Have you ever stood in front of a machine that costs less than your monthly subscriptions and wondered whether it could really behave like the hulking, oil-scented monoliths you see in industrial shops?

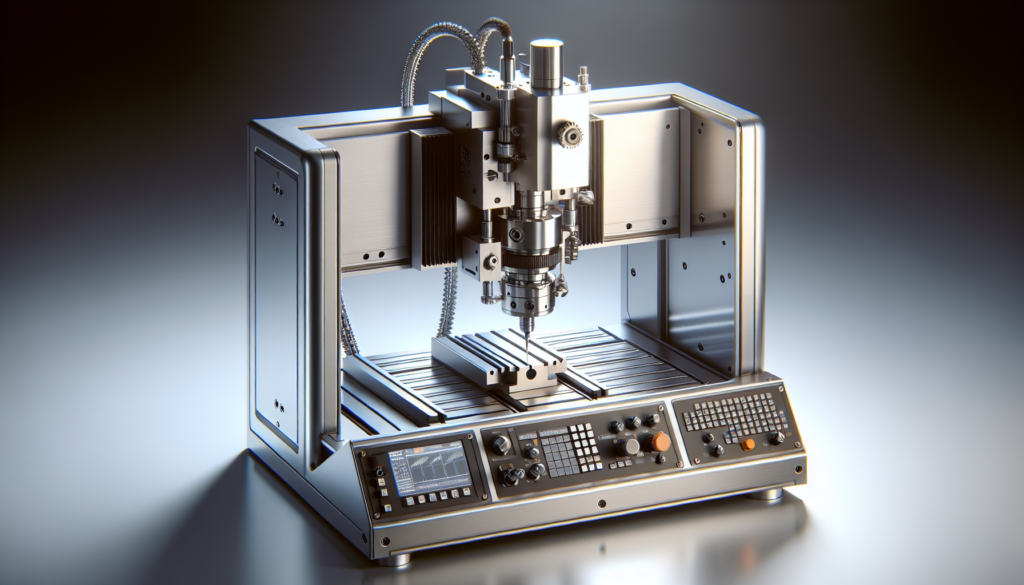

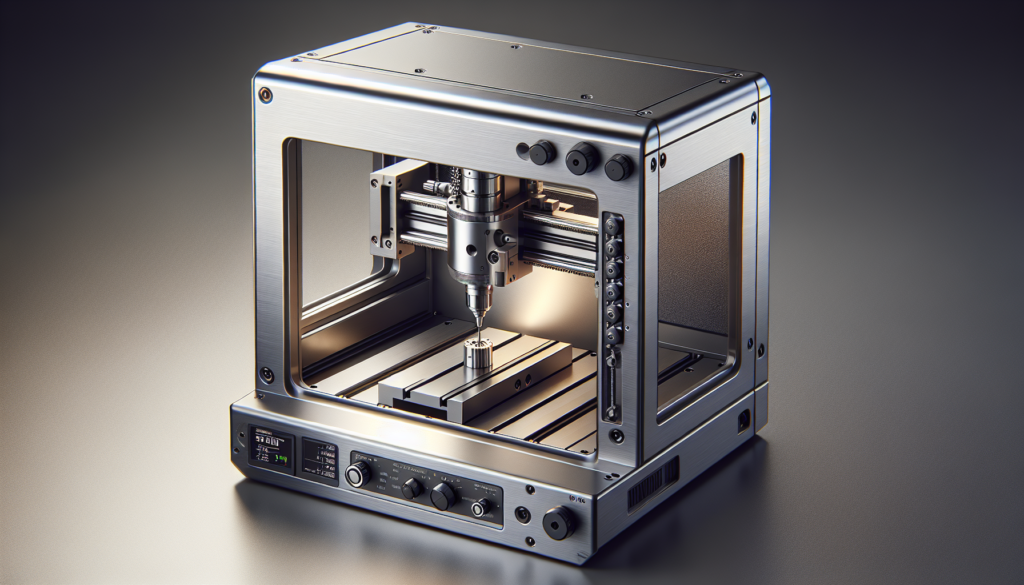

CNC Machines Under $2,500 In 2026 That Perform Like Industrial Units

You’re searching for a CNC that fits a budget without fitting into the stereotype of “toy.” You want rigidity, repeatability, and a predictable workflow — the kind that would make a shop foreman nod approvingly — but you don’t want to mortgage your future to get it. In 2026, the market is crowded with surprisingly competent machines under $2,500. Some of them perform closer to small industrial units than you might expect, especially after a few strategic upgrades and a bit of tuning. This article walks you through what you should expect, which models stand out, how to upgrade them, and how to use them in a real shop setting.

Why a Sub-$2,500 CNC Can Be a Smart Purchase

You might think low price equals low performance, but that isn’t always true. In the past decade, improved electronics, better stepper motors, and more sophisticated open-source control software have closed the gap between hobby-level machines and light industrial units. For many uses — prototyping, small-lot production, model-making, PCB milling, and mold masters — a well-configured machine under $2,500 can deliver the same outcomes as a pricier industrial unit.

You’ll still run into limits: spindle power, long-term rigidity, thermal stability, and absolute high-speed throughput. But if you pick the right machine and invest in a few upgrades, the difference becomes operational rather than fundamental.

What “Perform Like Industrial Units” Actually Means

You probably imagine a CNC that tolerates millimeter-long production runs, keeps tolerances to a few thousandths of an inch, and runs for days without complaint. That’s a fair image, but you should translate it into realistic expectations for a budget machine:

- Repeatability: You should aim for consistent results part-to-part rather than comparing to the best-in-class high-end mills.

- Rigidity: Enough to cut aluminum and dense plastics at sensible feeds and speeds with minimal chatter.

- Reliability: Continuous operation for hours, not weeks, without catastrophic failure.

- Precision: Tolerances around ±0.005″ (±0.125 mm) are realistic for many machines, better with careful setup.

- Workflow: Industrial-like CAM-to-machine processes, fixturing, and tool management are achievable.

If you can accept those boundaries, you’ll find plenty of affordable machines that behave admirably.

How to Read Specs Without Getting Hoodwinked

Specs will try to seduce you. Use them, but don’t worship them.

- Work area: Measured travel vs. usable travel. A 400×300 mm table may include frame and spoilboard, so usable cuts could be less.

- Spindle vs. router: “Spindle” usually means an ER collet spindle; routers are cheaper but less durable. Spindles give consistent speeds, better bearings, and quieter operation.

- Frame: Aluminum extrusion is common; steel frames or heavy plywood bases are stiffer.

- Motion: Ball screws are preferable to lead screws for backlash; rack and pinion can be fine for longer travel.

- Electronics: Closed-loop steppers or affordable servo kits reduce missed steps and improve reliability.

- Software compatibility: GRBL, Mach3/4, LinuxCNC, or proprietary controls — choose the ecosystem you can live in.

Top Value Machines (Under $2,500 in 2026)

Below are several models that, as of 2026, give you the most “industrial-like” bang for your buck. Prices are approximate and reflect typical retail or kit prices you’d find in 2026; they may vary by region, options, and promotions.

| Model (2026) | Type | Approx Price (USD) | Work Area | Spindle | Strengths | Limitations |

|---|---|---|---|---|---|---|

| Carbide 3D Nomad 3 | Desktop 3-axis milling | $2,199 | 8.5″×7.5″×3″ | 65,000 RPM sealed spindle (ER11) | Excellent build quality, enclosed, great software, tight tolerances | Small work area, limited Z travel |

| LongMill (Ooznest/LongMaker) 12×30 Mk3 | Benchtop router CNC | $1,399 (kit) | 12″×30″×4″ | 1.5–2.2 kW spindle (optional) | Large work area, rigid, scalable, great community | Requires assembly, router-level accuracy unless upgraded |

| BobsCNC E4/Pro | Wooden frame router CNC | $1,199 | 24″×24″ (varies) | Router mount (upgradeable to spindle) | Large cutting envelope, low cost, hobby-friendly | Frame stiffness, less precise for metals |

| SainSmart Genmitsu PROVer XL 4030 | Desktop/benchtop | $999–$1,299 | 400×300×80 mm | 300W brushless spindle | Good starting accuracy, compact, upgrade path | Lower spindle power for metals |

| XTool Paser / XTool M2-4 (CNC version) | Desktop combo (laser/CNC) | $1,299–$1,999 | ~420×400 mm (varies) | 800W air-cooled spindle (on CNC configs) | Versatile, good electronics, multifunction | Hybrid compromises; spindle may be less industrial grade |

| Sienci Labs LongMill Pro (metal kit) | Heavy benchtop | $1,800–$2,200 | Custom | 1.5 kW spindle option | Rigid build, purpose-built for heavier cutting | Requires substantial setup and upgrades |

Note: Several manufacturers offer modular kits allowing you to step up spindle power, change drive types, or install closed-loop motor systems. That’s where small-budget machines become industrial in practice.

Use Cases Where These Machines Shine

You should match machine capabilities to applications. Under-$2,500 machines excel at:

- Prototyping and small-batch production: Repeatable prototypes and parts numbering in small runs.

- Signs, plaques, and woodwork: Deep cuts into hardwoods and composites.

- Jewelry and precision crafts: With the Nomad 3 or a similar desktop mill, you can achieve exquisite tolerances in metals and wax.

- PCB milling and electronics fixtures: High RPM spindles can mill FR4 with correct tooling.

- Mold masters and vacuum form masters: Rapid one-off masters for silicone molds or thermoforming.

You’ll struggle when you push these machines into heavy-duty continuous production of hard metal parts or very large runs. In those cases, a full industrial machine is worth the cost.

Upgrades That Turn a Budget Machine Industrial-like

You can take a good, inexpensive CNC and make it perform like a small production mill with a handful of upgrades. Think of these as the wardrobe changes that turn a thrift-store find into a respectable suit.

- Spindle swap: Replace router motors with a water-cooled or air-cooled spindle (ER11/ER16) and a VFD. Cost: $150–$600.

- Stiffer mounts & bed: Replace or reinforce the frame, upgrade gantry plates, add ribbing or a thicker spoilboard. Cost: $50–$400.

- Ball screws / upgraded rails: Reduce backlash and improve rigidity. Cost: $200–$800 depending on axes and machine.

- Closed-loop stepper or servo kit: Prevent missed steps and improve torque. Cost: $150–$1,000.

- Better controller: Replace GRBL with a controller supporting acceleration profiles, probing, and advanced motion. Cost: $100–$500.

- Tool probing and touch-off: Improve setup speed and reduce human error. Cost: $50–$300.

- Dust collection & misting: Keep chips off the parts, cool the cutters, and extend life. Cost: $100–$500.

- Thermal management: Add spindle cooling and consistent ambient control for tighter tolerances. Cost: $50–$300.

If you’re willing to invest in 10–30% of the base machine cost in targeted upgrades, you’ll see exponential improvements in capability.

Real-World Setup: From CAD to Finished Part

You want a workflow that’s predictable. Here’s a practical pipeline many shops use with these machines:

- CAD: Design parts in Fusion 360, Onshape, or FreeCAD. Use parametric modeling for repeatables.

- CAM: Generate toolpaths in Fusion 360 or Carbide Create. Set appropriate feeds, speeds, and passes for your material and cutter.

- Fixturing: Use T-slots, threaded fixtures, or vacuum tables for consistent clamping. Include dowel pins or sacrificial alignment blocks for repeatability.

- Tooling: Use high-quality endmills: HSS for plastics, upcut/downcut carbide for wood and composites, and suitable coatings (TiN, TiAlN) for metal.

- Setup: Touch off using a probe or paper method. Zero consistently to the same datum.

- Run: Start conservatively with single-pass depth-of-cut and increase if no chatter or deflection occurs.

- Inspect: Use calipers, micrometers, and a dial indicator to verify distances. Keep logs of feeds/speeds for materials and cutters.

You’ll find that following these steps turns theoretical capability into practical results.

Safety and Shop Best Practices

You’re not just buying a machine; you’re buying moving metal and rotating tools. Treat safety like a non-negotiable habit.

- Emergency stop: Ensure E-stop is tested and immediately accessible.

- Enclosure or chip guards: Use shields for high-speed operations, especially woods and plastics that throw chips.

- Dust collection and ventilation: Fine particles from wood, composites, and FR4 will float everywhere if not managed.

- Eye and ear protection: Even quiet spindles can be loud. Protect your hearing and eyes.

- Tool inspection: Check flutes and collets regularly. A fatigued tool destroys parts and can produce dangerous failures.

A clean, documented, and repeatable shop practice is what separates “hobby” from “production.”

Detailed Comparison: Typical Specs and What They Mean

Here’s a table comparing key specs and why they matter so you can match the machine to your needs.

| Spec | What it means for you | Target for light industrial-like use |

|---|---|---|

| Spindle horsepower (or wattage) | Determines material capability and depth-of-cut | ≥1 kW for frequent aluminum work; 300–800 W acceptable for occasional metal |

| Travel (X×Y×Z) | Limits maximum part size | Match to the largest part you plan to cut with margin |

| Axis drive type | Affects backlash and precision | Ball screws or quality rack-and-pinion; avoid cheap lead screws for metal |

| Frame material | Affects vibration damping and thermal stability | Melted steel or thick aluminum extrusion for best results |

| Controller type | Determines software features and reliability | Controllers supporting acceleration curves, probing, and closed-loop controls are better |

| Repeatability | How close parts are to each other | ±0.005″ (0.125 mm) is a practical target for production-like results |

| Open vs. closed-loop motors | Steps lost on high loads | Closed-loop eliminates missed steps under load |

Reading specs with these translations will help you make realistic choices.

Case Studies: Realistic Production Scenarios

You like stories. Here are abbreviated case studies that show what these machines can do with some elbow grease.

Case study 1: Prototype aerospace fixtures

- Setup: LongMill 12×30 Mk3 with upgraded 1.5 kW spindle, ball screws on Y-axis, probe for Z-touch.

- Result: Single-operator runs producing 100 fixtures in a week, consistent to ±0.003″ after process optimization.

- Key improvement: Improved dust/mist cooling and tacky fixturing.

Case study 2: Jewelry production

- Setup: Carbide 3D Nomad 3 for high-precision wax masters and direct soft metal milling.

- Result: Repeatable rings and small parts, ready for casting. 20–30 pieces per run, excellent surface finish.

- Key improvement: Rigid clamping and carbide micro-endmills for fine detail.

Case study 3: Signage and display

- Setup: BobsCNC E4 with a water-cooled spindle, upgraded bed, and HDPE spoilboard.

- Result: Large-volume signage with deep reliefs, 12-hour continuous run times, low maintenance.

- Key improvement: Dust collection and spindle cooling for consistent finish.

These are plausible workflows that show budget machines can perform under modest production conditions.

Tooling, Cutters, and Feeds: The Small Details That Matter

You’ve heard rumors that the cutter does the work, not the machine. There’s truth there.

- Carbide vs. HSS: Carbide is stiffer, holds geometry, and runs at higher speeds. Use carbide for production.

- Coatings: TiAlN or similar coatings for heat resistance during aluminum machining.

- Flute counts: Fewer flutes evacuate chips better from plastics and wood; more flutes are better for hard materials and improving surface finish.

- Tool length: Keep tools short to minimize deflection. Use extension only when necessary.

- Feeds and speeds: Conservative start values are crucial. Increase feeds slowly if you achieve stable cutting behavior.

- Pecking and step-downs: For deep pockets or broken chips (e.g., plastics), pecking and controlled step-down reduce heat and improve chip evacuation.

Spending a little on good cutters will save you hours of rework.

Troubleshooting Common Performance Issues

When machinery gets moody, you want a checklist.

- Chatter: Increase spindle speed or decrease feed, shorten stick-out of the cutter, or add rigidity to the setup.

- Poor surface finish: Dull cutter, wrong feeds, or too much tool deflection. Try a new cutter or lower the feed.

- Lost steps: Check for overheating motors, loose belts, or insufficient acceleration settings. Consider closed-loop motors.

- Overheating spindle: Ensure proper cooling and avoid prolonged heavy cuts on weaker spindles.

- Vibrations: Add mass to the machine base, increase belt tension, or upgrade travel components.

Most issues respond to systematic diagnosis rather than guesswork.

Cost Breakdown: What $2,500 Buys You and What Extra Cost to Expect

A realistic budget includes machine, essential accessories, and likely upgrades.

- Base machine: $900–$2,200.

- Essential accessories: Quality cutters, collets, clamping kit, spoilboard: $150–$400.

- Recommended upgrades: Spindle swap, closed-loop motors, or ball screws: $300–$1,200 (choose based on material needs).

- Safety & workspace: Dust collection, E-stop, PPE: $200–$600.

If you’re frugal and hands-on, you can stay near $2,000 for a capable setup. If you want a near-turnkey, industrial-like box, expect to add another $500–$1,200 in upgrades and shop tooling.

Software: CAD/CAM and Control Choices

Your machine is only as good as the instructions you feed it.

- Fusion 360: Excellent all-in-one CAD/CAM, good for hobbyists and small shops. CAM post-processors for many controllers.

- Carbide Create & Motion: Lightweight and great for Carbide machines.

- LinuxCNC & Mach4: For more control and industrial features if you prefer on-premise control.

- GRBL: Cheap and open, but limited for advanced pipelines unless extended by plugins.

- VCarve/ Aspire: Commercial CAMs that are very capable for woodworking and signage.

Choose software based on the ecosystem your machine supports and the complexity of jobs you’ll run.

Maintenance Practices to Keep That Industrial Feel

You should treat your machine like a living roommate that cleans up after itself.

- Weekly: Clean chips, check belts/lasers, and inspect collets.

- Monthly: Check backlash, test homing switches, and lubricate leadscrews or rails.

- Quarterly: Verify belt tensions, re-tighten fasteners, and check spindle runout.

- Yearly: Replace worn belts, check motor bearings, and recalibrate steps/mm.

A disciplined maintenance log yields predictable uptime and long controller life.

Final Recommendations: Which Machine to Buy Based on Use Case

You’re probably deciding between size, precision, and upgrade path. Here’s an actionable guide.

- If you need high precision for small parts (jewelry, PCBs): Carbide 3D Nomad 3. Small footprint, excellent finish.

- If you need larger panels and signage, with potential for heavy wood/aluminum: LongMill 12×30 Mk3 with 1.5 kW spindle and ball screw upgrade.

- If you need large-format, low-cost cutting and are willing to reinforce the machine: BobsCNC E4/Pro with a spindle upgrade and bed stiffening.

- If you want a hybrid tool for crafts and light metal work: XTool or SainSmart hybrid machines configured with a proper spindle.

Always match the machine to repeatability and rigidity needs, not just price.

How to Decide: A Short Checklist You Can Use Now

Before you hit “buy,” run through this quick checklist.

- What materials will you cut most often?

- What maximum part size do you need?

- How tight do tolerances need to be?

- Are you willing to do upgrades and tuning?

- Do you need enclosed operation for dust, noise, or safety?

- What software ecosystem do you prefer?

If you can answer these, you’ll avoid buyer’s remorse and get a machine that actually gets work done.

Closing Thoughts (That Don’t Sound Like a Sales Pitch)

You want performance without the industrial price tag. In 2026, that’s not fantasy; it’s engineering plus an enormous maker community and better electronics. With an honest appraisal of limitations and a small budget for targeted upgrades, your under-$2,500 CNC can look like an industrial unit in action — not in raw brute force, but in predictability, repeatability, and throughput that matters in the real world.

If you like the idea of turning a smart purchase into a dependable production tool, you’ll enjoy the process. It’s part mechanical tuning, part process engineering, and part watching the machine chew through a piece of hardwood while you sip something warm and write down the speeds you’ll never forget.