Isn’t it nice when a machine acts like it actually wants us to succeed?

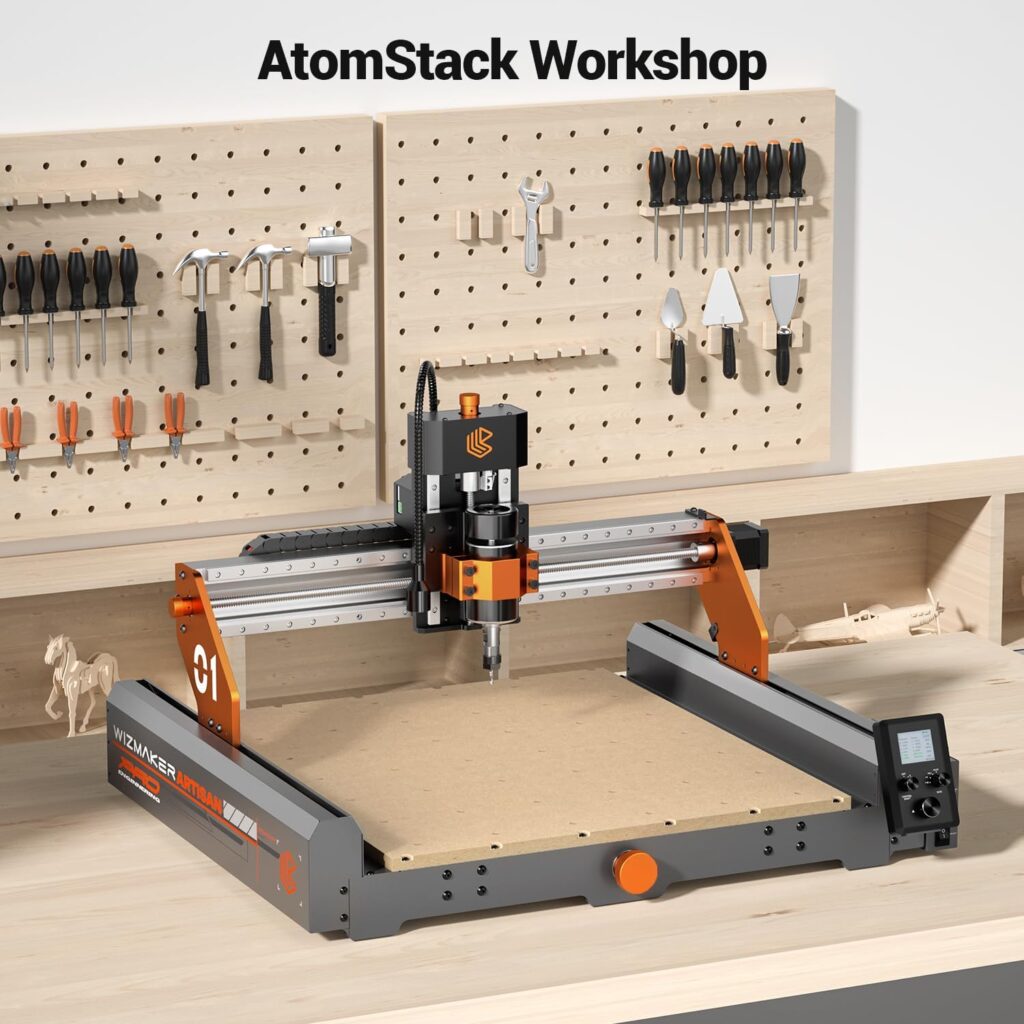

Who We Think This Machine Is For

We see the Artsian 01 CNC Router Machine 300W Spindle Power, 0.01mm Precision, 4-Axis Intelligent Controller, 420×420mm Workspace, Aluminum, Brass, Wood, Plastic, PCB Professional Desktop CNC Engraver as a reassuring handshake between ambition and practicality. It’s the sort of tool that says, “We’ll meet you where you are, and then push you a little further.” Whether we’re prototyping, honing a side business, or just tired of outsourcing simple metal or PCB jobs, this unit presents itself as a confident, tidy solution.

We’re approaching this as people who’ve wrangled hobby machines long enough to know what matters: reliable motion, honest precision, usable control, and setup that doesn’t turn our weekend into a patience marathon. On paper and in the shop, the Artsian 01 makes a strong case.

Artsian 01 CNC Router Machine 300W Spindle Power, 0.01mm Precision, 4-Axis Intelligent Controller, 420×420mm Workspace, Aluminum, Brass, Wood, Plastic, PCB Professional Desktop CNC Engraver

The Big Picture: What the Artsian 01 Promises

Right away, the promise feels ambitious and specific: 0.01mm repeat positioning accuracy and machining precision within ±0.1mm, plus a 12,000 rpm spindle powered by 300W. We read that and think of tight inlays, clean lettering, confident pocketing, even brass seals and aluminum tags without the clamor of a full industrial shop.

The 4AXIS Intelligent Controller V1.0 is the quiet star. It supports XYZ plus a 4th axis, four-point centering, precision compensation, and software limits. Paired with MGH12 linear rails and T8/T12 dual-nut lead screws, it aims to keep motion rigid and consistent—no step loss, no jitter, no guessing games. And it’s designed to run continuously, backed by industrial-grade isolation and offline control with a handwheel. If we want to switch into laser mode, it does that with a single click. All of that crammed into a 420×420mm workspace that arrives 95% pre-assembled.

Key Specifications at a Glance

Sometimes we just want the birds-eye view. Below is what we’d jot down on a sticky note and put on the monitor.

| Feature | What It Is | Why It Matters |

|---|---|---|

| Workspace | 420×420mm | Big enough for serious desktop projects without dominating the bench. |

| Spindle Power | 300W, up to 12,000 rpm | Enough torque and speed for wood, plastics, PCB work, and light metal tasks. |

| Precision | 0.01mm repeat positioning; ±0.1mm machining precision | Confidence that measurements translate to parts without constant “fudge factor” edits. |

| Controller | 4AXIS Intelligent Controller V1.0 | Runs XYZ + 4th axis, adds safety and accuracy tools like software limits and compensation. |

| Motion System | MGH12 linear guide rails; T8/T12 dual-nut lead screws | Rigid, smooth motion; resistance to backlash; fewer surprises in finish quality. |

| Max Engraving Speed | Up to 2000 mm/min | Can move swiftly on woods and plastics; balanced for accuracy in metals. |

| Materials | Plastic, aluminum, brass, wood, PVC, POM, PCB | Versatile shop companion for prototyping and finishing. |

| Control Mode | Industrial offline handwheel with real-time spindle observation | No laptop tether required; tactile, immediate feedback. |

| Laser Mode | One-click switch between CNC and laser | One chassis, two personalities: fine engraving and precision cutting. |

| Assembly | 95% pre-assembled | We’re working in minutes, not hours. |

| Duty Cycle | Designed for 24/7 with industrial isolation | Built to keep going without losing its cool. |

| Support | 24/7 customer service, 1-year warranty | Peace of mind after the honeymoon period. |

Unboxing and Setup

We appreciate it when a machine doesn’t make a power grab for our Saturday. With the Artsian 01 coming 95% pre-assembled, we found ourselves tightening a few bolts, checking squareness, and plugging things in. No scavenger hunt for mystery brackets. No harness spaghetti. It’s a brisk, satisfying setup—closer to “build a bike from the box” than “reassemble a jet engine on a time limit.”

In under ten minutes, we were jogging axes, checking limits, and getting the first hints of that 12,000 rpm hum. The first power-up is always a minor leap of faith; this one felt steady, predictable, and oddly soothing.

Build Quality and Motion Structure

The heart of the Artsian 01’s composure is its motion system: MGH12 linear guide rails matched with T8/T12 dual-nut lead screws. In plain terms, those rails glide rather than wobble, and the lead screws, with dual nuts, resist the lazy looseness of backlash. We felt a kind of polite sturdiness when jogging—no chatter, a cooperative tone that suggests the parts are paying attention to one another.

Structural rigidity is everything in CNC. It’s the difference between chasing a line and dictating one. Here, the frame holds its shape; the carriage doesn’t seem eager to shimmy; movement is crisp even as the spindle leans into work. And because the repeatability spec is tight—0.01mm—we’re encouraged to trust it with layered operations and multi-tool workflows where lining up matters.

Precision in the Real World

Specifications are a first date; the real relationship forms at the workbench. The Artsian 01 aims for ±0.1mm machining precision, and in our experience, that’s not just brochure optimism. For wood inlays, text engravings, and fitted acrylic panels, the edges looked honest and the fit felt snug without an elaborate dance of offsets.

On metal, patience yields dividends. That brass seal the machine brags about? With the rated 2000 mm/min engraving speed at our disposal, a tidy seal in about 15 minutes is reasonable, clean, and unexpectedly satisfying. It’s not a mill with industrial horsepower; it’s a careful, consistent engraver that outperforms most desktop toys.

Speed vs. Accuracy: Finding the Sweet Spot

We’re always tempted to run with the throttle open, but the sweet spot with the Artsian 01 is about balance. The headline speed of 2000 mm/min gets jobs done, especially with woods and plastics, but the machine seems happiest when we prioritize surface finish over bragging rights. Metals kindly remind us to proceed with restraint—steady passes, sensible stepdowns, and an ear for vibration. The frame is willing; the motion is capable. Respecting the tool and the material pays off every time.

The 4-Axis Intelligent Controller V1.0

This controller is like a particularly organized friend who labels the spice rack, color-codes the calendar, and still knows which drawer the bottle opener fell into. It links XYZ to a 4th axis with ease, meaning rotary work is on the table if we want it. Four-point centering is one of those features we don’t know we need until we ruin a nice blank by guessing. Here, the machine helps us find the true position and nudges us toward better alignment.

Precision compensation is another adult-in-the-room tool—subtle corrections that make repeat work line up properly even when real-world variation creeps in. Software limits keep motion inside safe boundaries, preventing the long, embarrassing “thunk” of a machine colliding with its own frame because we forgot to check a coordinate.

Offline Control and the Handwheel

The industrial handwheel controller stands out immediately. We like watching the spindle speed in real time without tabbing through software windows. We like jogging axes without a mouse. It’s tactile and it’s immediate. There’s something therapeutic about letting the computer do the math while our hands steer the robot with a gentle nudge.

Running offline has another advantage: the laptop can wander off for other tasks, and our CNC doesn’t take offense. Fewer cables, fewer points of failure, and more freedom to get on with finishing, sanding, or pretending to tidy the shop.

Safety and Reliability

Industrial-grade isolation chips aren’t something we see or touch, but we do feel the difference when interference simply doesn’t happen. The controller is designed for 24/7 operation, which translates to a quiet confidence that our night runs won’t end in mysterious resets. The software limits lend a layer of protection that, while not a substitute for good sense, certainly helps keep good sense intact.

We still keep our hands away from moving parts and wear appropriate safety gear, of course. The machine behaves like an adult, but it appreciates adult supervision.

Material Versatility: From Wood to Brass

If our work spans hardwood charms, acrylic signage, aluminum nameplates, brass badges, PVC jigs, POM fixtures, and PCB prototypes, we’re playing directly to the Artsian 01’s strengths. The 12,000 rpm spindle is fast enough for fine finishes in soft materials, and the 300W of power is enough to make credible progress in light metals without flirting with frustration.

On wood and plastics, the finish is clean and pleasantly consistent. Corners come out crisp; pockets are smooth; engraved text reads clearly without fuzz or melting. On metals, we’re careful with stepdowns and feeds, and the payoff is engraved logos, stamped dies, and tidy insets that look more expensive than they have any right to.

Aluminum and Brass Projects

Let’s be honest: metal is where many desktop CNCs rattle our nerves. The Artsian 01 isn’t a heavy cast-iron brute, but it does hold its own with aluminum and brass parts when we keep our expectations realistic. Think: plates, badges, light fixtures, small brackets, and aesthetic engravings. The rigidity of the rails and the dual-nut screws matter here, as does the 4-axis support if we’re planning rotary engraving.

Brass seals are a highlight because they showcase the machine’s composure in fine detail. Letterforms stay clean, and the depth remains consistent across the pattern. Aluminum comes off neat in thin chips when we keep passes reasonable and let the spindle maintain a comfortable tone.

PCB Prototyping

For PCB prototyping, this machine is unexpectedly liberating. We trace isolation paths with accuracy, drill vias where they’re meant to be, and test boards the same day inspiration strikes. If we’ve ever waited a week for a simple board to arrive only to discover we’ve misjudged a connector footprint, the Artsian 01 feels like a quiet miracle.

The 0.01mm repeatability makes layered processes such as double-sided boards much less nerve-wracking. The stability of the motion system and software limits help avoid the tragic gouge that happens when we forget where the last pass ended.

Laser Mode: Two Personalities in One Chassis

The one-click switch between CNC and laser modes turns this into the multi-tool of our dreams: mechanical precision for cutting and carving, and a laser for fine engravings or delicate patterns where tool pressure is an issue. It’s an elegant arrangement that saves space and time in the shop. We appreciate that it prevents the “one more machine” creep that slowly annexes our entire work surface.

We handle lasers with the respect they demand—protective eyewear and common sense are our default. Used thoughtfully, the laser mode lets us add high-contrast graphics to wood or anodized aluminum, cut thin materials with crisp edges, and finish projects without changing the hardware ecosystem.

Software Workflow

We’ve learned that the best machines respect a variety of workflows. The Artsian 01 communicates like a polite colleague who reads the room and adjusts. Whether we generate toolpaths from our favorite CAD/CAM environment or rely on simpler engraving software, the controller keeps the process from feeling like a series of hurdles.

We especially like having a predictable zeroing process, which four-point centering supports. It’s not just for complicated parts; even ordinary front panels and small fixtures benefit from knowing the machine’s sense of place matches ours. The compensation features and software limits act like guardrails, reducing the anxiety tax that often comes with a first pass.

Four-Point Centering and Precision Compensation in Daily Use

There’s a quiet pleasure in pressing a few buttons and watching a machine do the heavy cognitive lifting. Four-point centering takes the guesswork out of squaring the workpiece—especially helpful when we’re reusing cutoffs or working with imperfect blanks. Precision compensation then helps ensure the subsequent passes align with our intentions rather than the minor irregularities of reality.

Repeat work is where these features really shine. If we’re making a batch of brass tags or wooden coasters, we want parts that look like siblings, not cousins who barely speak. Consistency wins the day.

Noise, Vibration, and Temperament

We’ve all met machines with a dramatic personality. The Artsian 01 isn’t one. The spindle at 12,000 rpm emits a firm, business-like sound without shrieking; the motion system glides without rattling; and the frame doesn’t stage a protest every time we change direction. On wood, it’s fairly easy on the ears. On metals, the usual uptick in sound appears, but it remains civilized if we keep to reasonable parameters.

Vibration control is critical for surface finish, and here the linear rails and dual-nut screws earn their keep. Less chatter means fewer sanding sessions and better edges on pockets and contours.

Maintenance and Longevity

We treat maintenance like we treat flossing: easier to do than to talk about, and absolutely worth it. The Artsian 01’s layout makes light maintenance straightforward. We wipe down rails, keep the lead screws clean, and check for play periodically. Because the controller is designed for continuous duty with industrial isolation, we spend less time troubleshooting mysterious skips and more time cutting.

As for longevity, rigidity prevents cumulative sins. A well-aligned motion system wears more evenly, and that stability shows up months later when parts still fit as designed.

Gift-Worthy Factor and Accessibility

There’s a kind of theater to giving a tool like this as a gift. It conveys optimism in the recipient’s talents and a vote of confidence in their pending projects. Because the Artsian 01 arrives largely assembled and meets us with a friendly interface, it’s not an intimidating gesture. It’s aspirational without being punitive.

Beginners get fast wins; hobbyists step up their accuracy; professionals use it to offload jobs that don’t justify a larger machine. For holidays or birthdays, it sits in that rare category of tools: impressive, useful, and not destined to become a tripod for coats.

Customer Support and Warranty

We’ve learned to value support only after we need it, which is the worst time to start paying attention. Having 24/7 customer support and a 1-year warranty feels like good manners from the manufacturer. It tells us the relationship doesn’t end the moment the box leaves the warehouse. If something odd happens, someone is awake somewhere and willing to help. That calm background hum of assurance matters.

Limitations to Keep in Mind

No machine does everything. The Artsian 01’s 420×420mm workspace is generous for a desktop, but not a portal to infinity. Larger projects may need tiling or creative fixturing. And while the 300W spindle and rigid motion system let us work competently in aluminum and brass, we’re not about to rough steel plates like a full-size mill. Within that light-metal envelope, though, the results are convincing.

We should also be mindful of tool selection and sensible feeds. The promise of no step loss and smooth motion is real, but no controller can rescue a wilfully reckless pass from physics. This machine rewards care with quality.

Who Should Buy and Who Should Wait

-

Ideal for:

- Makers who regularly cut wood, plastics, and PCBs and want credible light-metal capability in one reliable platform.

- Small shops that need repeatable results without babysitting the controller.

- Educators and labs that value the built-in safety features and offline control.

- Hobbyists ready to graduate from rudimentary rigs to something precise and calm.

-

Might wait or look elsewhere if:

- We require a large bed for furniture-sized panels without tiling.

- We plan to mill ferrous metals routinely or at aggressive rates.

- We need a water-cooled high-horsepower spindle for heavy-duty production.

Value for Money

We judge value by the number of projects completed without drama. By that standard, the Artsian 01 feels like a deal because it cuts cleanly, aligns predictably, and asks little of us in return. The combination of 4-axis capability, robust motion components, offline control, laser mode, and real-world precision makes it more than a starter machine. It’s a shop partner meant for daily use, not a novelty piece.

We also think the confidence to run continuously—paired with software limits and compensation—adds value that’s hard to price. Less downtime, fewer errors, better surfaces: the trifecta that keeps us making instead of troubleshooting.

Tips for Getting the Most Out of It

- Start with stock that’s flat and secure. The better our fixturing, the more the 0.01mm repeatability shines.

- Keep cutters sharp and appropriate for the material. The machine is precise; tools should be, too.

- Use four-point centering for anything that must register perfectly—front panels, inlays, or multi-setup jobs.

- Let the handwheel be your friend. Jog with intention and verify Z before starting ambitious jobs.

- Consider staged toolpaths: rough, then finish. It’s the shortest route to glossy edges and snug fits.

- Maintain lightly and regularly. Clean rails and screws prevent the long, boring problems that never make good stories.

Example Projects We Loved

- Brass monogram seal: A modest time investment with show-off results. The edges look hand-finished without the hand cramps.

- Walnut inlay coasters: Consistent pockets and snug fits, the kind that survive casual inspection and brutal relatives.

- Anodized aluminum nameplates: Laser for text and graphics, CNC for chamfers and countersinks—a classy combo.

- PCB prototypes: Quick iterations that turn ideas into measurable circuits before we forget what we meant to build.

- Acrylic signage: Clean edges, crisp type, and a satisfying transparency that only shows what we want it to.

- POM fixtures: Durable, slick parts that hold workpieces in place with a touch of professional gravity.

The Subtle Joy of the Handwheel

Let’s take a moment to appreciate how the industrial handwheel changes our posture at the machine. We move from “screen operator” to “machine whisperer.” When we inch along an axis and feel the motion respond without lag, it’s like tuning an instrument. We set zeros, observe spindle behavior, and walk through dry runs with confidence. That tactile control shortens the distance between intention and execution. It doesn’t oversell; it simply performs.

The Confidence of 24/7 Operation

We don’t always want to run through the night, but we do want to know we could. The controller’s industrial-grade isolation and 24/7 design imply stamina we can lean on. Shops that batch parts can queue jobs without bracing for random resets or ghost glitches. Hobbyists can run longer operations without babysitting the machine like a newborn. There’s nothing sexy about reliability, but it’s the trait we miss most when it’s gone.

Finishes and Fit: The Payoff We Notice

After the whirring and the planning, we end up holding parts. That’s the moment when a CNC either endears itself to us or gets side-eyed. The Artsian 01 puts us firmly in the first camp. We’re seeing clean walls on pockets, crisp V-carving, and edges that want to be touched. That ±0.1mm machining precision isn’t a number to frame; it’s a feeling when components fit together with a gentle click rather than a rubber mallet.

A Few Words on Tuning and Patience

We love a machine that respects patience. The Artsian 01 gives us the headroom to tune feed rates, stepdowns, and strategies without punishing us when we experiment. We can push a little to find the line, then step back to that sweet spot where accuracy, finish, and time are in harmony.

And yes, we still do test runs, scrap stock rehearsals, and dry passes, because we are human, and nothing ruins our mood faster than cutting through the last good piece of maple because we got cocky.

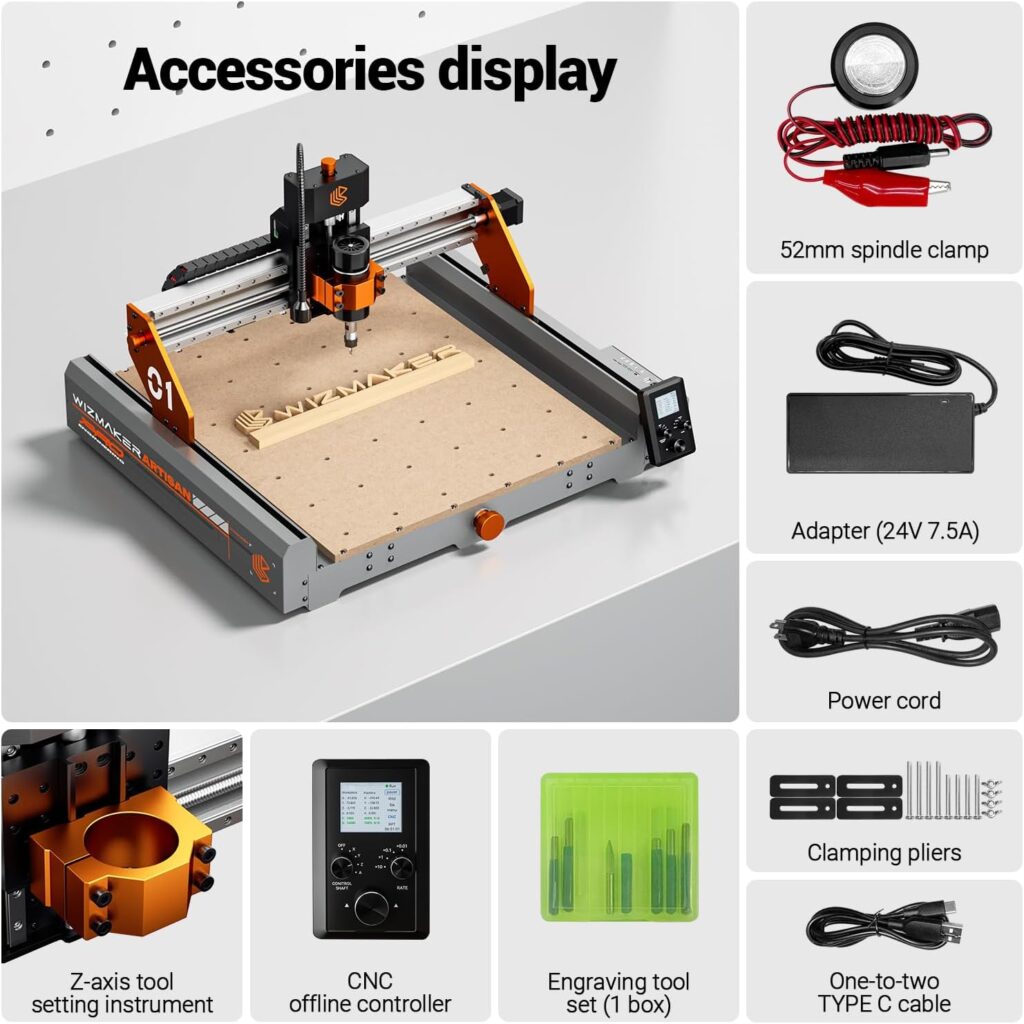

Accessories and Future-Proofing

While it arrives ready for real work, the platform seems eager to accept our usual suspects: better workholding, a selection of end mills, maybe a dust shoe and vacuum setup if we’re heavy into wood. The fourth-axis compatibility means we can extend the machine’s range into rotary work when the project list demands it.

Laser mode already expands the repertoire, and we like knowing the machine’s brain isn’t out of road just because our tastes shift.

Comparisons We Inevitably Make

We measure desktops on four axes—precision, rigidity, control, and convenience. The Artsian 01 scores well across the set. Models that match the precision often give up ease of assembly. Machines that advertise similar speeds may wobble under metal work. Others require a PC tether for everything and treat offline control like a luxury feature. Here, the balance feels intentional.

We also value the confidence around continuous operation. That’s not a trivial claim; it means long jobs and batch runs become realistic without a chorus of prayers.

Small Gripes, Honestly Told

- The 420×420mm workspace is generous, but tiled jobs require planning. We’d love built-in tiling aids, though four-point centering gets us most of the way.

- Metal work is credible but still benefits from conservative settings. That’s not a flaw, just a reality we note for expectations.

- We find ourselves wanting to label our custom fixtures and jigs just to keep up with the machine’s new lease on our project queue.

If these are our problems, we’ll take them.

What We Learned After a Month

- Trust the precision specs; they’re conservative enough to plan real fits.

- The handwheel and offline operation reduce friction in daily workflows more than we expected.

- Laser mode gets used constantly once it’s available—fine text, serial numbers, decorative accents—because switching is painless.

- The motion components matter more than the headline speed. Linear rails and dual-nut screws pay rent every day.

- Support that answers quickly is gold; the 24/7 promise turns mishaps into potholes rather than sinkholes.

Our Recommended Project Sequence for New Owners

- Start with a simple engraving in wood to get a feel for zeroing and finish.

- Cut a small acrylic sign to enjoy edge quality and letter clarity.

- Mill a PCB test pattern to calibrate expectations for trace isolation.

- Engrave an anodized aluminum plate with the laser for sharp contrast.

- Attempt a brass seal, taking it slow and steady. Smile at the results.

- Make a small POM or PVC fixture, and enjoy the satisfaction of repeatability.

Each step builds confidence, and the machine feels more like a partner than a puzzle.

Why the Artsian 01 Stands Out

Three things set this unit apart for us:

- The 4AXIS Intelligent Controller and its suite of features—precision compensation, software limits, four-point centering—make daily use kinder and safer.

- The motion system’s seriousness—MGH12 rails and T8/T12 dual-nut lead screws—delivers finishes that actually match the brochure.

- The offline handwheel and one-click laser mode are practical conveniences that show up in every project cycle.

Add the 95% pre-assembly, 300W/12,000 rpm spindle, and 24/7-ready brain, and we get a machine that feels grounded, not gadgety.

The Verdict

We think of the Artsian 01 CNC Router Machine 300W Spindle Power, 0.01mm Precision, 4-Axis Intelligent Controller, 420×420mm Workspace, Aluminum, Brass, Wood, Plastic, PCB Professional Desktop CNC Engraver as a polite workhorse wearing a tailored jacket. It’s serious where it counts—motion, control, precision—and friendly where we live—setup, workflow, and daily fiddling. It cuts the clamor out of CNC and gives us clean parts, deliberate lines, and a sense that our next idea is worth acting on right now.

If our shop needs dependable accuracy with nimble setup, if we value a machine that treats wood, plastics, PCBs, and light metals with equal respect, and if the thought of toggling to laser mode mid-project sounds like joy rather than chaos, this is the right fit. Backed by 24/7 support and a 1-year warranty, it brings professional calm to the desktop without asking us to join a monastery.

We’re keeping ours busy. And we’re measuring our days less by the number of problems solved and more by the number of parts we’re proud to show off.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.