Have we met a desktop CNC that behaves more like a polite roommate than a finicky houseguest?

What Is the CNCTOPBAOS CNC 3018-PRO-MAX?

We’re talking about a compact, beginner-friendly CNC router that fits on a desk and doesn’t demand a garage or a mortgage refinance. The CNCTOPBAOS CNC 3018-PRO-MAX gives us a 30 x 18 x 4.5 cm working area (about 11.8 x 7.1 x 1.8 inches) inside a sturdy 42 x 35 x 27 cm frame.

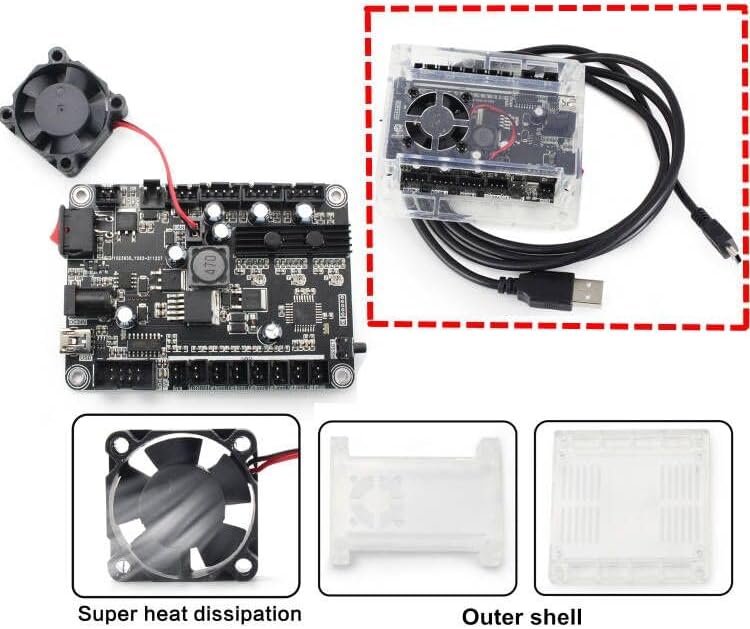

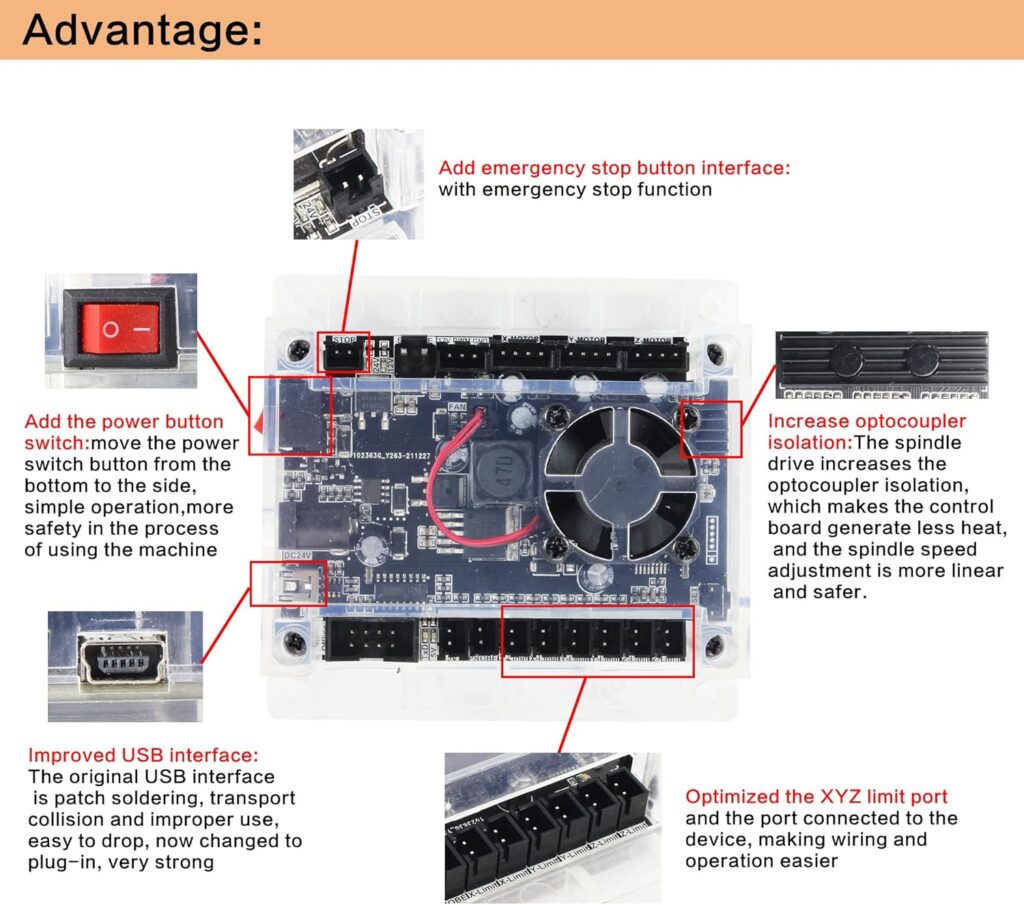

It runs GRBL, speaks G-code, and plugs into our computer with a USB cable the way a well-behaved peripheral should. The parcel includes a 4G USB flash drive with the GRBL software, installation instructions, and an English user manual, which makes us feel slightly spoiled in the best way. This MAX version adds thoughtful touches to the control board—an outer casing, a fan, E-stop and probe ports, limit ports, an offline controller port, and a power button—so our bench looks less like a science fair explosion.

CNCTOPBAOS CNC 3018-PRO-MAX 3 Axis Desktop DIY Mini Wood Router Kit Engraver Woodworking PCB PVC Milling Engraving Carving Machine GRBL Control with ER11 Collet (3018-PRO-MAX)

Why the “PRO-MAX” Matters More Than It Sounds

We’ve owned gear where “Pro Max” meant “same thing, shinier sticker.” Here, the “PRO-MAX” badge actually denotes functional upgrades that reduce headaches. The improved GRBL 1.1f control board supports spindles up to 20,000 rpm, and the included 775 120W spindle runs happily at 24V and 10,000 rpm.

Between the E-stop port, limit switch ports, and probe port, we can build a safer, smarter workflow. We’re not getting a toy; we’re getting a small machine with a checklist of the basics done right.

Specifications at a Glance

We like specs in a neat grid, partly because it makes us feel like responsible adults and partly because our attention span appreciates structure. Here’s what we’re working with.

| Feature | Details | Why It Matters |

|---|---|---|

| Model | CNCTOPBAOS CNC 3018-PRO-MAX | Compact CNC router for desktop use |

| Working Area | 300 x 180 x 45 mm (11.8 x 7.1 x 1.8 in) | Big enough for signs, PCBs, inlays, small panels |

| Frame Size | 420 x 350 x 270 mm (16.53 x 13.78 x 10.63 in) | Fits on most desks or shop benches |

| Control | GRBL 1.1f, USB connection | Widely supported, reliable control |

| Supported Files | .nc, .txt, .tape, .gcode | Standard G-code formats |

| OS Compatibility | Windows XP/7/8/10, Linux | Easy software pairing on common systems |

| Spindle | 775 120W, 24V, 10,000 rpm | Suitable for wood, plastics, PCBs, soft metals |

| Max Board Support | Up to 20,000 rpm spindle | Room to upgrade if we want higher speed |

| Collet | ER11 (3.175 mm) supports 0–7 mm | Accepts common 1/8” bits and more with collets |

| Stepper Motors | NEMA 17 (1.33A / 0.3N·m / 43 oz-in) | Adequate torque for light-duty milling |

| Control Board Features | Casing, fan, power button, E-stop/limit/probe/offline ports | Better cooling, safety, and expandability |

| Materials | Wood, acrylic, PVC, PCB; soft metals like copper and aluminum | Versatile for hobby projects |

| Laser Support | 12V 3-pin PWM/TTL, 0.5–20W module (optional) | Swap to laser for engravings on wood/leather/kraft paper |

We can build, engrave, and mill small pieces without introducing the neighbors to industrial noise. And yes, we can upgrade thoughtfully over time.

Unboxing and First Impressions

We rarely feel elegant when unpacking a kit, but this one avoids chaos. The parts come labeled, the manual is in English, and the included USB stick means we aren’t hunting software in a dark corner of the internet.

Initial impressions are positive: aluminum extrusions feel solid, the acrylic/ABS panels don’t flex like playthings, and the control board’s casing is a welcome change from exposed components. Our first thought was, “This looks like it might behave.” Our second thought was, “This might actually fit under the bookshelf.”

Assembly: From Flat-Pack to First Shavings

Putting the CNCTOPBAOS CNC 3018-PRO-MAX together is easier than assembling an existential crisis, which, in our shop, is the usual Saturday. With the manual in one hand and a hex key in the other, we finished in about 90 minutes, including a break to find the screw we swore we didn’t drop.

The frame goes together with straightforward fasteners. The linear rods align with the gantry, and the leadscrews for X, Y, and Z move freely when we hand-turn them. If we’ve ever built the standard 3018 platform, we’ll recognize the process immediately—the “MAX” adds niceties on the electronics side, not new acrobatics for assembly.

Tips for a Smooth Assembly

We learned a few things that made the process less fussy. None require a Ph.D. in patience.

- Square the frame before fully tightening. We loosely assembled everything, measured diagonals, and only then tightened those corners. Our future selves say thanks.

- Check couplers and leadscrews. We made sure the couplers are tight and the leadscrews aren’t binding. A little alignment now saves a lot of confusion later.

- Mind the wiring paths. USB cable to the board, stepper wires to their axes, spindle wires to spindle terminals. The board’s labeled ports make this saner than average.

- Keep dust out of the control board. The casing and fan help, but it’s still a good habit to mount the board where chips don’t land.

- Verify Z clearance. The 45 mm Z height is what we get, so we placed our spoilboard where we could still clear clamps and materials.

If we’re careful, we’ll avoid those first-day errors that turn into second-week myths of “bad machines.” This one is fine; it just wants to be squared and snug.

Software Setup: GRBL, G-code, and Control

Once assembled, we plug in the USB and feel like we’re introducing two polite acquaintances. The 3018-PRO-MAX runs GRBL 1.1f, which is essentially the lingua franca of small CNC routers. The included 4G USB flash drive holds the GRBL control software and installation instructions, and we’re grateful not to chase version numbers across forum posts.

Compatible systems include Windows XP/7/8/10 and Linux. The board shows up as a USB serial device; we choose a COM port and set 115200 baud in our sender software. We’ve had smooth results with Candle (often bundled with 3018 kits), Universal Gcode Sender, and, for laser use, LaserGRBL. If we’re on macOS, we can still use open-source senders that support GRBL, though official documentation focuses on Windows and Linux.

G-code Workflow in Plain Terms

Our general process looks like this, and it keeps us from confusing a toolpath with a shopping list.

- Design: We sketch in vector software or CAD (Inkscape, Fusion 360, FreeCAD, Carbide Create, or similar).

- CAM: We generate toolpaths—profiles, pockets, engravings—into G-code (.nc/.txt/.tape/.gcode).

- Sender: We load that G-code into Candle or UGS, connect via USB, and set zeroes on the machine.

- Run: We start the job and watch for the first minute to ensure the toolpath makes sense. If the machine tries to carve the air above the work like it’s conducting an orchestra, we pause and re-zero Z.

We keep an eye on GRBL parameters ($100–$132 for steps/mm and travel limits) and back them up when we’re happy with performance. It’s surprising how often a “mystery drift” is just a changed setting.

Using the Enhanced GRBL Control Board

The PRO-MAX’s control board looks like someone finally attended a meeting about usability. It has an outer casing to protect components, a fan to keep it from running hot, and ports that future-proof the build a bit.

The E-stop port and power button give us safer start/stop control. The probe port means we can add a simple Z probe for tool length setting. The limit switch ports support homing and travel limits, though we’ll need to add switches if they’re not in our kit. There’s also an offline controller port, so we can run the machine without a tethered PC, which feels somewhat liberating, like walking a trustworthy dog without the leash.

First Cuts: Performance and Accuracy

We expected small and pleasant; we got small, pleasant, and reasonably precise. With proper assembly and squaring, we’re seeing repeatability in the 0.05–0.1 mm range on wood and acrylic. Obviously, reality depends on feeds, speeds, tool sharpness, and how much caffeine we had while tightening screws. Still, the 3018-PRO-MAX behaves better than its size suggests.

The 775 120W spindle at 10,000 rpm is well suited to wood, acrylic, PVC, PCBs, and soft metals like aluminum and copper. The control board can drive a spindle up to 20,000 rpm if we upgrade later, but we didn’t feel lacking in the beginning. On thin aluminum, we kept depth of cut light, set conservative feed rates, and let the machine take smaller bites. This is not a steel-cutting monster, and when we treat it like one, it pouts.

Realistic Feeds and Speeds

Our favorite reminder is “good chips, not dust or smoke.” Here are starting points that kept us out of trouble; we adjust based on material and bit:

- Hardwood with a sharp 1/8″ two-flute end mill: 8,000–10,000 rpm, 200–400 mm/min, 0.2–0.5 mm per pass

- Softwood: 10,000 rpm, 400–600 mm/min, 0.5–1.0 mm per pass

- Acrylic/PVC: 10,000 rpm, 300–500 mm/min, 0.2–0.5 mm per pass, single-flute if possible

- Aluminum (6061) with 1-flute or 2-flute end mill: 10,000 rpm, 150–300 mm/min, 0.05–0.2 mm per pass, lubrication if available

We treat these as starting points, and we watch chips. If we’re making powder, we increase feed or lower rpm. If we’re burning, we reconsider life choices and reduce speed.

Noise and Vibration

If the 3018-PRO-MAX were a neighbor, it’d be the quiet one who returns our mail on time. The spindle is audible but not nerve-jangling. When cutting, most noise comes from the interaction between cutter and material. We mount the machine on a dense surface—MDF or a rubber mat—to absorb resonance. A 3018 can sound far more refined with a decent base, which also reduces walking vibrations and, quite possibly, metaphysical rattling.

Bit and Collet Choices: Making the ER11 Earn Its Keep

The included ER11 collet set focuses on 3.175 mm (1/8”) shanks, which is perfect for the bits most of us enjoy on small projects. The ER11 system can accommodate shanks from 0–7 mm with the right collets, so we’re not stuck with a single size.

We keep a tiny library of bits:

- 1/8″ two-flute end mill for general pocketing

- 1/8″ single-flute O-flute for plastics and aluminum

- 1/16″ end mill for finer details in wood and PCBs

- 20°–60° V-bits for engraving and inlays

- Ball-nose end mills for relief carving

We always seat the bit fully, then pull it back about 1 mm before tightening, just to ensure we’re not bottoming out. Tightening an ER collet correctly—bit snug, nut tightened evenly—makes a big difference in chatter.

Working With Different Materials

We like a machine that treats materials like a buffet rather than a dare. The CNCTOPBAOS CNC 3018-PRO-MAX handles the classics and tolerates small experiments.

Wood: The Happy Place

Wood is where this machine shines. We’ve done plaques, inlays, and small joinery templates with clean edges and predictable finishes. Hardwoods like maple and walnut cut beautifully with a sharp tool; softwoods do fine if we watch for tear-out and use appropriate stepovers. A coat of blue painter’s tape and CA glue between the workpiece and spoilboard holds small parts without leaving clamp dents.

Acrylic and PVC: Smooth Sailing (Mostly)

Acrylic and PVC require sharp bits and careful chips. We’ve had smooth cuts with single-flute O-flute cutters, lower stepdowns, and attention to chip evacuation. If our chips start welding to the bit, we pause, clear debris, and adjust feed or RPM. If we must, we consider a light mist of coolant—though with a desktop, we keep it gentle and clean.

PCBs: Tiny Tracks, Big Satisfaction

The working area fits standard hobby PCB sizes well. With a sharp V-bit and a meticulously leveled spoilboard, we can isolate traces for prototypes without sending ourselves to a fab house. We’ve had success using a simple Z-probe to get repeatable depths and using Candle’s height map functions when the surface isn’t perfectly flat.

Soft Metals: Know the Limits

Aluminum and copper are viable if we treat them like a delicate soufflé. Short stick-out, small stepdowns, proper feeds, and a willingness to let a job run longer help prevent tool deflection and chatter. We don’t try to cut deep slots in a single pass; we nibble. It’s not quick, but it’s surprisingly effective for small plates, nameplates, and light brackets.

Laser Module Option: Swapping the Spindle

If we add a 12V 3-pin PWM/TTL laser module (0.5W–20W range supported by the board), the 3018-PRO-MAX becomes a tidy engraver for wood, leather, and kraft paper. We like that the control board’s PWM/TTL makes laser power control straightforward in LaserGRBL or similar software.

We keep separate tool profiles and safety routines for lasers. That means eye protection rated for the specific wavelength, a nonflammable surface, and ventilation. We also never leave a laser job unattended; nothing starts a friendship-ending story like an accidental scorch.

Safety Considerations We Actually Follow

We don’t want a tool that robs us of our eyebrows or our sense of humor. Safety is simple but essential.

- Eye protection every time. Chips happen.

- E-stop wired and within finger reach. Pausing software is fine, but a hard stop is better when things misbehave.

- Dust management. MDF produces fine particles; we vacuum often and consider a small dust shoe or enclosure.

- Clamps clear of toolpath. We’ve all had a clamp jump scare; we keep them low and out of the way.

- Respect materials. No ferrous metals or anything outside the machine’s power envelope. The 3018 is not a mill for steel.

- If using a laser: proper eyewear, active supervision, and good airflow.

Maintenance: The Ten-Minute Ritual That Saves Hours

We live in a universe where dust is a constant. A small ritual after each session keeps the CNCTOPBAOS CNC 3018-PRO-MAX delightful.

- Brush and vacuum chips from rails, leadscrews, and the control board area.

- Wipe the linear rods lightly and apply a suitable lubricant sparingly.

- Verify couplers and stepper set screws are tight.

- Re-square the spoilboard occasionally; skim with a light facing pass if needed.

- Back up GRBL settings—especially steps/mm—before experimenting.

These tiny habits prevent 90% of the gremlins that masquerade as “bad machines.”

Troubleshooting: Problems We Solved So You Don’t Have To

If something feels off, it usually is, but the fix is often simple. We write these down so we won’t pretend the machine “just did that on its own.”

- Wandering cuts: Check frame squareness, loose couplers, and tool stick-out. Recalibrate steps/mm if moves aren’t to scale.

- USB disconnects: Use a decent cable, avoid hubs, and keep the cable away from spindle power wires to reduce interference.

- Burned edges in wood: Lower RPM or increase feed; ensure sharp tools.

- Fused plastic chips: Switch to a single-flute cutter, increase feed, reduce RPM, and improve chip evacuation.

- Chatter: Reduce stick-out, tighten collet properly, lighten pass depth, and check for loose fasteners.

- Z inaccuracies: Verify probe thickness setting if using a probe; re-check collet grip and bit seating.

We also like running simple calibration squares and circles periodically to verify motion accuracy on X, Y, and Z. It’s like a dentist checkup, but without the lecture.

The Offline Controller and Limit Switches

The control board’s offline controller port means we can add a handheld controller later if we want to run files without a PC. For some of us, that’s a relief; fewer cables, fewer things to spill coffee on.

Limit switch ports are provided, and we recommend installing switches if we intend to run homing cycles and keep jobs within bounds automatically. Once set up, homing to a known corner simplifies repeatable workflows, especially when we’re batching little projects like keychains or coasters.

Comparing the 3018-PRO-MAX to Common Alternatives

There’s a sea of 3018s and slightly bigger cousins. We won’t play brand bingo, but in practical terms, here’s what stands out.

- Versus basic 3018 or 3018-PRO: The PRO-MAX adds a cased control board, fan cooling, proper ports for safety and accessories, a power button, and support for higher-RPM spindles. Those things sound small until we don’t have them.

- Versus larger machines (3040, 4030, etc.): Bigger work area and potentially stiffer frames come with more cost, more space, and often more noise. The 3018-PRO-MAX wins on footprint and beginner friendliness, while larger machines handle bigger stock and deeper cuts.

We view the CNCTOPBAOS CNC 3018-PRO-MAX as the sweet spot for learning, prototyping, and making small polished items without reconfiguring the house.

Projects We Loved on the CNCTOPBAOS CNC 3018-PRO-MAX

We measure machines by the smiles on our faces after we make something that didn’t exist before. A few favorites:

- Personalized wood signs with V-carving, finished with a little black paint and sand-back for contrast.

- Acrylic keychains and tags with crisp engraving.

- PCB prototypes that spared us shipping delays and cleared up our circuit doubts.

- Aluminum nameplates with shallow engraving that looked disarmingly professional.

All of these fit comfortably within the 3018’s work area and spindle capability. None required a second mortgage or a therapist on speed dial.

Tips and Tricks We Wish We Knew on Day One

We love a good shortcut more than we love admitting we needed one. These saved us time and face.

- Face the spoilboard. A quick surfacing pass gives us a perfectly parallel Z reference and cleaner pockets.

- Use fixtures. For repeated parts, make a simple jig with locating pins so we can swap materials and keep alignment.

- Start with V-carves. Engraving with a V-bit on wood gives quick wins and hides minor Z inconsistencies.

- Keep bits sharp and short. Dull tools and long stick-out are a recipe for chatter and bad language.

- Use blue tape + CA glue for small parts. It’s gentler than clamps and works wonders on thin pieces.

- Mark our zero. A small scribed corner or a reference pin on the spoilboard helps us return to a known origin if the cat unplugs the USB (hypothetically).

Who This Machine Is For

We see the CNCTOPBAOS CNC 3018-PRO-MAX as an enthusiastic accomplice for:

- Beginners wanting a practical way into CNC without overwhelming cost or complexity

- Hobbyists who enjoy working with wood, plastics, and light metals on a small scale

- Makerspaces and classrooms that benefit from GRBL familiarity and compact size

- PCB tinkerers who want repeatable, at-home prototyping

- Anyone who likes the idea of upgrading over time instead of buying everything at once

Who it’s not for: people cutting steel, running large production batches, or milling thick aluminum plates. This is a precision hobby tool, not a job-site mill.

Pros and Cons

We don’t pretend everything’s perfect. We enjoy honesty almost as much as working machines.

Pros:

- Compact and light, genuinely desktop-friendly

- GRBL 1.1f with a protected, fan-cooled control board

- Thoughtful ports: E-stop, probe, limit, offline controller

- Solid documentation and software included on a USB drive

- Good performance on wood, plastics, PCBs, and soft metals with proper technique

- ER11 collet system accepts common 1/8” tools and more with additional collets

- Easy assembly with a stable frame

Cons:

- Stock spindle is 120W/10,000 rpm; fine for hobby work, but not a metal hog

- Z travel of 45 mm requires planning with fixtures and thicker stock

- Limit switches may require additional purchase and setup

- No official macOS mention; Windows/Linux are the documented routes

- Aluminum is feasible but slow; patience is not optional

We’ll take that list any day for a machine of this size and price category.

Cost of Ownership and Sensible Upgrades

We sometimes assume “cheap machine = expensive upgrades.” That’s not the case here. Smart, gradual upgrades extend what we can do without reinventing the wheel.

- Spoilboard and T-track clamps: Improves workholding and reduces heart palpitations.

- Z probe: Faster, more accurate tool setting.

- Limit switches: Homing adds repeatability and protects travel limits.

- Dust shoe and small shop-vac: Keeps chips in check and our brain cells happy.

- Laser module (optional): Turns the unit into a multifunction engraver for wood/leather.

- Higher-RPM spindle (optional): The board supports up to 20,000 rpm, which can help with plastics and fine detail.

We prefer upgrades that improve reliability and repeatability over raw power. It’s satisfying to see the machine grow with our skills.

Accuracy, Repeatability, and Tuning

We treat accuracy as something we earn with setup, not something we demand without foreplay. The 3018-PRO-MAX responds to careful tuning:

- Steps/mm calibration: Use a dial indicator or precise ruler to measure commanded vs. actual motion and adjust $100, $101, $102.

- Backlash mitigation: Snug our anti-backlash components and keep leadscrews clean.

- Tramming: Ensure the spindle is perpendicular to the spoilboard. Even small improvements pay off in smoother pocket bottoms.

- Feed optimization: Keep chips healthy, adjust stepover and stepdown, use proper bits for material.

In practice, we get crisp lettering, tidy pockets, and consistent depths when we treat the machine with respect. Which, to be fair, we all crave.

The Little Quality-of-Life Touches

The fan-cooled, cased board may be our favorite upgrade from earlier versions. Thermal stability and dust prevention improve longevity and consistency. The power button on the board makes powering down feel like a conscious act rather than yanking a cord.

We also appreciate that the machine accepts a wide range of common G-code file extensions. It means we can use our favorite CAM tools without conversion acrobatics.

Teaching and Learning With the 3018-PRO-MAX

We’ve seen this machine win hearts in classrooms and maker clubs. GRBL is widely documented, and the mechanical concepts—leadscrews, steppers, collets—are easy to grok with hands-on practice. It’s approachable enough for ambitious beginners and capable enough not to feel like a toy a month later.

We also like that mistakes here are teachable, recoverable, and relatively inexpensive. A broken 1/8″ end mill is a learning tax we can afford.

A Day in the Life With This CNC

We clamp a piece of maple to the spoilboard. We set our X and Y zero at the lower-left corner and touch off Z with a feeler or probe. We load a V-carve file for a small sign, press go, and listen for that cheerful purr that says the feed and speed gods are pleased. After ten minutes, we sand lightly, add a quick black paint fill, and wipe off the excess to reveal striking letters. It feels a little like alchemy and a lot like good process.

Yes, there’s setup. Yes, we clean afterward. But the result sits in our hand like a real thing—a tangible, tidy object—and for a moment, our desk looks less like a workshop and more like a studio.

Frequently Asked Questions

Q: Can we cut steel? A: No. The machine is suited for wood, plastics, PCBs, and soft metals like aluminum and copper. Steel is beyond its design.

Q: What software do we need? A: A design/CAM tool to generate G-code (like Fusion 360, Carbide Create, or Inkscape with a CAM plugin) and a sender like Candle or Universal Gcode Sender to communicate with GRBL.

Q: Does it work with macOS? A: Officially, Windows and Linux are noted. Many GRBL senders run on macOS, but documentation focuses on Windows/Linux. It’s doable; we just plan our software choices accordingly.

Q: Is the 24V 775 spindle enough power? A: For wood, plastics, PCBs, and careful aluminum work—yes. It’s 120W at 10,000 rpm, and the control board can support higher-RPM spindles if we upgrade.

Q: How accurate is it? A: With proper assembly and calibration, we’ve seen repeatability around 0.05–0.1 mm on typical materials. Results depend on tuning, tooling, and workholding.

Q: How hard is assembly? A: Manageable. Expect an hour or two the first time. The included manual is clear, and the parts are well-labeled.

Q: Can we add an emergency stop? A: The board includes an E-stop port; we recommend adding a proper E-stop button for safety.

Q: What about lasers? A: The control board supports a 12V 3-pin PWM/TTL laser module (0.5W–20W). We swap the spindle for a laser module and use appropriate laser software and safety gear.

Q: What files can it read? A: G-code formats: .nc, .txt, .tape, .gcode.

Q: Is it loud? A: Reasonable for a desktop machine. Most noise is cut-dependent. A solid base and smart feeds help keep it neighbor-friendly.

Our Honest Take on Value

For a desktop tool with this feature set—a cased, fan-cooled GRBL 1.1f board, E-stop/probe/limit/offline ports, a decent 120W spindle, and an ER11 collet system—the CNCTOPBAOS CNC 3018-PRO-MAX feels like good value. The included 4G USB flash drive with software and manuals lowers the barrier to getting started, which we appreciate.

We know there are bigger, faster, pricier machines. But the PRO-MAX balances capability, ease, and upgrade paths in a way that makes sense for beginners and tinkering pros alike.

The Verdict: A Small Machine That Makes Big Friends

We didn’t expect to like it as much as we do. The CNCTOPBAOS CNC 3018-PRO-MAX isn’t a miracle worker, but it’s a polite, dependable partner that rewards careful setup and reasonable expectations. It moves us from “someday I’ll try CNC” to “we just made a thing” without drama.

We’d recommend it to anyone starting out or stepping back into desktop CNC after a hiatus. It’s friendly, expandable, and grounded in proven GRBL control with sensible hardware choices. The working area covers a surprising number of projects; the software path is well-trodden; and the whole package feels thoughtfully assembled rather than slapped together.

We’ll keep ours for prototyping, signage, PCBs, and laser engraving jobs that deserve a home on the desk instead of a place on the waitlist. If our early projects are any indication, the hardest part isn’t the machine—it’s narrowing down what to make next.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.