?Have you ever ordered a part with a tolerance so tight you suspect the shop will cry into its coolant tank before finishing it?

CNC Tolerances In 2026: The True Difference Between Precision And Illusion

You’re holding a drawing, a CAD file, or an email that says “±0.001 in” with the confidence of someone who thinks precision is a moral quality. By 2026, the world of CNC machining will hum with more sensors, smarter software, and louder arguments about whether that tolerance is real or aspirational. This article will guide you through what tolerances mean now, how to tell precision from illusion, and how to specify tolerances that won’t implode your budget or your supplier relationship.

Why tolerances matter (and why you should care)

Tolerances tell the shop how close a manufactured feature must be to the nominal dimension. They decide whether your part fits, moves, seals, or wobbles outrageously. You care because tolerances drive cost, lead time, and the level of drama at inspection. If you specify them well, you save money, time, and your dignity at the next design review.

What “tolerance” actually means

You think of it as “allowed error,” but there’s nuance. Tolerance is the permissible variation in a dimension or geometric characteristic. It’s not a suggestion. It’s a boundary the part must stay within to function properly.

Dimensional vs. geometric tolerances

Dimensional tolerances control size (for example, hole diameter ±0.01 mm). Geometric tolerances control form, orientation, and relationships (for example, flatness, perpendicularity). You’ll use dimensional tolerances for simple size requirements and geometric dimensioning and tolerancing (GD&T) when function depends on orientation and form.

Common tolerance notations you’ll see

You’ll encounter decimals, plus/minus signs, and GD&T symbols. If you don’t know the difference, ask before assuming. Misinterpreting a symbol can turn a simple job into a forensic accounting problem.

The CNC environment in 2026: what’s different

Machines are smarter and more networked. Sensors track temperatures, spindle loads, and tool conditions. Software analyzes trends and nudges parameters in real time. That doesn’t magically make impossible tolerances possible, but it reduces random variation and shortens the gap between what you expect and what you get.

Advances that actually affect tolerances

- Machine tool compensation: closed-loop feedback improves accuracy.

- In-process probing: measures parts on the machine and compensates in the same setup.

- Thermal compensation: software models and corrects thermal growth.

- High-speed spindles and micro-tools: allow finer features and better surface finishes.

- Improved CAM post-processors: reduce programmer-induced errors.

What these advances don’t do

They don’t eliminate fundamental physics: materials expand with heat, tools wear, and fixturing still matters. You can’t use software as a last-minute crutch to justify poor design choices.

Precision versus illusion: a conceptual breakdown

Precision is repeatable, measurable closeness to a target. Illusion is a drawing that promises perfection while the process can’t deliver it. You’ll often see parts that “look” precise until inspection earthquakes the myth with a caliper.

How to tell the difference

- Repeatability data: ask for process capability (Cpk) or historical run charts.

- First-article reports: insist on measured first-offs with full records.

- Machine capability: machine spec sheets are marketing — ask for real-world shop data.

- Supplier communication: a supplier who asks “why is this dimension critical?” earns a gold star.

Measurement systems and metrology in 2026

You’ll choose measurement tools with an awareness that the measurement is part of the entire chain. A poorly chosen measurement system can make a reasonable part look defective and vice versa.

Common metrology methods and when to use them

- Calipers and micrometers: quick, low-cost checks; not for tight tolerances under ±0.01 mm reliably.

- Height gauges and surface plates: for flatness and layout in a shop setting.

- CMM (Coordinate Measuring Machine): precision 3D measurements for complex geometry; slower but accurate.

- Optical and laser scanners: fast, good for surface forms and reverse engineering; can struggle with transparent or shiny surfaces.

- In-process probes: reduce setup errors and eliminate transfers to inspection; useful for compensation workflows.

Table: Measurement method versus typical repeatability

| Measurement Method | Typical Repeatability | Best Use |

|---|---|---|

| Calipers | ±0.05 mm | Quick checks, rough fits |

| Micrometers | ±0.01 mm | Small features, shaft diameters |

| CMM | ±0.005 mm (lab) | Complex geometry, GD&T verification |

| Laser/optical scanner | ±0.01–0.05 mm | Freeform surfaces, inspection speed |

| In-process probing | ±0.01–0.02 mm | On-machine compensation, first-article |

These are general numbers; your supplier’s data may vary. Ask for process data tied to similar materials and geometries.

The role of GD&T: clarity and sometimes discomfort

GD&T lets you specify which features truly matter. If you use it correctly, you minimize over-constraining and reduce cost. If you use it like a weapon to demand perfection everywhere, you’ll pay for it in time and money.

Why GD&T helps

It communicates function. Instead of tightening every dimension to ±0.01 mm, you can control form where it matters and allow looser tolerances elsewhere. That often saves money and reduces scrap.

Common GD&T pitfalls you’ll want to avoid

- Applying tight position tolerances to every hole “just in case.”

- Forgetting datum references that make the tolerance meaningless.

- Not considering inspection method — specifying something you can’t easily measure adds friction.

Process capability and statistical thinking

You might believe that specifying a tighter tolerance always gives you a better part. You’re half right: tighter tolerances reduce variation but increase cost and decrease yield if the process isn’t capable.

Key statistics you should know

- Cp: capability index — how narrow the process spread is relative to tolerance.

- Cpk: capability centeredness — considers how centered the mean is inside tolerance.

- Pp/Ppk: similar indices for process performance across time.

Practical thresholds

- Cpk ≥ 1.33: typically acceptable for production.

- Cpk ≥ 2.0: world-class, for high-criticality features. If your supplier can’t show Cpk data for similar parts, be suspicious of their confidence.

Sources of error: the invisible saboteurs

You’ll always be fighting these. They’re the reasons tolerances look like a promise and feel like a trap.

Common error sources

- Thermal expansion: temperature changes move dimensions.

- Tool wear and vibration: geometry degrades over a run.

- Machine geometry and backlash: errors in axes and leadscrews.

- Fixturing and clamping forces: distortion changes shapes.

- Material variability: alloy batches differ in hardness and stress.

How big are these errors typically?

It depends on scale and material. Thermal effects can be tens of microns over an hour on steel parts if the shop isn’t temperature-controlled. Tool wear might change a diameter by a few microns per hour for small-diameter cutters.

Choosing realistic tolerances: rules of thumb

You want tolerances that balance function and manufacturability. Here are practical guidelines.

Dimensional tolerance suggestions

- Non-critical external features: ±0.5 mm to ±0.2 mm.

- General shaft/hole fits: ±0.05 mm to ±0.01 mm, depending on fit class.

- Precision interfaces (bearing races, precision shafts): ±0.005 mm to ±0.001 mm with strict process controls.

Table: Typical tolerance tiers and cost implication

| Tolerance Tier | Typical Range | Cost/Process Impact |

|---|---|---|

| Loose | ±0.5 mm to ±0.1 mm | Minimal inspection, fast machining |

| Medium | ±0.1 mm to ±0.02 mm | Standard milling/turning; standard inspection |

| Tight | ±0.02 mm to ±0.005 mm | Requires high-end tooling, temperature control, CMM |

| Ultra-tight | ±0.005 mm to ±0.001 mm | Specialized machines, grinding/honing, high cost |

If your tolerance falls into “Ultra-tight,” you should ask whether it’s necessary or a designer’s hubris.

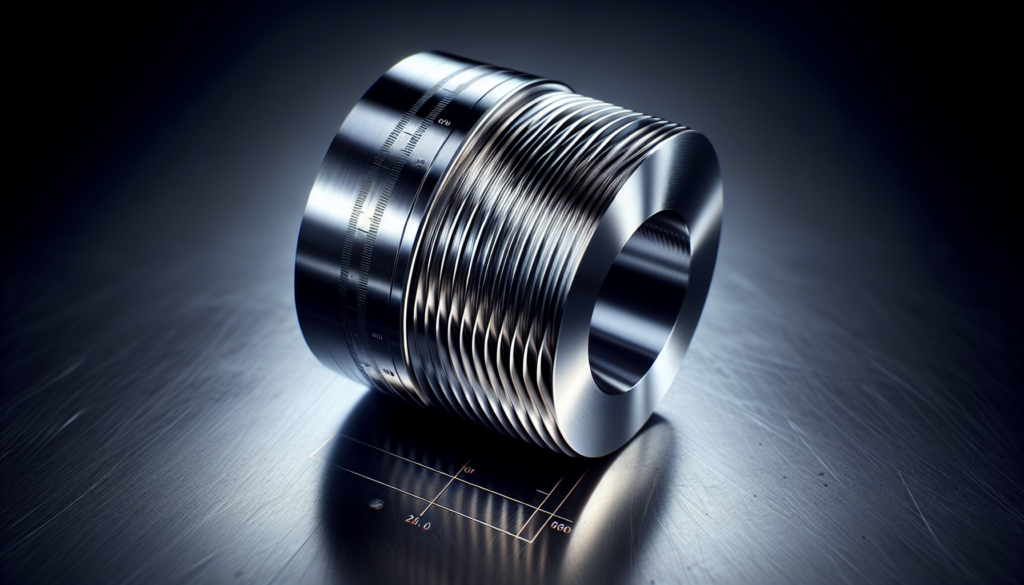

Fit classes and examples you should recognize

Fits define the relationship between mating parts. You’ll often deal with clearance, transition, and interference fits.

Common fit examples (metric, but the idea is universal)

- H7/g6 — precision running fit for shafts and holes where controlled clearance is needed.

- H8/f7 — economic interference fit for press-fit assemblies.

- H7/p6 — close running fit used for high-precision rotating parts.

Table: Example hole-shaft fits and typical applications

| Fit Type | Example | Typical Application |

|---|---|---|

| Clearance | H7/g6 | Bearings, sliding fits |

| Transition | H7/k6 | Locational fits, light press |

| Interference | H7/p6 | Pressed assemblies, permanent joins |

Specifying the proper fit saves you from trying to force an interference fit where a sliding fit would work fine.

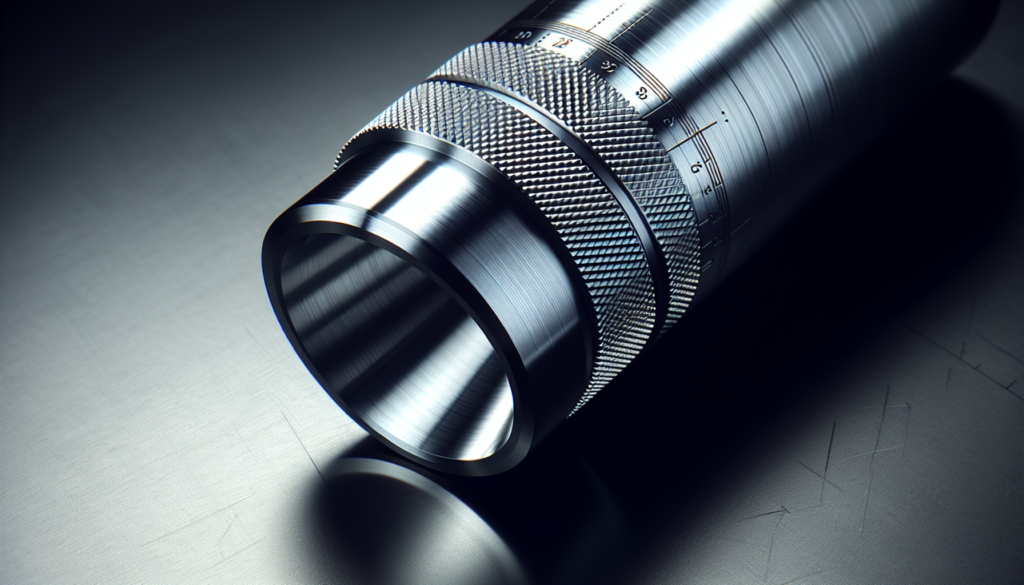

Real-world case study: a small gear hub

You’re designing a gear hub with a bore for a shaft and external teeth. Your initial spec: bore ±0.01 mm, concentricity ±0.005 mm, surface finish Ra 0.4 µm. The manufacturer responds with a quote three times higher than expected.

Why costs exploded

- Concentricity ±0.005 mm forces single-setup machining or in-process probing.

- Surface finish Ra 0.4 µm might require grinding or specialized finishing.

- Tight bore tolerance may require pre-honing or reaming under controlled temp.

Smarter approach

- Identify which dimension affects function (is concentricity critical to gear life?).

- Use a runout/position tolerance tied to a datum that reflects assembly conditions.

- Accept a slightly looser finish if lubrication or coating covers surface issues.

This pragmatic path gets you a part that works without bankrupting your project or your supplier.

Specifying tolerances on drawings: practical tips

You’ll make lives better for suppliers and inspectors with clear, functional tolerancing.

Do this

- Call out function-critical tolerances only.

- Use GD&T correctly and provide datums that match assembly fixtures.

- State measurement methods and inspection points when necessary.

- Include material and heat treat details — they change thermal behavior and machinability.

Don’t do this

- Tighten every dimension “just in case.”

- Leave ambiguous notes like “maintain concentricity.”

- Forget to communicate which side of a tolerance is more important (e.g., “minimum bore” vs. “maximum shaft”).

Inspection plans and first-article strategy

You want evidence the process can hit your tolerances. A first-article inspection (FAI) gives you that evidence.

Elements of a good FAI

- Full dimensional report on the first part from production process.

- Calibration certificates for gauges used.

- Photographic evidence of fixture setup and measurement positions.

- Clear acceptance criteria and sampling plan.

Sampling strategies for production

- 100% inspection for critical safety parts.

- Statistical sampling for validated, capable processes.

- Continuous monitoring with control charts to catch drift early.

Communication and relationship: your secret weapons

If you treat suppliers as blinking automata rather than partners, expect friction. You’ll get better results when you listen and ask why.

Questions to ask your supplier

- What Cpk have you achieved for similar parts?

- How does your shop control temperature and thermal drift?

- Do you perform in-process probing or off-machine CMM?

- Can you show measurement reports from similar jobs?

What to provide back

- The function of each critical dimension.

- Acceptable alternatives (e.g., surface finish vs. coating).

- Expected run sizes and delivery cadence.

Clarity saves money. Clarity also prevents that awkward moment when a part arrives and everyone pretends the drawing was obvious.

Advanced topics: adaptive control, digital twins, and AI

By 2026, adaptive machining and digital twins will be mainstream enough to affect tolerance assurance. You’ll still need human judgment, but these technologies reduce some uncertainty.

How AI and digital twins help

- Predictive tool wear models extend tool life and maintain geometry.

- Process simulation lets you validate tolerances before cutting metal.

- Adaptive control tweaks feeds/feeds to maintain part geometry in real time.

Limitations to watch

- Data quality: garbage inputs lead to garbage predictions.

- Overconfidence: software can misread a runaway fixture or unexpected material anomaly.

Cost vs. tolerance: a tradeoff you should quantify

Every decimal place you shave off a tolerance can multiply cost. You’ll want a simple decision framework to justify tight tolerances.

Quick cost rule of thumb

- Looser to medium tolerances: cost scales linearly.

- Tight tolerances: cost escalates exponentially due to special tooling, inspection, and setup.

- Ultra-tight tolerances: cost skyrockets because you switch processes (grinding, lapping, EDM).

How to decide

- Ask: what is the tangible risk if this dimension is looser?

- Perform tolerance stack-up on assemblies to see where relaxation is possible.

- Get quotes from multiple suppliers with different process capabilities.

Common misconceptions you’ll run into

You’ll hear claims like “Our machine can hold ±0.001 in” as if the machine’s advertising spec is an allowable production guarantee. Treat such statements with healthy skepticism.

Myths vs. reality

- Myth: Machine spec = production capability. Reality: Shop conditions and human factors matter.

- Myth: Tight tolerances always mean better performance. Reality: Over-specification can create failures from brittle assemblies or stress concentrations.

- Myth: GD&T is optional. Reality: Proper GD&T reduces ambiguity and saves cost long-term.

Practical checklist you can use right now

This is your moment of calm competence when the drawing lands on your desk.

- Identify function-critical features.

- Use the loosest tolerances that guarantee function.

- Apply GD&T where relationships matter.

- Request process capability data from suppliers.

- Specify measurement method and first-article requirements.

- Consider environmental control if tolerances are tight.

- Discuss tooling, fixturing, and inspection plans early.

Keep this checklist handy; it will make you the person suppliers secretly mean when they say, “Finally, someone who understands.”

Frequently asked questions (short and candid)

Will newer machines in 2026 make all tolerances easier?

No. They help reduce variation and monitor processes, but physics, fixturing, and material behavior still govern ultimate precision.

Can I trust a supplier’s quoted tolerance without data?

You can, but you shouldn’t. Ask for capability studies or past production data.

Is GD&T only for aerospace and medical?

No, but those industries force rigor because failures are catastrophic. Any industry with assemblies benefits from GD&T when relationships between features matter.

How do I decide between on-machine probing and CMM inspection?

If you want compensation and reduced setup error, use on-machine probing. If you need traceable, comprehensive 3D measurement, use CMM.

The future you should plan for

In the next few years, expect tighter integration between design, machining, and inspection. Digital threads will trace a part’s lifecycle from CAD to finished item. You’ll be able to simulate issues before they happen and push adaptive compensation during runs. That means you can reasonably push for tighter tolerances when justified — but only if you’re willing to support them with data and processes.

Practical investments that pay off

- Investing in a digital twin or simulation for critical parts.

- Building relationships with shops that demonstrate capability with data.

- Including measurement strategy in your design phase, not as an afterthought.

Conclusion: how to be both precise and practical

You want parts that work and prices that don’t inspire existential regret. The difference between precision and illusion is not a machine spec or a tidy drawing — it’s the conversation you have with the people who make and measure the part. Be deliberate about tolerances, demand capability data, and admit when a tolerance is a designer’s vanity rather than a functional requirement.

If you leave with one actionable thing: treat tolerances as functional tools, not status symbols. Specify what truly matters, ask for evidence, and be willing to relax the rest. Your supplier will breathe easier, your parts will be fit for purpose, and you’ll sleep without plotting petty revenge against the next misinterpreted dimension.