Have we finally found a desktop CNC that treats our nerves, projects, and budget with equal respect?

Quick note before we get started: we can’t write in the exact voice of any specific author, but we’ll keep things witty, conversational, and candid—like a friend who admits to their mistakes and then tells you exactly how to avoid them.

Why We Bought the FoxAlien CNC Router Machine XE-PRO

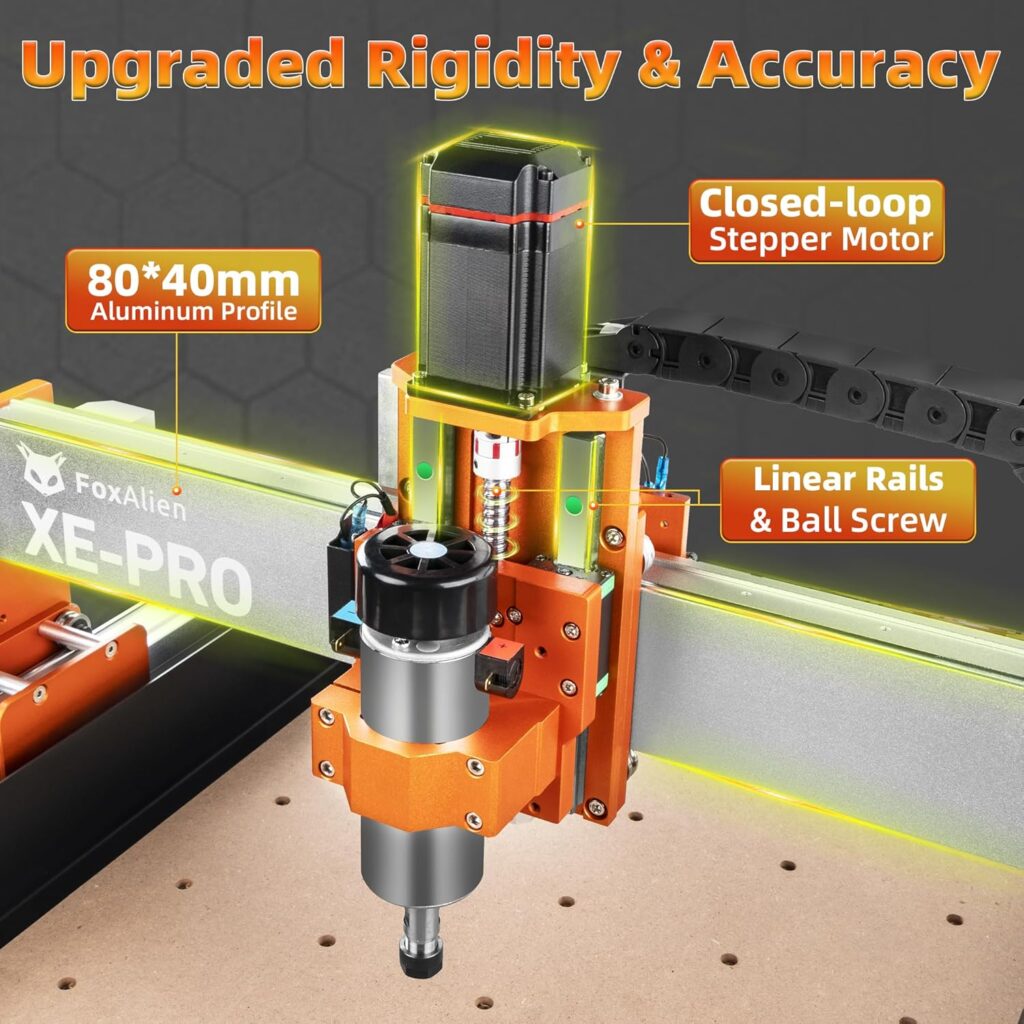

We wanted a machine that could cut wood cleanly, mill aluminum without theatrics, and finish a job without deciding to throw a tantrum halfway through. Our shortlist looked like a support group for makers who have known the heartbreak of missed steps and hairline chatter marks. The FoxAlien CNC Router Machine XE-PRO with Ball Screws, 400W Spindle, 3-Axis, and an upgrade path to linear rails kept coming up as the sensible choice for people who want a serious hobbyist machine that feels surprisingly professional.

We’re not trying to replace a full-size industrial mill; we just want repeatable accuracy, a straightforward setup, and a machine that won’t judge us when we clamp plywood with more hope than planning. The XE-PRO, on paper, promised all of that with less drama.

FoxAlien CNC Router Machine XE-PRO with Ball Screws, 400W Spindle 3-Axis Engraving Milling Machine for Wood Aluminum Cutting Upgradable to Linear Rails

EUR1205.91 In Stock

Who This CNC Is For

We think the XE-PRO fits a sweet spot. It’s for us—the folks who care about accuracy but aren’t ready to pour a concrete base in the garage. It’s for anyone who wants to mill hardwood, carve signs, prototype parts, make jigs, and cut aluminum plates without chewing up bits or ruining weekends.

If you’ve outgrown the tiny “first CNC” machines but aren’t stepping into industrial budgets, this strikes a balance. The closed-loop motors and ball screws help smooth out mistakes we didn’t mean to make. And the linear rail upgrade path means we’re not backed into a corner when we get ambitious.

At-a-Glance Specifications and Highlights

We like seeing the essentials laid out clearly. Here’s what stood out to us as we put the XE-PRO through its paces.

| Feature | Details |

|---|---|

| Motion Motors | Four NEMA23 closed-loop stepper motors |

| Max Travel Speed | Up to 5000 mm/min (faster and smoother than typical open-loop setups) |

| Drive System | 1204 ball screws on X, Y, and Z axes |

| Z-Axis Rigidity | Dual linear rails on Z for added stiffness |

| Upgrade Path | Upgradable to linear rails on X and Y (exclusive design) |

| Spindle Included | 400W spindle |

| Spindle Clamps | 52 mm, 65 mm, and 69 mm included |

| Control | GRBL-based (widely supported) |

| Assembly Time | About 25–30 minutes (main parts pre-assembled) |

| Compatibility | Works with FoxAlien engraving power modules, common trim routers, and popular CAM workflows |

| Noise | Lower than many open-loop hobby CNCs due to closed-loop motors (subjectively quieter) |

We appreciate that this isn’t a throwaway machine. It’s a platform. You can start with what’s included and then adapt as your skills and projects grow.

Unboxing and First Impressions

We always judge a machine by how it shows up. The XE-PRO arrived packaged as though someone at FoxAlien has watched too many shipping horror stories and vowed to prevent a sequel. The main assemblies are pre-built, which meant fewer chances for our assembly “creativity” to cause future alignment headaches.

Right away we noticed the frame felt substantial and the wiring harnesses were labeled in a way that didn’t ask us to be mind readers. The inclusion of multiple spindle clamps told us this machine wasn’t married to one setup. It’s genuinely open to the “use what you’ve got” approach—assuming what you’ve got fits a 52, 65, or 69 mm clamp.

Setup and Assembly: 30 Minutes That Actually Felt Like 30 Minutes

The manufacturer promises 25–30 minutes, which usually translates to an afternoon and a bag of zip ties. To our surprise, this was about as quick as advertised. The base and gantry were already together in meaningful ways, so our job was to square, tighten, and connect.

- We leveled our bench and checked the frame for squareness before tightening.

- We made sure the ball screw couplers had no play and all set screws were snug.

- We routed cables carefully to avoid snags and kept them away from moving components.

We recommend taking those extra ten minutes to double-check tram and tighten everything after the first power-on. That small investment pays off with better surface finishes.

Design and Build Quality: Confidence Without Arrogance

We’ve owned CNCs that looked great online and started to shimmy in person. The XE-PRO’s design feels thought-out. The use of ball screws on all three axes is a major step up from belt-driven hobby machines, and the dual linear rails on the Z axis really do reduce flex where flex hurts most—right where you’re applying force into the material.

The frame is solid. Nothing wobbled under normal cutting loads, and the overall stiffness inspires trust. You can hear the difference when the spindle meets the work—less vibration, more consistency. We love the quiet confidence of closed-loop NEMA23s. The machine moves smoothly, without that squeal of panic we’ve come to associate with open-loop stepper struggle.

Motion System: Closed-Loop NEMA23s and 1204 Ball Screws

This is the heart of the XE-PRO. Closed-loop stepper motors are like having a friend who actually texts you back. They know where they’re supposed to be and correct themselves if something goes sideways—literally. For us, that means fewer missed steps, smoother curves, and better chances that the 45-minute job we ran while checking our phone didn’t shift off by half a millimeter.

The 1204 ball screws (12 mm diameter, 4 mm lead) on X, Y, and Z are another big win. Ball screws convert motor torque into linear motion with high efficiency and minimal backlash. In real-life terms: less wandering during direction changes and fewer mystery ridges in your finish passes. Combine that with a 5000 mm/min max speed and we get a machine that moves smartly, not just quickly.

Z-Axis Rigidity and the Linear Rails Path on XY

The Z axis comes with dual linear rails out of the box. That matters. We’ve learned that the weak link in many hobby machines is the Z—where the downforce is concentrated, and where poor design turns into chatter and deflection. The XE-PRO’s Z-axis setup absorbed lateral forces nicely, especially noticeable when running aluminum with conservative step-downs.

And then there’s the upgrade path: you can convert the X and Y axes to linear rails. That’s an exclusive and very welcome touch. It means the machine can follow your ambition. Start with ball screws, then advance to linear rails for an even stiffer, more industrial feel. It’s a practical way to grow into tighter tolerances without replacing the whole platform.

Spindle Options: 52, 65, and 69 mm Clamps Included

We’re indecisive, and the XE-PRO supports that. The included 400W spindle works for a lot of tasks—woods, plastics, PCB work, and careful aluminum profiles. But the moment we want to push harder, we can swap in a larger trim router or different spindle using the included 65 and 69 mm clamps.

We like that it also supports FoxAlien engraving power modules, which opens up more project types and workflows. Having swappable spindle mounts saves time and gives us the freedom to match the tool to the job, not the other way around.

Control and Software: GRBL Done Right

The XE-PRO is GRBL-based, which is good news because GRBL has become the lingua franca of hobby CNC. CAM tools like Fusion 360, Carveco, VCarve, Carbide Create, and open-source options can all output GRBL-compatible g-code. This means the software learning curve is driven by your CAM of choice, not a proprietary vendor lock.

We prefer this approach. We can change post-processors and CAM strategies without feeling trapped. Also, because GRBL is so widely used, the online help is abundant. If we have a question about feed rates, post processors, or arc commands, someone has solved it and posted about it.

Performance in Wood: Smooth, Fast, and Predictable

In hardwoods like walnut and maple, the XE-PRO cut beautifully. We ran profile passes at moderate speeds with 1/4-inch upcut and compression bits and were impressed by the edge quality. The machine took pockets and contours in stride. We noticed the closed-loop motion showed its strength in contours—less risk of flat spots and more confidence in tight radii.

For softwoods, we actually had to remind ourselves not to get greedy. Just because a machine can move fast doesn’t mean the bit and material always agree. But with the right chip loads, we zipped through runs that used to make us nervous. The 400W spindle did fine on most of our standard wood projects. If we were doing production-level hardwood work, we’d consider upgrading to a more powerful router or spindle down the road—and the XE-PRO makes that easy.

Performance in Plastics: More Reliable Than Most

Plastics can be moody, especially acrylic. They want a clean cut and clear chips. The XE-PRO paired with sharp O-flutes handled acrylic at reasonable feed rates and proper step-downs. The motion precision helped us avoid dwell and melting. For polycarbonate, we dialed back forces to prevent edge welding, and the results were crisp.

Our advice: keep your chips flying. The included 400W spindle can do good work here, and the rigidity of the machine means fewer random stutters that cause heat buildup.

Performance in Aluminum: Respect the Metal, Get Respect Back

Let’s be clear: this isn’t a vertical machining center. But it’s also not a toy. With proper feeds and coolant (or at least a misting of lubricant), we milled 6061 aluminum plate with success. Taking light passes, using 3-flute end mills, and paying attention to chip evacuation gave us accurate parts without drama.

We noticed the Z-axis dual rails keeping things steady during entry moves, which is where lesser machines tend to flinch. The closed-loop motors helped with consistent motion and fewer hiccups on adaptive strategies. If you’re used to babying a belt-driven CNC through aluminum, this will feel like a welcome shift in confidence.

Speed, Noise, and Smoothness

We don’t have a sound lab, but our ears know the difference between noisy motors and well-behaved ones. The XE-PRO’s closed-loop NEMA23s run smoother and, in our experience, subjectively quieter than many open-loop setups. The advertised top speed of 5000 mm/min is respectable, and the machine moves with a kind of poised assurance that reassured us even during air cuts.

Actual cutting speeds depend on tool, material, and strategy. But the lack of missed steps and the overall stability meant we weren’t constantly undercutting speeds out of fear. That ease translates into better workflow and fewer late-night toolpath edits.

Accuracy and Repeatability: The Practical Stuff

Specs are comforting, but repeatability is what we live with. After tramming and squaring, we ran a series of test cuts and hole arrays, then checked with calipers and gauge blocks. The results were consistent enough for our jigs and small mechanical parts. More importantly, repeated jobs lined up exactly where we expected them to, even after re-zeroing and power cycling.

The ball screws reduce backlash, but remember: no consumer machine is immune to clamping issues or poorly set CAM. We got our best results by treating workholding as part of the machine, not an afterthought.

Spoilboard and Workholding Tips

We found that a properly surfaced spoilboard pays dividends. We added T-track and threaded inserts to cover more holding strategies. Because the machine is rigid, we dared to use smaller clamps for tighter areas without worrying the whole setup would shimmy.

Here’s what worked best for us:

- Surfacing the spoilboard right after assembly to ensure squareness to the spindle.

- Using cam clamps for quick jobs and toe clamps for aluminum fixtures.

- Blue tape and CA glue for small wood parts where clamps would be in the toolpath.

- Adding a dust shoe to keep chips from building under clamps and creating false flatness.

Software Workflow That Kept Us Sane

Our workflow settled into CAD in Fusion 360, CAM toolpaths with GRBL post-processing, and a sender like Candle or UGS. Nothing fancy, nothing locked-in. The big win is confidence. We could iterate quickly and know the machine would do what we told it to, not what it felt like.

We leaned on online tutorials for GRBL settings and general CNC best practices. Because the XE-PRO follows established standards, those resources apply well.

Safety and Reliability in Daily Use

We’re relaxed when our machine behaves. The XE-PRO inspired confidence. We still wear eye and ear protection and use dust collection—especially with MDF—but we didn’t feel like we were tap dancing on a cat’s tail. Closed-loop motors offset a lot of the small mishaps that cause missed steps, which in our book improves both safety and sanity.

We also appreciate that the machine is friendly to upgrades like emergency stops, drag chains, and higher-end spindle controls. We like knowing we can tailor the setup to our comfort level over time.

Maintenance and Care: The Boring That Saves Your Bits

A little care goes a long way. Here are our maintenance habits:

- Keep the ball screws clean and lightly lubricated. Debris is the enemy of smooth motion.

- Check couplers and fasteners after the first few hours of operation.

- Surface the spoilboard when you see ridges or glue residue building up.

- Keep cables clear of travel paths and add guides if needed.

With that, the XE-PRO kept humming. We didn’t encounter any surprises beyond the usual “Oh, that clamp was too close” moments that we only admit to in reviews like this.

Upgrades and Future-Proofing: Linear Rails on XY

The XY linear rail upgrade option is what made us comfortable investing here. We like machines that won’t make us start over in a year. As our projects demanded tighter tolerances on larger patterns, upgrading X and Y to linear rails became a realistic path. With linear rails, we expect even better rigidity, smoother motion, and improved finishes—especially on aluminum and deep hardwood operations.

Pair that with the ability to swap in a more powerful router or spindle and this platform grows with you, not away from you.

Community, Support, and Documentation

Because this machine is GRBL-based and FoxAlien has an established user base, we didn’t feel like pioneers headed into the unknown. Tutorials abound, user groups share settings and projects, and the general vibe is supportive. We saw clear assembly guidance and sensible wiring layouts that spared us from guesswork.

If you’re brand new to CNC, the learning curve is still real. But compared to many machines we’ve used, the XE-PRO makes it feel manageable. When we got stuck, we didn’t stay stuck.

Projects We Ran to Put It Through Its Paces

We don’t trust any CNC until it survives our specific brand of tinkering. Here’s what we ran:

- Hardwood sign with V-carving and pocketing: Clean lines and crisp corners.

- Aluminum bracket with precise hole spacing: Minimal deflection and accurate placement.

- Acrylic panel cut with O-flute: Smooth edges without melting.

- MDF jig plate with threaded inserts: Repeated patterns aligned perfectly across the grid.

Each project taught us something useful. Mostly, it taught us that the XE-PRO behaves predictably if we do our part with fixturing and CAM.

Everyday Quality-of-Life Details

It’s the little things that add up when you’re in the shop:

- Wiring that didn’t fight us during assembly.

- Clamps sized for common spindles and routers, making swaps painless.

- Motion that felt confident and repeatable.

- A frame that doesn’t flinch when we apply lateral cutting forces.

This is the kind of machine that encourages us to try more and fuss less.

Pros and Cons We Actually Care About

We made a list, argued with ourselves, then settled on this.

Pros:

- Closed-loop NEMA23 motors for smoother, more reliable motion.

- 1204 ball screws on all axes reduce backlash and improve cut quality.

- Dual linear rails on Z increase stiffness where it counts.

- Upgradable X and Y to linear rails—the path to “industrial grade” feel at home.

- Includes 52, 65, and 69 mm spindle clamps for flexibility.

- GRBL-based control means a huge ecosystem of CAM tools and tutorials.

- Quick assembly with pre-assembled main components.

Cons:

- The included 400W spindle is fine for many jobs, but aluminum or hardwood at higher productivity may benefit from a stronger spindle or router.

- You’ll want to invest in quality end mills, dust collection, and workholding to match the machine’s potential.

- Linear rail upgrade adds cost, though it’s a worthwhile path for serious users.

- As with any desktop CNC, stock and workholding will make or break your results—you can’t cut corners there.

What We’d Change If We Were in Charge

We’re greedy about rigidity and convenience. We’d love linear rails on XY from day one, even if it raised the base price. We’d also sign up for a plug-and-play dust shoe option tailored to the included spindle and common routers. These are more wishlist items than complaints, but we’re confident many users would pay for the extra polish.

Comparing It to Common Alternatives

Without calling out specific models, here’s how we’d generalize:

- Compared to small belt-driven hobby CNCs: The XE-PRO feels like a class upgrade. Ball screws and closed-loop motors cut cleaner and more reliably.

- Compared to mid-range hobby machines with aluminum frames: The XE-PRO competes well on rigidity thanks to the Z-axis rails and ball screws, and the linear rail upgrade path on XY tips the scales toward long-term value.

- Compared to big-ticket machines: You won’t beat industrial rigidity or power with a desktop unit, but for its size and price bracket, the XE-PRO holds its own in precision-focused workflows.

If your main output is signs, inlays, jigs, and small aluminum fixtures or plates, this makes a compelling case, especially if you plan to upgrade the spindle later.

Tips for First-Time Users

We’ve made enough mistakes to have strong opinions:

- Tram early and re-check periodically. Surface finish rewards you for it.

- Use quality end mills appropriate for your material—compression for plywood, O-flute for plastics, 3-flute for aluminum.

- Don’t skip chip evacuation. A small vacuum or dust shoe helps more than you’d expect.

- Keep your toolpaths honest. Let adaptive strategies do the heavy lifting and use finishing passes.

- Test feed and speed on scrap. Wisdom is expensive; scrap is cheap.

Troubleshooting That Saved Us Time

When cuts weren’t perfect, we checked these:

- Are the couplers tight and the ball screws clean?

- Is the workpiece truly flat and properly clamped?

- Is the tool sharp and appropriate for the material?

- Are we using reasonable step-downs and chip loads?

- Are GRBL settings correct for the toolpath’s demands?

Usually, the fix was not glamorous: cleaning, tightening, or reducing aggression in the toolpath. The XE-PRO’s closed-loop system kept us out of worst-case scenarios like lost steps that ruin parts in the last minute.

Long-Term Value: Why This Machine Still Makes Sense Later

We think of machines not just by what they can do now, but what they encourage us to do next. The XE-PRO encourages growth by offering a clear, supported upgrade path: go from ball screws and a 400W spindle to XY linear rails and a stouter spindle or router. It’s not throwing everything at you upfront; it’s building a platform you can grow into.

That kind of value matters in home shops and small studios. We don’t always know where our projects are heading, but we do know we’d rather have a machine that adapts with us.

Safety Add-Ons We Recommend

We’re not safety crusaders, but we’ve learned the hard way:

- Add an emergency stop that’s easy to hit.

- Wear eye protection and use dust collection, especially with MDF.

- Avoid long unattended runs. Closed-loop helps, but vigilance wins the day.

- Keep flammables away if you’re using mist or lubricant on aluminum.

The XE-PRO’s calm, predictable motion helps us feel comfortable, but we still respect the spindle.

Sample Projects That Shine on the XE-PRO

Some ideas for projects that fit the machine’s strengths:

- Precision jigs and fixtures for woodworking.

- Hardwood signs with layered pockets and inlays.

- Aluminum electronics plates with accurate hole patterns.

- Knife scales and tool handles with compound contours.

- Acrylic panels with clean edges and engraved text.

- MDF punch boards, assembly jigs, and modular clamping systems.

These are the kinds of projects that reward a rigid machine with good repeatability, which is exactly where the XE-PRO lives.

A Day in the Shop with the XE-PRO

Our favorite test day went like this: We surfaced the spoilboard in the morning, cut a set of hardwood drawer pulls after lunch, and milled a small aluminum bracket before dinner. Somewhere in there, we swapped to a different spindle clamp without incident, updated a Fusion toolpath, and vacuumed chips like we meant it.

It was strangely uneventful, which is high praise for a machine that could have chosen to be moody. We value machines that make our days feel boring in the best way.

Costs Beyond the Machine

We’ll say the quiet part out loud: you’ll likely spend money on:

- Quality end mills for your materials.

- Dust collection or at least a decent shop vac.

- A better spindle or trim router down the line if you want more aggressive cuts.

- Workholding—T-tracks, clamps, threaded inserts, and spoilboard material.

- A mist system or lubricant for aluminum.

That’s not unique to the XE-PRO, but it’s good to plan for it so you don’t blame the machine for gaps that accessories fill.

The 400W Spindle: Solid Starter, Sensible Limits

We like the included spindle for what it is: a capable starter that handles most wood, plastic, and light aluminum work. For sustained heavy hardwood passes or more demanding aluminum strategies, upgrading to a beefier router or spindle pays off. The good news is that the XE-PRO makes this simple, and the included clamps cover the common form factors.

We ran plenty of jobs on the 400W spindle and got excellent results by choosing appropriate tools and feeds. We felt no urgent need to upgrade on day one.

What the Upgrade to Linear Rails on XY Means in Practice

If you’re on the fence about the linear rails upgrade, here’s how we think it translates to real outcomes:

- Tighter tolerances and smoother motion in long runs.

- Better performance on materials that punish flex, like hardwoods and aluminum.

- Reduced reliance on extra-conservative toolpaths to compensate for deflection.

- A general feel of “the machine is in control,” especially on long diagonals and arcs.

It’s not mandatory for good work. It’s the runway for great work as your projects get more ambitious.

Our Setup Checklist for Consistency

Before starting a job, we walk through this:

- Check tool tightness and runout.

- Confirm workholding and double-check clamp clearance in the toolpath.

- Zero carefully and set safe Z.

- Vacuum the spoilboard to avoid debris-induced height inconsistencies.

- Confirm GRBL settings match the job’s scale and speeds.

The XE-PRO rewards consistency, and this checklist helped us keep results repeatable.

Where the XE-PRO Surprised Us

We expected to like the ball screws and closed-loop motors. We didn’t expect to feel such a distinct “calm” in operation. Carving circles, pocketing, and stepping through finishing passes all felt composed. We also appreciated how easy the machine was to assemble without wondering whether we’d made an unfixable alignment mistake.

It’s nice when a machine performs like a reliable coworker—present, steady, and not fishing for compliments.

Where It Didn’t

No machine solves every problem. We wanted more raw spindle power at times. That’s a limitation of the included 400W spindle rather than the motion platform. Also, as with any desktop CNC, you don’t escape the reality that workholding and chip control make or break a cut.

That said, these were compromises we knew going in, and the XE-PRO’s upgrade path addresses them gracefully.

The Learning Curve: Manageable and Worth It

If this is your first CNC, there’s a lot to learn—CAD, CAM, feeds, speeds, clamping, work offsets. The good news is that GRBL’s ubiquity means answers are easy to find, and the XE-PRO’s consistent behavior makes it easier to understand what went wrong when something goes wrong.

We recommend starting with simple projects in soft materials, then stepping into hardwoods, then aluminum when you’re ready. The machine will be ready before you are; the rest is practice.

Why Closed-Loop Matters Day to Day

Closed-loop motion changed how nervous we were about long jobs. We still keep an eye on the cut, but we aren’t bracing for the heartbreak of a mid-job skip that ruins a part at 95% completion. The feedback loop helps the motors stay on track and correct small errors. That alone justified the upgrade over cheaper open-loop machines we’ve used.

It’s hard to quantify peace of mind, but when you have it, you notice.

Final Calibration: Getting That Last 2%

Once we had a few hours on the machine, we:

- Re-trammed the spindle and re-surfaced the spoilboard.

- Checked machine squareness by cutting test squares and measuring diagonals.

- Adjusted CAM finishing passes to take very light cuts for cleaner edges.

That last 2% of polish is where the XE-PRO really shows its potential. Ball screws and a rigid Z axis reward careful setup with beautifully consistent finishes.

The Kind of Shop That Benefits Most

We picture the XE-PRO slotting into:

- Home shops where precision projects are a recurring obsession.

- Small studios that need prototypes and fixtures without outsourcing every part.

- Schools and makerspaces where a reliable, teachable CNC is required.

- Etsy and small-business workflows producing custom signs, plaques, and small aluminum components.

It’s a flexible machine that doesn’t punish ambition, which makes it a friendly long-term companion.

Our Closing Take on the FoxAlien CNC Router Machine XE-PRO

We bought the XE-PRO because we wanted a desktop CNC that felt like a grown-up. We stayed with it because it proved trustworthy. The combination of closed-loop NEMA23 motors, 1204 ball screws on all axes, and dual linear rails on the Z axis creates a motion platform that feels precise and steady. Add in a fast max speed, GRBL compatibility, upgrade options for XY linear rails, and a thoughtful bundle of spindle clamps, and we get a machine that doesn’t box us in.

Is the included 400W spindle the last word? No. But it’s an honest starter that handles more than you might expect with smart toolpaths and sharp bits. As our needs grow, the XE-PRO lets us upgrade intelligently without starting over.

In the end, our workshop felt calmer, our projects looked sharper, and our evenings didn’t end with us grumbling at misplaced decimals. The FoxAlien XE-PRO earned our confidence by doing what we asked, job after job, without making a spectacle of itself. For a desktop CNC, that’s the highest praise we can give.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.