Have you ever watched a pile of perfectly good metal get tossed into the scrap bin and felt a little personally insulted?

How Intelligent Fabricators Reduce Waste, Errors, And Rework

You will find that intelligent fabricators act like an efficient, slightly judgmental friend who refuses to let you ruin a good piece of material. They combine data, automation, and human know-how to stop problems before they become expensive embarrassments.

Why this matters to you

If you run or work in fabrication, every pound of scrap, every incorrect hole, and every hour of rework lands squarely on your schedule and your budget. You probably already suspect that smarter processes could save money and stress; intelligent fabrication shows you exactly how and quantifies it so you can stop guessing and start improving.

What is an intelligent fabricator?

An intelligent fabricator is not a single robot with attitude; it’s a connected system that uses sensors, software, and automation to make decisions, prevent mistakes, and learn from past production runs. You should think of it as a brain that sits above your shop floor, nudges machines into better behavior, and hands you readable facts instead of rumors.

Core capabilities you’ll rely on

You will depend on several capabilities that, together, transform your shop:

- Real-time monitoring: You see what’s happening now, not what happened last Tuesday.

- Automated control: Machines adjust feed, speed, and path to optimize quality.

- Digital instructions: Operators work from validated, versioned instructions instead of worn paper.

- Predictive analytics: The system predicts failures before they produce scrap.

- Traceability: You can trace every part back through its process history.

Key technologies that enable intelligent fabrication

These technologies are the tools that make the whole system work. You don’t need to worship any single one, but you will benefit when they play nicely together.

- Internet of Things (IoT) and sensors: IoT devices capture temperature, vibration, tool wear, and more so that the system knows when something is drifting out of spec.

- CAD/CAM integration: Your design files are automatically transformed into machine-ready programs, eliminating transcription errors.

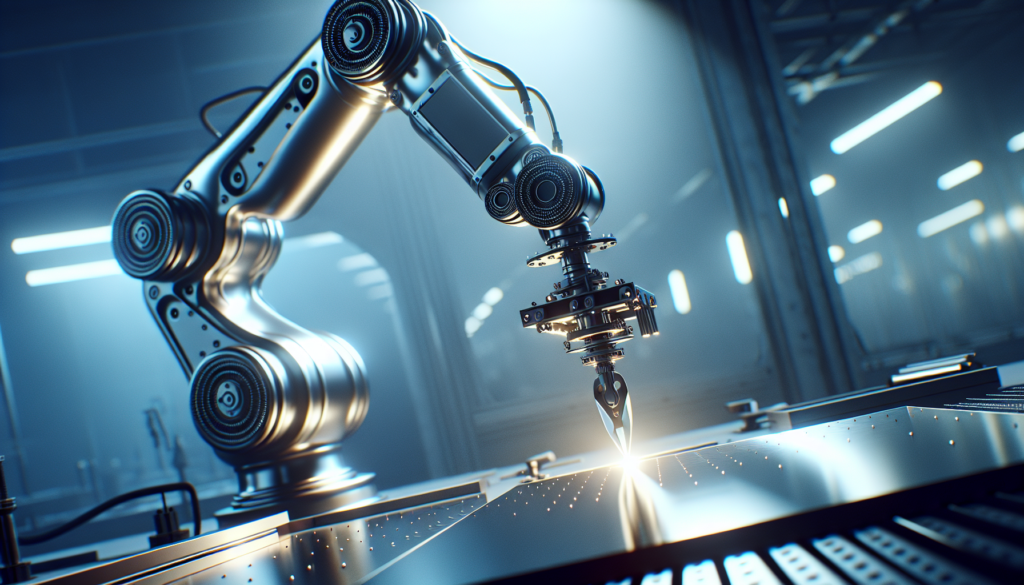

- CNC and robotics: Precision and repeatability reduce manual shaping errors and fatigue-driven mistakes.

- Vision systems and machine inspection: Cameras and AI detect surface defects, misalignments, and missing features in real time.

- Machine learning and predictive maintenance: Algorithms predict failures and recommend maintenance before scrap appears.

- Digital twin and simulation: You can simulate a process virtually to catch problems before you commit material.

- Additive and subtractive hybrid tooling: Flexibility for complex parts reduces the number of setups and associated errors.

How intelligent fabricators reduce waste

Your waste stream shrinks because the system minimizes the reasons parts get scrapped.

- Better nesting and material utilization: Software optimizes how parts nest on raw plates, squeezing more parts from every sheet and reducing offcuts.

- Optimized cutting and tool paths: More efficient tool paths cut cycle times and reduce heat-affected zones that otherwise produce micro-cracks and scrap.

- Preventive maintenance: When sensors warn that a blade or tool is dull, you change it before it tears a part apart.

- Process standardization: Digital work instructions ensure every operator follows the same validated method, so you stop getting heroic improvisations that produce extras.

- Real-time correction: If sensors detect drift in a process, the system can compensate immediately, avoiding a whole batch of bad parts.

How intelligent fabricators reduce errors

The system is designed to intercept the most common ways humans and machines produce errors.

- Version-controlled work instructions: You will never have someone following an obsolete paper drawing because the digital instruction is always current.

- Automated setup verification: Before a machine ever moves, the system verifies clamps, fixtures, and alignment so you catch setup errors.

- Visual aids and AR overlays: Operators see exactly where to place parts and tools, reducing misfeeds and incorrect orientations.

- Error-proofing (poka-yoke): Simple sensors confirm part presence and orientation before machining, preventing catastrophic cycles.

- In-process inspection: Vision systems and sensors find errors as they occur, letting the system stop and correct instead of finishing a flawed batch.

- Closed-loop feedback: Measurements feed back to adjust subsequent passes or future runs, so the process learns from each part.

How intelligent fabricators reduce rework

Rework is the slow, polite cousin of scrap; it costs time, materials, and dignity. Intelligent systems cut down on rework by controlling variability and offering early correction.

- Traceable records: If a rework is required, you can quickly see which machine, program, operator, or batch caused the deviation.

- Root-cause analysis tools: The system can point to causes — wrong fixture, worn tool, bad program — so you fix the source rather than repeating the fix later.

- Automated rework routing: Parts marked for rework are automatically routed and prioritized so they don’t sit unnoticed.

- Predictive quality controls: When the system senses a trend toward out-of-spec, you can halt a job, correct parameters, and avoid reworking dozens of parts.

Quick comparison: Traditional vs Intelligent fabrication

| Aspect | Traditional Fabrication | Intelligent Fabrication |

|---|---|---|

| Material utilization | Often suboptimal; manual nesting | Automated nesting; higher yield |

| Error detection | Post-process inspection | In-process detection and correction |

| Rework handling | Manual, reactive | Automated routing and prioritized correction |

| Machine maintenance | Time-based or reactive | Predictive and condition-based |

| Traceability | Paper trails, incomplete data | Digital, searchable, end-to-end |

| Throughput consistency | Variable, dependent on operator | Consistent with closed-loop control |

| Data-driven improvement | Limited | Continuous learning and optimization |

You will notice that the intelligent side almost reads like the future you hoped for but thought required a small miracle.

Metrics and KPIs you should track

To know whether intelligent fabrication is helping you, measure the right things. Your decisions will be better informed when you can point to numbers.

- Scrap rate (kg or % of production): Lower is better; intelligent systems should reduce this significantly.

- First-pass yield (FPY): The percentage of parts that meet specifications without rework.

- Overall Equipment Effectiveness (OEE): Measures availability, performance, and quality.

- Mean time between failures (MTBF) and mean time to repair (MTTR): Predictive maintenance should raise MTBF and lower MTTR.

- Material utilization %: How much of the raw material becomes finished parts.

- Rework hours per period: Total hours spent correcting parts.

- Cost per part: Includes labor, material, energy, and overhead.

- Lead time and on-time delivery (OTIF): Faster, more predictable throughput improves your customer commitments.

Track these metrics before and after you implement intelligent systems so you can tell whether the magic is real or just expensive magic.

Implementation roadmap you can follow

You shouldn’t treat intelligent fabrication like a kitchen renovation that starts with new tiles and ends with a sink in the hallway. Plan deliberately, pilot prudently, and scale steadily.

- Assessment and goals

- Identify the biggest pain points (scrap, errors, bottlenecks).

- Set clear, measurable goals: reduce scrap by X%, cut rework hours by Y.

- Data readiness and infrastructure

- Ensure you have reliable network connectivity and a plan for collecting data from machines and sensors.

- Decide whether to use cloud, on-premises, or hybrid approaches.

- Choose a pilot area

- Start with a process that produces measurable volume and is representative, not a corner case.

- Keep the pilot scope small enough to control yet big enough to show impact.

- Integrate systems

- Connect CAD/CAM, MES (Manufacturing Execution System), ERP, and machine controllers.

- Ensure data flows with minimal manual intervention.

- Implement monitoring and alerts

- Configure dashboards and alerts focused on your KPIs so you can act on deviations immediately.

- Train operators and technicians

- Human skill still matters; provide targeted training in using digital instructions, interpreting alerts, and performing corrective actions.

- Iterate and scale

- Use pilot results to refine parameters and governance, then expand to more lines.

- Continuous improvement

- Establish a feedback loop for regular reviews and improvements based on collected data.

Cultural shifts you’ll need to manage

Technology doesn’t succeed on its own; people adopt it — or resist it — with dramatic flair. You will face cultural change management tasks.

- From tribal knowledge to documented process: Encourage people to accept that recorded instructions can make their work easier, not replace them.

- From reactive to preventive mindset: Teach teams to treat machine alerts as helpful warnings rather than nuisances.

- Empowerment through data: Let operators see metrics that matter to them, so they can take ownership of improvements.

If you handle the cultural work poorly, even the best sensors will gather dust on shelves labeled “future project.”

Common challenges and how to overcome them

You will encounter obstacles. The difference between success and a stalled project is less about tech and more about foresight.

- Data quality and integration issues

- Solution: Start with a small set of high-value signals and standardize data formats.

- Legacy equipment that won’t speak modern protocols

- Solution: Use retrofit sensors and edge gateways to bridge gaps.

- Cost concerns

- Solution: Build a clear ROI case using pilot data and phased investments.

- Staff resistance

- Solution: Involve operators early, reward process improvements, and provide visible wins.

- Security and IP worries

- Solution: Implement strong network segmentation, authentication, and encryption.

ROI and cost considerations

You should expect an upfront investment in hardware, software, and change management. The payoff comes in reduced material costs, lower labor for rework, improved delivery performance, and often lower warranty claims.

Example ROI scenario (illustrative):

| Item | Baseline | After intelligent implementation | Annual savings |

|---|---|---|---|

| Scrap rate | 6% | 2% | $120,000 |

| Rework labor hours | 4,000 hrs | 1,200 hrs | $84,000 |

| Production uptime | 85% | 93% | $60,000 |

| Tooling/consumables | $150,000 | $120,000 | $30,000 |

| Total annual savings | — | — | $294,000 |

Assume a project cost of $600,000 for sensors, software, training, and integration. At $294,000 annual savings, your simple payback is just over two years. Your real numbers will vary, but the pattern — moderate investment, clear recurring benefits — holds true.

Case study sketches you can relate to

You might recognize these scenarios because they almost certainly resemble something in your shop.

Case A: The Plate Shop that Hated Offcuts

- Situation: A plate shop had 7% scrap from inefficient nesting and poor plate handling.

- Intervention: Automated nesting software integrated with cutting machines and barcode tracking for plates.

- Result: Scrap dropped to 2%, material utilization increased, and the shop no longer told stories about mythical sheets that “changed size overnight.” You saved both material and the dignity of the nesting engineer.

Case B: The Welding Cell with a Temperamental Robot

- Situation: Weld quality varied with weld cell temperature and electrode wear, causing rework of subassemblies.

- Intervention: Sensors tracked weld parameters, a vision system verified bead placement, and the MES prevented parts from entering the next stage until quality passed.

- Result: First-pass yield improved from 82% to 96%, and the weld technician stopped carrying around a notebook with cryptic notes like “try turning it the other way.”

Case C: The Furniture Fabricator Who Learned to Predict the Future

- Situation: A smaller fabricator had frequent machine breakdowns that ruined full production runs.

- Intervention: Predictive maintenance algorithms analyzed vibration and current signatures to predict spindle failures.

- Result: Breakdowns became scheduled maintenance events; you lost the drama but gained predictable schedules and fewer crushed deadlines.

Best practices and tips to get you started

You will appreciate a few simple rules that prevent common missteps.

- Start with visible wins: Choose pilot projects where results are easy to measure and communicate.

- Keep human expertise central: Automation augments, it doesn’t replace, good operators.

- Standardize data naming and units: Avoid the chaos of “mm vs inches” and “sheet 1 vs plate A.”

- Use modular integration: Prefer API-based connections so you can swap components without redoing everything.

- Set realistic KPIs: Don’t expect overnight miracles; aim for steady, measurable improvement.

- Maintain governance: Decide who owns data, dashboards, and change control to avoid blame games.

- Document everything: Today’s decision logic becomes tomorrow’s training material.

Regulatory, safety, and sustainability benefits

You will find that intelligent fabrication doesn’t only save money; it reduces risk and makes compliance easier.

- Safety improvements: Automated checks and machine interlocks reduce operator exposure to hazards.

- Easier compliance: Electronic records simplify traceability for audits and safety inspections.

- Sustainability gains: Better materials utilization and energy-optimized processes reduce your environmental footprint, which your customers and regulators increasingly care about.

Future trends you should watch

The field keeps moving. If you pay attention, you can pick the trends that matter to your shop.

- Generative design and advanced CAM: Design tools that create parts optimized for manufacturing will reduce unnecessary material and complexity.

- Autonomous cells: Cells that can retool and reprogram themselves for short runs will make custom orders more profitable.

- Federated learning: Systems will learn from multiple sites while preserving privacy, giving you better predictive models without sharing your secrets.

- Circular manufacturing: Intelligent traceability will enable reuse and remanufacture strategies, closing the loop on materials.

Frequently asked questions you might ask

You will have practical concerns. Here are concise answers to the most common ones.

- How long before I see benefits?

- Pilot projects often show measurable improvements in 3–6 months; full rollouts take longer depending on scale.

- Do I need to replace my machines?

- Not necessarily. Many legacy machines can be retrofitted with sensors and edge devices.

- Is my workforce at risk?

- The work changes. Operators will move from repetitive tasks to oversight and problem-solving roles.

- What about data security?

- Use segmentation, VPNs, and identity management. Treat production data as you would financial data.

What success looks like for your operation

You will know you’ve succeeded when:

- Scrap and rework numbers are trending steadily down.

- Operators trust the system and use alerts to improve processes.

- Maintenance is proactive, scheduled, and rarely chaotic.

- Customers notice delivery improvements and fewer quality issues.

- You can prove ROI with clear metrics rather than anecdotes.

Final thoughts

You are trying to run a profitable, reliable fabrication operation in a world that rewards precision and punishes waste. Intelligent fabrication gives you systems that catch the small errors before they become expensive disasters. It won’t make your problems vanish overnight, but it will give you leverage: better data, fewer surprises, and the ability to scale improvements across your shop.

If you move deliberately — start small, measure results, involve people, and keep improving — you’ll find that what once looked like an intimidating technological overhaul becomes, over time, the most boring and valuable part of your business. And boring, in manufacturing, is a very good thing.