Have we ever wanted to turn a quiet afternoon into a small parade of personalized gifts, etched cookies, and weirdly satisfying wood coasters that smell like a campfire minus the camping?

Our Experience With the Cloudray 5W Diode Laser Engraver

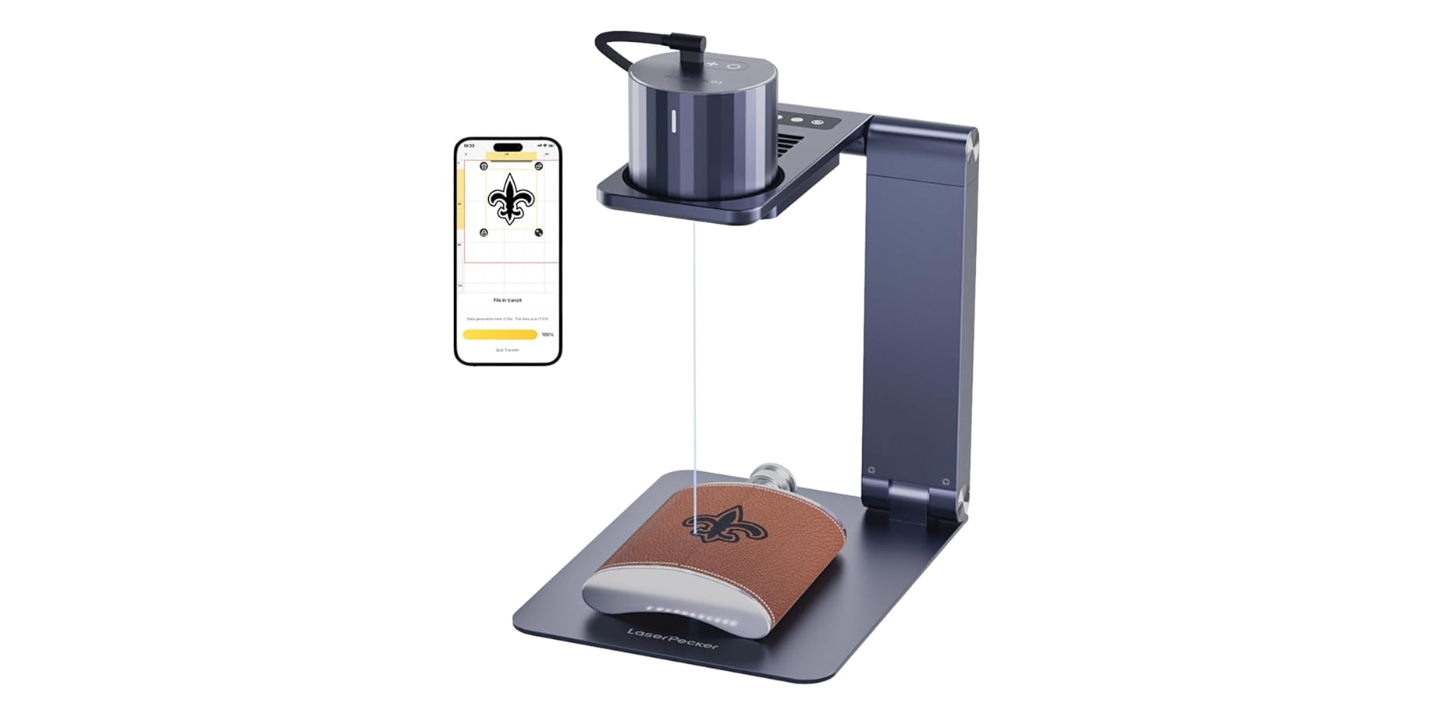

We brought the Cloudray 5W Diode Laser Engraver into our workspace like a houseguest we hoped would quietly do chores and not burn anything down. It’s a compact, enclosed Class 1 machine with 5000mW output, and once we discovered it could engrave a cookie and a pet tag in the same session, we started treating it like a friendly appliance rather than a mysterious tool. The enclosure helped; nothing reassures us like clear walls and a fan valiantly sucking smoke away.

Compared with open-frame diode engravers we’ve used, this one felt much more at ease in a normal home environment. We were less worried about stray reflections or that creeping dread that comes with exposed beams and curious pets. As far as first weeks with a machine go, this was breezy: minimal tinkering, quick setup, and lots of ways to succeed with small projects.

Cloudray 5W Diode, Laser Engraver Machine Mini Laser Etching Cutter for DIY Wood Leather Silicone Paper Glass Acrylic Cloth Enclosed Design Class1, 5000mW

$179 In Stock

Who This Machine Is For (And Who It Isn’t)

There’s a sweet spot for this laser, and it lives somewhere between craft-happy hobbyist and small-shop tinkerer who’s allergic to gargantuan equipment.

We’d recommend it to:

- Beginners who want a plug-and-play start and a safe, enclosed design.

- Teachers and STEM clubs needing a reliable, contained laser for classroom projects.

- Makers who work on small items like coasters, gift tags, wallet-sized art, pet tags, key fobs, and PCB labels.

- Bakers and food artists looking to surface-mark treats like macarons and cookies with a delicate touch (and proper food-safety practices).

- Side-hustlers selling personalized goods in compact batches.

We would not recommend it if:

- We plan to engrave metal regularly. Coated or anodized metals can work, but if bare metal is our future, let’s consider a Cloudray 50W fiber laser.

- We need to cut thick materials frequently. A 5W diode can kiss-cut and lightly cut thin stock but is not a lumberjack.

- We require a large working area for signs or long tiling runs. The 80×80 mm area is intentionally compact.

Safety and Design: The Calm of a Class 1 Enclosure

We’re fond of machines that take our health and eyesight seriously. The Cloudray’s fully enclosed Class 1 design is a like a hug for our nervous system. The lid shuts, the light stays contained, and the tilt protection quietly watches over everything like a minuscule lifeguard. If the machine is jostled or tipped, it responds appropriately. That little internal guardian might be our favorite feature after the fan.

The built-in exhaust fan gives us a serious leg up in managing smoke from wood and leather. We still aim for good ventilation—windows, open air, and ideally a simple fume path—but that onboard fan moves the smell in the right direction and makes the process feel at home on a desk instead of exiled to a garage.

Setup: Plug In, Point, and Produce

We tried to see how “plug-and-play” this really was, and it passed the fuss test. Assembly was minimal. Within minutes we had it powered, connected to a laptop, and nudging the laser module around. We felt comfortable guiding a beginner through setup over a video call, which is our metric for whether a tool will cause family arguments or not.

The box-to-first-engrave path goes something like:

- Remove and place the unit. It’s compact and portable at 7.04 lbs and roughly 8.03 x 8.96 x 7.39 inches.

- Connect to power and our computer.

- Choose software (CutLabx, LaserGRBL, or LightBurn, which is included).

- Drop in a test material and check focus.

- Import a design and set speed/power.

- Press go and watch it do what lasers do best: make our coworkers ask questions.

We liked that the learning curve never felt punishing. If we were new to lasers, we could operate safely and make something worth keeping on day one. If we were experienced, we could refine settings, build jigs, and run small batches without the sensation of driving a bus with a dinner fork.

Software: Making Friends With CutLabx, LaserGRBL, and LightBurn

We tried each software option in turn to see what felt natural.

- LaserGRBL is the fast, no-frills path for basic designs, line art, and grayscale tests. It’s refreshingly simple.

- CutLabx felt like a user-friendly bridge from beginner to intermediate—fewer knobs to turn at first, but enough control to adjust power and speed in sensible ways.

- LightBurn (included) is the go-to for refined workflows, layering, variable power, and organizing project libraries. We appreciated the deeply configurable settings and how easily it adapted to our muscle memory from past machines.

We gravitated toward LightBurn for nearly everything beyond a quick test burn. Its preview and optimization tools made it easier to balance speed and quality, especially with small fonts and intricate vectors.

The Numbers: Speed, Accuracy, and Working Area

We’re not usually number-driven romantics, but in lasers, specs matter. Here’s how the Cloudray 5W performed in our hands:

- Engraving speed up to 5000 mm/min. For clean marking, we often ran slower, but the ceiling is there when we need it.

- Accuracy of 0.01 mm, which we could feel on crisp text, QR codes, and fine patterns.

- A compact engraving area of 80 x 80 mm. At first glance, that feels tiny, but it turns out many daily “giftable” projects live comfortably within that footprint. If we needed to handle slightly larger pieces, we built cardboard jigs and tiled simple designs.

The small area actually encouraged better project discipline. Instead of sprawling into signage, we got tactical—coasters, bookmarks, layered tokens, ornaments, and small desk items. Sometimes constraints make us braver, or at least tidier.

Materials: What It Handles (and What It Politely Declines)

This laser is meant for a broad swath of everyday materials. It’s the sort of machine that grabs the stuff already in our drawers and quietly brands it better.

We had good results with:

- Wood (especially light woods): Coasters, ornaments, little badges, and bookmarks came out lovely. We liked how lightly scorching the surface gave us depth without smoke run. A thin layer of masking tape prevented residue on finished pieces.

- Leather: Wallets, tags, and cord organizers looked high-end with subtle darkening. We used vegetable-tanned leather for predictable outcomes.

- Acrylic (with backing paper): Engraving was clean when we kept the protective film or used paper backing. Glossy acrylic benefitted from extra patience and careful power.

- Plastic: Select plastics took well; we avoided those with unknown fillers. We did small test patches and looked for clean contrast without melting.

- Paper and cardstock: Perfect for greeting cards, gift tags, and packaging details. The precision made us feel like fancy stationers who own a cat and several pairs of stylistic glasses.

- Fabric and cloth: We got nice marks on light cotton, denim, and felt. A light tack spray or masking helped eliminate shifts.

- Silicone: Dog tags and watch bands acquired personality, as did a few kitchen items—though we kept food-safety in mind.

- Coated metals: Anodized aluminum tags and powder-coated flasks engraved neatly. Bare metals were outside its comfort zone.

For glass and acrylic, we used a backing paper as recommended. The paper trick ensures the beam has something to grab when marking smooth surfaces, and it cuts down on scatter and smudges. For metal marking on bare, uncoated surfaces, we’d need to upgrade to a Cloudray 50W fiber laser—that’s a different tool entirely, and we appreciated Cloudray being direct about that boundary.

Cutting vs. Engraving: Line in the Sand (or Sawdust)

The product bills itself as an engraver and cutter. Practically speaking, the cutting side lives in thin material territory—think paper, card, poster board, and some thin fabrics. For woods, we stuck to scoring or shallow passes unless dealing with very thin stock. If our dreams included slicing through thick plywood like a deli slicer, a diode at 5W isn’t the right knife.

We did, however, enjoy layering techniques:

- Score outlines on thin wood, then finish with a knife for precise shapes.

- Cut paper inlay pieces and drop them into shallow recessed engravings on wood.

- Create stencils and masks for later painting or frosting projects.

It’s not a lumber-cutting tool, but it excels at intricate, repeatable mark-making and light cuts that feel crisp rather than ragged.

Real Projects We Tried (And Loved)

We find machines more charming when they make useful things, not just smoke and noise. Here are some projects that gave us joy:

- Personalized wood coasters: We tested floral line art and vintage map fragments. The 0.01 mm accuracy crisped up delicate details, which felt like a flex.

- Anodized aluminum pet tags: Names and phone numbers popped with excellent contrast. We did a two-pass approach to deepen the mark.

- PCB labels: Nothing like labeling a board without smearing ink. This is where the small area and precision shine.

- Leather wallet initials: Subtle, classy, and immediately gift-worthy.

- Cookie surface art: We etched patterns onto macarons and sugar cookies, taking care to follow food-safe practices. Keep in mind, we only surface-marked toasting the tops lightly—no cutting. Afterward, we wiped down the interior and treated it like any tool used near food: clean surfaces, avoid cross-contamination, and separate our “food projects” from anything that leaves chemical residue or melts.

- Fabric tags and patches: Denim took delightful, deep marks. Felt came out nicely too, provided we dialed in power and kept airflow steady.

- Glass test tiles with backing paper: Frosted-style markings for small motifs. Clean, restrained, and surprisingly elegant.

The small workspace never felt like a punishment with projects like these. If anything, it matched the scale of our gift-giving attention span.

Performance Habits: What Worked Best

The more we used the machine, the more we favored settings that leaned conservative on power and compensated with multiple passes. This gave cleaner edges on wood, less charring on leather, and smoother gradients on fabrics. The included exhaust fan helps, but technique matters more.

We also appreciated:

- Masking tape: It saves cleanup time and keeps scorch marks from traveling.

- Test squares: A 20 mm test grid for each new material saved hours of guesswork.

- Focus checks: A quick focus check before each session kept lines tack-sharp. Minor focus issues show up as fuzz on tiny fonts.

- Organized project files: LightBurn libraries kept consistency across batches, which mattered when we revisited a successful setting weeks later and wanted to replicate it without rediscovering fire.

Living With the Machine: Noise, Smell, and Space

On the noise spectrum, the Cloudray’s fan hum is part of the background. It’s not silent, but it’s far quieter than heavy workshop tools. Conversations and podcasts continued without us turning into mime artists.

Smell is unavoidable when burning organic material, but the enclosure and fan reduce it to something manageable. We still prefer an open window or a simple duct path for longer sessions. If we’re in a classroom or shared office, schedule the wood jobs on days when the social calendar is lighter, or stick to materials with gentler odor profiles.

Space-wise, the footprint is friendly. It perches comfortably on a shelf or a desk corner and doesn’t demand absolute territory like bigger CO2 systems. We stored a small bin of materials alongside it—coasters, tags, felt, scrap acrylic, and a little notebook of settings.

Safety Mindset: What Class 1 Means for Us

Class 1 is a comforting designation. It means the laser’s hazardous emissions are contained during normal operations, which is what our nerves and eyeballs want to hear. That said, we still keep a safety habit:

- We never leave any laser unattended; even a safe design can’t babysit a rogue piece of material that flares.

- We maintain ventilation and keep flammable clutter away from the enclosure.

- We use materials we understand. Unknown plastics might produce fumes we’d rather not meet.

- We let the machine cool between marathon runs, and we keep the lens area clean. A clean lens is a happy lens.

The tilt protection is an extra layer—a polite bouncer that ushers us away from bad situations.

Workflow for Beginners: From Idea to Finished Piece

We remember being new to lasers and thinking, “Will this behave like a printer?” Sort of, but with a little more cause and effect.

Our beginner’s loop:

- Pick a material that’s forgiving (light wood, cardstock).

- Import a simple vector design (clean lines, no microscopic details on the first try).

- Start with mid-speed, mid-power. Avoid maxing out power on a first pass.

- Run a small test square with varying power to see where contrast peaks without char.

- Focus carefully and secure the material with low-tack tape or a jig.

- Run the job and watch. If edges smoke, lower power or raise speed.

- Clean edges with a soft cloth. Celebrate in a restrained manner, then do it again.

We learned more in three or four small runs than in a night of reading settings from strangers. The machine rewards our growing intuition.

Advanced Touches: Jigging, Batch Runs, and QR Codes

Once we hit our stride, we made a cardboard jig with cutouts for coasters and tags. That turned one-offs into neat little batches. We’d load a set, run the job, then reload without re-aligning.

QR codes worked better than we expected—just keep module focus tight and don’t make them microscopic. Engraving emails and URLs on the backs of gifts feels oddly professional, in a “we thought this through” way. If you’re doing school projects, QR links to a student portfolio add a lovely dimension.

We found that keeping text slightly heavier (think bold or semi-bold fonts) helps at small sizes. Delicate stroke fonts are lovely until 0.01 mm accuracy meets the battlefield of reality and the strokes vanish. We adjusted font weights instead of begging physics to behave.

Where It Sits Among Alternatives

We imagine a triangle of choices: diode, CO2, and fiber. The Cloudray 5W diode is clearly on the diode side: compact, safe, affordable, and friendly for smaller jobs.

Why choose this over a 10W or 20W diode?

- Safety and enclosure: Many higher-watt diodes are open-frame unless you seek an enclosed variant. If we want an easy home/school fit, this Class 1 enclosure is compelling.

- Footprint: It’s easier to fit in small studios and classrooms.

- Cost/complexity: 5W plus the right technique handles a surprising range.

Why not a CO2?

- CO2 brings more power and larger beds, but it ups the space and ventilation demands. It’s wonderful for cutting thicker acrylic and wood, but we treat CO2 as a committed relationship. The Cloudray 5W diode feels more like an amicable roommate who pays rent on time.

Why not fiber?

- Fiber is the king for bare metal. But it’s not a generalist for woods and leathers, and the cost is in a different stratosphere. We choose fiber when metal is the mission.

A Practical Spec and Use-Case Snapshot

Below is an at-a-glance breakdown based on our time with the machine and the provided specifications.

| Aspect | What We Noticed | Why It Matters |

|---|---|---|

| Laser Type & Power | 5W (5000mW) diode | Ideal for engraving a wide range of materials and light cutting of thin stock. |

| Safety | Class 1 enclosed, tilt protection | Feels appropriate for home, school, and small studios. Reduces anxiety and glare. |

| Exhaust | Built-in fan | Helps manage smoke; pair with fresh air for comfort. |

| Work Area | 80 x 80 mm | Compact but perfect for coasters, tags, patches, and small art. |

| Speed | Up to 5000 mm/min | Plenty fast for small-format work; slower passes often yield cleaner results. |

| Accuracy | 0.01 mm | Fine text, QR codes, and line art look sharp. |

| Software | CutLabx, LaserGRBL, LightBurn (included) | Smooth path from beginner to advanced workflows. |

| Materials | Wood, acrylic (with backing paper), leather, plastic, paper, cloth, silicone; coated metals | Versatile for crafts and small business goods. For bare metal, step up to a 50W fiber laser. |

| Dimensions & Weight | ~8.03 x 8.96 x 7.39 in, ~7.04 lbs | Easy to place, lift, and store. |

| Skill Level | Beginner to pro | Plug-and-play start with plenty of room to grow. |

Using It in a Classroom or Workshop

We tried to imagine the worst possible day in a classroom: someone’s late, someone else is chewing gum like it’s an Olympic sport, and everyone wants to engrave at once. The enclosure and tilt protection made us relax. A small queuing system—students prepping files in LightBurn and dropping into a shared folder—kept the flow steady. We used a simple sign-up sheet and limited sessions to small, quick jobs. When attention spans frayed, we switched to cardstock projects because they run fast and smell gentler.

We also liked how the small area naturally reins in ambition to something measurable inside a class period. A laser that finishes the job before the bell rings is a good laser.

Maintenance and Care

The Cloudray 5W diode doesn’t demand much, but it appreciates kindness:

- Keep the lens area clean. Dust and resin haze ramp up burn marks and cut contrast.

- Periodically wipe the enclosure window and interior surfaces where fumes settle.

- Check the fan path; a clear route keeps air moving, which keeps everyone happier.

- Keep a small log of settings and results. We learned to love our notebook as much as our masking tape.

None of this is arduous. It’s more like houseplant care than engine maintenance.

Troubleshooting: The Little Things That Make a Big Difference

We developed a shortlist of fixes for common hiccups:

-

Engraving looks faint:

- Lower speed or increase power in small increments.

- Ensure proper focus; a hair off can make a big difference.

- Try multiple passes instead of a single heavy pass.

-

Edges look charred on wood:

- Use masking tape to protect the surface.

- Increase speed slightly and offset with another pass.

- Ventilate better; smoke buildup scorches more.

-

Fabric looks melted or puckered:

- Drop power and raise speed.

- Use a light tack spray or masking to minimize movement.

-

Acrylic looks cloudy or smeared:

- Keep the backing paper on, or add it if none is present.

- Use gentler power and tighter focus.

-

Design won’t align across runs:

- Make a simple jig to position items consistently.

- Zero the origin and check it each run.

- In LightBurn, save the exact workspace and project.

-

Coated metal lacks contrast:

- Run an additional pass at slightly higher power.

- Clean the surface with isopropyl alcohol before engraving.

Food Decoration: A Word About Sensible Practices

We enjoyed etching simple patterns on macarons and sugar cookies. When we ventured into this edible territory, we stuck to sensible practices:

- Reserve a clean, food-only workspace for edible projects.

- Use fresh parchment or backing to avoid contact with residues.

- Keep the surface etching light—no deep burns, no melting sugar into oblivion.

- Clean the interior and lens area before and after, and segregate “food days” from other material days.

If our goal is elaborate food art, we’d create laser-cut stencils from paper or thin plastic (food-safe), then dust or spray on edible pigments. The Cloudray excels at making those stencils with precise detail.

The Learning Curve: Gentle, With Room for Mastery

We appreciated how quickly we got from a blank screen to something giftable. And the machine didn’t cap our ambitions. Once we learned the basics, it rewarded all the classic maker habits: jigging, material logs, tidy design files, and the occasional risk in the name of beauty.

We believe the measure of a good tool is in whether we find ourselves thinking of projects when we’re not in the room with it. This one prompted a borderline annoying number of ideas: bridesmaid gifts, family reunion coasters, teacher appreciation bookmarks, pocket notebooks with leather fronts, etched fabric patches, and a collection of absurd awards (“World’s Most Patient Neighbor,” etc.) that made every barbecue more ceremonial than it needed to be.

Pros and Cons

We like an honest list. It keeps us grounded when we fall in love with a machine’s personality.

Pros:

- Class 1 enclosed design feels genuinely safe and classroom-friendly.

- 5W power, 0.01 mm accuracy, and 5000 mm/min speed suit small-format projects beautifully.

- Works with CutLabx, LaserGRBL, and LightBurn (included), covering novice to pro workflows.

- Built-in exhaust fan reduces odor and smoke inside the enclosure.

- Compact footprint fits nearly anywhere.

- Versatile across wood, leather, acrylic (with backing paper), plastic, paper, cloth, silicone, and coated metals.

Cons:

- The 80 x 80 mm area is intentionally small—fantastic for tags and coasters, limiting for larger pieces.

- It’s not a thick-material cutter; think engraving-first, cutting-second.

- For bare metal marking, you’ll need to upgrade to a 50W fiber laser.

Frequently Asked Questions

-

Can it engrave metal?

- It can mark coated or anodized metals. For regular marking on bare metal, upgrade to a Cloudray 50W fiber laser.

-

Can it cut wood?

- It can lightly cut thin stock and score wood accurately. For cutting thicker wood or acrylic, a higher power machine is better.

-

Do we need experience to use it?

- No. It’s designed for beginners, with software options that grow with us.

-

What software does it support?

- CutLabx, LaserGRBL, and LightBurn (included). Start simple, then move up to LightBurn for more control.

-

Is it safe for a classroom?

- The Class 1 enclosed design with tilt protection and built-in exhaust fan makes it well-suited to supervised educational settings. Good ventilation and attentive operation still apply.

-

Can we engrave glass or acrylic?

- Yes, with backing paper. That helps the laser mark cleanly and protects the surface.

-

What about food?

- It can surface-etch items like macarons and cookies. Use careful, food-aware practices: clean the interior before and after, separate edible work from other materials, and keep passes light.

A Few Project Recipes We Loved

Sometimes it helps to have a playbook. Here are three fast recipes that show off the machine’s strengths.

- Anodized Aluminum Pet Tag

- Software: LightBurn

- Material: Anodized aluminum disc

- Settings: Moderate speed, moderate power, 2 passes for depth

- Tips: Use a jig to hold the disc; add test text at 3-4 font weights to see what pops best at size.

- Result: High-contrast, durable engraving that looks crisp from across a room.

- Wood Coaster with Line Art

- Software: LightBurn

- Material: Light birch or bamboo coaster, masked with painter’s tape

- Settings: Slightly slower speed, modest power, 1–2 passes

- Tips: Use masking tape to prevent smoke transfer. Remove tape immediately after engraving for clean edges.

- Result: Detailed illustration with minimal char, suitable for small batch gifting.

- Cookie Monogram (Surface Etch)

- Software: LaserGRBL or LightBurn

- Material: Flat sugar cookie or macaron

- Settings: High speed, low power, brief pass

- Tips: Separate edible projects from other materials; clean interior; keep the pass light to prevent scorching or excessive odor.

- Result: A delicate mark that feels celebratory without becoming dessert drama.

When We Wanted More Power

There were moments—usually when cutting—that we wished for something beyond 5W. A diode with more wattage or a CO2 would have been helpful for slicing thicker materials. But then we’d glance at our desk, notice the utter absence of an attached air scrubber the size of a washing machine, and forgive the 5W limit. It’s a tool built for human spaces, not just workshops. If we primarily engrave and occasionally kiss-cut thin stock, it fits like a glove.

Our Favorite Quirks

- The satisfying, contained theater of watching a job through the enclosure and knowing the light stays where it belongs.

- The way a tiny 80 x 80 mm canvas encourages thoughtful design decisions.

- The quiet relief of built-in tilt protection, which made us less precious about unplugging it every time we sneezed near the desk.

The Value Proposition

We’re not listing prices here, because they move around like cats, but we can talk value. This machine gives us:

- A safe, compact, Class 1 enclosure that belongs in homes, classrooms, and small studios.

- A set of software options that support simple projects up through more sophisticated workflows, with LightBurn included.

- Speed, precision, and a build that doesn’t feel finicky.

- A path to real products fast: tags, coasters, leather goods, packaged cards, and small batch items.

We’ve spent more on craft supplies and half-baked gadgets that produced less delight. This one keeps paying dividends in small, useful things that look professional and sellable.

What We Wish We’d Known on Day One

- Masking is our friend. It’s easier to prevent char than to invent a miracle cleaner.

- Backing paper on acrylic and glass is not optional if we want tidy results.

- A jig made from something simple (cardboard, MDF) is a lifesaver for aligning small objects.

- Two lighter passes can beat one heavier pass, both in looks and in fumes.

- A material test grid tells the truth. Trust it.

The Emotional Part (Because Yes, Lasers Have Feelings)

We sometimes expect tools to be loud declarations of intent: the giant saw, the industrial cutter, the dramatic ventilation duct that makes a living room look like a shipyard. This laser isn’t that. It’s small, reliable, and a little shy at first glance. But within a week, it had woven itself into our daily making. We found ourselves engraving things we’d never bothered personalizing before—drawer labels, box lids, the occasional tuxedoed cookie—and wondering how we managed without it.

It’s the difference between telling someone we thought about them and handing them a coaster with their handwriting etched in. People feel that difference. We did too.

Final Thoughts: Where It Lands in Our Workshop

The Cloudray 5W Diode Laser Engraver won us over by doing what it promises: safe, precise engraving in a compact, enclosed form. It supports beginners without condescension and gives experienced users enough control to do elegant work. Its small workspace is a feature if our projects match it, and a constraint if we need something larger; we learned to love what it pushed us to make.

For coated metals, wood, leather, acrylic-with-backing, plastics we trust, paper, fabric, silicone, and cookies that didn’t know they wanted monograms, this machine performed exactly as we hoped. When we dream of bare-metal marking or thick cutting, we know to look at fiber or CO2. But for the world of small-format personalization and prototypes—especially in places where safety and space matter—this little Class 1 box earns its keep.

We’ll keep using it for the quiet magic it delivers: an afternoon’s worth of gifts that look like we thought ahead, even when we didn’t. And in a life that sometimes feels like a scramble of keys, coffee, and misplaced intentions, precision delivered in a tidy 80 x 80 mm square feels like a kindly reminder that we can still make beautiful things, one neat engraving at a time.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.