Could we write in the exact voice of a specific author? We can’t, but we’ll keep the tone witty, observant, and conversational—light on jargon and heavy on practical detail—so the review feels personable and useful.

Why We Picked the GWEIKE G2 Pro 30W Fiber Laser Engraver

We wanted a fiber laser that didn’t shy away from the hard stuff—deep engraving, fine detail, and clean color work on metals—without making us feel like we’d accidentally enrolled in a graduate optics course. The GWEIKE G2 Pro 30W promised industrial-grade speed, 3D and deep engraving, a crisp working area, and a detachable design that actually travels.

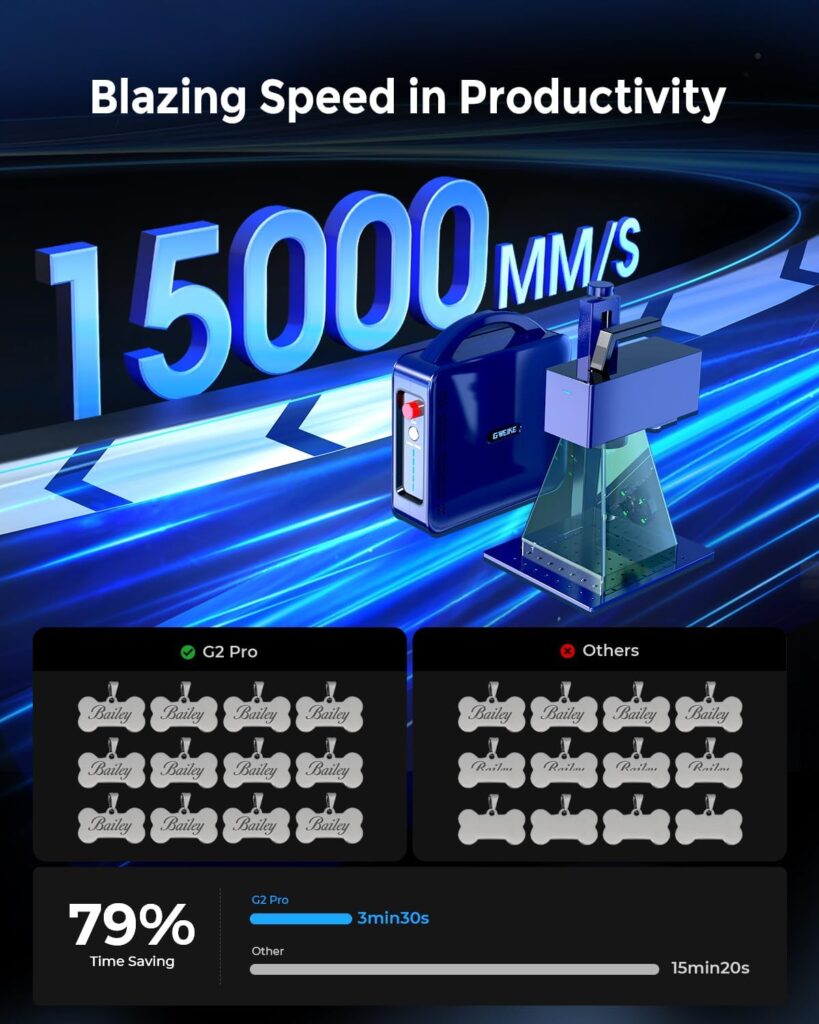

We were also tempted by its 90+ color capacity on stainless steel and titanium, its compatibility with LightBurn, and the promise of a 15000 mm/s top speed. That’s not just a number; it’s a workflow promise—less waiting, more doing.

GWEIKE G2 Pro 30W Fiber Laser Engraver with 3D & Deep Engraving, 15000mm/s Fast Laser Engraver Machine, 110x110mm Working Area, Portable Laser Marking Machine for Metal, Jewelry, Leather, Dog Tags

The Headline Specs That Matter

Let’s keep it simple. When we look at a fiber laser, we want to know what it can do on our desk and on the clock. These are the points we keep coming back to when deciding whether something earns a permanent spot in our shop.

| Feature | What It Is | Why It Matters |

|---|---|---|

| 30W 1064 nm Fiber Laser | High-power infrared laser tuned for metals | Strong marking and deep engraving on steel, titanium, brass, and more |

| 15000 mm/s Speed | Industrial-grade galvo scanning | Faster production, smooth gradients, less time per project |

| 8K Engraving Resolution | Ultra-fine vector and raster sharpness | Crisp micro-text, detailed logos, tight hatching without fuzzy edges |

| Accuracy up to 0.001 mm | High-precision positioning | Repeatability for small parts and tight brand standards |

| 3D Embossing & Deep Engraving | True depth control across passes | Engraved reliefs, recessed serials, and tactile metal surfaces |

| 110 x 110 mm Working Area | Standard marking field for small goods | Ideal for jewelry, tags, pins, coins, knives, and small plates |

| Portable, Detachable Design | Handheld/bench modes | Mark on-site, on uneven or large objects |

| Red Light Preview & Dual Positioning | Fast framing and precise aim | Fewer misprints, faster setup, less scrap |

| 90+ Color on Metals | Controlled oxidation on stainless/titanium | Premium finishes and custom effects |

| Wi-Fi & USB + LightBurn | Flexible connectivity and a familiar UI | Smooth integration with existing workflows |

| Class 4 Safety, E-Stop, Glasses, Guard | Built-in safety protections | Safer operation in busy workshops |

| FDA Accession Number: 2211667-002 | Compliance transparency | Extra peace of mind for regulated environments |

Build and Design: Industrial Brain, Practical Body

We appreciate machines that don’t feel like a science experiment. The GWEIKE G2 Pro looks like it was designed by someone who has actually tried to engrave a 7-inch wrench at 11 p.m. The body is compact and sturdy, the head is detachable, and the hardware feels like it’s meant for use, not just admiration.

The 110 x 110 mm field is a sweet spot for small-to-medium objects. It’s large enough to do dog tags, pendants, coins, knives, buckles, nameplates, and small batches of promotional items, but still compact for tight benches or pop-up booths. The detachable head is the real twist; we carried it to a workpiece and aligned on the spot, which saved us time and a few new creative curse words.

Setup and Software: Not a Degree, Just a Plan

We want a clean path from design to mark. With the G2 Pro, the process is refreshingly direct. We connected over USB and Wi-Fi, dropped designs into LightBurn, and got moving. LightBurn support feels like meeting an old friend—if you’ve used it on diode or CO2 machines, you’ll settle in here quickly.

File formats weren’t a problem, and transfer speeds felt fast enough that we didn’t notice them. The preview tools worked as promised, and the dual red light positioning took the guesswork out of centering designs on small items. We liked how quickly we could test settings for different metal finishes, especially color work on stainless steel.

If you’re new to fiber lasers, the learning curve is less about connecting and more about understanding material behavior. That’s where presets and test grids come in. We created a simple test pattern—power vs. speed on stainless steel—and in under 30 minutes had a usable library for common items like tags, rings, and pendants.

Speed and Resolution: Where Time Meets Texture

The 15000 mm/s claim sounds like marketing until you see how fast raster filling and hatching complete on a medium-density logo. It’s a real advantage for production runs. We finished test plates in minutes that used to take much longer on slower galvo systems.

The “8K engraving resolution” language translates to very fine control over dot placement and vector rendering. We ran micro text at sub-millimeter height and could still read it under magnification. Curves looked smooth, corners stayed sharp, and complex line art didn’t turn into a fuzzy hash.

The 0.001 mm accuracy claim is overkill for most branding work but perfect when we need to align layers for multiple passes. When we moved into deep engraving, that consistency added up: each pass landed exactly where it should, and the edges stayed crisp instead of melting into an indistinct bevel.

3D Embossing and Deep Engraving: Texture You Can Feel

This is where the G2 Pro won our affection. A 30W 1064 nm laser can do a lot more than surface annealing. With the right settings, we carved deep into stainless and brass, and even created embossed-style reliefs with contour mapping. The trick is pacing—power, speed, and the number of passes.

We layered graphics to create a recessed background and raised logo on stainless steel. The results were tactile and beautiful, with a darkened base that made the raised elements pop. On brass, deep engraving takes less time due to the material’s softness; we got clean edges with less heat hazing than expected.

If you’ve ever wanted to make high-value custom items—bag charms, coins, unique tags, or keepsakes—with real depth, this machine puts that within reach. The combination of speed and repeatable accuracy means you can produce detail without waiting a lifetime or burning the surface to a frosty mess.

Color Engraving: 90+ Shades and Plenty of Patience

Color marking on stainless steel and titanium is a wonderful mix of science and art. The G2 Pro can produce a wide palette—over 90 colors—by adjusting speed, power, line spacing, and other parameters. The colors result from controlled oxidation and interference effects, and they’re more durable than paint but not quite the same as anodizing.

We got strong blues, purples, bronzes, and greens on stainless. The finishing was consistent enough for product lines, not just one-off curiosities. Expect to spend time building a parameter library; once you dial in a palette for your stainless stock, you’ll take a big step from “Look what we made” to “Here’s our catalog.”

A word of advice: color work is sensitive. Small shifts in parameter, focus, and even surface finish can tilt the hue. We had the best results on polished or brushed stainless that was clean and degreased. When colors looked dull, it was almost always because the surface wasn’t prepped or we were slightly out of focus.

Materials and Results: What Worked Best for Us

We used the G2 Pro on metals like stainless steel, titanium, anodized aluminum, and brass, plus non-metals like leather, certain plastics, colored ceramics, black acrylic, and stone. As a rule, 1064 nm fiber lasers excel at metals and select synthetics. They won’t cut wood, and they don’t love clear acrylic, but this model’s compatibility with black acrylic and colored ceramics adds creative options.

Leather engravings were crisp without the charred look that CO2 sometimes leaves, and the contrast was clean. On black acrylic, we achieved striking logos with fine lines that didn’t smear or melt. Stone can be unpredictable, but polished surfaces took well to simple marks and line art.

If you’re coming from a diode or CO2 machine, you’ll notice a different personality here. The fiber beam interacts with materials more surgically; it’s less about burning and more about precise, high-energy marking that feels clean and permanent.

Red Light Preview and Positioning: Small Things, Big Savings

We thank the dual red light positioning every time we place a tiny design on something like a pendant or ring face. The preview shows the bounds clearly and responds quickly, and it’s especially reassuring when you’re running batches of small, costly items like jewelry.

The industrial-grade digital galvano system keeps the preview snappy and trustworthy. Our success rate on first tries improved simply from being able to see the placement boundary with confidence. This is also a time saver when we switch between objects—no more ghosting or guessing.

Working Area and Ergonomics: 110 x 110 mm Done Right

It’s tempting to want a bigger field, but for personalized goods, the 110 x 110 mm area hits a happy medium. We can fit jigs for multiple dog tags, run serials on knives, and engrave a small buckle without rearranging the entire shop. When we need to go off-fixture, the detachable design rescues us from awkward setups.

For those who produce multiples, consider a small indexing fixture or a grid jig to keep items aligned. This is also where the repeatable accuracy shines. Create a plate once, save the job, and the G2 Pro will hit the same marks over and over without drift.

Portable and Handheld Use: Off the Bench and Into the World

The detachable, portable nature of the G2 Pro matters. We brought the head to a heavy metal fixture that couldn’t move and engraved directly on-site. It’s a quiet kind of freedom—not dramatic, but deeply practical. You can mark components in place, personalize items at events, and work around odd shapes that won’t fit under a fixed head.

We recommend planning your cable path and having a small clamp or third hand for particularly awkward angles. The machine’s compact weight helps, and the build feels solid enough that we weren’t nervous about taking it off the stand.

Workflow and Compatibility: LightBurn, Wi-Fi, USB

We’re fans of machines that don’t lock us into exotic software. The G2 Pro connects over Wi-Fi or USB, handles common file formats, and plays nicely with LightBurn, which many of us already know. That made it easy to import vector art, add variable text for serials, and build production templates.

Sending jobs from a laptop or even moving files from a phone wasn’t a chore. We appreciated that connectivity didn’t feel like a feature demo—it felt like a normal part of work. The G2 Pro slotted into our workflow with minimal fuss, and we could focus on testing materials rather than wrestling with a software bridge.

Safety and Eco-Friendly Considerations

This is a Class 4 laser, which is serious business. The G2 Pro includes an emergency stop, protective glasses, and a protective cover. We used the cover religiously and placed an exhaust solution nearby. The FDA Accession Number (2211667-002) offers extra reassurance for shops that need documentation.

As for eco-friendly practice, consider fumes and debris capture. Metals produce fine particulates; leather and plastics can produce fumes you shouldn’t inhale. Ventilation and filtration are essential, not optional. The upside is that fiber lasers often produce less soot and char compared to burning processes, so cleanup can be easier and the working area cleaner.

Real Projects We Loved: Jewelry, Metal, and More

Sometimes the best review is a list of work we’d happily do again. Here are a few projects that felt like this machine’s sweet spot.

- Jewelry personalization: We ran initials, layered crests, and micro-text on rings and pendants. Sharp, legible, and consistent, even when we zoomed in.

- Branded metal cards: A matte black steel card with a deep-engraved logo and a brushed frame sold us on the machine’s aesthetic range.

- Dog tags: Fast batching, variable text for names and numbers, and a simple fixture saved serious time.

- Leather tags and patches: Crisp edges and clean contrast without a scorched halo.

- Stainless bottles and gear: The detachable head let us mark items that would never fit under a traditional gantry.

A Quick-Start Settings Snapshot

We all want a starting point. Consider these as ballpark settings; you’ll need to calibrate for your material, finish, and desired effect. We used LightBurn percentages relative to the G2 Pro’s 30W maximum.

| Project | Material | Starting Speed | Power | Passes | Notes |

|---|---|---|---|---|---|

| Deep logo | Stainless steel | 600 mm/s | 80–100% | 6–12 | Tight hatch spacing; clean between passes |

| Micro-text | Stainless steel | 2000 mm/s | 30–50% | 1–2 | Focus carefully; test character fill |

| Color “blue” | Stainless steel | 700–1200 mm/s | 20–40% | 1 | Surface prep matters; keep focus tight |

| Dog tag batch | Stainless steel | 1200–1800 mm/s | 50–70% | 1–3 | Use a jig; variable text for names |

| Engraved crest | Brass | 1000 mm/s | 40–60% | 2–5 | Brass engraves faster; watch for burrs |

| Leather logo | Vegetable-tan leather | 2500–3500 mm/s | 20–35% | 1 | Clean, quick, low odor compared to CO2 |

| Black acrylic mark | Black cast acrylic | 1500–2000 mm/s | 30–45% | 1–2 | Avoid overburn; test small hatches |

Precision and Repeatability: Why It Matters for Production

It’s one thing to make a single beautiful sample. It’s another to produce 100 of them without drift. The G2 Pro’s precision, along with the digital galvano system, gave us confidence that batch three would look like batch one. When we set up multi-item fixtures, the laser kept hitting the same corners and edges. That’s how you win back minutes on each run and hours across a week.

We also appreciated the fine control over hatch angle and spacing. Changing the direction between passes helped us avoid ridging, and we could knock back surface texture where needed without losing edge sharpness.

What’s the Catch? Field Size, Learning Curve, and Color Patience

We love a perfect machine as much as the next person, but we haven’t met one yet. The 110 x 110 mm field is ideal for small goods, but if you want to mark a laptop or a large panel in one pass, this isn’t the right field size. Color engraving is glorious but requires patience and a methodical approach. And if you’re brand-new to fiber, the early days will include test grids and minor triumphs punctuated by occasional “What did we just do to that spoon?”

But none of those are deal-breakers. They’re just the realities of real tools that can do real work. The G2 Pro doesn’t hide from the learning curve—it shortens it where it can.

Fiber vs. CO2 vs. Diode: Where This Machine Fits

We keep all three technologies in our shop for a reason.

- Fiber (like the G2 Pro): Best for metals. Fast, precise, and capable of deep engraving and color marking on stainless and titanium. Less useful for wood and clear acrylic.

- CO2: Excellent for organic materials—wood, paper, leather, and many plastics. Good for cutting, but weak on metals unless you’re using coatings.

- Diode: Affordable and portable, great for basic engraving on wood and coated metals. Slower and less powerful, and not ideal for deep metal work.

If metals and permanent markings are your bread and butter, fiber is the right foundation. The G2 Pro sits squarely in that space: a production-ready tool with thoughtful features.

Pros and Cons: Our Honest Snapshot

We like it when the good and not-so-good share a page. It keeps us honest.

-

Pros:

- Industrial-grade speed (15000 mm/s) that actually cuts production time

- 30W 1064 nm power suitable for deep metal engraving and 3D relief

- Outstanding precision and an “8K” detail feel for crisp graphics and micro-text

- Dual red light preview for accurate placement on tiny objects

- Handheld/portable design for on-site marking and awkward shapes

- 90+ color marking on stainless and titanium—premium finish potential

- LightBurn compatibility and flexible connectivity (Wi-Fi, USB)

- Safety features that help us sleep at night (E-stop, glasses, protective cover)

-

Cons:

- 110 x 110 mm field limits single-pass large items

- Color engraving requires testing and a meticulous parameter library

- Fiber laser learning curve if you’re coming from CO2/diode only

- You’ll need solid ventilation and safety discipline (Class 4)

Tips We Wish We Knew on Day One

We picked up a few habits that paid for themselves in fewer mistakes and better results.

- Build test grids: Make a few test patterns for each material—power vs. speed with small swatches. Save them in LightBurn and re-use.

- Focus like it matters: Because it does. We saw better color consistency and sharper edges when we took an extra minute to confirm focus height.

- Clean the surface: Degrease metals, remove fingerprints, and keep dust down. It’s a boring secret to better marks.

- Layer smart: For deep engraving, use multiple passes and vary hatch angles between passes to reduce ridges and improve floor flatness.

- Log everything: Keep a simple spreadsheet of settings for each material, finish, and desired effect. Label samples and store them.

- Use fixtures: Even a simple jig plate helps with batch work and repeatability. It takes time once and saves time forever.

- Preview religiously: Dual red light positioning reduces scrap. We run a preview every time, even if we’re feeling confident.

- Don’t rush color: One parameter change at a time, and take photos by the same light so you can actually compare results.

- Ventilate well: Capture fumes at the source and wear your protective glasses. Safety isn’t a feature; it’s a habit.

Maintenance and Care: Keep It Sharp

The G2 Pro didn’t demand much, but we kept a regular routine.

- Lens and window: Lightly clean the optics according to manufacturer guidance. Dust and residue ruin fine detail.

- Fans and vents: Keep airflow clear; capture and remove particulates.

- Motion and mount checks: Ensure fasteners remain tight if you frequently detach the head.

- Calibration: If your marks start drifting, check focus and alignment before chasing settings.

- Environment: Stable temperatures and a dry workspace help with consistency.

We also scheduled a monthly “settings review” to update our parameter library and toss bad habits that crept in.

Troubleshooting: The Greatest Hits

We learn as much from mistakes as from triumphs. Here are the fixes that solved most hiccups.

- Faint or inconsistent marks: Check focus, clean the surface, reduce speed or increase power, and confirm you’re using the right hatch type.

- Color looks off: Re-check focus, ensure uniform surface finish, and adjust speed/power incrementally. Avoid dirty or oxidized surfaces.

- Edges look ragged: Tighten hatch spacing, try a different hatch angle, or add a cleanup pass with lower power.

- Ghosting or misalignment: Confirm your workpiece is fixed in place and re-check the red light preview frame on the actual surface.

- Overburn on plastics: Increase speed and lower power; test on scrap. Not all plastics respond well to fiber—use the materials that do.

- Batch drift: Use a jig and lock your origin. If issues persist, recalibrate your alignment workflow and verify fixation.

Who This Machine Is For

We’d recommend the GWEIKE G2 Pro to anyone who needs:

- Professional-quality metal engraving with depth and detail

- Color work on stainless steel and titanium for premium finishes

- Fast turnaround for product runs and batch personalization

- A portable head for on-site marking or irregular shapes

- A reliable partner tool for jewelry, tags, knives, coins, plates, and promotional items

If your work is mainly wood, paper, or large acrylic signs, a CO2 laser might be a better match. But for metal-forward shops or small businesses that want to add high-value personalization, this hits the mark.

Business Case: Speed, Value, and Repeatability

Here’s where the G2 Pro makes a practical argument. The industrial-speed galvo system, high resolution, and 30W power compress job times. That translates to more units per hour, and for personalization businesses, repeatable quality is what keeps customers coming back.

- Batch dog tags with variable text? Easy and quick.

- Deeply engraved logos that feel like sculpture? Within reach.

- Color logos on stainless that stand out at craft fairs and online shops? Yes, with a little refinement and note-taking.

We think of this machine as a revenue multiplier. It doesn’t just let us do new things—it lets us do them on a schedule that makes sense for business.

A Closer Look at Color: Repeatable Palettes

If you’re planning to sell color-marked stainless pieces, build a stable palette. Keep your material source consistent—different alloys can drift in color response. Document speed and power settings carefully. Photograph results under the same lighting, and store a physical color card made with your G2 Pro. When a customer says “We want this exact blue,” you won’t be guessing.

One more tip: beware of fingerprints and oils. We’ve seen a session of perfect colors go sideways because someone handled the metal with lotion on their hands. Degrease, dry, and then engrave. We learned the hard way, so maybe you won’t have to.

The Handheld Edge: Personalization Outside the Shop

We took the G2 Pro’s head to a venue to mark stainless tags and leather pieces. We built a small travel kit with safety glasses, a portable smoke absorber, and a simple clamp. The detachable design let us mark items people brought from home. It felt a little like doing magic tricks at a party, except the end result was a monogrammed fob instead of a rabbit.

If you offer on-site personalization, the ability to bring the laser to the workpiece opens niches: custom knives at shows, nameplates on factory machines, serialized parts, or even commemorative pieces at events.

How It Compares to Other Fiber Units We’ve Used

We’ve tested other 20–30W fiber lasers in this price and performance class. The G2 Pro distinguishes itself with:

- Noticeably faster job completion at high quality due to its galvo system

- User-friendly placement and preview that saved us scrap

- A portable head that isn’t just a novelty but a frequent solution

- Color capability that felt consistent enough for product lines

It’s not the only good option, but it’s a strong one. The value lives in the speed, detail, and mobility combination—plus the LightBurn integration we prefer.

Small Touches That Won Us Over

- The red light preview feels honest and precise. We stopped triple-checking out of paranoia.

- The working area is just big enough for small batch jigs. When we got a rhythm, we cruised.

- The deep engraving doesn’t force ugly heat blooming if you pace the passes right.

It’s a machine that respects our time, which is more than we can say for most electronics we’ve owned.

Frequently Overlooked Details

- Surface finish is half the battle. Brushed vs. polished stainless can drastically change color outcomes and contrast.

- Engraving too slow can sometimes cause unwanted heat effects. Faster speeds with more passes often look better.

- Keep your optics clean. When detail slips, it’s not always your settings—it might be dust.

We didn’t come in expecting to become amateur metallurgists, but a little curiosity goes a long way.

The Dog Tag Problem We Didn’t Know We Had

We once spent a truly absurd amount of time hand-aligning dog tags for a fundraiser. The G2 Pro turned that memory into a cautionary tale. With a basic jig, dual light preview, and variable text in LightBurn, we blew through a batch, and every tag looked like it had been created by someone who knew what they were doing on purpose.

Names, numbers, even QR codes—all sharp. If you sell pet tags or ID plates, this machine is a time machine.

If You’re Coming From a CO2 Laser

We’ve been there. The biggest surprise is the crispness on metals. Where CO2 often needs coatings for marking, fiber goes straight to the metal. You’ll miss cutting wood, but you’ll gain the ability to produce professional-grade metal marks that feel permanent—which they are.

Plan a week for testing and building a reference library. Once you’ve got your materials dialed, you’ll wonder how you ever tried to engrave stainless with anything else.

Practical Safety Habits That Stick

We like to keep safety low-drama and easy to repeat:

- Glasses on, cover on, vent on—every time.

- No spectators without protection, especially in portable mode.

- Keep a small “pre-flight” checklist taped near the machine. We do, and it helps.

- Label scrap bins clearly. Don’t test on unknown plastics.

Class 4 means we treat the beam with the respect it deserves. The built-in protections help, but habits are what keep a shop running.

Support, Documentation, and Confidence

We value clear documentation and compatibility with tools we already know. The G2 Pro integrates with LightBurn, which cuts the learning curve in half. We didn’t have to rewire our brains; we just applied what we knew to fiber behavior. The device’s FDA Accession Number (2211667-002) is a sign that the manufacturer takes compliance seriously, which matters if you work with clients who ask for documentation.

The Bottom Line on Value

The GWEIKE G2 Pro 30W is a production-ready fiber engraver with a knack for crisp detail and reliable speed. It shines on metal, handles deep and 3D engraving with grace, and unlocks color marking that turns stainless into a canvas. The portable head is more than a nice-to-have—it solves real problems by bringing the tool to the work.

We keep coming back to this: it respects our time. Less fiddling, more making. We can bring it to a part, frame the job clearly, and trust it to hit the same marks again and again. That’s what turns a machine into a partner.

Final Verdict: Our Recommendation

If your work lives on metal—jewelry, dog tags, knives, badges, nameplates, stainless bottles, titanium accents—this is a strong choice. The 30W power at 1064 nm, industrial-speed galvo, 8K-level detail, and deep engraving capability provide a serious toolkit. Add the dual red light preview, LightBurn compatibility, Wi-Fi/USB, and safety features, and you have a package that blends precision with practical daily use.

We’d choose the GWEIKE G2 Pro 30W Fiber Laser Engraver with 3D & Deep Engraving, 15000 mm/s speed, and a 110 x 110 mm field for any shop or studio that wants to produce premium marks reliably—especially if handheld portability and color on stainless and titanium are on the wish list. It’s the kind of machine that doesn’t just do the job; it makes us want to invent new ones.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.