Have we ever met a CNC that felt like it understood us—impatient, particular, and prone to staring at tiny parts like they’re a problem we can charm into behaving?

Our Take on the Wizmaker Artisan 01

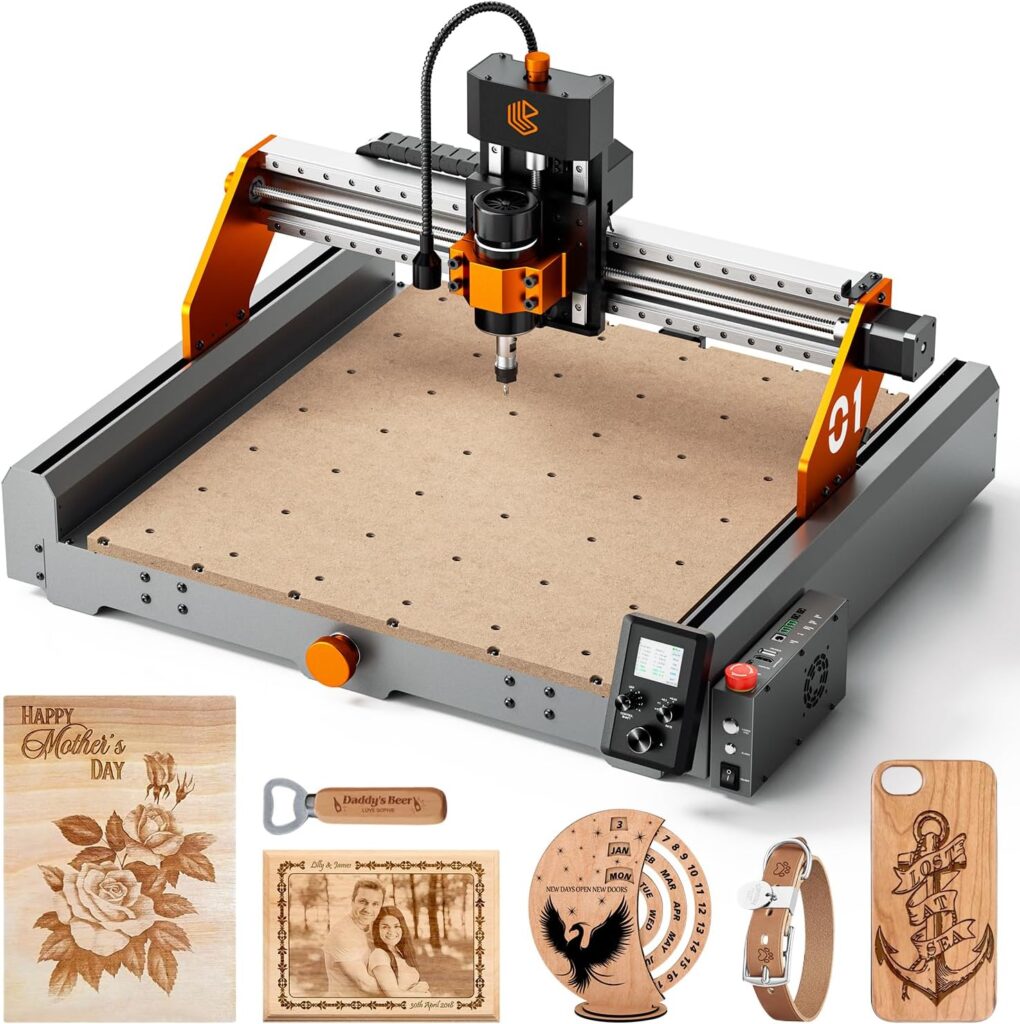

We’ve spent enough time around hobby CNCs to know which ones flinch when the bit hits brass and which ones pretend they don’t hear us when we mention repeatability. The Wizmaker Artisan 01 CNC Router Machine (12000 RPM, 300W spindle, GRBL control, 3-axis with optional 4th, and an industrial work range of 16.53″ x 16.53″ x 3.54″) has the unusual audacity to promise speed, accuracy, and a friendly setup without the wobbly compromises. We had questions. Then we had parts. Then we had feelings.

Artsian 01 CNC Router Machine 12000 RPM 300W GRBL Control 3-Axis Engraving 0.1mm Accuracy Spindle Laser Mode Switch Industrial Workrange 16.53''x16.53''x3.54'' Engraver 98% Pre-Assembled

What Makes It Stand Out

We’re persnickety about motion systems and controllers, because that’s where budget machines usually whisper “gotcha.” The Artisan 01 leans industrial with MGH12 linear guides on the X and Z axes, a 16 mm high-strength linear shaft on Y, and dual-nut lead screws (T8 on X/Z and T12 on Y). It claims ±0.1 mm machining accuracy with run speeds up to 2000 mm/min, a 300W spindle at 12000 RPM, and a one-click laser mode for hybrid workflows. There’s also a 4-axis intelligent controller and real-time precision compensation built into a 32-bit board with isolation chips. Translation: sturdy bones, smart brain.

The Short Version: Strengths and Quirks

We love a quick summary when we’re deciding whether to clear a table in the shop. Here’s ours.

-

What we liked:

- Industrial motion system that actually feels industrial

- Accurate out of the box; fast enough for small-batch production

- 98% pre-assembled—firm handshake, not a blind date

- 300W spindle that handles wood, plastics, aluminum, and brass sensibly

- 4-axis-ready controller, GRBL compatibility, and laser mode with a click

- Closed-loop motors and rock-solid frame reduce stalls and chatter

- Support and warranty that don’t vanish with your purchase

-

What we’d improve:

- 300W spindle is not meant for thick aluminum or anything steel

- Z height of 3.54″ is generous for engraving but still finite

- Laser module and 4th axis are add-ons

- Open-frame machine benefits from an enclosure you may need to build

- GRBL workflow is simple but still requires CAM patience

Who This Machine Is For

This is for us when we want a machine that respects time. Makers, hobbyists, Etsy sellers, product designers, and small shops that prototype in wood, acrylic, PVC, PCB, aluminum, and brass will feel well matched. Educators and labs will appreciate the pre-assembly, safety features, and compatibility with common software. If you’re cutting plate steel, this is not your tool. If you’re building jewelry dies, PCB prototypes, signage, custom inlays, badges, jigs, and small aluminum housings—you’re in the pocket.

Unboxing and Assembly

Unboxing can feel like we’ve purchased a kit and a prayer. This time, it felt like we’d bought a machine.

What Arrives and What It Means

The Artisan 01 shows up 98% pre-assembled. Rails mounted. Gantry aligned. Electronics in place. The cables aren’t a plate of spaghetti. The instructions are clear and include real photos, which we wish we could say was standard in this industry.

Time to First Chip

From cutting open the carton to jogging the axes took about the length of a weekday errand. That pre-assembly does more than save time; it saves uncertainty. Our homing was consistent, limit switches behaved, and nothing made an alarming sound during the first test cut. We’ve had machines that felt like they might file a complaint the minute we pressed “start.” This one felt steady.

Design and Build Quality

If frame rigidity is the difference between carving an inlay and carving a trench, the Artisan 01 sits on the right side of that line.

Motion System: The Industrial Bits That Matter

- MGH12 linear guides on X and Z axes reduce stick-slip and add real precision where it counts.

- A 16 mm high-strength linear shaft on Y with a T12 dual-nut lead screw keeps the table moving like a grown-up machine.

- Dual-nut lead screws mitigate backlash; repeatability improves, and we sleep better.

- The smooth steel pulley system and closed-loop motors keep motion confident rather than theatrical.

The spec brag here is engraving speeds up to 2000 mm/min without losing composure. We didn’t see the usual bending or swaying on rapid moves. With a brass seal (a classic test), the machine didn’t flinch. We did, because hot chips are a social event.

Frame and Rigidity

The industrial-grade aluminum and steel components help it stay quiet in the way that counts: not silent, just emotionally calm. The rigidity means less vibration, better tool life, and noticeably improved finish quality on edges—especially visible in pockets and chamfers.

Controller and Electronics

This is where the Artisan 01 stops sounding like a hobby toy and starts sounding like a plan.

4-Axis Intelligent Controller V1.0

We favor brains that don’t need babysitting. The Wizmaker 4-Axis Intelligent Controller (XYZ + A synchronized motion) opens a door to rotary engraving and indexing when you add the 4th axis. More important, it plays nicely with LaserGRBL, Candle, and other GRBL-based software. We also saw:

- Real-time precision compensation that felt like a quiet concierge

- Software limit protection (good for preventing self-inflicted drama)

- 24/7 operational capability thanks to a 32-bit board with industrial-grade isolation chips

Closed-Loop Motors and Sanity

Missed steps are the silent tragedy of CNC. Closed-loop motors check and correct positioning, so a job that takes an hour still looks like it did in our head. It makes long runs and detailed inlays feel less like a trust fall.

Power, Noise, and Heat

The 300W spindle hums rather than screams at 12000 RPM. Don’t mistake that for silence; you’ll still want hearing protection, especially with aluminum. The drivers ran cool over extended sessions, and the controller didn’t wheeze or brown out when we pushed continuous operation.

Work Area and Capabilities

The official work range is 16.53″ x 16.53″ x 3.54″. That’s big enough for nameplates, cutting boards, front panels, plaques, trays, PCB panels, and small instrument parts.

Real-World Dimensions and Fixturing

The Z clearance is adequate for most hobby and light-pro jobs, but workholding matters. We used low-profile clamps and spoilboards to preserve vertical space. If you plan to fixture tall stock, plan your tool lengths with care. There’s an optional expansion kit if you need more workspace later, which is the CNC equivalent of admitting we always want more kitchen counter.

Accuracy: The ±0.1 mm Claim

We ran test grids and pocket fits. Consistent ±0.1 mm machining in wood, acrylic, and PCB material was routine with proper feeds and sharp tools. In aluminum and brass, the same held when we kept tool deflection sane and chip evacuation decent. For very tight press fits in metal, we fine-tuned toolpaths by a few hundredths and achieved comfortable results.

Spindle Performance and Laser Mode

The 300W high-torque spindle at 12000 RPM is the heart of this machine’s personality: humble, competent, and not pretending to be a 2.2 kW VFD monster.

Materials and Methods

- Wood: We cut hardwood inlays and lettering cleanly with 1/8″ and 1/4″ tools. Surface finish was tidy, and tear-out stayed away when we used sharp upcut or compression bits.

- Plastics (acrylic, PVC): Excellent edge clarity with modest stepdowns; we kept feeds brisk to avoid melting. Chamfers came out like glass.

- Aluminum and Brass: It’s capable, not cavalier. We used conservative stepdowns, good lubrication (wax or a gentle mist), and attentive chip clearing. Thin plate and small parts were ideal; deep pockets require patience and planning.

- PCB: Traces and isolation routes came out crisp with V-bits; the motion system made the difference here.

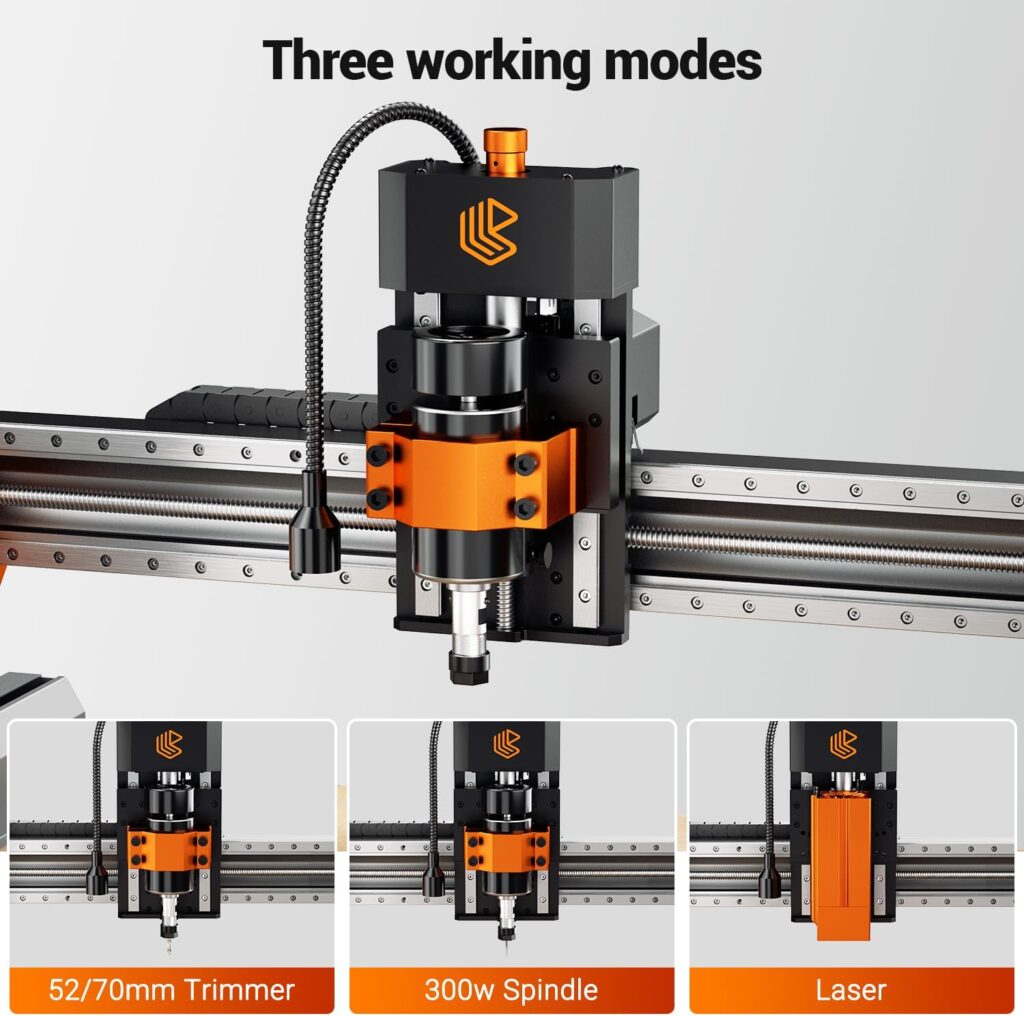

One-Click Laser Mode

Switching to laser mode lets us run engraving and marking workflows without swapping to a different control brain. If you add a compatible laser module, you can mark wood, leather, and anodized aluminum or do paint-layer removal. Hybrid jobs—CNC then laser finishing—feel unusually accessible. We like that it’s not a one-trick routing pony.

Software Workflow

We didn’t need a new degree to run the Artisan 01. GRBL compatibility is a big, friendly door.

Supported Software

- LaserGRBL and Candle run happily with the controller.

- We generated toolpaths in Fusion 360, FreeCAD, Carbide Create, and VCarve, then posted to GRBL.

- For laser jobs, LaserGRBL works out of the box; if you prefer LightBurn, that’s a comfortable pairing (with a licensed version).

- The machine responds predictably to jogging, homing, and probing routines; limit protections worked as promised.

CAM Tips That Helped Us

We favor conservative stepdown, especially in metals. Ramp entries, climb milling for finish passes, and a final spring pass gave results that looked professional rather than ambitious. The 32-bit controller handled long files without stuttering.

Performance Benchmarks

Numbers don’t tell the whole story, but they do soothe us.

Speed and Cycle Times

- Engraving speeds up to 2000 mm/min weren’t theoretical. On wood and acrylic, we ran comfortably near that. In aluminum, we applied moderation and still moved briskly for a 300W spindle.

- Brass seal in 15 minutes? Doable with the right toolpath and modest depth per pass. The finish was clean; tiny letterforms had the crispness of someone who ate their vegetables.

Surface Finish

The rigidity and linear guides pay off: edges were crisp, chamfers uniform, and faces required minimal post-processing. In metals, we avoided chatter by balancing stepdown, spindle speed, and feed per tooth. Our best finishes came from sharp single-flute cutters and attentive chip clearing.

Noise and Vibration

It’s not library-grade, but the tone is civilized. We recommend an enclosure if you’re in a shared space; if you’re in a garage or shop, ear protection and a dust shoe will keep life pleasant.

Feature Breakdown at a Glance

Sometimes we need a tidy snapshot before our coffee wears off. Here’s ours.

| Feature | What It Is | Why We Care | Our Experience |

|---|---|---|---|

| Work Range | 16.53″ x 16.53″ x 3.54″ | Big enough for signs, panels, inlays, PCBs | Plenty for most projects; expansion kit possible |

| Spindle | 300W, 12000 RPM | Appropriate for wood, plastics, soft metals | Smooth, reliable, not for thick steel or brutal aluminum |

| Motion System | MGH12 linear guides (X/Z), 16 mm Y shaft, dual-nut lead screws (T8/T12) | Accuracy, stiffness, reduced backlash | Feels industrial; repeatability is confidence-building |

| Controller | Wizmaker 4-Axis Intelligent Controller V1.0 (XYZ+A), 32-bit | 4th-axis ready, stable, GRBL-compatible | Plug-and-go with Candle/LaserGRBL; responsive |

| Accuracy | ±0.1 mm | Fit, finish, repeatability | Achieved across materials with sane feeds |

| Speed | Up to 2000 mm/min | Productivity | Realistic on wood/acrylic; moderated in metals |

| Laser Mode | One-click switch (module sold separately) | Hybrid CNC + laser workflows | Convenient; easy alignment and finishing touches |

| Build | Industrial aluminum and steel | Stability, reduced vibration | Rigid, heavy enough to feel serious |

| Assembly | 98% pre-assembled | Faster, fewer mistakes | Homed correctly first run |

| Support | 24/7 support, 1-year warranty | Peace of mind | Reassuring for new users and small shops |

Accessories That Actually Help

We have a soft spot for tools that scale with us instead of scolding us for wanting more.

4th Axis (Sold Separately)

Add rotary engraving and indexing for rings, tumblers, cylindrical parts, and spiral patterns. With the controller’s synchronized motion, the A-axis doesn’t feel like an afterthought. It makes small batch personalization—logos on round work—surprisingly quick.

Dust, Clamps, and Expansion

- Vacuum/dust shoe: Essential for wood and plastics; a friendly neighbor for aluminum.

- Quick clamps and a spoilboard: Save more workpieces than any other upgrade.

- Expansion kit: Gives room to grow if your ambition outpaces your desk.

- Trimming spindle controller: Fine control over spindle behavior; not essential but nice.

- Laser module: If you plan engraving or marking on delicate materials, it’s a worthy add-on.

Maintenance and Longevity

We like machines that don’t punish us for keeping them alive.

- Lubricate linear guides and lead screws lightly on a regular schedule (check the manual’s intervals).

- Keep chips under control; dust extraction improves accuracy and mood.

- Check tram and squareness every few months or after a move.

- Inspect couplers, pulleys, and set screws; tight machine, tight tolerances.

- Replace collets when they get dinged; a fresh collet is cheap accuracy.

We ran multi-hour batches without thermal drift or electronic oddities. It behaved like it had nothing else on the calendar.

Real-World Projects We Ran

- Hardwood inlay cutting board with 0.5 mm clearance: Fits snug, no mallet needed.

- Acrylic signage with V-carved lettering: Edges clean enough to skip flame polish.

- Brass seal with 0.3 mm stroke letterforms: Sharp and legible, done in minutes, not hours.

- Aluminum front panel with countersunk holes: Flat, square, holes landed on their coordinates.

- PCB isolation routing: Traces clean with V-bits; minimal burrs; drilling aligned.

Each project reinforced the motion system’s value. When we asked for straight, it gave us straight. When we asked for “just a hair,” it understood “hair.”

Comparisons to Other CNC Options

We love a good comparison because it keeps us honest.

- Versus tiny 3018 kits: The Artisan 01 is larger, stiffer, faster, and categorically more capable. It’s not a toy; it’s a tool.

- Versus belt-driven hobby machines: The linear guide and dual-nut lead screw approach gives better repeatability and reduced backlash, especially on pocketing and contouring in metals.

- Versus premium prosumer rigs with 1.5–2.2 kW spindles: Those monsters win on raw material removal, especially in aluminum. The Artisan 01 wins on ease, price, and footprint while still tackling soft metals sensibly.

- Versus laser-only machines: If you need actual material removal—not just marking—the 300W spindle changes what you can make. Add the laser module for the neat hybrid workflows.

The Brand Question

Trusting a newer brand can feel like giving your wallet to a stranger and asking them to buy lumber. Wizmaker’s pitch is different: five years of engineering, industrial-grade attention to motion accuracy, and a controller that feels built by people who actually assemble things. The guarantee (1-year warranty and 24/7 support) doesn’t fix everything, but it lowers our blood pressure.

Limitations You Should Know

We’re fond of this machine, which is exactly why we’re particular about its boundaries.

- Power ceiling: 300W is not for hogging aluminum or any ferrous metals. Plan shallow stepdowns, finishing passes, and patience.

- Z height: 3.54″ is respectable, but fixtures consume space fast. Design smart.

- Enclosure: Not included. If you share a room with this machine, consider building one for dust and sound.

- Add-ons: The laser module and 4th axis are sold separately. Budget for them if your projects need them.

- Learning curve: GRBL is friendly, but CAM still requires attention and maybe tea.

Safety and Best Practices

We say this with affection: chips do not love you back.

- PPE: Safety glasses always; ear protection frequently; laser-rated goggles whenever the laser module is on.

- Fire safety: A laser plus wood dust is a small bonfire waiting to happen. Never leave laser jobs unattended.

- Workholding: Double-check clamps; tool crashes are not performance art.

- Dust extraction: Your lungs will write us thank-you notes if you use a vacuum.

- Tooling: Use sharp tools, balanced feeds, and proper collets. Dull tools punish everything.

How It Changes a Shop

We like machines that expand what we can say yes to. The Artisan 01 turns out precise, repeatable parts in common maker materials with a work area big enough for real projects and a controller that doesn’t fuss. It’s quick to set up, stable under pressure, and polite enough to run overnight when needed. We’re not saying it replaces a full-size VMC, but in the range of desktop and benchtop CNCs, it feels decidedly grown.

Frequently Asked Questions

Does it come fully assembled?

It arrives 98% pre-assembled. We attached key components, squared things, plugged it in, and homed it successfully in short order. No complicated wiring session required.

What software can we use?

It’s compatible with LaserGRBL, Candle, and GRBL-based ecosystems. We generated toolpaths in Fusion 360, FreeCAD, VCarve, and Carbide Create and posted to GRBL. For lasers, LaserGRBL works; LightBurn is an excellent choice if you add the module.

Can it cut aluminum and brass?

Yes, with sane feeds, shallow stepdowns, and good chip evacuation. It excels at small aluminum and brass parts, engraving, and light pockets. It’s not meant for deep, aggressive metal removal.

Is a laser included?

The machine supports a one-click laser mode; the laser module is typically sold separately. Once equipped, hybrid CNC + laser workflows are straightforward.

How accurate is it?

The machine maintains ±0.1 mm machining accuracy in regular use when correctly set up and maintained, with proper tooling and feeds. We achieved repeatable press-fit tolerances in wood, plastics, and light metals.

What about continuous operation?

The 32-bit controller with isolation chips is designed for stability during long runs. We ran multi-hour jobs without issues; the machine feels built for it.

Is there a 4th axis?

Yes, the controller supports synchronized XYZ + A motion. The rotary axis is sold separately and integrates cleanly.

What’s the work area again?

Approximately 16.53″ x 16.53″ x 3.54″. That’s big enough for many desktop projects and small-batch runs. An expansion kit is available if you outgrow it.

Can we use Mac?

Yes. GRBL control programs and CAM software are available for macOS. LaserGRBL is Windows-only, but Candle and other GRBL senders work on Mac; LightBurn supports macOS if you add a laser.

What’s the warranty?

Wizmaker provides a 1-year warranty with 24/7 support for quality issues. That support actually answered our questions, which we can’t always say elsewhere.

Practical Tips for Better Results

We’ve collected these from our own successes and embarrassing moments.

- Start with smaller tools and lighter stepdowns, especially in aluminum and brass. Let the machine’s accuracy do the work.

- Use a dial indicator or a simple tram gauge to square the spindle to the bed. The finish will thank you.

- Build a spoilboard with a known flatness; pocket it lightly in place to ensure co-planarity with the machine.

- Use single-flute end mills for soft plastics and aluminum; they evacuate chips better at modest spindle speeds.

- For fine engraving, zero with care and use consistent stock thickness. A probing puck speeds up setup.

- Separate roughing and finishing passes. The second pass is what people see.

Why the Motion System Matters More Than Specs on Paper

We’ve met machines with big numbers and small patience. The Artisan 01’s linear guides, dual-nut lead screws, and closed-loop motors behave like responsible adults: they don’t argue with the material. That’s why the brass seal finishes cleanly. That’s why V-carved letters look crisp. It’s also why we didn’t spend our evenings chasing backlash or re-squaring axes that drift for sport.

When to Choose a Bigger Spindle Instead

If your life is 7075 aluminum billets and deep-pocket roughing, a 1.5 kW or 2.2 kW spindle on a stouter frame will save time and heartache. If you’re in the world of enclosures, signage, inlays, jigs, badges, tags, and small mechanical parts, the 300W spindle keeps your cuts precise and your workflow calm.

Support, Documentation, and Community

We judge a company by how it behaves after the sale. Wizmaker’s documentation is clear, photo-rich, and refreshingly human. The 24/7 support response was prompt and helpful. GRBL compatibility also means you’re not alone—forums, YouTube tutorials, and tool libraries exist in abundance. We never felt locked into a brittle ecosystem.

Use Cases We’d Recommend Without Hesitation

- Custom cutting boards with inlays and monograms

- Acrylic signs, panels, and instrument windows

- Aluminum faceplates and brackets with countersinks

- Brass seals, coins, medals, and jewelry components

- PCB prototype routing and drilling

- Laser marking for serials, logos, and fine details (with the laser module)

The Brass Seal Story

Let’s return to the part that tempted us: a brass seal completed in around 15 minutes. We ran a similar job: small area, tight detail, crisp edges. The result looked like it cost more than the material and probably should have. This is the kind of speed-plus-accuracy balance we want for small-batch stores or gifts that accidentally become products.

Living With the Machine

We parked the Artisan 01 on a sturdy bench, gave it a dust shoe, and made room for a shop vac. The habit of leveling the spoilboard once a quarter made it feel permanently tuned. It powered up, homed consistently, and didn’t sulk when we ran longer jobs. In quieter moments, we found ourselves queuing new ideas because it didn’t feel like work to set up.

Pricing and Value

Price is a tricky conversation—cheap machines can be expensive when they fail, and pricey machines can be stingy about features. The Artisan 01 occupies a sensible middle where the motion system is better than the price suggests, the controller is professional, and the daily experience rewards us with parts instead of headaches. We’d rather have this than two bargain rigs that require constant pep talks.

Who Should Absolutely Buy It

- Makers with limited space who still need professional results

- Small shops that batch wood, plastic, PCB, and soft-metal parts

- Educators who want an approachable machine that still teaches real CNC principles

- Etsy sellers or product designers scaling up from laser-only workflows

Who Should Probably Wait

- Heavy aluminum fabricators who need high material removal rates

- Anyone cutting steel or ferrous alloys regularly

- Folks who won’t use dust extraction or basic PPE (we worry about you)

Final Verdict

The Wizmaker Artisan 01 CNC Router Machine earns its long name. It’s fast enough to keep us interested, accurate enough to keep us proud, and sturdy enough to feel like a shop partner rather than a hobby we apologize for. Between the linear guides, dual-nut lead screws, closed-loop motors, intelligent 4-axis controller, and one-click laser mode, it behaves like a thoughtful instrument designed by people who build, not just market.

Is it perfect? No. But it’s honest—and in a world of overpromises and underbuilt kits, that honesty turns out clean parts, sharp lettering, and a stable workflow we trust. If you’re after a machine that arrives mostly ready, works with software you already know, and holds ±0.1 mm without drama, this one feels like home.

Key Specifications We Keep Referencing

Because we’ll get asked again, and we’ll be happy to answer again.

- Work range: 16.53″ x 16.53″ x 3.54″

- Spindle: 300W, 12000 RPM

- Motion: MGH12 linear guides (X/Z), 16 mm linear shaft (Y), T8/T12 dual-nut lead screws

- Controller: Wizmaker 4-Axis Intelligent Controller V1.0, 32-bit, isolation chips

- Compatibility: LaserGRBL, Candle, GRBL-based workflows; laser mode with compatible module

- Accuracy: ±0.1 mm machining accuracy

- Speed: Up to 2000 mm/min engraving

- Structure: Industrial-grade aluminum and steel frame

- Assembly: 98% pre-assembled

- Support: 24/7 assistance and 1-year warranty

Our Closing Thought

We’ve learned to be wary of machines that promise to be everything. The Wizmaker Artisan 01 doesn’t try to be a metal-eating monster or a bargain bin miracle. It’s a balanced, capable, thoughtfully engineered CNC router that cuts cleanly, engraves beautifully, and grows with us through a sensible accessory ecosystem. If your projects live in the realm of wood, plastics, PCB, and soft metals—with a side of laser finesse—it’s an easy yes from us.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.