? Have you ever ordered something made exactly for you and wondered how a factory with hundreds of others could possibly make it appear so personal, so singular, and still ship it in three days?

How Intelligent Fabrication Enables Custom Products At Scale

You know the feeling: you click through a product configurator, choose a color that matches the shoes you wore to a middle school dance, adjust dimensions so a shelf fits between two oddly placed studs, and press “confirm.” Somewhere on the other side of that click, the machinery hums and a chain of decisions—some made by people, most made by software—transforms raw materials into something that seems handcrafted but was produced alongside a thousand other slightly different things. This is intelligent fabrication: the convergence of digital design, automated production, machine learning, and human judgment that lets manufacturers serve individual tastes without sinking into chaos.

What is intelligent fabrication?

You can think of intelligent fabrication as manufacturing with a brain. It’s not just robots doing repetitive tasks; it’s systems that sense, adapt, and optimize in real time. Intelligent fabrication fuses software and hardware to turn data into decisions that guide machines, people, and processes.

This concept blends four big ideas:

- Digitization of product design and manufacturing processes

- Autonomous or semi-autonomous production equipment

- Real-time data feedback loops and predictive analytics

- Modular and flexible production strategies

Why intelligent fabrication matters to you

If you’re a product designer, operations manager, or entrepreneur, intelligent fabrication changes the rules. You can offer more variety, reduce inventory risk, shorten lead times, and increase customer satisfaction. If you’re a consumer, you get goods that fit your life better without paying artisanal prices.

You should care because it unlocks mass customization—mass production with the feel of bespoke items. That’s lucrative and efficient when done right.

The shift from mass production to mass customization

For decades, economies of scale favored large batches of identical items. You’ve seen the evidence: the same bland toaster in every showroom, the uniformity of mass-market clothing. Intelligent fabrication inverts that model by making variety efficient.

You can use modular design, parametrized CAD models, and flexible production lines to produce many variants with minimal setup cost. The idea is to change what you produce without changing how you produce it.

The economics behind the change

When you adopt intelligent fabrication, your cost structure shifts. Fixed costs remain—machines, facilities—but variable costs per variant drop because you eliminate manual retooling and reduce batch sizes. Pricing models can move from cost-plus to value-based, and you can capture premium margins on customization while keeping competitive base prices.

You’ll want to track metrics such as unit cost per variant, time-to-delivery, first-pass yield, and customer return rates to see if the model really works for your product.

Key technologies that enable intelligent fabrication

If this were a dinner party, the technologies would be the guests: each one brings something useful, and together they make lively conversation possible.

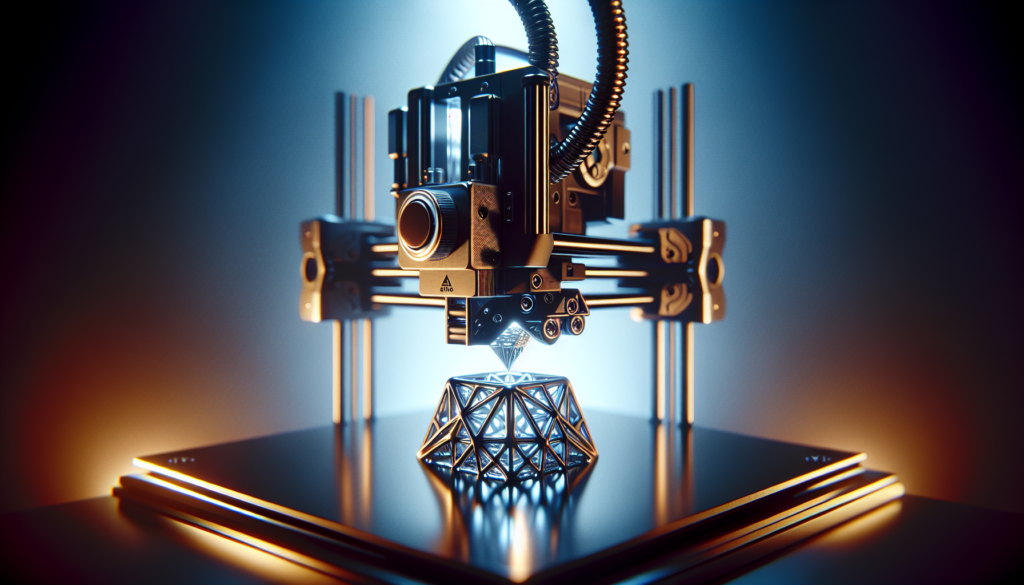

- Additive manufacturing (3D printing)

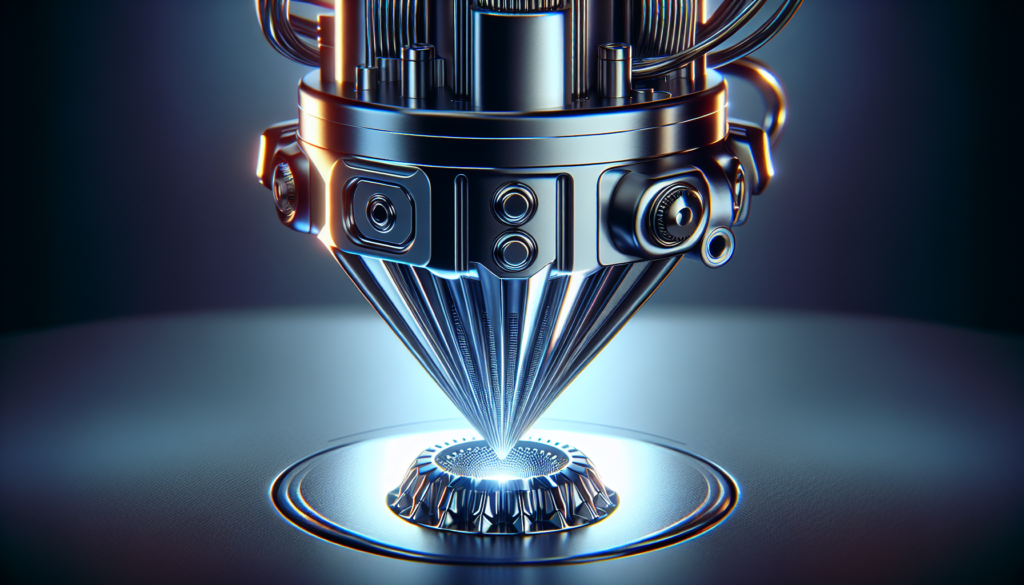

- Advanced CNC and robotic machining

- Computer-aided design (CAD) with parametric and generative design

- Digital twins and simulation platforms

- Product configurators and CPQ (configure, price, quote) systems

- Industrial IoT (sensors, actuators, connectivity)

- Machine learning and predictive analytics

- Vision systems and automated inspection

- Flexible fixturing and quick-change tooling

- ERP/MES systems integrated with the digital thread

Short descriptions of key technologies

Additive manufacturing lets you create complex geometries without the waste of subtractive methods. CNC and robots provide repeatable precision for higher volume parts. CAD systems give you parametrized models that can be tweaked by software or customers. Digital twins simulate behavior before you cut metal or lay down filament. CPQ systems enable customers and salespeople to configure products that are guaranteed to be manufacturable. IoT devices feed the system the data it needs to keep processes tight. Machine learning turns that data into predictive actions, and vision systems ensure the product meets criteria. Flexible tooling reduces downtime between variants.

You’ll find that these technologies don’t work in isolation—intelligent fabrication is orchestration.

How design for manufacturing changes with personalization

Design no longer lives in an isolated CAD file. You’ll design with manufacturing constraints and customer options in mind from day one. The goal is to create product platforms that can be configured in many ways without requiring new tools or skills.

Principles of design for mass customization

- Parameterization: make dimensions and features adjustable through variables.

- Modularization: break products into interchangeable modules.

- Tolerance management: design tolerances that accommodate variant assembly.

- Standardization of interfaces: ensure modules connect reliably.

- Manufacturability rules: embed manufacturing constraints into design tools.

You will want to work closely with manufacturing engineers early in the design process to avoid late surprises that waste money and time.

Digital thread and the role of the digital twin

A consistent digital thread carries product data from concept to customer. The digital twin is the virtual representation of a product or process that mirrors reality and evolves with it.

The digital thread improves traceability, reduces errors, and speeds problem resolution. The digital twin lets you test changes virtually and predict outcomes—saving you from spending time and material on trial-and-error.

Example: how a digital twin saves time

If you change a wall thickness to reduce weight, the digital twin can immediately show stress results, adjust toolpaths for machining, and estimate changes in cycle time. Without the twin, you’d run a physical prototype loop that might take weeks.

You save not only time but also avoid cascading mistakes that happen when changes are made in silos.

Automation: from tasks to decisions

Automation used to mean replacing manual muscle with mechanical precision. Nowadays it means automating decisions as well as actions. You’ll see software that decides which machine should run a job, when to change tools, and when to route a unit for inspection.

This shift reduces human error and enables scale—machines can make thousands of small decisions per minute that would be impossible for a human workforce.

Where human judgment still matters

You still need people for context-sensitive decisions, exception handling, creative problem solving, and customer interactions where empathy is required. Intelligent fabrication augments your team; it doesn’t obliterate them.

You’ll want to train staff to work alongside autonomous systems, focusing on supervision, interpretation, and continuous improvement.

Production strategies that support customization at scale

You can’t simply bolt a configurator onto a traditional assembly line and expect miracles. You’ll need flexible systems designed for change.

- Modular production lines: rearrangeable cells that handle different modules.

- Batch size of one manufacturing: lines optimized for single-unit variability.

- Mixed-model assembly: different variants move down a line without stopping.

- Just-in-time subassembly: parts are produced or delivered to match demand.

- Distributed manufacturing: small localized facilities to reduce logistics time.

Table: Traditional vs Intelligent Fabrication

| Aspect | Traditional Mass Production | Intelligent Fabrication |

|---|---|---|

| Product variety | Low | High |

| Changeover time | Long | Minimal |

| Inventory | High finished goods | Low finished goods, more digital inventory |

| Human role | Repetitive tasks | Supervision, exception handling, design |

| Data usage | Limited | Continuous, real-time |

| Speed to customize | Slow | Rapid |

| Cost structure | High fixed costs per variant | Lower variable cost per variant |

You’ll notice that intelligent fabrication moves value upstream into design and systems rather than into carrying inventory.

Software: the brain of the factory

The software stack—the digital nervous system—ties everything together. If you’re building intelligent fabrication capabilities, your stack will typically include:

- CAD/CAE for design and simulation

- PLM (product lifecycle management) for part and process data

- CPQ for customer-facing configuration

- MES (manufacturing execution system) for shop-floor orchestration

- ERP for enterprise resource planning

- IoT platforms for data collection

- AI/ML platforms for analytics and prediction

Integrations you’ll prioritize

You’ll make sure PLM, MES, and ERP share a common data model. CPQ must pull manufacturability rules from PLM so you don’t sell something you can’t build. Machine telemetry should flow to your AI platform for condition monitoring and optimization.

You should plan integrations carefully: a brittle stack makes scaling painful.

Quality assurance in an era of variation

When every product is slightly different, quality assurance becomes trickier. You can’t rely on the same sample inspection plans you used for thousands of identical parts.

Intelligent fabrication uses inline inspection, statistical process control, and automated vision systems to ensure quality. Machine learning can identify subtle patterns that predict defects and recommend corrective action.

Techniques for ensuring quality with customization

- In-line automated inspection at multiple process stages

- Statistical control charts for parameters rather than fixed part counts

- Virtual inspection via digital twin comparisons

- Traceability via serialized digital records for each unit

- Adaptive process control to correct deviations in real time

You’ll find that prevention becomes significantly cheaper than end-of-line rejection when product variations are common.

Supply chain and logistics for custom products

You’ll need a nimble supply chain that can handle variability without exploding costs. That means close collaboration with suppliers, tiered inventory strategies, and local sourcing where it reduces risk.

Key strategies include:

- Vendor-managed buffers for configurable modules

- Flexible contracts that accommodate small batch orders

- Distributed inventory models to shorten last-mile delivery

- Advanced demand sensing to align procurement with configuration trends

Risk mitigation in the supply chain

Because customization increases SKU complexity, you should use scenario planning, dual sourcing for critical components, and supplier digital integration to reduce surprises.

You’ll benefit from real-time visibility into supplier inventories and production statuses.

Workforce considerations: skills and culture

Your people will need new skills: digital literacy, data interpretation, robotics maintenance, and systems thinking. You’ll also need cultural change—teams that previously tolerated long lead times may now need to react faster and collaborate across functions.

Training programs, apprenticeships, and partnerships with universities will be essential. Your human workforce becomes a critical differentiator in the age of intelligent tools.

Typical roles you will add or expand

- Automation engineers and robot programmers

- Data scientists and machine learning engineers

- Digital twin and simulation specialists

- Systems integrators for shop floor software

- Customer experience engineers to link configurators to production

You’ll find that investing in people reduces friction when you adopt new technologies.

Business models enabled by intelligent fabrication

Intelligent fabrication opens up possibilities beyond make-and-sell:

- Mass personalization: offer individualized options at scale

- Product-as-a-service: retain ownership, provide customization over time

- Build-to-order: manufacture only after purchase, reducing inventory

- On-demand production: localized manufacturing for fast fulfillment

- Subscription upgrades: modular products that evolve with the customer

Revenue implications

You can charge premiums for customization, reduce return rates by offering a better fit, and improve customer lifetime value by enabling upgrades and services.

You’ll need to measure new KPIs: configuration conversion rate, average revenue per configured unit, and time-to-build.

KPIs and metrics to track success

You’ll want to assess both manufacturing performance and customer impact. These KPIs will help you understand whether intelligent fabrication is improving outcomes.

Manufacturing KPIs:

- First-pass yield by variant

- Changeover time between variants

- Average cycle time per configuration

- Machine utilization and OEE (overall equipment effectiveness)

- Scrap and rework rates

Customer and business KPIs:

- Order lead time

- Customer satisfaction and NPS

- Customization uptake rate (percentage of customers choosing custom options)

- Average selling price for configured products

- Return and complaint rates for configured products

You should track these metrics over time to spot trends and make informed investments.

Implementation roadmap: how you get started

You don’t flip a switch and get intelligent fabrication overnight. Plan a staged implementation:

- Pilot: Choose a product family with high customization demand and low risk.

- Digitize: Create parametric CAD models and map manufacturability rules.

- Instrument: Add sensors and data collection to key machines.

- Automate: Deploy automation for repetitive tasks; integrate vision inspection.

- Integrate: Connect PLM, MES, CPQ, and ERP to form the digital thread.

- Scale: Expand to other product lines and facilities after proven ROI.

Quick checklist for your pilot

- Define success metrics and timeline

- Identify cross-functional team members

- Capture current process maps and pain points

- Implement a minimal viable digital twin for the pilot product

- Pilot with a manageable number of SKUs

- Plan for workforce training and supplier engagement

You’ll want short, measurable milestones to keep momentum and secure funding for expansion.

Common challenges and how you address them

No transformation is without friction. You’ll likely face technical, organizational, and supply chain challenges. Here’s how to deal with typical problems:

- Data silos: insist on a common data model and APIs for integration.

- Legacy equipment: use retrofit kits for sensors and edge computing to bring old machines into the modern stack.

- Change resistance: involve operators early and show them how automation reduces drudgery.

- Variants explosion: apply rules and constraints in the configurator to limit impossible combinations.

- Cybersecurity: secure OT networks, use zero-trust architectures, and separate critical control systems from public networks.

You’ll find that addressing people issues early prevents most technical delays.

Case examples and use cases

Reading about others helps you imagine practical applications. Here are a few brief case scenarios that illustrate real-world success.

- Custom furniture: Parametric CAD models feed CNC routers and additive components while a CPQ ensures joints and connections always match. The company reduces inventory and delivers unique pieces in days.

- Orthotics and prosthetics: Patient scans become digital twins, additive manufacturing produces personalized components, and adaptive algorithms tune fit—resulting in better outcomes and faster delivery.

- Automotive interiors: Modular components are configured for trim and features; flexible assembly cells switch without long retooling, enabling small-batch luxury trims.

- Consumer electronics housing: Additive manufacturing creates limited-run colors and textures for premium customers, while injection molding handles standard variants. Intelligent scheduling balances costs.

You’ll want to study these and identify parallels to your industry.

Sustainability and waste reduction

One of the best parts of intelligent fabrication is its potential for sustainability. You’ll reduce waste by producing only what’s ordered, optimizing material usage with additive techniques, and lowering transport emissions through distributed manufacturing.

Lifecycle thinking helps: you can design modules for repair or reuse, and use data to extend product life.

Measuring sustainability gains

Track:

- Material utilization rates

- Energy consumption per unit

- Transport emissions and miles

- Waste and scrap rates

- Reuse or recycling rates

You’ll find sustainability often aligns with cost savings when you factor in reduced material and inventory expenses.

Security and regulatory considerations

As you connect machines and systems, security becomes essential. Protect production secrets, intellectual property, and customer data. Regulatory requirements may affect data handling, worker safety, and product certifications.

Put governance in place:

- OT and IT segmentation

- Identity and access controls

- Secure update mechanisms for embedded systems

- Compliance tracking in your digital thread

You’ll want a risk register and periodic audits.

Future trends you should watch

If you like planning for the future, keep an eye on these trends that will shape intelligent fabrication:

- More advanced generative design that optimizes for manufacturability automatically

- Widespread adoption of metal additive manufacturing for production parts

- Increased use of edge AI for real-time process adjustments

- Low-code configurator platforms that let non-engineers create new options

- Greater decentralization of manufacturing via micro-factories

- Advanced human-robot collaboration with safer, more intuitive interfaces

You’ll benefit if you build flexible architecture now to adapt as these trends mature.

Measuring ROI and building the business case

You can justify investments in intelligent fabrication with a clear business case that combines direct savings and strategic benefits:

- Reduced inventory carrying costs

- Shorter lead times and higher sales conversion

- Higher margins on customizable options

- Lower scrap and rework costs

- Improved customer loyalty and repeat business

Use pilot data to estimate payback period and create conservative projections that account for training and change management costs.

Simple ROI formula to start with

Net benefit = (Reduced inventory + Increased revenue from customization + Lower scrap + Labor efficiency gains) – (Implementation cost + Training + Ongoing maintenance)

You’ll refine this calculation as data from pilots becomes available.

Practical tips for success

You don’t need to reinvent everything at once. Some practical tips:

- Start small with one product family

- Invest in digital models before automating hardware

- Build cross-functional teams including design, operations, IT, and sales

- Limit configuration options to those that truly add value

- Partner with technology vendors for integration expertise

- Use the digital twin to test before you buy new machines

You’ll save time and money by focusing on quick wins that prove the concept.

Conclusion: how intelligent fabrication changes what you can offer

By combining design agility, real-time data, automation, and human skill, intelligent fabrication lets you offer customization at scale. You’ll create products that fit individual needs, reduce waste, and open new revenue streams. It’s honest work: systems replace monotony, people gain new skills, and customers get items that feel made for them.

You’ll need patience, good data, and a willingness to rethink how design and production talk to one another. But if you manage to thread those pieces together, the result is manufacturing that’s smarter, faster, and oddly more human—kind of like finding a tailor who also understands spreadsheets.