Have you ever stood in a factory and felt as if the machinery was secretly gossiping about your production schedule?

Fabrication Intelligence As A Competitive Advantage

You’re reading about a concept that turns machines, data, and humans into a single, gossiping organism that actually helps you make better decisions. This article will unpack how fabrication intelligence becomes a strategic edge you can measure, manage, and—if you are lucky—brag about at an industry dinner.

What you should expect from this article

You’ll get definitions, practical steps, real-world scenarios, and a few wry observations about how your procurement manager and your newest predictive model are probably trying to replace each other. The focus is on helping you move from curiosity to implementation with less confusion and fewer Excel night terrors.

What is Fabrication Intelligence?

Fabrication intelligence is the practice of applying advanced analytics, machine learning, and contextualized domain knowledge to manufacturing and fabrication processes. You can think of it as the brain that sits above your shop floor, learning from every weld, cut, and delay, and whispering suggestions that actually reduce waste and improve throughput.

The core idea in plain terms

You feed the system data from machines, sensors, ERP, and people, and it feeds you back insights that are actionable rather than inscrutable. This is not just a dashboard full of pretty charts; it’s a system that helps you change outcomes.

Why fabrication intelligence matters to you

If you are trying to beat competitors on cost, quality, or lead time, fabrication intelligence gives you a way to do that without resorting to heroic overtime or outsourcing to regions with questionable infrastructure. It lets you optimize assets, predict failures, standardize best practices, and make your operations less dependent on tribal knowledge.

The strategic upside

You’ll be able to reduce cycle times, lower scrap, and improve first-pass yield while freeing your skilled people from repetitive troubleshooting. In short, you’re buying predictability, and investors love predictability.

Key components of a fabrication intelligence system

A fabrication intelligence stack is composed of data ingestion, storage, analytics, machine learning, visualization, and integration layers that tie into your existing systems. Each component must be chosen to suit your scale, domain complexity, and tolerance for change.

Components explained briefly

You need reliable data capture (sensors, PLCs, MES), a place to store and model the data, analytics engines to generate insights, and interfaces so the people on the floor can act on those insights. Security and governance are not optional; they are the seatbelts.

| Component | What it does | Why it matters |

|---|---|---|

| Data capture | Collects signals from machines, PLCs, sensors, and manual inputs | Without data you have opinions, not intelligence |

| Data storage & integration | Centralizes and normalizes data from disparate sources | Enables historical analysis and correlation |

| Analytics & ML | Generates predictive and prescriptive models | Turns raw data into actions |

| Visualization & HMI | Presents insights in usable formats for operators and managers | Ensures adoption and fast reaction |

| Integration & orchestration | Connects intelligence to control systems, ERP, and workflows | Enables automated or semi-automated response |

| Security & governance | Ensures data integrity and compliance | Protects IP and builds trust across teams |

How fabrication intelligence creates competitive advantage

You get advantages from speed, cost, quality, and flexibility. When your production system signals problems before they become crises, you win on delivery. When you reduce rework, your margins improve. When you identify best practices and replicate them across sites, your quality becomes a brand asset.

Tangible benefits you’ll feel

Expect fewer late-night firefighting sessions, shorter lead times, fewer expedited shipments, and a clearer path to continuous improvement. You’ll also find new negotiating leverage when quoting customers because your confidence in delivery becomes quantifiable.

Typical use cases and examples

There are dozens of use cases, ranging from predictive maintenance to process optimization, real-time quality monitoring, and dynamic scheduling. You can start small on a single critical asset and scale to line-wide or plant-wide intelligence.

Use cases you can pilot this quarter

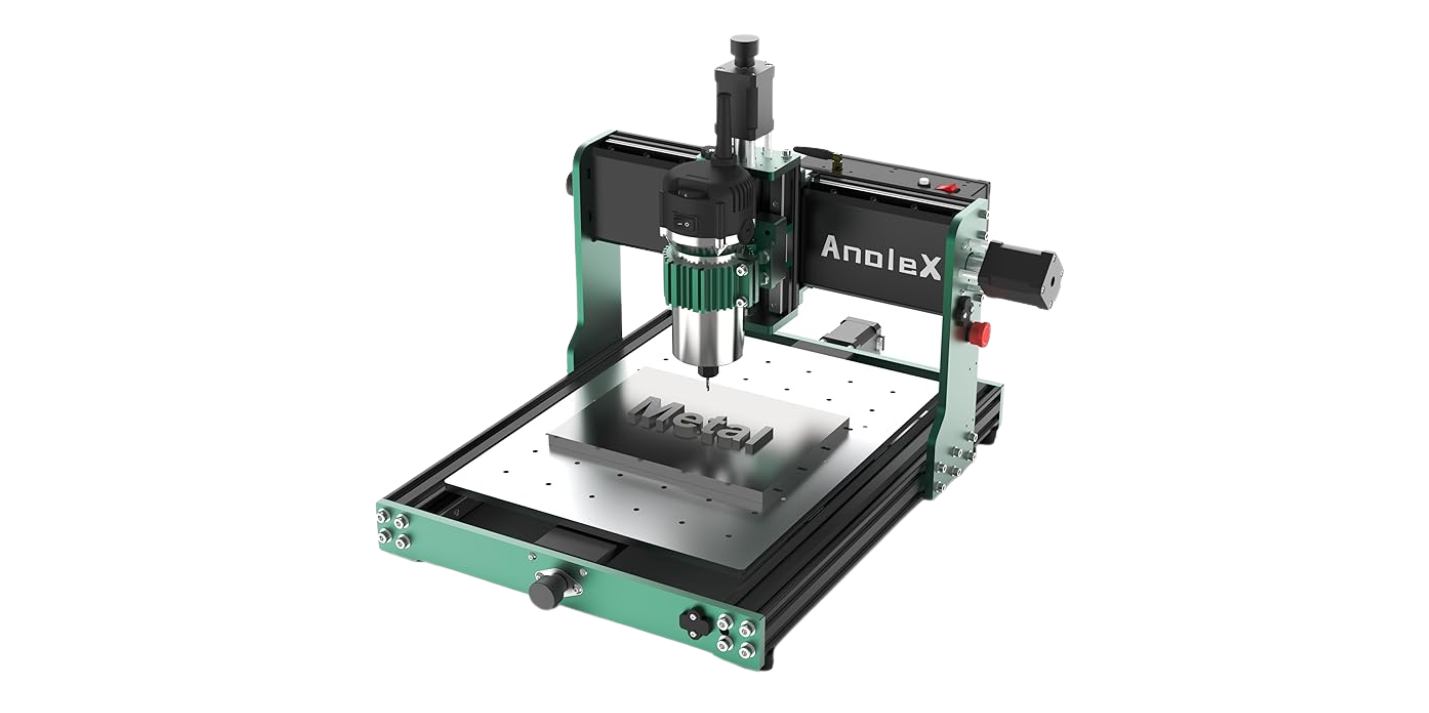

- Predictive maintenance to reduce unplanned downtime. Two sentences: You place sensors on spindle motors or hydraulics and train models to detect anomalous vibration or temperature patterns. The models give you maintenance windows instead of surprises.

- Real-time quality inspection using vision and ML. Two sentences: Cameras and models detect defects earlier than human inspection, reducing scrap and rework. You gain consistent quality control even during shift changes and staffing shortages.

- Process parameter optimization for consistent output. Two sentences: Models learn which combinations of temperature, pressure, and cycle time yield the best results. That reduces variability and increases first-pass yield.

Technologies that underpin fabrication intelligence

You’ll encounter IoT devices, edge computing, cloud platforms, time-series databases, ML frameworks, and integration middleware. Choosing technology is less about novelty and more about interoperability and long-term maintainability.

How to choose technologies

Pick technologies that match your operational tempo—edge for low-latency control, cloud for heavy analytics and historical models—and prioritize open standards to avoid vendor lock-in. Also, evaluate vendor support for industrial protocols and cybersecurity features.

Data you’ll need and where to get it

You’ll use time-series sensor data, event logs, process parameters, quality inspection results, maintenance records, and ERP data about orders and supply. If you can’t access this data reliably, the intelligence will be incomplete and occasionally misleading.

Gathering data without breaking the factory

Start by mapping data sources and understanding timestamps and clocks—time alignment is hugely underrated. Work with plant engineers to install gateways for legacy equipment and implement lightweight tagging on manual steps to capture human inputs.

Metrics and KPIs to measure success

You’ll want a mix of operational and business KPIs to prove value. Operational metrics show immediate improvements; business metrics show strategic impact.

Suggested KPIs to track

- Overall Equipment Effectiveness (OEE): Two sentences: This tells you utilization, performance, and quality all in one number. Use it to quantify improvements across sites.

- Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR): Two sentences: These indicate reliability and maintenance effectiveness. Reduced MTTR shows your maintenance processes are working.

- Scrap rate and rework cost: Two sentences: Show direct financial impacts of quality improvements. Lower scrap increases margins immediately.

- Lead time variability and on-time delivery: Two sentences: Better predictability improves customer satisfaction and reduces premium shipping costs.

- Cost per unit: Two sentences: The bottom-line metric that ties intelligence back to profitability. Use it in ROI calculations for stakeholder buy-in.

| KPI | Why it matters | Typical target |

|---|---|---|

| OEE | Consolidates availability, performance, and quality | +5–15% improvement in 6–12 months |

| MTBF / MTTR | Measures equipment reliability | MTTR |