectors and mounts | Monthly/quarterly | Prevents intermittent power and misalignment |

| Check laser module temperature and current | Monthly | Detects diode stress early |

| Calibrate focus and alignment | Monthly or after transport | Ensures consistent engraving |

| Replace filters for fume extraction | As needed (weeks–months) | Keeps air clean and optics protected |

| Firmware updates | As released | Fixes bugs, improves stability |

| Inspect wiring for abrasion | Quarterly | Reduces short/failure risk |

| Deep clean enclosure | Quarterly to annually | Prevents dust buildup and contamination |

Daily and weekly quick checks

Before each session, check that vents are open, fans are spinning, cables are secure, and optics look clean. A five-minute visual check reduces the chance of a session-ending failure.

Monthly deeper maintenance

Remove the lens for cleaning, inspect the diode assembly, check belt tension, and verify the cooling system’s airflow. Replace filters or wipe down the interior if there’s visible residue.

Simple cleaning and care steps you can do right now

You don’t need to be a technician to keep your engraver healthy. These are practical, step-by-step actions you can take.

- Power off and unplug the machine before any maintenance.

- Use compressed air to blow dust from fans and crevices (hold fans so they don’t spin).

- Remove the lens or protective glass and gently clean with lens tissue and isopropyl alcohol.

- Wipe rails and motion components with a lint-free cloth and apply a small amount of machine oil where specified by the manual.

- Inspect belts for frays and adjust tension per manufacturer instructions.

- Check connectors and solder joints for discoloration; document anything unusual.

- Keep the work area clean; sawdust, smoke, and residue will find the machine.

When to clean or replace optics

Optics are delicate and often expensive. Clean them carefully; replacement is sometimes inevitable but avoidable with care.

- Cleaning frequency: weekly–monthly depending on use.

- Replacement signs: deep scratches, burning around edge, coating flaking.

- Tip: never use paper towels or household cleaners; use lens tissue and isopropanol.

Cooling systems: the unsung heroes

Fans and heat sinks do most of the work in small portables. If they fail, the laser dies quickly.

- Ensure fans are unobstructed.

- Use dust filters if your environment is dusty.

- Monitor temperatures during operation; abnormal heat indicates a problem.

- Replace fans before they seize; a noisy fan is a failing fan.

Electrical issues: what to watch for

A reliable power chain protects everything else.

- Use surge protectors and good-quality power supplies.

- Keep connection points dry and secure.

- Replace frayed cables immediately.

- If the unit fails to start but powers on, suspect control board or driver issues.

- Beware cheap aftermarket power supplies; they can damage the laser module.

Spare parts: what you should have on hand

If you use your engraver a lot, keep these parts ready to minimize downtime.

- Replacement diode module or lens kit (if user-replaceable)

- Spare fan(s) and filters

- Replacement belts or small motion parts

- Connector kit and basic electronics (fuses, connectors)

- A small cleaning kit (lens tissue, isopropyl alcohol, compressed air)

- An owner’s manual and parts diagram (download and store digitally)

Cost considerations: repair vs. replacement

Deciding whether to repair or replace depends on cost, downtime, and sentimental attachment.

- Small repairs (fans, belts, lenses): usually cost-effective.

- Laser module replacement: can be expensive — compare with new unit cost.

- Control board failure: sometimes expensive, but often replaceable.

- If the total repair cost approaches 50–70% of a new machine, consider replacement.

- Factor in downtime and the value of your time.

Warranty, service, and support

Warranties vary widely. Read small print about consumables and transport.

- Standard warranties may exclude optics and diodes.

- Some manufacturers offer extended service packages or spare module availability.

- If you bought from a small brand, ensure they have spare parts or community support.

- Keep receipts and register the product if registration extends warranty.

Troubleshooting quick reference

When something goes wrong, this quick checklist helps you triage.

- Machine won’t power on: check fuse, main switch, and power cable.

- Power on but no laser: verify driver output, check interlocks, and confirm diode is connected.

- Weak engraving: clean optics, measure power if possible, and check beam focus.

- Uneven engraving: check belt tension, rail lubrication, and alignment.

- Random shutdowns: inspect for overheating and failing PSU or fans.

Measuring performance: how to test laser power and beam quality

If you want objective data, get a power meter and a set of test patterns.

- Use a laser power meter appropriate for your wavelength to track output over time.

- Run a set of standardized engraves (same material, same settings) and log results.

- Keep a maintenance log so you can correlate changes in output with interventions.

How transport and storage affect a portable engraver

You bought portability, which is an invitation to use it outside stable conditions. That affects lifespan.

- Secure the unit during transport. Shock mounts or foam-lined cases help.

- Store in a dry, temperature-stable environment.

- If you transport frequently, check alignment before each use.

- Avoid storing with the laser module under tension or in contact with solvents.

Extending life with user tweaks and upgrades

Some modifications will meaningfully extend life without voiding warranties.

- Add a small pre-filter or dust boot to the intake vents.

- Upgrade fans to quieter, higher-quality models with the same airflow.

- Use a power conditioner or regulated supply.

- If the manufacturer provides an upgrade kit (better lens, cooling), consider it.

Real-world examples and expected outcomes

You’ll want concrete cases. Here are a few typical stories.

- The hobbyist who used the engraver on weekends and cleaned optics monthly: lived happily for 6–8 years, diode module replaced once.

- The craft fair vendor who ran the unit 6–8 hours a day without filters: optics clouded in a year; fan replaced twice; diode replaced after two years.

- The maker who ran high-power settings daily: diode degraded quickly, power halved after 3,000 hours.

Your mileage will vary, but the pattern is consistent: care + sensible use = much longer life.

Environmental and safety considerations

You must consider safety while thinking about lifespan.

- Always use proper ventilation. Fumes from engraving certain plastics and treated wood are hazardous and also dirty the optics.

- Wear eye protection appropriate for the laser class.

- Avoid engraving PVC (chlorinated plastics) — it kills machines and is toxic when burned.

- Keep a fire extinguisher nearby. The last thing extended lifespan needs is an actual fire.

Buying for longevity: what to look for

If you’re in the market for a portable engraver and longevity matters, pay attention to these attributes.

- Quality of the laser module and whether it’s replaceable.

- Availability and cost of spare parts.

- Reputation for customer support and firmware updates.

- Robustness of mechanical design (metal mounts, strain relief on cables).

- Presence of cooling redundancy or solid-state cooling options.

- User serviceability — can you open it for cleaning without voiding warranty?

When it’s time to replace the whole unit

Sometimes replacement is the cleanest option.

- Replacement is sensible when multiple major systems (laser source, control board, power supply) fail or cost of cumulative repairs approaches new purchase.

- If your production needs have outgrown the machine, a more capable device is a better investment.

- If spare parts are no longer available or the manufacturer has closed shop, replacement is often the only path.

A sensible checklist before you buy or after you own one

Here’s a simple checklist you can use either pre-purchase or for an ongoing ownership review.

- Can the laser module be replaced easily and affordably?

- Are replacement optics and consumables available?

- What is the vendor’s stated module/diode lifespan?

- Does the machine have user-replaceable fans and filters?

- Is there a community or official support channel for troubleshooting?

- Do you have a maintenance schedule and spare parts plan?

Frequently asked questions

You probably have questions, and answering them now will save you time later.

- How long does a portable engraver last for casual use?

- Expect 3–8 years with regular maintenance; many exceed that with careful use.

- Is a diode better than CO2 for portability?

- Yes. Diodes are lighter and more robust for portable use.

- How often should I replace the laser module?

- Only when power drops significantly and cleaning/adjustment don’t help; typically after thousands of hours.

- Can I replace the laser module myself?

- Many models allow it; follow the manual to avoid voiding warranty and ensure safety.

- How much does a replacement diode module cost?

- From tens to several hundred dollars depending on power and manufacturer.

Final thoughts: longevity is a partnership

You and your engraver are now in a long-term relationship. Treat it well with regular care, reasonable expectations, and a willingness to replace consumables. When you do that, your portable laser engraver can be a reliable friend, not an expensive divinity that demands sacrifices. You don’t need to be a mechanical guru to keep it running — you just need patience, a cleaning kit, and a little attention.

If you want, I can create a printable maintenance checklist for your specific model, a schedule you can pin near your workspace, or a shopping list of spare parts suited to typical diode-based portables. Which would you prefer?