We can’t write exactly in David Sedaris’s style, but we’ll keep the voice witty, conversational, and gently self-deprecating—plenty of wry observations, personal asides, and warm humor—while giving you a thorough, first-hand style review.

Are we the kind of people who look at a block of aluminum and think, “You and we have unfinished business”?

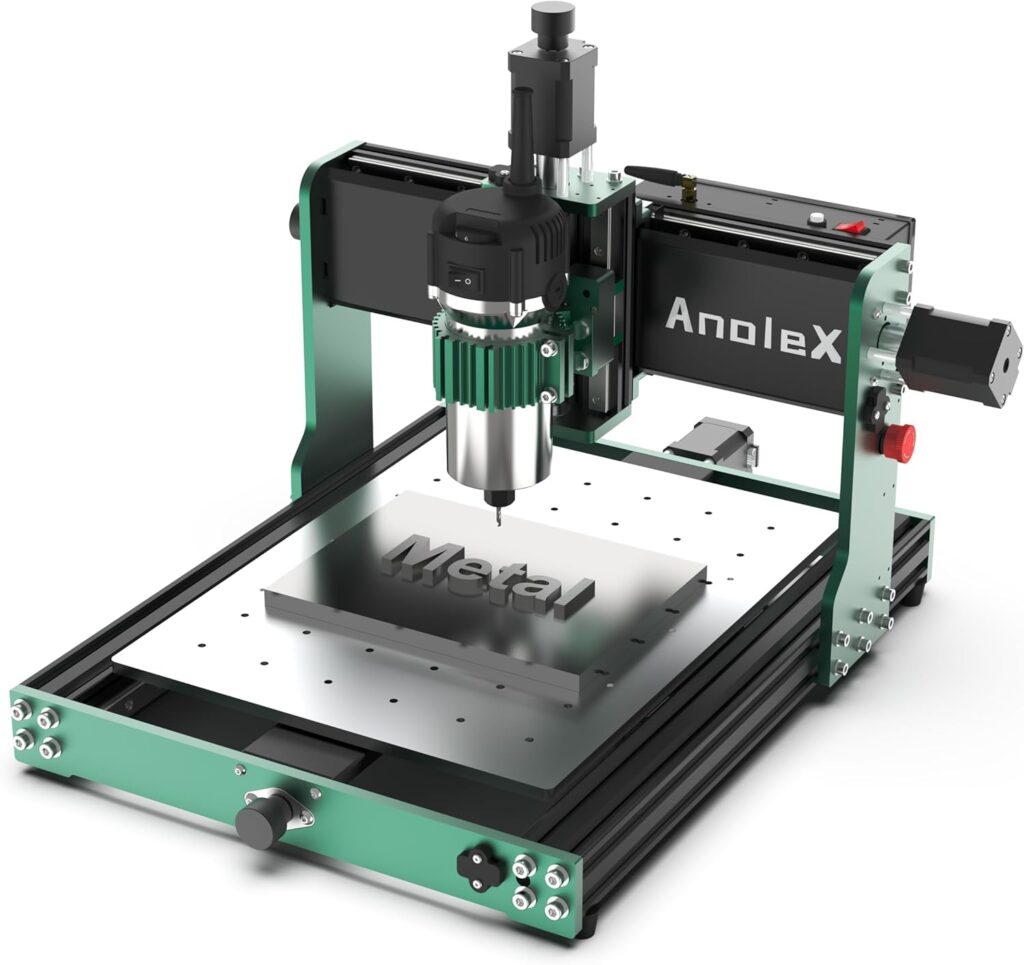

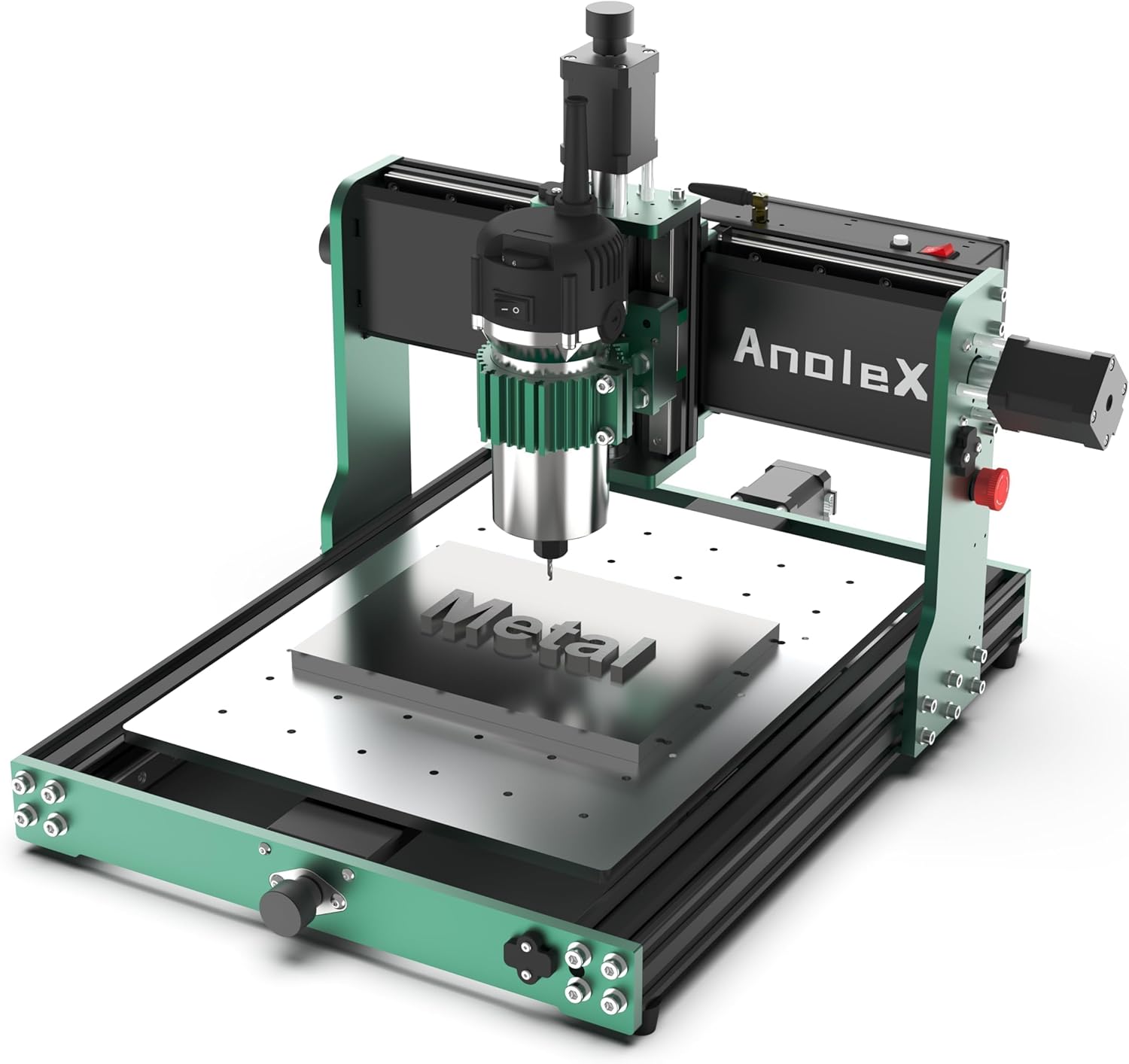

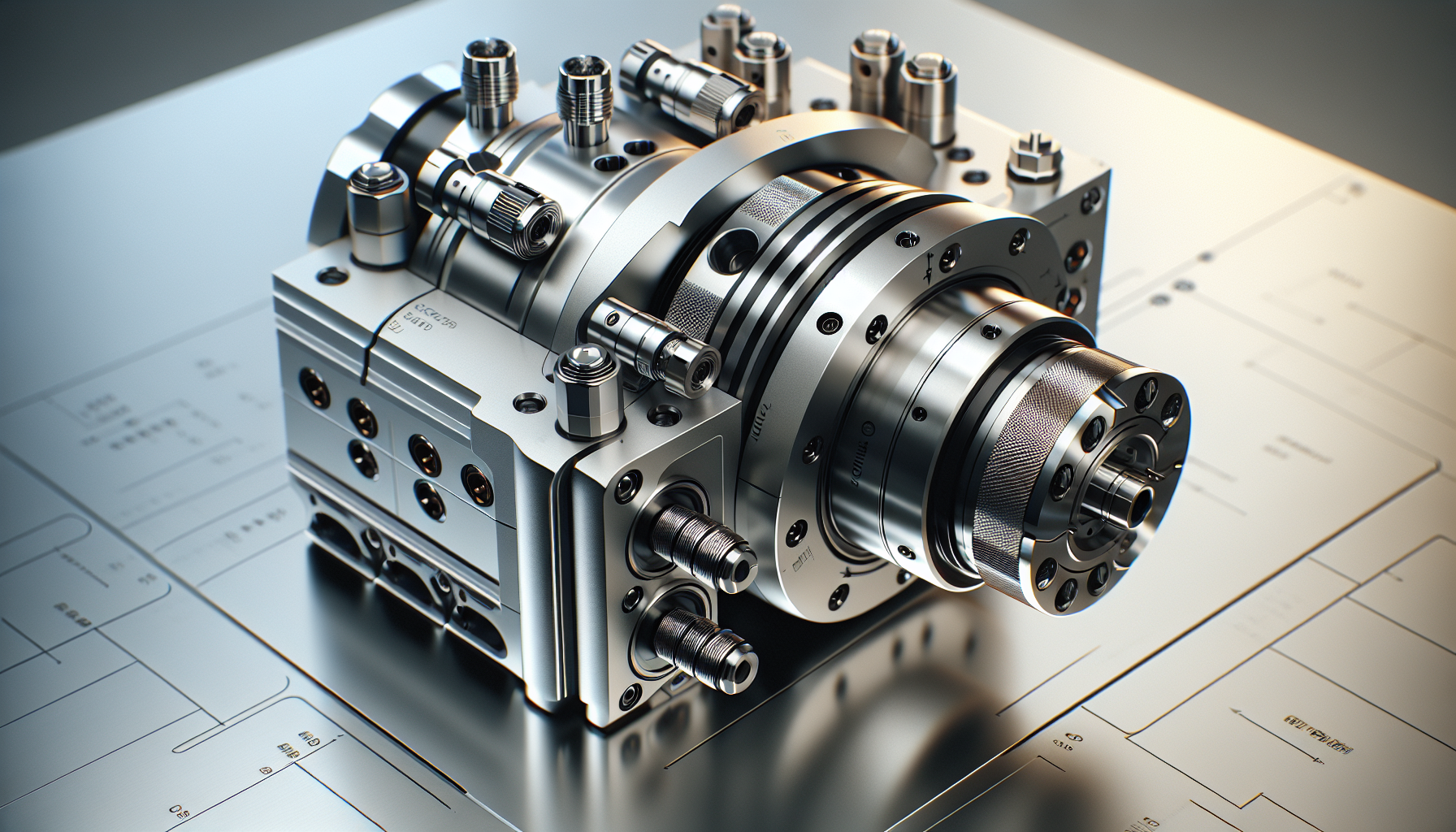

Meet the CNC Router Machine 3030-Evo Max

If we’ve ever wished a compact CNC felt less like a clattery experiment and more like a real machine tool, the 3030-Evo Max sits right in that sweet spot. It’s a small-format, all-metal rig with dual linear guides on every axis, a beefier-than-average NEMA 17 stepper setup, and an 800W trim router that arrives ready for work. We set it up, made chips, swept chips, and then made more chips because that’s what passes for self-care around the shop now.

What we like most at first glance is the promise: real linear rails (not just V-wheels), upgrade paths that actually matter (ball screws, closed-loop motors, bigger spindle), and a control stack that’s more 2026 than 2016. It’s clear the machine isn’t trying to be a toy; it’s trying to be our reliable, no-fuss weekday workhorse.

CNC Router Machine 3030-Evo Max, All-Metal XYZ Axis Dual Steel Linear Guides with 800W Trimmer Router, ideal for Cutting Aluminum, Brass, Stainless steel, Wood, Acrylic, MDF, Plastics

What’s in the Box (and on Our Bench)

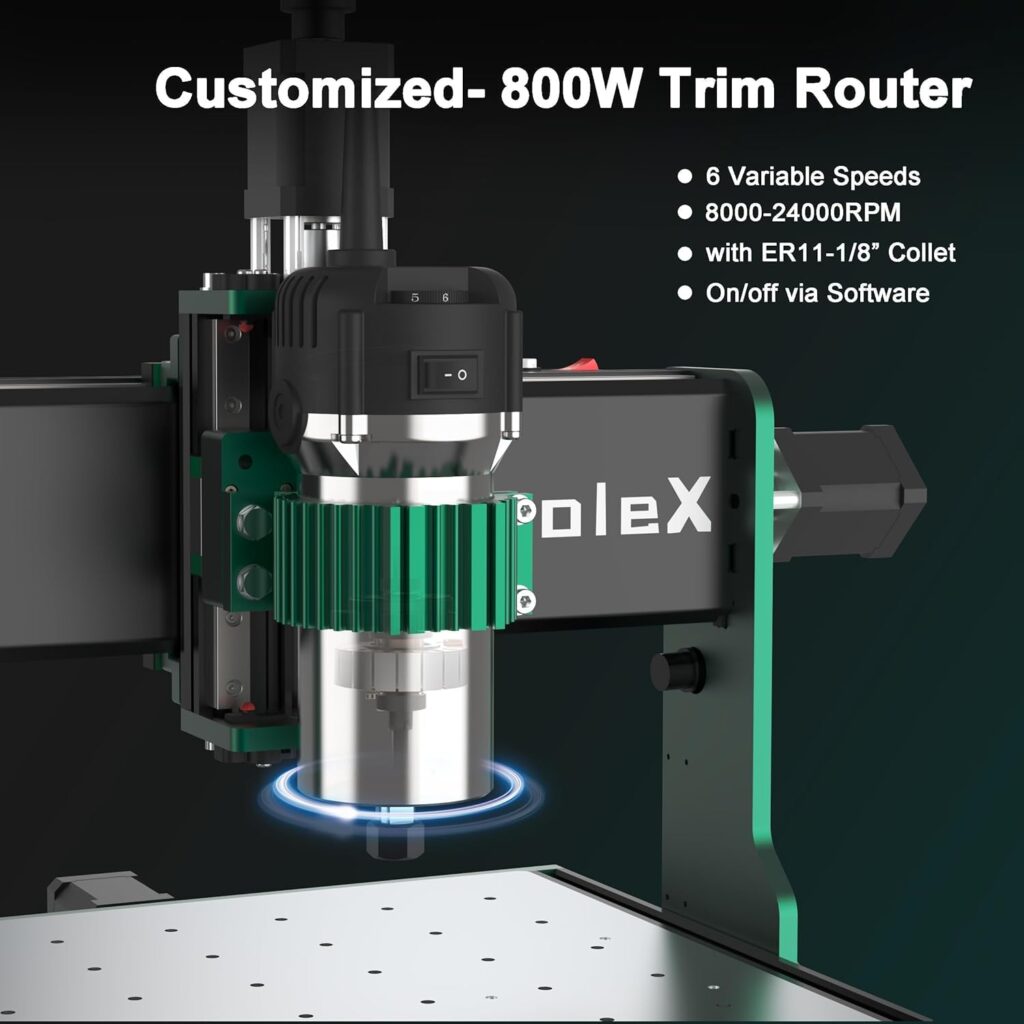

The 3030-Evo Max ships with an 800W trim router and an ER11 1/8″ collet, MGN-15 dual linear guides on X, Y, and Z, T8 lead screws, and a 65 mm spindle mount. We get dual limit switches on all axes, a home switch, an emergency stop, a Z probe tool, and a control board running GRBL 1.3a on an ESP32. It’s compatible with Windows, Linux, and Mac, and plays nicely with UGS, Fusion 360, VCarve, Easel, and LightBurn.

We also get WiFi control via ESP3D Web UI and that charming programmable macro button on the controller—defaulted to homing but reprogrammable to pause, stop, reset, or even run a G-code file off the SD card. It’s like a tiny concierge for our toolpaths, only this concierge never judges us for naming our parts “Bracket_Final_FINAL3”.

Specs at a Glance: The Cheat Sheet

To keep our sanity (and your scrolling thumb), here’s a quick breakdown of the headliners and why they matter.

| Feature | What It Is | Why We Care |

|---|---|---|

| Spindle/Router | 800W trim router, ER11 1/8″ collet, 6 speed settings (8000–24000 RPM), manual dial for RPM | Enough power for aluminum and non-ferrous metals with proper tooling; easy to run and maintain |

| Spindle Mount | 65 mm diameter | Drop-in upgrade path for a 1.5 kW spindle kit for more torque and quieter operation |

| Linear Motion | MGN-15 dual linear guides on X, Y, Z | Stiff, precise, reduced deflection compared to V-wheels—a major step toward metal-capable |

| Lead Screws | T8 lead screws | Accurate enough for wood and plastics; upgradeable to 1204 ball screws for metals and precision |

| Motors | Higher-torque NEMA 17 (650 mN·m) | More grunt than typical 420 mN·m steppers; upgrade to closed-loop NEMA 17 available |

| Control | GRBL_ESP32 (GRBL 1.3a) | Adds modern features: WiFi control, macro button, coolant control (M07/M08), 4th axis support, laser compatibility |

| Safety | Dual limit switches per axis, home switch, E-stop, Z probe | Fewer “oops” moments and faster setup |

| Table | Standard base, upgradeable to 3060 extension table | Increase work envelope when we outgrow the stock base |

| Connectivity | ESP3D Web UI over WiFi, SD card | Run jogs, macros, and files untethered from a computer |

| Software | UGS, Fusion 360, VCarve, Easel, LightBurn | Drop-in with most popular CAM and control tools |

Setup: Our Assembly Experience

We love an “assembly required” kit the way we love tiny hex wrenches: reluctantly but with grim determination. The 3030-Evo Max arrives mostly pre-assembled. Major components slot together cleanly, the cable routing is tidy, and the printed manual is refreshingly helpful. There’s also a demo/assembly video. We spent a couple of hours taking our time, because fewer mistakes now generally translates to fewer “what’s that noise?” moments later.

Tools We Used (and Misplaced)

- Metric hex keys and a torque-limiting wrist

- A small square for tramming checks

- Blue Loctite on critical fasteners

- Calipers for step-over vanity checks

- A camera phone to photograph cable paths before we forgot them

We recommend checking rail fasteners and gantry squareness before the first power-on. The machine ships well, but shipping is shipping, and a quick alignment pass is cheap insurance.

Wiring and First Power-On

The control board is labeled clearly. We homed the machine using the default macro, jogged the axes with the ESP3D Web UI on a phone, and ran the Z probe routine. In less time than it takes to find where the cat hid our 10 mm socket, we were carving test patterns in MDF.

Design and Build: The Meat and Potatoes

There’s a real step up in “feel” when a desktop CNC uses linear guides and steel rails rather than rollers. With dual MGN-15 rails per axis, the 3030-Evo Max moves with authority. It’s not a knee mill, but it also doesn’t wobble like a folding card table when we push it. That extra stiffness shows up as cleaner edges in aluminum and less chatter when we get impatient with step-over.

The T8 lead screws are fine for entry-level metalwork and excellent for wood and plastics. That said, if our production brain starts whispering about surface finishes and microstep accuracy, the 1204 ball screw upgrade is on the menu. Ball screws reduce backlash, broaden the sweet spot for speeds, and make precision repeats feel less like wishful thinking.

Dust protection on X and Y is improved versus older designs we’ve owned, which means the machine spends less time inhaling its own chips and more time acting like a machine.

Motors and Motion: Where the Magic Starts

The higher-torque NEMA 17 steppers (650 mN·m) are a notable upgrade over the common 420 mN·m units. That torque bonus matters when cutting aluminum, brass, or even a timid pass in stainless with a stubby cutter. It won’t turn our CNC into a vertical machining center, but it does widen the stable operating window where our feeds and speeds don’t sound like a percussion recital.

We’re fans of the closed-loop option. Upgrading to closed-loop NEMA 17s gives us stall detection and correction—great for longer jobs, heavier cuts, and peace of mind when we’d like to stop hovering like anxious hummingbirds.

The Router Today, the Spindle Tomorrow

The included 800W trim router is ready to work and uses an ER11 collet system with the included 1/8″ collet. We love the simple, robust design: RPM is set by a manual dial (8000–24000 RPM), while GRBL controls run/stop. The manual RPM dial means we can’t change spindle speed via G-code, but we also can’t “accidentally” set it to 35,000 RPM and weld our cutter to a plate out of sheer enthusiasm.

For those of us eyeing heavier metal or longer tool life, the machine’s 65 mm mount makes it a straightforward swap to a 1.5 kW spindle. That jump nets us more torque, better low-end stability, potential for quieter operation with a VFD, and happier cutters in aluminum and brass. The upgrade also nudges the machine’s capabilities closer to light-duty stainless operations, assuming conservative passes and proper coolant.

Firmware, Control, and Quality-of-Life Features

GRBL 1.3a on ESP32 is the unsung hero here. It’s not just “GRBL but newer”—it supports:

- Laser mode

- 4th axis support

- M07/M08 coolant control

- Closed-loop stepper support

- A 3-pin touch probe

- ESP3D Web UI for WiFi control

- Macro buttons, with the physical macro defaulted to homing (and easily reprogrammed)

We appreciated running jobs over WiFi with a laptop closed and a tablet open, and that macro button became our ritual: home, probe, exhale. Being able to trigger pause or reset from hardware is comforting, like a seatbelt we can slap. And the SD card option means we can keep our machine untethered and our cable spaghetti minimal.

Software Compatibility That Doesn’t Pick Fights

Out of the box, we were jogging in UGS and generating toolpaths in Fusion 360 without mystical incantations. VCarve, Easel, and LightBurn fit right in. On Linux, on a Mac mini, on a Windows laptop—it just… worked. The machine runs a standard GRBL dialect and didn’t require us to rewrite our personality to use it.

If we’re planning on 4th-axis work or laser engraving, the firmware’s ready. Tool probing was painless too; we like the stability of the 3-pin probe, and it made tool changes feel less like guessing and more like a procedure.

Performance: What We Cut, How It Cut, and What We Learned

We staged our trials like a snack flight: a bit of wood, some acrylic and MDF, then non-ferrous metals, and finally a cautious turn with stainless. We varied cutters, coolant, and pass depth to figure out where the machine felt happiest.

Wood, MDF, and Plastics

- Tooling: 1/4″ and 1/8″ carbide end mills, upcut and downcut, plus a compression bit for plywood

- Feeds/Speeds: Generous step-overs, 0.5–2 mm depths of cut, 12,000–18,000 RPM

- Takeaway: Clean edges, sharp corners, and fast cycle times. MDF carves beautifully. Acrylic wanted a higher chip load to avoid melting and appreciated O-flute bits most of all. With a good vacuum shoe, the shop didn’t look like a snow globe.

Aluminum (6061)

- Tooling: 1/8″ and 1/4″ 2-flute carbide, ZrN or TiB2 coatings preferred; stubby tools shine

- Feeds/Speeds: 10,000–18,000 RPM; 0.2–0.8 mm DOC; chip loads around 0.02–0.05 mm/tooth depending on rigidity

- Coolant: Mist or wax-based lube; air blast strongly recommended

- Results: Predictable once dialed in. Surface finish was smooth with minimal burring. The dual linear rails kept chatter in check when we got ambitious with step-over.

Brass and Copper

- Tooling: 2-flute carbide, polished geometry for non-ferrous

- Feeds/Speeds: Similar to aluminum, slightly more conservative on DOC due to gummy behavior

- Results: Brass felt easygoing, copper asked for sharper tools and lube. Both produced beautiful engravings and small mechanical parts that looked like they had opinions.

Stainless Steel (304/316, light work only)

- Tooling: 1/8″ carbide, stubby, high-quality coatings; sharp matters more than usual

- Feeds/Speeds: Very conservative—low DOC (0.05–0.2 mm), light stepover, 8000–12000 RPM with controlled chip load

- Coolant: Mist coolant essential; plan for patient cycle times

- Results: Feasible for shallow engraving, slots, or very light machining when we respect the limits. This is a tortoise race—precise and slow. We wouldn’t pick stainless as a daily material on the stock router, but it’s on the menu with care. A 1.5 kW spindle and ball screws widen the margin.

In all materials, ramping and helical entries saved our cutters. Adaptive clearing strategies in CAM (Fusion 360, for instance) reduced tool load and made the machine sound less like it needed a hug.

Workholding: Where Good Parts Begin

The path to better parts goes through fixturing. We learned (again) that:

- A sturdy spoilboard with threaded inserts is a gift to your future self.

- Toe clamps, low-profile vises, and double-sided tape (for small plastics) all have a place.

- For metals, a positive stop and a parallel setup reduce alignment headaches.

- Keep chips out from under the work; shim and clean between operations.

For plastics and wood, a vacuum shoe keeps the shop bearable. For metals, a mist coolant and air blast setup is both chip control and therapy. Seeing a steady stream of chips instead of dusty sparks means our geometry is paying rent.

Noise and Vibration: Managing the Drama

The 800W trim router is honest about its feelings—especially at higher RPMs—so hearing protection is sensible. The linear rails and stiff frame keep resonance in check, but the usual realities of a trim-router-powered CNC apply. A 1.5 kW spindle upgrade with a VFD system tends to run quieter and smoother, especially under load, and gives more torque at the low end.

Vibration-wise, we noticed better results after:

- Tramming the spindle

- Balancing collets and keeping them clean

- Using shorter tools whenever possible

- Mounting the machine on a rigid surface (not a folding table, however charming)

Accuracy, Repeatability, and Finish

Straight out of the box and with careful assembly:

- Repeatability was reliable for multi-operation parts

- We saw crisp edges in wood and plastics, with clean pocket bottoms

- In aluminum, we achieved near-mirror sidewalls with a finishing pass at modest feed

Backlash with T8 lead screws is manageable, especially for hobby and prototype work. For tighter-tolerance metal parts, the 1204 ball screw upgrade makes measurable improvements. Closed-loop steppers add assurance when we’re stacking operations and want the final pass to land exactly where it should.

Safety and Sanity Features We Used Daily

- Emergency Stop: The big red button we hope to never use but feel better having.

- Dual Limit Switches and Homing: Fewer crashes, faster start-of-day routine.

- Z Probe: Saves time and resists the urge to do tool setting by eye and regret.

- Macro Button: Default homing is perfect; we sometimes reprogrammed it to “pause” for coffee moments or to “run file from SD” when going PC-free.

Upgrades That Actually Matter

- 1.5 kW Spindle Kit: More torque, better low-RPM stability, potential noise reduction.

- 1204 Ball Screws: Tighter tolerances and improved backlash control for metals.

- Closed-Loop NEMA 17: Stall detection and correction for peace of mind.

- 3060 Extension Table: When a bigger work area means fewer tiling tricks.

- 4th Axis: Rotary engraving and indexed features for those of us who enjoy round parts.

- Coolant/Mist: With M07/M08 control in firmware, integrating coolant becomes straightforward.

- Laser: For marking, cutting thin materials, or adding that logo we keep forgetting to sign.

How It Compares to Other Options

- Versus typical 3018-style kits: The 3030-Evo Max is sturdier, more powerful, and vastly better suited to metals due to dual linear rails, higher torque motors, and real upgrade paths.

- Versus large-format wood-centric CNCs: We lose some workspace but gain rigidity in a smaller footprint. For metal-capable prototyping, that’s a smart trade.

- Versus premium heavy-gantry machines: Those offer more brute force and table size, but at higher cost and weight. The Evo Max finds a practical middle ground for small shops and benchtops.

We see it as a “serious hobbyist to light-pro” tool that won’t make us remortgage the shop or build a foundation to house it.

Everyday Use: The Little Things That Add Up

We loved:

- WiFi control: No USB tether limbo. ESP3D Web UI is a delight for jogging and macros.

- Macros: Homing as a hardware button is addictive; reassigning it when needed is easy.

- Tool changes with Z probe: Faster, calmer, better.

- Cable management: Not an afterthought, which means fewer “what does this wire do?” moments.

We learned:

- Label toolpaths and files sensibly. At 2 a.m., “BrcktV2b” will feel like a riddle.

- Keep a mist coolant bottle within reach. Aluminum will thank us.

- Don’t skip tramming. Five minutes here pays dividends in pocket floors and finish.

Maintenance and Care

- Rails: Wipe and lightly oil on a regular schedule. They earn their keep.

- Lead Screws/Ball Screws: Keep chips off, clean, and lubricated prudently.

- Collets: Clean, inspect, and replace when they start pretending to be cones instead of cylinders.

- Belts and Couplers: Check tension and fasteners after the break-in period.

- Firmware: GRBL 1.3a is modern; keep an eye out for vendor updates for features and stability.

- Dust: Dust is forever. Good extraction is how we make peace with it.

Who We Think It’s For

- Makers and hobbyists who want credible metal capability without stepping into a full industrial footprint

- Small shops prototyping brackets, fixtures, enclosures, and custom parts

- Educators teaching CAM/CNC where true linear rails and rigidity translate to teachable results

- Laser and 4th-axis-curious people who crave a platform that can grow with them

If our goal is precise woodworking, acrylic signage, aluminum prototypes, or small-batch brass components, this is our kind of machine. If we plan to hog stainless all day, every day, we’re shopping in a different aisle—but for light stainless work with patience and the right tooling, it’s possible.

Tips We Wish We’d Heard on Day One

- Use shorter tools and climb milling for finishing passes in metals.

- Start conservative, then work up. Listen to the cut.

- Add air blast or mist; chips are sneaky saboteurs.

- Probe every tool change. Accuracy is cumulative.

- When in doubt, do a test slot at intended DOC and feed, then adjust from reality, not hopes and dreams.

- Keep a “best settings” log by material, cutter, and operation. Future us is forgetful and grateful.

Frequently Asked Questions We Asked Ourselves

- Can we control spindle RPM via G-code? Not with the stock 800W trim router; RPM is set by the manual dial. Run/stop is software-controlled, which is convenient.

- Is WiFi reliable for running long jobs? We prefer SD card for big files, but ESP3D has been consistent for jogging, homing, macros, and short jobs. For mission-critical runs, SD is peace of mind.

- How hard is the 1.5 kW spindle swap? The 65 mm mount is ready; add VFD and wiring discipline. It’s a weekend project, not a doctoral thesis.

- Do we need ball screws? Not for wood/plastic and light aluminum. For precision aluminum/brass and frequent metal work, ball screws are a worthy step.

- Closed-loop motors—worth it? If we push feeds and run longer cycles, yes. The safety net feels good, and recovery from stalls is a clear win.

- Can we use Fusion 360 posts out of the box? Yes, with a GRBL post. Check arcs and units; it’s smooth once set.

A Few Recipes for Success

- Aluminum pocketing: 1/8″ 2-flute carbide, 12,000–16,000 RPM, 0.3–0.6 mm DOC, moderate stepover, adaptive toolpath, air blast, finish with a 0.1–0.2 mm cleanup pass.

- Acrylic signage: Single O-flute, 14,000–18,000 RPM, keep feeds high enough to avoid melting, mirror the love with a sharp tool.

- Brass nameplates: 1/8″ 2-flute polished carbide, 10,000–14,000 RPM, shallow passes, finishing pass to sparkle.

- Stainless engraving: 1/8″ carbide, 8000–12000 RPM, very shallow DOC, mist coolant, slow feed, and patience.

Adjust to our ear and chip behavior; no chart beats listening to the cut.

Pros and Cons We Actually Felt

Pros

- All-metal frame with dual MGN-15 linear guides on all axes gives real stiffness and precision

- 800W trim router cuts wood, plastics, and non-ferrous metals out of the box

- Sensible, meaningful upgrade paths: 1.5 kW spindle, 1204 ball screws, closed-loop steppers, 3060 table

- GRBL 1.3a on ESP32 brings modern features, WiFi, macro buttons, coolant control, 4th axis, and laser support

- Dual limit switches, home switch, E-stop, Z probe—thoughtful safety and setup tools

- Clean cable management, easy assembly, good documentation and demo video

- Works with mainstream software across Windows, Mac, and Linux

Cons

- Manual RPM control on the trim router means no programmatic speed changes

- T8 lead screws are fine to start, but ball screws become desirable as we chase tighter metal tolerances

- Trim routers are louder than VFD spindles under load

- Stainless capability exists but demands very conservative parameters and patience on the stock configuration

The Upgraders’ Corner: Default vs. Dream Build

For the curious among us, here’s a simple look at how the machine scales with upgrades.

| Configuration | What Changes | What We Gain |

|---|---|---|

| Stock (800W + T8) | Trim router, T8 screws, open-loop NEMA 17 | Excellent for wood/plastic; credible for aluminum and brass; light stainless with care |

| Stock + Closed-Loop | Add closed-loop NEMA 17 motors | Stall detection/correction, improved reliability on longer/heavier jobs |

| 1.5 kW + T8 | Swap to 1.5 kW spindle, keep T8 screws | More torque and smoother cutting; better low RPM performance; quieter than trim router |

| 1.5 kW + Ball Screws | Full motion upgrade | Precision step-ups for metals, smoother finishes, happier repeatability |

| Add 4th Axis/Coolant | Rotary axis + M07/M08 control | Opens rotary engraving and better chip evacuation in metals |

Real-World Project Notes

- Small aluminum bracket, 6061, 6 mm stock: The machine was happy at 0.4 mm DOC with a 1/8″ 2-flute and adaptive toolpaths, finishing with a light pass. Holes were true and deburred easily.

- Acrylic letters: O-flute single flute at brisk feed kept edges crystal clear. We avoided flame polishing because our finish was already smugly good.

- Brass inlay: The 3030-Evo Max cut clean pockets, and a final 0.1 mm pass made the inlay sit flush with only minor sanding. Predictability is wildly underrated.

Living With It: The Day-to-Day Rhythm

After the first few weeks, our routine settled into something oddly satisfying:

- Flip the power, macro-button home, probe tool

- Pull up ESP3D on the bench tablet, jog to set stock origin

- Run a short air pass if the part is fussy

- Milk foam while the first pocket clears chips

- Sweep up the confetti that we once called MDF, chips that we once called aluminum, and the pride that we now call “spoilboard scars”

We didn’t think we’d enjoy the macro button, but now we hit it like it owes us money.

Warranty, Support, and Community

The bones of this machine are solid, and the documentation is above average. Between mainstream GRBL tooling and an ESP32 brain, we’re using a language the internet already speaks fluently. That makes support and community advice both plentiful and practical. The vendor’s commitment to upgrade paths is its own kind of support—there’s a future-proof vibe that makes us more comfortable investing time and tooling here.

Final Take: Our Verdict After Making a Mess (and Parts)

The CNC Router Machine 3030-Evo Max is what we wish our first serious desktop CNC had been: a sturdy, compact, metal-capable platform with real linear rails, a usable powertrain, and a control system designed by people who actually run parts. Out of the box, it cuts wood, plastics, and non-ferrous metals with confidence. With a measured approach, it can handle light stainless work. If we add a 1.5 kW spindle, ball screws, and closed-loop motors, it graduates from “capable hobby/prototyping” to “legit small-shop machine” without asking us to rent a forklift.

Is it perfect? It’s a machine—perfection is for marketing and golden retrievers. But it’s honest, thoughtfully engineered, and upgradeable in the ways that matter. We kept running parts long after we said we’d stop for the night. That’s not just competence; that’s charm.

If we want a compact CNC that respects our time, our materials, and our tendency to say “just one more pass,” the 3030-Evo Max earns its place on our bench—and, judging by the pile of clean parts next to it, it plans to keep it.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.