Have we been waiting for a compact CNC router that can actually keep up with our ambitions and our coffee schedule without throwing a tantrum halfway through a cut?

Our Hands-On Review of the FoxAlien Masuter 3S CNC Router Machine

We took the FoxAlien Masuter 3S CNC Router Machine with NEMA 23 Closed-Loop Stepper Motor and a 400W spindle for a long spin—figuratively and literally. We wanted a machine that could carve wood, acrylic, and soft metals like aluminum without wobbling like a folding chair at a family reunion. This one didn’t just behave; it felt like a small shop’s worth of hardware in a desktop footprint.

Why This Review Matters to Us

We measure a machine not just by specs, but by how it behaves when we ask it to cut something slightly ambitious while we fumble with clamps and pretend to know where we put the calipers. The FoxAlien Masuter 3S brought stability, accuracy, and a sense of calm to our seat-of-the-pants workshop routine, and that’s worth talking about.

FoxAlien Masuter 3S CNC Router Machine with NEMA 23 Closed-Loop Stepper Motor, 400W Spindle 3 Axis Engraving Milling Machine for Wood Acrylic Aluminum Carving Cutting

$829 In Stock

The Short Story of a Serious Machine

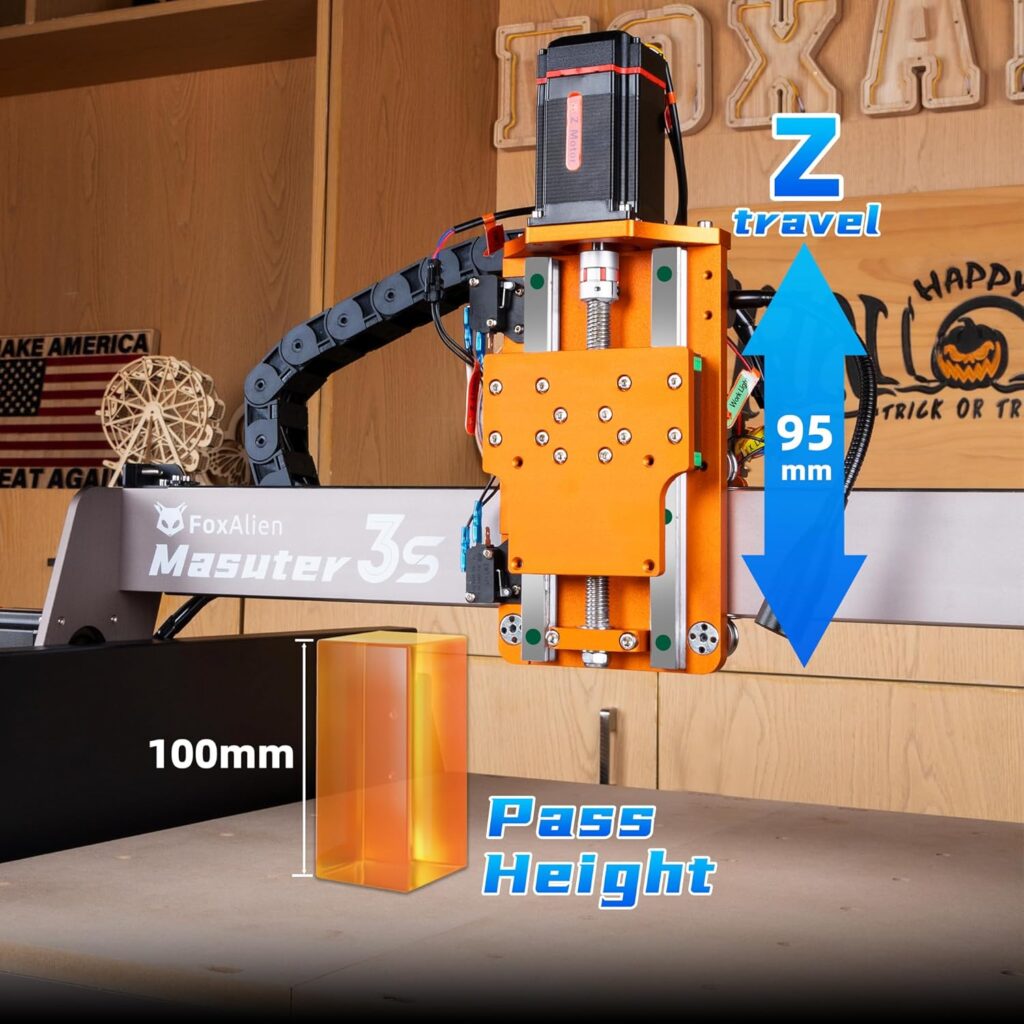

The Masuter 3S comes stacked with NEMA23-76 closed-loop stepper motors pushing up to 2.2 Nm of torque and speeds up to 10,000 mm/min. It delivers engraving accuracy down to 0.05 mm. There’s a sturdy frame, dual HG-15 linear rails on the Z-axis, a T12 lead screw, and a 400W spindle that can handle aluminum without sounding like it’s filing for workers’ comp. It’s compact, too, with a 400 x 400 x 95 mm work area and optional expansion on the X-axis for larger projects.

What We Were Looking For

We wanted more than a hobbyist toy. We wanted a machine that wouldn’t lose steps, drift out of square, or require the sacrificial offering of a goat before every job. With the Masuter 3S, we got consistency, control, and an approachable ride for people who know enough to be dangerous but want results that look like we knew what we were doing all along.

At a Glance: Specs and What They Mean

We love a spec sheet that translates to real-world results. These features aren’t just for bravado; they change the way our fingertips relax when we hit “Start.”

| Feature | Specification | Why It Matters |

|---|---|---|

| Motors | NEMA23-76 closed-loop steppers, 2.2 Nm torque | Better torque, fewer missed steps, reliable positioning |

| Speed | Up to 10,000 mm/min | Faster rapids and efficient toolpaths for production runs |

| Accuracy | Engraving accuracy of 0.05 mm | Crisp details for fine text, inlays, and mechanical parts |

| Z-Axis | Dual HG-15 linear rails, T12 lead screw | Smooth, rigid motion; reduced wobble and chatter |

| Spindle | 400W air-cooled, 65 mm clamp included | Cuts wood, acrylic, and soft metals; allows router upgrades |

| Frame | Heavy extrusions, added base supports | Stability across the entire work area |

| Motion | Steel wheels pulley system | Smoother, quieter travel and longer lifespan |

| Work Area | 400 x 400 x 95 mm (15.75″ x 15.75″ x 3.74″) | Fits most maker projects and small batch jobs |

| Controller | Dust-proof box with shortcut buttons | Cleaner, faster operation without digging through menus |

| Offline Option | Supports FoxAlien offline controller (B0DC6HHNH4) | Runs jobs without a computer |

| Expandability | X-axis extension kit (B0D5HK72MP) available | Larger projects as our ambition grows |

Setup and Assembly: When the Allen Keys Come Out

Most of us don’t buy a CNC to rebuild it before the first cut. We want something that goes together like a sensible puzzle, not a punishable offense. The Masuter 3S asked for our time, yes, but it paid us back in rigidity and precision.

Unboxing and First Impressions

Everything arrived thoughtfully packed, and we didn’t need to run to the hardware store for missing screws. The extrusions felt substantial and straight. The linear rails on the Z-axis were a welcome sight—no flimsy motion here. The controller box looked like it could survive a dust storm and still check email.

Assembly Process and Tips

The instructions were clear, and the labeled wiring saved us from the particular humiliation of plugging the Z motor into the X port. We squared the gantry with a machinist’s square and took an extra moment to seat the base supports, which contribute to a flatter spoilboard and less bowing under clamping pressure.

- We tightened the frame bolts progressively and in sequence—think of it as torqueing lug nuts.

- We trammed the spindle to the spoilboard with a dial indicator. Not required to run, but worth it for perfectionist results.

- We checked pulley tension and adjusted the steel wheel tracks for smooth rolling without binding.

The Controller and Electronics: Quiet Confidence

A pleasant controller box doesn’t guarantee a pleasant life, but it helps. Ours has shortcut buttons that actually do things we want quickly. Backup and pause are right where we need them.

Closed-Loop Steppers: What They Do for Us

Closed-loop steppers keep track of their position and correct errors in real time. That means if we hit an aggressive cut in aluminum or wood knots, and the motor gets challenged, it doesn’t just stumble and pretend nothing happened. It corrects course and carries on, which is the kind of resilience we like in both machines and friends.

Offline Operation and Dust-Proofing

The dust-proof controller is a kindness we didn’t realize we needed until our old machine’s board looked like it had been breaded and fried. We also appreciate the support for FoxAlien’s offline controller (B0DC6HHNH4), so we can run jobs from a thumb drive when the shop laptop is sulking.

Mechanical Design: Built to Keep Bit and Material on Speaking Terms

The Masuter 3S makes a strong first impression in the frame department. It’s built from heavy extrusions and supported by additional bracing underneath that helps keep the surface flat and true.

Z-Axis Rails and Lead Screw

The Z-axis gets dual HG-15 linear rails and a T12 lead screw. That combination keeps the spindle moving smoothly along Z without wiggle or drama. We’re not chasing chatter ghosts here, which means cleaner edges and the courage to take deeper passes.

Steel Wheels and Pulleys

The upgraded steel wheels gliding along the rails feel like an adult decision. The motion is smooth and quiet, with less give. We get repeatable positioning and fewer gremlins when cutting materials that like to fight back.

Spindle Power: The 400W That Could

We’ve run into machines that list a wattage and deliver a spirited whisper. This 400W spindle actually bites. It’s not going to cut steel plates or race a 1.5 kW water-cooled unit, but for wood, plastics, and aluminum, it’s a diligent worker that doesn’t complain.

Realistic Material Expectations

- Wood: Pine, hardwoods, plywood, MDF—smooth cuts with the right bit and feed rates.

- Acrylic: Clear edges with single-flute bits and good chip evacuation; avoid melting with conservative RPM and proper feeds.

- Aluminum: Absolutely doable with single-flute cutters, shallow depths of cut, and a patient hand on the coolant bottle (or mist).

Feeds, Speeds, and Passes We Used

These are our real-world starting points. Your toolpaths, bit geometry, and material will vary, so we tweak while we go.

- 1/8″ single-flute carbide in aluminum: 10,000–12,000 RPM, 300–600 mm/min, 0.2–0.4 mm DOC, 30–40% stepover. Add lubricant or mist to clear chips.

- 1/4″ two-flute upcut in hardwood: ~12,000 RPM, 1000–1500 mm/min, 2–3 mm DOC, 40–50% stepover.

- 1/8″ single-flute in cast acrylic: 10,000–12,000 RPM, 700–1000 mm/min, 1–2 mm DOC, 30% stepover. Aim for forest of chips, not strings.

We’ve learned to keep an eye on chip evacuation like we’re watching a pet too quiet to trust. When chips clear, everything runs cool and gracious.

Work Area and Expansion: The Space We Needed, with Room to Grow

The 400 x 400 x 95 mm work volume gives us room for signs, trays, front panels, coasters, plaques, and small mechanical parts. For larger pieces, the X-axis extension kit (B0D5HK72MP) is ready when we are.

Clamping and Workholding

We use a threaded insert spoilboard. It’s the friend that never complains about being perforated and replaced. Cam clamps, low-profile vise fixtures, and painter’s tape with CA glue cover most of our weird holding needs, including thin acrylic sheets and small aluminum blanks.

Accuracy, Precision, and Repeatability: Where the Numbers Calm Our Hearts

The Masuter 3S claims 0.05 mm engraving accuracy. We felt those standards in practice. After surfacing, our pocket depths stayed consistent, and small text survived scrutiny without looking like it had been drawn by a nervous squirrel.

How We Tested

We cut a 100 mm square and measured each side, then measured diagonals, then cut pockets and repeated the pattern on separate days. We ran a hole pattern test. The results? Within 0.05–0.1 mm in our setup, which is more than enough for the kind of work this machine is meant to do.

Software Workflow: The Human Side of G-Code

A CNC is only as relaxing as the software that sits between us and it. We were happy with the Masuter 3S because it speaks the language of GRBL-style controllers and plays nicely with common tools.

CAD and CAM Choices

- CAD: Fusion 360, FreeCAD, and Shapr3D all did fine for model design.

- CAM: Carbide Create, Fusion 360 CAM, VCarve, and Easel produced clean toolpaths for our use cases.

We export G-code and send it with Candle or Universal Gcode Sender (UGS). LightBurn fans can use FoxAlien’s optional laser modules (if we go that route later), but for milling and engraving, any GRBL-compatible sender gets the job done.

Offline Sending for Shop-Only Days

We keep a set of TAP/NC files on a USB stick and run them from the optional offline controller. It’s nice not to babysit a computer when we’re already babysitting a spindle.

Projects We Actually Cut

We didn’t just admire the machine quietly while it sat there judging us. We ran a handful of projects that tested its patience and ours.

Hardwood House Plaque

We used a 1/4″ upcut to pocket and a 60-degree V-bit to letter. We surfaced the spoilboard first, then trammed the spindle lightly. The plaque came out with crisp edges; the V-carve definition looked like we knew our fonts. We finished with oil and pretended it had always been this easy.

Acrylic Control Panel

We cut 3 mm cast acrylic for a small electronics project. The key was to leave a thin skin on the cutouts to avoid part movement, then clean them with a final pass. We avoided melting by keeping RPM moderate and making sure chips didn’t pile around the bit. The edges were clear and polished enough to make us smug.

Aluminum Brackets

Using 6061 aluminum, we cut small brackets with 1/8″ single-flute carbide, WD-40 as a light lubricant, and shallow passes. The edges were clean; holes were on size; the finish deserved a light Scotch-Brite pass but was good enough even raw. No step loss, no drama.

Noise, Vibration, and Dust: The Shop Reality

No machine is silent, and dust is the invisible roommate we didn’t invite. The Masuter 3S, however, was reasonable on both counts.

What Our Ears Heard

The 400W spindle is relatively quiet compared to a trim router. Cutting noise depends on the material and bit, but we didn’t feel like we were taxiing a small plane in the living room. Closed-loop motion is smoother, and the steel wheels help damp any twitches.

Dust Collection Strategy

We ran a compact dust shoe linked to a shop vac with a cyclone separator. For acrylic and aluminum, we prioritized chip evacuation over dust collection, then vacuumed. For wood, a dust shoe is practically mandatory unless we enjoy decorating our lungs with MDF.

Safety Matters More Than Our Pride

We all want full sets of fingers. This machine won’t hurt us if we don’t give it stupid things to do, but a few habits are non-negotiable.

The Gear We Wear and Use

- Safety glasses always.

- Hearing protection when cutting hardwood, MDF, or aluminum.

- Respirator when cutting MDF or any fibrous composite.

- An outlet with emergency shutoff within arm’s reach.

Workholding and Clearance

We double-check clearance with air passes when uncertain. We probe Z carefully and set safe heights that don’t snap bits on clamps. Nothing summons grief faster than a proud cam clamp that meets a spiral bit at speed.

Maintenance: The Boring Stuff That Keeps It Brilliant

Maintenance on the Masuter 3S is blessedly straightforward. A little care keeps it cutting true and keeps us out of the troubleshooting forum at midnight.

Our Maintenance Routine

- Vacuum chips after each job.

- Wipe rails and steel wheels weekly; avoid harsh solvents.

- Keep the T12 lead screw lightly lubricated with a dry film or suitable grease—less is more.

- Check pulley and belt tension periodically.

- Re-surface the spoilboard when pocket depths start to wander.

- Square check monthly: gantry parallelism and spindle tram.

Upgrades and Accessories We Appreciate

The Masuter 3S is already capable, but we love giving machines gifts like doting relatives.

65 mm Clamp and Router Upgrade Options

The included 65 mm spindle clamp means we can swap to a trim router later if we want more speed. A Makita-style router offers higher RPM, which can be helpful for tiny end mills in wood and plastics. We still like the stock 400W spindle for aluminum jobs due to its adequate torque and controlled speed range.

Offline Controller and Extension Kit

- Offline controller (B0DC6HHNH4): Run G-code without a computer attached. Peace of mind if our laptop is in the house streaming questionable documentaries.

- X-axis extension kit (B0D5HK72MP): Move into bigger signage and panel work as projects grow.

Workholding Staples

A threaded insert spoilboard, low-profile clamps, and a touch probe make a noticeable difference. The touch probe is a sanity-saver when zeroing aluminum stock with precision.

The Real-World Strengths

We won’t pretend every machine is perfect. We will say this one has strengths that make it stand out for its class and price.

What It Does Better Than We Expected

- Holds tolerances day-to-day without babying it.

- Cuts aluminum reliably with proper technique.

- Keeps motors honest with closed-loop feedback; fewer ruined parts from stall-induced wandering.

- Offers an intuitive controller box that doesn’t feel like a science fair project.

Where It Shows Its Limits

We owe it to future us to be honest.

The Sensible Caveats

- The 400W spindle is competent but not a monster. Large bits and aggressive cuts aren’t its thing.

- Z-height is enough for typical projects but not for tall fixturing or exotic setups.

- It’s still a benchtop CNC. Vibration and rigidity are excellent for its size, but it’s not a 2000-pound milling center.

- In aluminum, we plan our toolpaths and take our time. Wrong end mills plus reckless feeds equal broken feelings.

Troubleshooting: Our Checklist for Calm Recovery

When something doesn’t go right, we walk through these checks instead of blaming the coffee.

Our Quick Fix Routine

- Re-zero Z after tool changes, especially if we don’t have a fixed tool length setup.

- Check collet integrity. Worn collets slip under load and create ragged misery.

- Tighten wheel preload if axes start to chatter; not too tight or we’ll bind the motion.

- Inspect belts/pulleys for dust buildup. Clean and re-tension if necessary.

- Verify workholding. Most “machine” problems are actually “stock moved” problems.

- Confirm CAM settings: feed per tooth, stepover, and DOC often need small nudges.

Comparing It to Other Options

We’ve owned or tested a handful of desktop CNCs. The Masuter 3S inserts itself into a sweet spot we wish more machines hit.

Against Typical 3018-Class Machines

This isn’t a 3018 with dreams. It’s more rigid, more accurate, and more powerful with a larger working area. If we’ve outgrown a basic beginner machine, this is a serious jump in capability without jumping straight into industrial costs.

Against Higher-End Prosumer Rigs

Compared to premium units with ball screws and 1–2 kW spindles, the Masuter 3S won’t out-muscle them, but it also won’t demand our savings account. The closed-loop steppers and Z-axis rails give it a leg up over many belt-only, open-loop hobby rigs.

Who Should Buy This

We think of the FoxAlien Masuter 3S as the “grown-up starter” that doesn’t require a second mortgage. It suits:

- Makers and small shops wanting reliable accuracy and modest aluminum capability.

- Sign makers, panel engravers, and Etsy sellers who need consistency for batch work.

- Tinkerers who value mechanical quality but don’t want to spend a week just tuning.

If we’re building motorcycles out of billet or cutting thick steel, we’re shopping in a different aisle. If we’re doing woodworking with occasional aluminum, this is our lane.

What We Wish We Knew Before Starting

We would have ordered a better selection of single-flute cutters earlier. We also would have built a dust shoe right away. And we would have stopped pretending we’d never replace the spoilboard because it’s basically a sacrificial cutting diary we write in with end mills.

The Everyday Experience: Living With the Masuter 3S

We judge machines by whether we find reasons to use them or reasons to avoid them. This one is a yes machine. We look forward to projects because we trust the cuts and the workflow doesn’t make us swear at inanimate things.

Speed of Setup and Changeovers

Swapping bits and fixtures is quick. The controller’s shortcut keys help. We keep a small kit beside the machine: 3 mm and 4 mm Allen keys, collet wrenches, a brush, and an air puffer for chip clearing. The less we walk around the shop looking for tools, the more our projects finish the same day they begin.

Safety and Smart Practices We Stick To

We treat bits like they’re disposable. Dull tools cause problems that multiply like rabbits. We verify every toolpath’s start height and safe travel. We run a perimeter check in the air when we’re pushing clearances, especially with clamps that like to lurk.

Our Personal Rules

- No loose sleeves, no jewelry.

- Vac off before we stick our hands anywhere near the moving parts.

- Pause is not panic—if anything looks off, we hit it, reassess, and restart after calming the gremlins.

Support, Warranty, and Community

We reached out to FoxAlien with a setup question and received a timely, useful response. That’s the kind of support that helps when chips are flying and a deadline is looming. The community around the machine is active enough to get practical advice when we’re learning a new material or trying a neat trick someone else shared.

What We Expect Over the Long Run

The linear rails and steel wheels look built for many seasons of cutting. With basic maintenance, we fully expect this machine to hold its calibration and character. If something wears, it’s usually user serviceable and not a mysterious black box.

Cost, Value, and Return on Investment

ROI is more than money. It’s how much time we stop wasting on machines that need therapy. The Masuter 3S bought us time and confidence. We spent less energy troubleshooting and more time finishing work we wanted to show people.

What We Saved

- Fewer scrapped parts from step loss with closed-loop control.

- Less time sanding out chatter lines, which is basically community service for your forearms.

- Compatibility with common software kept us from buying niche licenses or getting stuck.

Pros and Cons at a Glance

We like tidy lists, even if they make us sound decisive.

What We Loved

- Closed-loop NEMA 23 steppers with real torque and correction.

- Dual linear rails on Z and T12 lead screw for excellent rigidity.

- 400W spindle that genuinely handles aluminum with sensible settings.

- Thoughtful controller box: shortcut buttons, dust-proof design.

- Strong frame and extra base supports for a flatter work area.

- Smooth, quiet motion with steel wheels and pulleys.

- Room to grow with X-axis extension and 65 mm clamp.

Where We Compromised

- Spindle power caps heavy cutting; use patience and proper tooling.

- Z clearance limits tall fixtures; plan Fixturing 101 ahead of time.

- It’s still a benchtop unit—don’t expect industrial metal removal rates.

Tips and Habits That Made Us Better

We collected these the hard way, so we’re sharing them like the shop elders we hope to become.

- Surface the spoilboard right after assembly.

- Tram the spindle lightly; it pays off in pocket bottoms that don’t look like topographical maps.

- Use single-flute cutters for aluminum and acrylic—they’re the miracle we didn’t know we needed.

- Keep a log of feeds and speeds that worked. We call ours the “Book of Not Screwing Up Twice.”

- Pause and clean chips during aluminum jobs; packed flutes are heartbreak waiting to happen.

What Makes Closed-Loop So Important Here

We used to think stepper motor drama was just part of life. The closed-loop system changed our expectations. On longer jobs, especially with repetitive operations, the machine holds position like it’s sworn an oath. We don’t re-home mid-job or cross fingers with every restart.

You Can Hear the Difference

It’s not just less noise; it’s smoother transitions and fewer twitchy corrections. On tight curves, the machine moves with grace rather than lurching like it’s avoiding small ghosts.

Design Choices That Won Us Over

It’s the little things. The extra base frame supports keep the work surface true. The dust-proof controller is practical, not marketing fluff. The 65 mm clamp means FoxAlien understands we’ll want to grow into other spindle options. And the Z-axis rail setup is simply the right call for a machine that claims accuracy.

The Work Area Sweet Spot

We’ve used machines with more space and machines with less. This 400 mm square envelope hits that “do 90% of our projects” sweet spot. The extension option keeps it from being a corner we paint ourselves into.

The Best Audience for This Machine

If we’re a maker who wants boutique-quality results without boutique-level pricing, the Masuter 3S makes a solid case. We saw the most joy in:

- Woodworkers needing precise signs and inlays.

- Electronics builders cutting enclosures and acrylic panels.

- Hobbyists producing metal brackets or small fixtures without a Bridgeport in the garage.

We might outgrow the spindle one day, but the frame and mechanics are a reliable base that can evolve with us.

A Note on Tooling

We’ve learned that tooling is a relationship, not a fling. We spend a little more on good carbide, and we get a lot in return: cleaner cuts, less heat, longer life. We match bit geometry to material: upcut for wood, O-flute for plastics, single-flute for aluminum. And we change dull tools before they start negotiating their retirement with our cut quality.

Calibrating Expectations and the Machine

We calibrated steps-per-mm after assembly. We measured real-world travel distances and fine-tuned in firmware. We squared the gantry and locked the adjustments. That short calibration session gifted us accuracy that stayed accurate.

The Payoff of Patience

Precision doesn’t come from pressing “Start Harder.” It comes from setup. The Masuter 3S rewards setup with results that look like we paid someone else to do it.

Environmental Considerations

We kept the workspace temperature stable because expansion and contraction are real. We placed the machine on a level, non-flexing surface. We bolted the frame to a torsion box, and our cuts stopped behaving like a haunted carnival ride.

Keeping Clean

Dust isn’t just annoying; it gunked up our prior machines and started the slow march toward slop. The dust-proof controller here and a weekly wipe-down routine kept motion smooth and conscience clear.

FAQs We Asked Ourselves

Because we certainly did.

Can it cut aluminum reliably?

Yes, with the right bits, shallow passes, and chip evacuation. We prefer single-flute cutters, light lubricant or mist, and conservative stepdowns. It’s not a big mill, but it makes aluminum brackets and plates that fit and look good.

Does it need a computer to run?

It can, but it doesn’t have to. The controller supports FoxAlien’s offline controller (B0DC6HHNH4), letting us run G-code from a USB stick. We still like using a sender for live adjustments.

What software works?

Anything that outputs standard GRBL-friendly G-code: Fusion 360 CAM, VCarve, Carbide Create, Easel. G-code senders like Candle and UGS worked smoothly for us.

How accurate is it, really?

We measured engraving accuracy within 0.05 mm after careful setup. Repeatability stayed tight across sessions, which gives us the confidence to run jobs without shadowing the spindle like a nervous parent.

How noisy is the spindle?

Quieter than a trim router, louder than quiet. Cutting noise depends on material and tooling. With decent bits and proper settings, it’s workshop-appropriate. Hearing protection is still smart.

Should we upgrade to a trim router?

If we need higher RPMs for tiny bits in wood or plastics, a 65 mm router upgrade can help. For aluminum, we actually like the stock 400W spindle’s torque and control.

The Verdict We Can Live With

The FoxAlien Masuter 3S CNC Router Machine with NEMA 23 Closed-Loop Stepper Motor and a 400W spindle hits a rare balance. It’s serious without being moody. It’s compact without being flimsy. It’s accurate without demanding a monk’s vow of silence during setup. The closed-loop motors and Z-axis rails do the heavy lifting for precision, while the controller and frame design support a workflow we find refreshingly civilized.

Our Bottom Line

- For makers graduating from entry-level kits, it’s a meaningful upgrade.

- For small-batch production in wood, acrylic, and aluminum, it’s dependable.

- For those who love tinkering, it’s tunable without being finicky.

We kept looking for reasons not to like it, and the machine kept cutting clean, quiet lines through our skepticism.

Final Thoughts We Whisper to Other Makers

We’ve had machines that needed hand-holding and machines that needed holy water. The Masuter 3S asked for neither. It wanted a careful assembly, a measured calibration, and a sensible approach to materials. In return, it handed us results that were repeatable and, honestly, a little bit proud. The day we cut a run of aluminum brackets without a single hiccup, we realized it had quietly shifted from “new tool” to “shop standard.”

If our wishlist includes accuracy, closed-loop confidence, a strong Z-axis, and a spindle that’s better than a sticker on a box, this is the machine we’d suggest to ourselves if we were buying again tomorrow. And that, for us, is the sharpest compliment we can give.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.