Are we the sort who think we’re not “tool people,” right up until the day we find ourselves whispering to a machine as if it’s a sourdough starter?

What This CNC Actually Is, and What It Isn’t

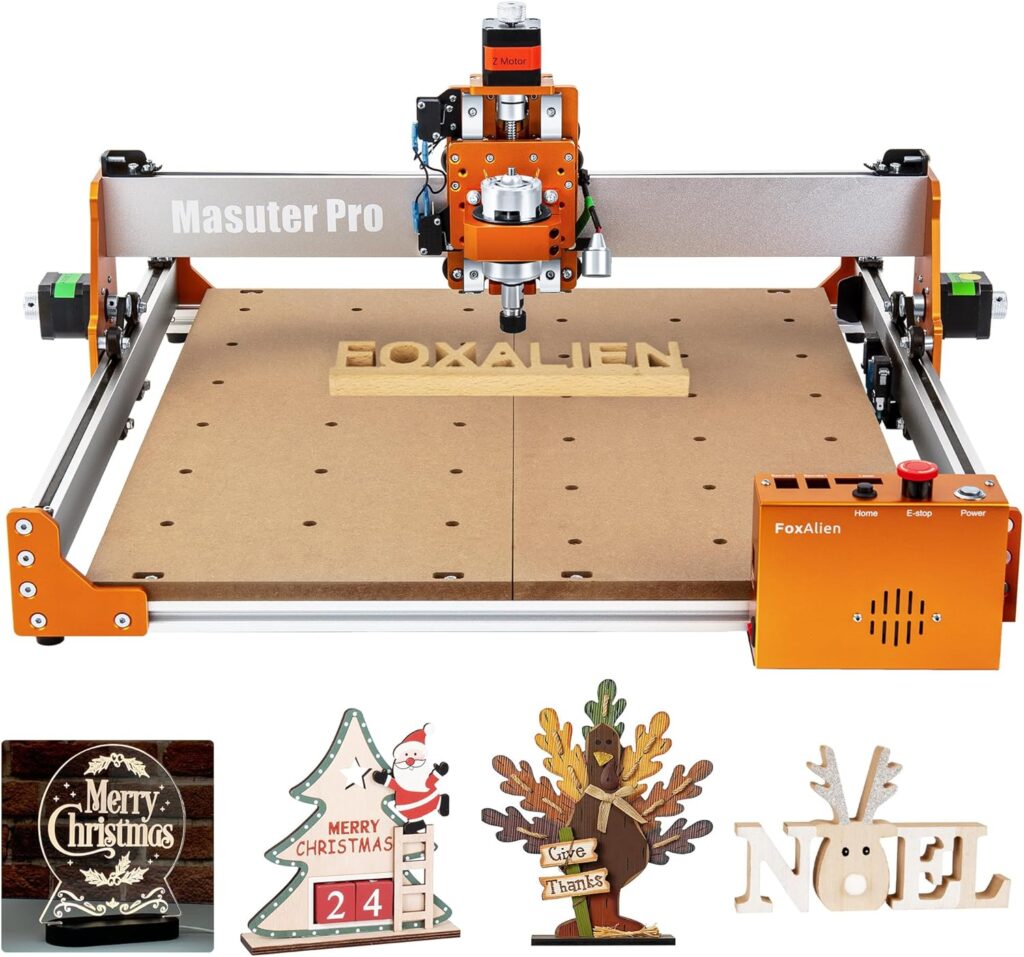

We picked up the FoxAlien Masuter Pro 3-Axis CNC Router Machine because we wanted a beginner-friendly path to clean, repeatable cuts without the wobbly compromises that often haunt entry-level machines. The all-aluminum structure and the linear rail on the Z-axis make a strong first impression, and not the kind you feel obligated to pretend is strong. It’s solid in a way that matters when the bit meets the wood.

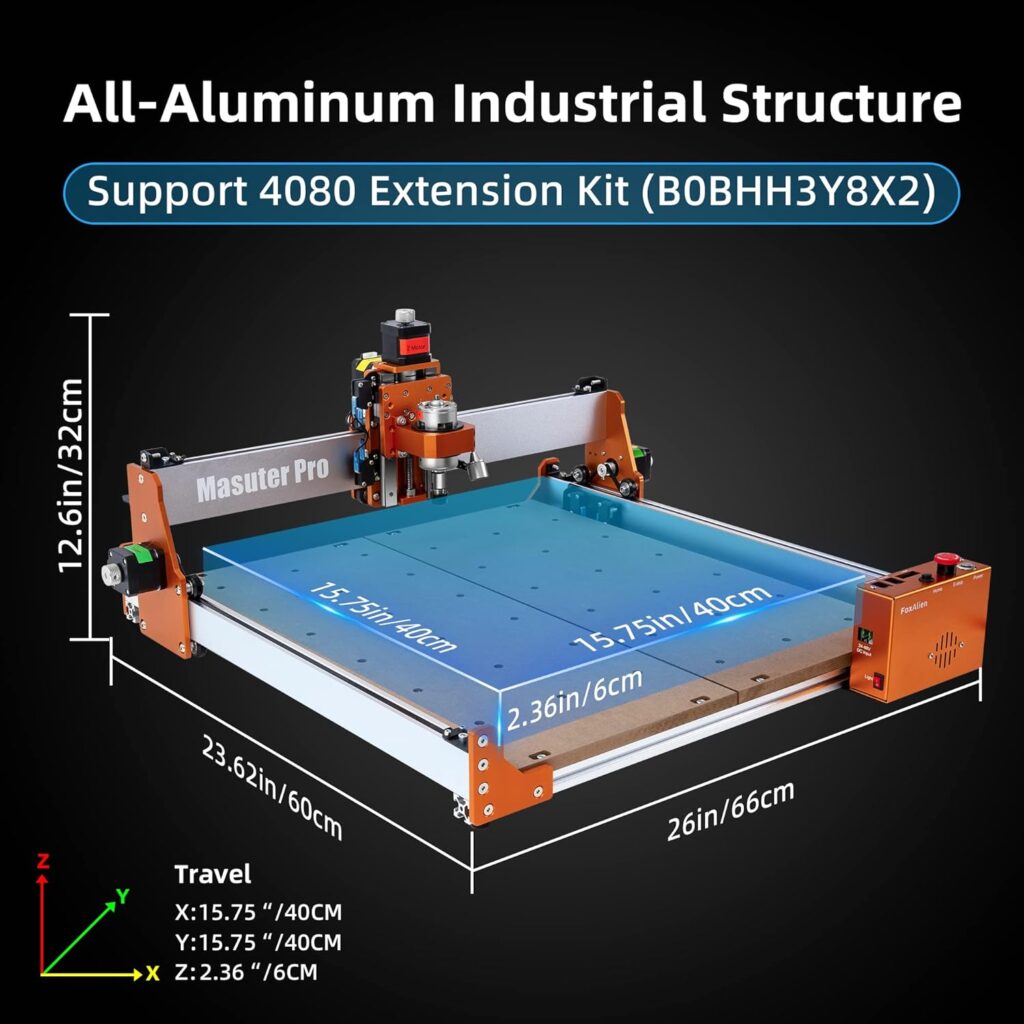

We’re talking about a machine aimed squarely at hobbyists and DIY tinkerers—people like us who want detailed engraving and cutting on wood, acrylic, MDF, nylon, and similar materials. With a generous 15.75 x 15.75 x 2.36-inch working area (400 x 400 x 60 mm) and the option to expand along the Y-axis, it’s a platform that grows with us rather than shaming us for our ambitions.

FoxAlien Masuter Pro 3-Axis CNC Router Machine, Beginner Hobby Engraving Machine All-Metal Structure for Wood Acrylic MDF Nylon Routing Milling Carving

$599 In Stock

Key Specs at a Glance

We like seeing the essentials laid out side by side, as if the machine were trying to make a good first impression on our parents. Here’s a quick breakdown to help us decide if it fits our shop, our projects, and our patience.

| Feature | What It Means | Our Notes |

|---|---|---|

| All-aluminum structure | Rigid frame for better accuracy and reduced flex | Feels durable and stable, especially noticeable on longer jobs |

| Linear rail Z-axis | Smooth, precise vertical motion | Helps with consistent depth and cleaner cuts |

| Working area: 15.75” x 15.75” x 2.36” (400 x 400 x 60mm) | Plenty for signs, trays, inlays, and panels | Optional Y-axis extension kit available for bigger projects |

| Controller: dust-proof, compact | Keeps dust out; simpler maintenance | Emergency stop and Home buttons are front-and-center |

| Emergency Stop & Home | Safety and easy setup | We actually use them, which says a lot |

| Spindle clamps: 52mm & 65mm included | Works with 60W and 300W spindles | Supports 65mm routers and 1.5KW spindles; 69mm clamp optional (separate) |

| Quick assembly | Pre-wired, main parts pre-assembled | Set up in 10–15 minutes, with a clear manual |

| Materials supported | Wood, acrylic, MDF, nylon | Consistent results with sane feeds and sharp bits |

| Expandability | Y-axis extension kit and spindle upgrades | A solid path from beginner to braver |

We’re not big on spec sheets for their own sake, but in this case the details really do add up to a machine that feels thoughtfully designed, especially for a first CNC.

Unboxing and First Impressions

Right out of the box, the Masuter Pro feels less like a kit and more like a quiet promise. The components arrive pre-wired and the main subassemblies already together, which means fewer moments of “Wait, what’s this bolt for?” and more moments of “Oh, we’re actually going to make something today.”

The all-metal chassis doesn’t do the flimsy rattle that some budget machines do when we tap them. There’s a sturdiness we can feel in the frame and a smoothness in the Z-axis travel. The controller’s compact, dust-resistant design comes off as pragmatic rather than ornamental—like someone in engineering had actually used a CNC in a room full of sawdust.

Assembly: 10–15 Minutes That Actually Feel Like 10–15 Minutes

We expected to budget a weekend, because that’s how these things go: you open the box, make coffee, and discover this is now your entire personality until Sunday. But the Masuter Pro proves surprisingly respectful of our time. With the main parts pre-assembled and wiring pre-run to the controller, we moved from box to bench in less time than it takes a cheesecake to disappoint.

The step-by-step instructions make sense, which is a gift. A handful of bolts, some sanity checks on squareness, and a double-check of wiring orientation and we were ready to home the axes. The emergency stop button is right where our instincts want it to be, and the Home button is equally accessible, which is perfect for our “measure twice, still want to home it” anxiety.

Tips We Wish We Knew Before Tightening the First Bolt

- Don’t rush squaring the gantry. A minute here pays dividends in cleaner cuts.

- Place the controller box somewhere you can reach without leaning over the machine. Our back thanks us now.

- Leave the spoilboard slightly overhanging the front edge. It makes clamping less theatrical.

- Run a dry homing and a mock job before the first cut. We like knowing our zero is zero.

Design and Build Quality

The all-aluminum frame is the backbone that separates this from bargain-bin machines that flutter when the spindle sneezes. We’re not ambiently nervous about deflection at the edge of the working area, and that helps, especially when we’re cutting inlays or tight-fitting parts. The Masuter Pro feels like it was designed to be used, not just photographed.

Cable management is tidy, which matters for more than aesthetics. Cables snagging on dust hoses is an avoidable way to gain new gray hairs. The Z-axis is where we notice the biggest step up: it’s on a linear rail, and that little detail makes a big difference in the consistency of depth cuts and surface finishes.

The Z-Axis: Where Precision Lives

Vertical motion isn’t just up and down—it’s the place where precision hides and waits for us to forget to retighten something. The linear rail keeps the carriage motion smooth and aligned, so the bit enters the material accurately and stays honest throughout a pocket or profile. This is the part we silently appreciate when we run a multi-pass cut and the final layer meets the first without picking a fight.

Controller and Everyday Workflow

We’ve used controllers that feel like they came from a homebrew kit and controllers that belong in a glass case. The Masuter Pro’s dust-proof controller sits neatly between those extremes: practical, compact, calm. The E-stop is a big, comforting button, and the Home button is right there too, encouraging us to develop good habits.

Everyday workflow feels routine in the best way. We set our origin, we double-check our clamps like a nervous parent fastens a car seat, and we hit start. Nothing about the interface feels like an obstacle course, and that means we focus on the part rather than the machine.

Safety That Doesn’t Scold Us

We appreciate that the safety features are visible without feeling dramatic. The emergency stop is our “we’d rather not” button, and we’ve used it a couple of times during test runs without shame. The Home button is similarly helpful, letting us establish a repeatable baseline before we cut. It’s the kind of design that nudges us toward consistent process, not because it’s preachy, but because it’s easy.

Spindle Options and How They Change the Game

What we clamp in the Z-axis determines the kind of cutting we can do. The Masuter Pro includes both a 52mm and a 65mm spindle clamp, which is a small thing with big implications. It means we’re ready for a modest 60W spindle for engraving and fine detail, a 300W spindle for more substantial work, and we have headroom to move up to a 65mm router or even a 1.5KW spindle later. If we want to run a 69mm spindle, that clamp is supported too (we just need to buy it separately).

We like choices, especially when the choices don’t try to shame us. If we want quiet and cautious, we can do that. If we want faster removal rates and thicker stock, we can do that too. It’s our shop, our ears, and our attention span.

Our Preferred Setup (and Why)

We found a sweet spot with a 300W spindle for most day-to-day cutting. It offers a good balance of speed, noise, and control for materials like hardwood, MDF, acrylic, and nylon. For deeper pockets or larger surfacing jobs, stepping up to a 65mm router or a 1.5KW spindle makes sense, but we do keep in mind the extra weight and torque, and we adjust our conservatism accordingly. If we had neighbors who frown at joyful noise, we might stay with lower power and sharper tools.

Working Area and Projects That Fit

With a 400 x 400 x 60mm working area (15.75 x 15.75 x 2.36 inches), we can tackle signs, trays, charcuterie boards, cutting board inlays, wall art panels, small furniture components, and instrument parts with room to breathe. The Z height of 60mm is enough for most hobby work, especially when we’re not tempted to turn every project into a sculpture.

If we find ourselves repeatedly tiling longer projects, the optional Y-axis extension kit starts to look like an easy win. We like that it exists; we also like not being forced to buy it on day one.

Fixturing Without Tears

Holding material down is where many good intentions go to panic. We’ve gotten good results with the following setup:

- A replaceable MDF spoilboard, surfaced flat to the machine.

- A few low-profile clamps that don’t stick their elbows into passing toolpaths.

- Painter’s tape and CA glue tricks for delicate parts.

- A mental note to clamp from two axes whenever possible.

We resurface the spoilboard whenever we see the telltale stripes of uneven tooling marks. It’s not glamorous, but it’s the grooming that keeps our machine honest.

Materials and Real-World Results

We judge a machine’s worth by the parts that walk off it. The Masuter Pro handles the materials it promises—wood, acrylic, MDF, and nylon—without melodrama. With sharp bits and thoughtful settings, it produces clean edges, repeatable pockets, and curves that don’t look like they were drawn by a caffeinated toddler.

Wood

Hardwoods like maple, walnut, and cherry cut cleanly when we resist the urge to go faster than our chips can evacuate. Softwoods are forgiving but squirrelly: climb cutting on final passes can help reduce tear-out. We like a light finishing pass around the perimeter to erase tool marks and make us look more meticulous than we feel.

Acrylic

Acrylic rewards patience and punishes friction. We keep our bits sharp and our chips large enough to carry heat away. When the chips flow like confetti at a parade we did not plan, we know we’re in the zone. Edge polishing depends largely on bit geometry and conservative finish passes. Avoiding frosted edges is all about heat management and chip evacuation.

MDF

MDF is the polite dinner guest who still manages to get dust everywhere. The Masuter Pro handles it elegantly, but we double up on dust collection and wear a mask. We get crisp pockets and smooth surfaces, and a surfacing bit turns MDF into something that looks oddly luxurious when you squint.

Nylon and Plastics

Nylon has a way of reminding us that not all plastics behave the same. It wants sharp bits, gentle ramp-ins, and feed rates that keep chips moving. We’ve had good results making fixtures, brackets, and small mechanical parts—places where chatter would have ruined our day on flimsier machines.

Precision, Repeatability, and Tuning

A rigid frame and a linear rail on the Z-axis put us in a good place right away. But precision is a partnership between us and the machine. We take the time to:

- Calibrate axis motion with small test cuts and adjust our workflow as needed.

- Check squareness by cutting a square and measuring diagonals.

- Tram the spindle so surfacing doesn’t leave ridge lines that feel like a topographical map.

The machine gives us the head start; we try not to squander it through impatience. With a little care, we’re getting repeatable results that actually stack—literal boxes that fit, not boxes that call our measuring tape a liar.

Noise and Vibration

Noise is about three things: material, bit, and spindle. The frame itself doesn’t sing or wobble, which reduces vibration-related chatter. MDF and hardwoods tend to be polite; plastics can get shrill depending on the bit and speed. If we switch to a larger router or 1.5KW spindle, we do it with the tacit agreement that our ears are now part of the project plan. Ear protection is cheap. Regrets are loud.

Dust, Chips, and Staying Sane

The controller’s dust-proof construction feels less like a nicety and more like a necessity once we’ve run a few MDF jobs. We’re grateful for any design choice that keeps grit out of electronics. We also pair the machine with a dust shoe or at least a strategically placed vacuum hose—a move our lungs and our keyboard will both appreciate.

We treat dust as an inevitability and a solvable problem. A shop vac, a filter that isn’t decorative, and the habit of cleaning as we go all add up to a workspace that doesn’t look like a snow globe made of regret.

Cleaning Routine

- Brush chips and vacuum between runs, not just at the end of the day.

- Wipe the rails and check for any build-up on the Z-axis carriage.

- Re-seat clamps while the machine is idle, so we don’t chase them mid-cut.

- Every few sessions, confirm our homing is still consistent and our spoilboard is still flat.

Software and File Workflow

The Masuter Pro fits into a familiar workflow for hobby CNC work. We design in our CAD program of choice, set toolpaths in a CAM package, and export standard G-code. Then we send that code to the machine with our preferred sender. We keep things simple and repeatable—heavy on convention, light on heroics.

We favor a clean handoff: design, toolpath, post, send. The fewer moments of “Where did that setting go?” the better our parts look and the nicer we become as people.

From Idea to Cut: A Simple Checklist

- Home the machine.

- Secure and surface the spoilboard if needed.

- Clamp or adhere the workpiece so it can’t move, twist, or dream of freedom.

- Install the correct spindle clamp and bit; confirm the bit is seated and tight.

- Set origin (X, Y, Z) precisely.

- Run a air pass above the work to confirm toolpath sanity.

- Start the job and hover like a concerned parent for the first few minutes.

Maintenance and Longevity

We’re suspicious of machines that promise a maintenance-free life. The Masuter Pro instead offers a maintenance-sane life. We check fasteners periodically (vibrations don’t care about our feelings), keep the dust off the motion components, and re-surface the spoilboard when it starts to look like a relief map of the Alps.

A little light lubrication on moving interfaces helps, though we’re conservative with where and how much. Dust tends to fall in love with grease, and not the good kind of love. We would much rather spend five minutes on preventative care than fifty minutes explaining to the machine that our love language is not “squeal.”

Upgrades and Accessories Worth Considering

We like how the Masuter Pro keeps the upgrade path straightforward and optional. We don’t have to commit to a high-powered spindle on day one. But if we want to later, the machine has our back.

- Spindle upgrades: 65mm router or a 1.5KW spindle for faster cuts in dense materials. We check weight and mounting compatibility before we commit.

- Spindle clamp: If we want a 69mm spindle, we can add that clamp (sold separately).

- Y-axis extension kit: For longer projects without tiling.

- Bits: A range of sharp end mills, a surfacing bit for spoilboards, and a few V-bits for engraving.

- Clamping solutions: Low-profile clamps, cam clamps, and perhaps a t-slot or threaded insert spoilboard.

We keep upgrades tied to projects we actually want to do, not just “things that sound cool.” The cool things collect dust; the useful things get dull and make us buy more.

Who It’s For

We’d recommend the FoxAlien Masuter Pro to anyone who wants a stable, capable, beginner-friendly CNC router that doesn’t require a semester of mechanical sympathy to operate. Woodworkers adding inlay work, DIYers wanting to make accurate panels, makers approaching small-batch parts for shops or gifts—it’s well-suited to those use cases. The short setup time and pre-wired build are what make this feel friendly.

If we’ve never run a CNC before, this machine teaches gently. If we’ve used one and swore never again, this one just might coax us back.

Who Might Want Something Else

If we routinely need to machine large furniture panels in one go, we’ll either want the Y-axis extension kit or a larger format machine. If we plan to cut a lot of metals, that’s a separate category and calls for different rigidity, workholding, and cooling needs. The Masuter Pro is for wood, acrylic, MDF, nylon, and similar materials; it shines in those lanes and doesn’t pretend otherwise.

Value and Cost of Ownership

There’s the sticker price, and then there’s the long-term price of surprises. The Masuter Pro keeps the latter low by being simple to assemble, easy to keep clean, and flexible with spindle choices we might already own or plan to upgrade into. Being able to start with a modest setup and then tune for performance later means we’re not overbuying on day one or stuck when our projects get bolder.

Consumables are bits and spoilboards and the odd clamp we’ll drop on the floor and find three weeks later with our sock. In exchange, we get repeatable projects, faster progression from idea to prototype, and the confidence to press “Start” more often.

Troubleshooting Common Hiccups

We like to think of troubleshooting as the machine’s way of telling us it needs a glass of water. Here are a few things we’ve seen and what fixed them:

- Rough edges on wood: Dull bit, aggressive feed, or too little chip evacuation. Sharpen the bit, lighten the final pass, improve dust removal.

- Melty edges on acrylic: Too much heat. Increase chip load modestly, use a sharper bit, improve evacuation.

- Misaligned pockets: Check that we’ve homed correctly and that the stock isn’t shifting under clamp load. Re-zero Z after changing bits.

- Wavy surfaces: Tram the spindle, resurface the spoilboard, and confirm the workpiece is truly flat.

- Chatter on heavier passes: Reduce depth of cut or step-over; confirm everything is tight, especially at the spindle clamp.

Our favorite fix remains “a calm second pass.” We underestimate it at our peril.

Projects That Made Us Happy

A machine earns its place by making things that spark joy, confusion, or both. We’ve had good luck with:

- Signage with v-carved lettering and clean borders that don’t fuzz out.

- Cutting board inlays where the fit feels like sorcery and not like we snuck up on it.

- Custom trays with pockets for tools, chargers, or whatever daily chaos we’re pretending to organize.

- Acrylic panels for lighting projects that turn the whole room into a vibe we can’t quite explain.

- Nylon brackets and fixtures that save us two days of waiting for shipping.

We like running a test cut in scrap before committing to the nice material. Scrap is honest and forgiving. Nice material is neither.

Day-to-Day Ergonomics and Use

We care about where our hands go during setup, because that’s where mistakes and inconvenience happen. On the Masuter Pro, we can reach the e-stop and Home without leaning through a tangle of cables. The bed height is friendly if we put the machine at a standing bench. We try to keep the vacuum hose out of the spindle’s personal space, usually by securing it overhead or to a side arm.

The spindle clamp swap is quick, so we’re not dreading configuration changes between engraving and more assertive cutting. We still label our clamps with tape like we’re in kindergarten, because it saves a minute on the fourth project when we’re feeling too clever to be careful.

The Learning Curve, Honest Version

A CNC is honest in the way a kitchen scale is honest: it tells us what we really did, not what we think we did. On this machine, the learning curve is more about workflow than about wrestling hardware. That’s a gift. We build good habits—homing every time, securing stock well, setting Z carefully, running a verification pass—and the machine rewards us by doing exactly what we asked.

The first projects are where we learn to underpromise and overdeliver to ourselves. We start with simple profiles and pockets, add engraving, then try multi-tool jobs with tool changes and careful re-zeroing. Nothing about the Masuter Pro gets in our way as we learn.

How the Masuter Pro Changes Our Shop

The thing we didn’t expect is how many offhand ideas become tangible because the machine isn’t a production. With quick setup and a predictable working envelope, we go from “we should make a jig for that” to “the jig is running” in the time it used to take us to look for a jig in the garage and discover an entire unrelated pile of camping equipment.

We end up designing more, iterating sooner, and taking more risks with projects because the cost of failure is just a bit of MDF and a sheepish grin. That’s worth more than we’d like to admit.

Comparing Expectations to Reality

We expected a basic entry-level machine and were ready to forgive the little crimes of youth: wobble, noise, set-screw wander. What we got was a stable, respectful partner that cuts cleanly and asks only that we meet it halfway with a squared frame, sharp bits, and sane speeds.

We didn’t expect to like the controller as much as we do. Dust-proof isn’t glamorous, but it makes us exhale in a way only people who’ve vacuumed a circuit board will understand.

Pros and Cons

We appreciate lists when the coffee wears off and our attention span clocks out. Here’s where the Masuter Pro shines and where it politely declines to pretend.

Pros:

- All-aluminum frame and a linear rail Z-axis for improved rigidity and precision

- Dust-proof, compact controller with easily accessible E-stop and Home buttons

- Two spindle clamps (52mm and 65mm) included, with support for upgrades like 65mm routers and 1.5KW spindles; 69mm clamp supported (sold separately)

- Quick assembly with pre-wired components and a straightforward manual

- Useful working area (400 x 400 x 60mm) with optional Y-axis extension for larger projects

- Friendly for beginners without capping room for growth

Cons:

- Working area limits one-piece large furniture panels (expansion kit helps)

- Dust management still requires accessories and discipline (inevitable with CNC)

- Upgrading spindle power raises noise and setup complexity

- We may spend too much time making gifts for other people and forget we were going to make a clock for ourselves

Frequently Asked Questions

Is it beginner-friendly?

Yes. The pre-wired, pre-assembled design, plus sensible controls, make it approachable. The manual doesn’t assume we’re psychic.

How long does assembly take?

About 10–15 minutes. It feels like a generous estimate that turns out to be accurate, as long as we’re not building it while cooking dinner.

What materials can we cut?

Wood, acrylic, MDF, nylon, and similar materials. With the right bits and settings, we’ve had consistent success.

What’s the working area?

15.75 x 15.75 x 2.36 inches (400 x 400 x 60mm). It’s large enough for signs, trays, and small furniture components. The optional Y-axis extension kit opens up bigger projects.

Can we upgrade the spindle?

Yes. It supports 60W and 300W spindles with the included 52mm/65mm clamps, and we can move to a 65mm router or 1.5KW spindle. If we need a 69mm spindle, we can get the compatible clamp separately.

Is the controller protected from dust?

It is. The compact controller box is dust-resistant, which we appreciate for longevity and reliability.

Is there an emergency stop button?

Yes, and it’s right where our anxious thumb expects it. There’s also a Home button for quick, consistent starting positions.

What about noise?

Noise depends on the spindle and the material. A 300W setup is modest; a larger router or 1.5KW spindle will be louder. Ear protection is wise regardless.

Do we need special software?

We can use a typical CAD/CAM program to generate G-code and a sender to stream it to the machine. Our best results come from keeping the workflow simple and consistent.

Can it handle production runs?

For small batches of repeat parts in wood, acrylic, MDF, or nylon, yes. We plan our toolpaths well and keep the machine maintained. For industrial volume, we’d move up a class.

The Part of the Review Where We Admit What We Did Wrong

We tried to rush the first inlay. It went poorly. Then we slowed down, ran a test in scrap, and discovered the machine had not betrayed us; we’d betrayed the machine with optimism. We learned to be methodical: careful clamping, zeroing with intent, small verification passes, and believing our test cuts instead of our impatience.

We also learned that the e-stop is not a confession of failure; it’s just a quick way to renegotiate terms when we realize the bit is headed for a clamp it doesn’t respect.

The Subtle Joy of Repeatability

We used to think “craft” was a synonym for “accepting small unpredictabilities with grace.” Now we think craft is what happens when you can repeat the result, not just get lucky once. The Masuter Pro helps us repeat. We run three copies of a panel and they stack. We make a set of coasters and they actually match. We don’t have to explain away imperfections as “quirky,” which has done wonders for our relationship with poly finish.

What We’d Tell Our Past Selves Before Buying

- Budget for clamps, a surfacing bit, and one sacrificial board you’ll pretend isn’t sacrificial.

- Spend ten minutes squaring and tramming on day one; save ten hours later.

- Start with smaller, simpler projects and let competency grow. Competency, it turns out, is like a plant—it thrives on consistent sunlight and not much drama.

- Don’t be shy about the spindle upgrade path, but also don’t jump into a screaming router if you don’t need the speed yet.

- Keep the controller box dust-free. Future us will send a thank-you note.

Final Take

The FoxAlien Masuter Pro 3-Axis CNC Router Machine makes a better first impression in use than it does on paper, and it looks great on paper. The all-aluminum frame and the linear rail Z-axis change the way the machine feels under load—confident, steady, trustworthy. The dust-proof controller with a big, red, unambiguous stop button and a friendly Home button turns daily use into a rhythm instead of a ritual.

We like that it meets beginners where they are and offers an honest upgrade path without holding our projects hostage. We can start with a 60W or 300W spindle and then, as we get braver or more impatient, move up to a 65mm router or 1.5KW spindle. The working area is generous for most hobby projects, and the optional Y-axis extension kit keeps our ambition intact.

Most importantly, what we cut with it looks like what we designed. That’s not always a given at this price. Wood, acrylic, MDF, and nylon all behave themselves when we keep our bits sharp and our feeds sensible. The machine stays stable, the Z-axis stays true, and our projects move from idea to reality without asking us to become machinists overnight.

We find ourselves starting the Masuter Pro more often than we expected because it’s simple to set up, clean to run, and predictable in its results. It earns its footprint in our shop by being both teacher and tool—friendly, sturdy, and ready for the next excuse we invent to make something. If our goal was to give our creativity a dependable engine, this feels like the right one, humming along without drama, waiting patiently for our next bright idea.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.