Could we write this review in David Sedaris’s exact style? We can’t—but we can bring a witty, self-aware, and warmly conversational voice to the task, so here’s our take with that spirit in mind.

What We’re Reviewing

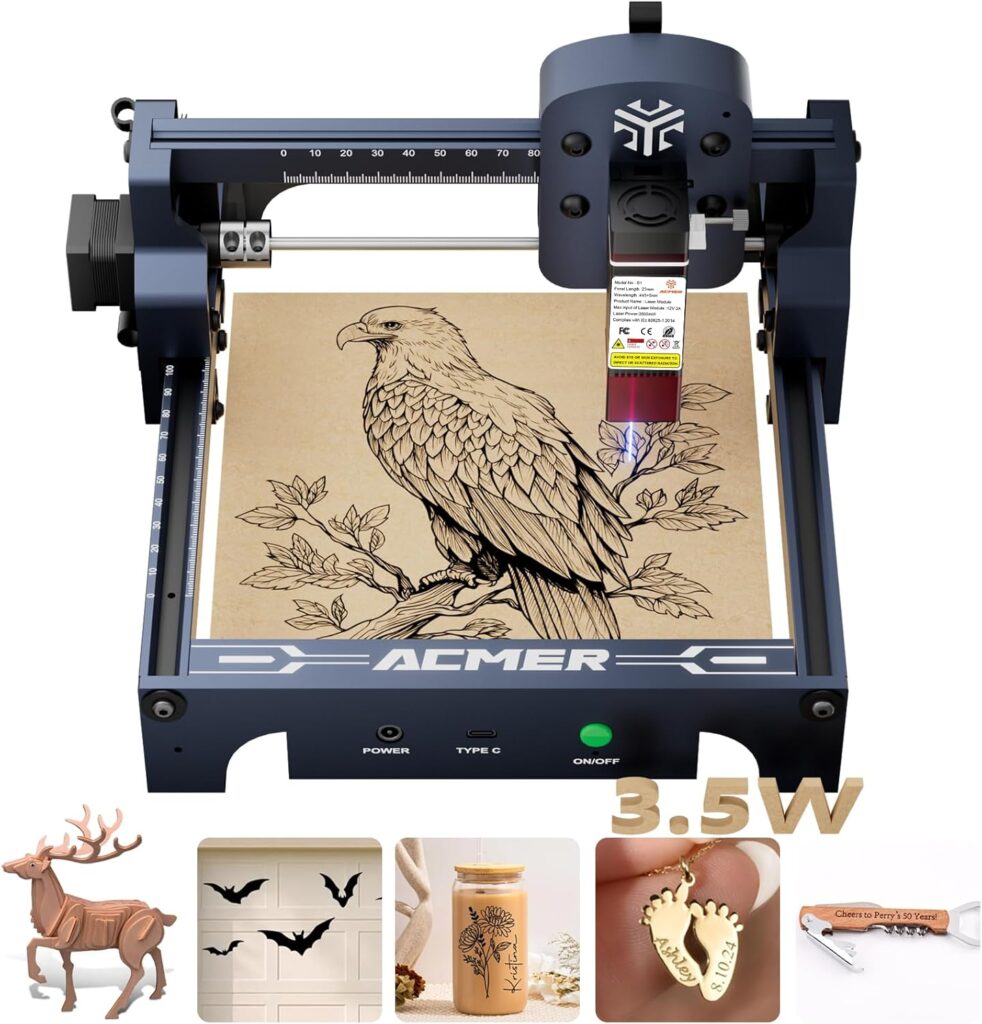

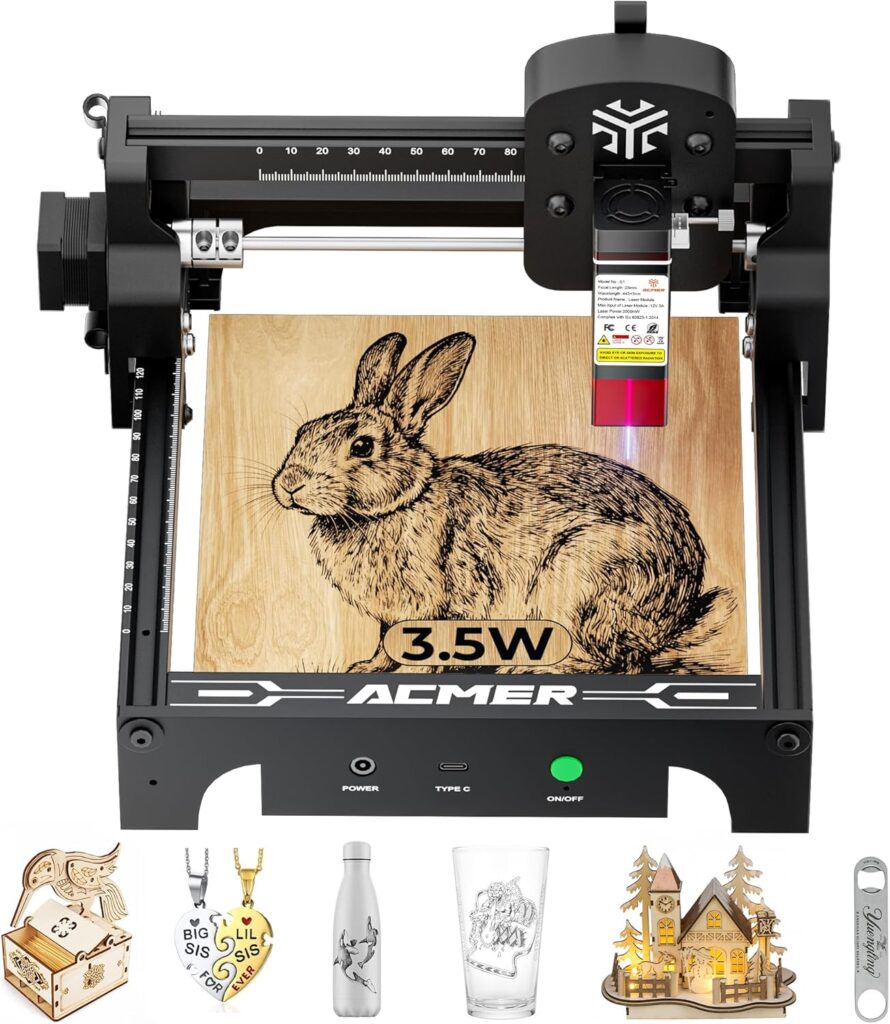

We’re looking at the ACMER S1 Laser Engraver, 3500mW Laser Engraver Machine Higher Accuracy Wood Cutter and Engraving Machine with Working Area 130x130mm, 0.04mm Laser Spot for Wood Acrylic Metal Glass. We’re treating it as a compact, beginner-friendly engraver that promises precise results without asking us to rewire our entire household to make room for it.

Why This Particular Model Caught Our Eye

We’re drawn to anything that thinks it can be precise, portable, and user-friendly all at once, because that often sounds like trying to juggle a watermelon, a cat, and a lit candle. The ACMER S1 claims to be that unicorn: ultra-fine engraving and cutting, preassembled design, and a footprint smaller than some coffee table books.

How We Structured This Review

We’re focusing on setup, software, performance across materials, real-world workflow, and who this machine suits best. We’re also including hands-on tips and a couple of neat tables to make the decision easy even when our coffee runs out.

ACMER S1 Laser Engraver, 3500mW Laser Engraver Machine Higher Accuracy Wood Cutter and Engraving Machine with Working Area 130x130mm,0.04mm Laser Spot for Wood Acrylic Metal Glass

$129.99 In Stock

Key Specs at a Glance

Sometimes the best way to set expectations is to lay everything out neatly, like a tiny charcuterie board of technical facts. Here are the essentials we kept coming back to whenever we wanted to evaluate performance versus practicality.

Core Specifications and Compatibility

We’re including the “need-to-know” items that determine whether this machine fits our projects, desk space, and patience level. If any one of these specs makes your eyebrows arch in a good way, you’re probably the intended audience.

| Feature | Detail |

|---|---|

| Laser Type & Power | Diode laser, 3500 mW optical power |

| Machine Output | 36 W total machine output |

| Wavelength | 455 ± 5 nm |

| Focal Length | 2 mm |

| Laser Spot Size | 0.04 mm |

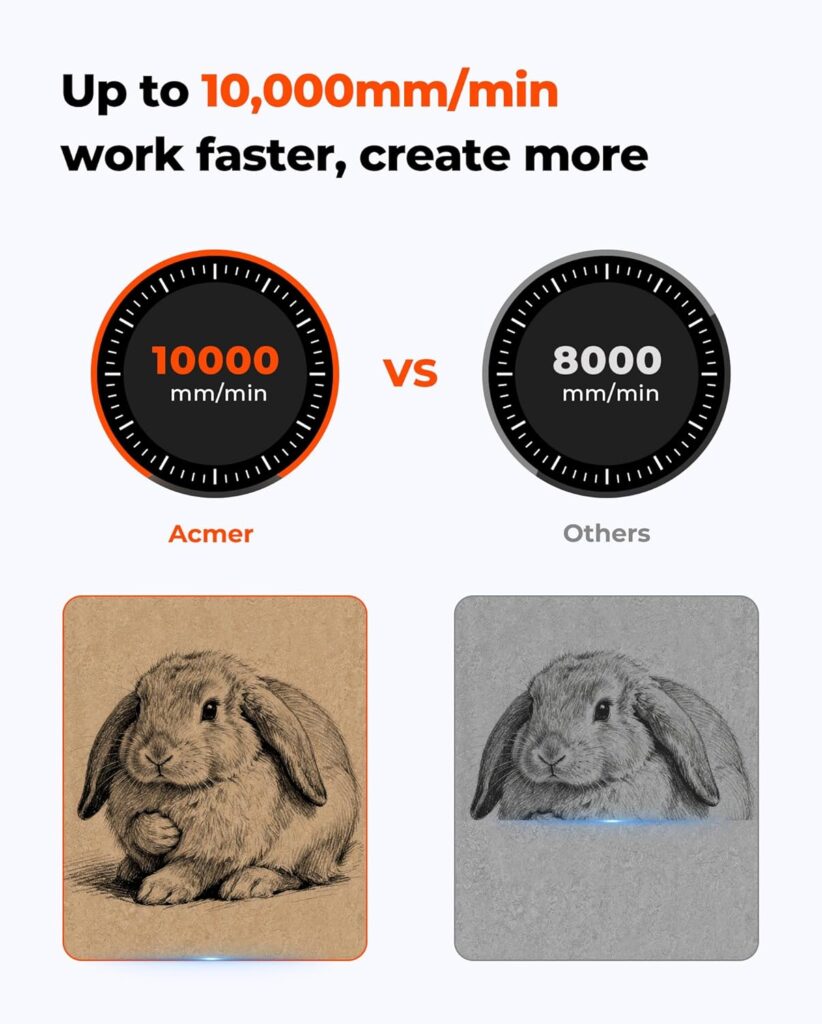

| Max Engraving Speed | Up to 10,000 mm/min |

| Repeatable Positioning | 0.01 mm |

| Working Area | 130 x 130 mm |

| Machine Size | 250 x 250 x 162 mm |

| Weight | ~2 kg |

| Materials (Engrave) | Wood, bamboo, leather, plastic, PCB, aluminum oxide, ceramics, coated metals, glass (with proper prep) |

| Materials (Cut) | Thin plywood, MDF, acrylic (multiple passes as needed) |

| Software Included | AcmerTool (free, optimized) |

| Other Software Support | LightBurn, LaserGRBL |

| OS Compatibility | macOS, Windows, Linux |

| File Formats | NC, DXF, BMP, JPG, PNG |

| Safety & Certification | Class 4 laser, IEC 60825-1 compliant |

| Warranty & Support | 12-month warranty, 24/7 support |

| Processor | High-performance multi-core controller (supports multiple units) |

Setup and First Impressions

We love when a machine arrives mostly assembled; it feels like a manufacturer out there fought on our behalf to save us from ourselves. The ACMER S1 shows up 99% preassembled, with just a quick laser head installation that takes about a minute.

Unboxing Without the Drama

We appreciated the tidy packaging and how little time it took to go from cardboard to carving initials on scrap plywood. We didn’t have to hunt for exotic hex keys or interpret hieroglyphics just to get the head mounted.

The Moment of Truth: First Power-On

We powered on, installed AcmerTool, and tested a small vector logo within minutes. That first engraved line looked crisp enough to make us feel like we’d paid extra for a sense of accomplishment.

Build Quality and Design

If we could outfit every tool in our workshop with industrial-grade aluminum alloy, we would. The ACMER S1’s chassis feels tough yet light enough to carry one-handed like a fancy lunchbox.

Compact and Properly Portable

With a footprint of 250 x 250 mm and a height of 162 mm, this machine earns its space. It’s sturdy, but not imposing—we moved it from desk to shelf to kitchen table (don’t tell our family) without needing a spotter.

Working Area: Realistic Expectations

A 130 x 130 mm work area sounds small until we start designing projects that fit comfortably within it. Phone cases, coasters, keychains, plaques, name tags, and small signs all work beautifully here.

Software Experience

We’ve become wary of “free software included” because sometimes “free” means “free to frustrate us.” But AcmerTool is genuinely helpful and clearly tuned for this hardware.

AcmerTool: Ready Right Out of the Box

AcmerTool’s layout is straightforward: quick device connection, clean job preview, and easy control of speed, power, and passes. We were engraving test patterns before our tea went from hot to mildly accusatory.

Third-Party Options for Tinkerers

We also appreciated the support for LightBurn and LaserGRBL. If you’ve built a groove around those tools, you won’t have to relearn everything. File compatibility (NC, DXF, BMP, JPG, PNG) makes it easy to carry designs across software ecosystems.

Safety and Certification

We don’t mess around with lasers, and we don’t recommend you do either. The ACMER S1 is a Class 4 laser device, IEC 60825-1 compliant, which translates to: treat it with respect and don’t stare at it like it’s a campfire.

Practical Safety Habits We Actually Follow

We wear proper protective eyewear rated for the wavelength, keep the work area ventilated, and avoid leaving the machine unattended. We keep a fire extinguisher nearby, especially when working with wood or cardboard.

Materials That Demand Extra Care

Reflective or glossy surfaces can scatter light unpredictably, so we proceed at lower power and with extra caution. Acrylic and plastics can produce unpleasant fumes, so ventilation isn’t optional—it’s your nose’s future thanking you.

Performance: Accuracy and Speed

We didn’t buy a laser engraver to admire it from across the room; we want fine lines and predictable results. With a 0.04 mm spot size and 0.01 mm repeatable positioning, the ACMER S1 surprises us by how detailed it can get.

Engraving Detail That Holds Up Close

Text as small as 4–5 pt is legible on lighter woods with the right speed and power. Line art and logos look sharp enough for client work, and halftone photo engraving is feasible with thoughtful testing.

Speed That Feels Respectful of Our Calendar

At up to 10,000 mm/min, we find the S1 fast enough for batches of small items. We’re realistic: not every material wants to be rushed, but the machine gives us headroom for fast raster passes.

Material Results: What We Achieved

Materials behave like characters in a novel—some are eager show-offs, others need coaxing, and a few only behave if we feed them pancakes first. Here’s what worked for us with measured expectations.

Engraving Across Different Surfaces

- Wood/Bamboo: Consistently great results. High contrast, sharp edges, and lovely shading at lower power.

- Leather: Clean and dark with a bit of smoothing pass. We keep power moderate to avoid char that rubs off.

- Plastics: Good on laser-safe types; we avoid PVC or anything that releases toxic fumes.

- PCB: Fine traces and labels engrave neatly. Great for prototyping and labeling boards.

- Aluminum Oxide/Ceramics: Etches cleanly for markings, logos, and serials.

- Glass: Works best with a surface prep (e.g., coating with paint or a marker) to improve contrast.

Cutting Behaviors and Best Use Cases

- Thin Plywood/MDF: Multi-pass cutting works; the machine’s 3500 mW laser can handle small decorative pieces, tags, and inserts. We mind material quality and glue types, which affect charring and edge finish.

- Acrylic: Works on certain types (cast acrylic cuts cleaner than extruded). For thicker sheets, patience and multiple passes are our friends.

Quick Reference: Material Outcomes and Tips

We like a cheat sheet we can glance at before starting a job, because nothing ruins our momentum like guesswork. These are typical outcomes; your mileage will vary based on material, color, and settings.

Handy Material Guide

We’ve summarized how the S1 handled some common materials in our workshop. It’s not a recipe book, but it’s a trustworthy starting point.

| Material | Engraving Quality | Cutting Ability | Notes |

|---|---|---|---|

| Birch Plywood (2-3 mm) | Excellent contrast | Good with multiple passes | Blue tape helps reduce scorch marks |

| Bamboo | Excellent | Limited cutting | Engraves with deep contrast; watch for grain |

| Leather (veg-tan) | Very good | Limited | Lower power to reduce odor and char |

| Acrylic (cast, 2-3 mm) | Good | Fair with multiple passes | Better with slower passes; good ventilation needed |

| MDF (2-3 mm) | Good | Fair with multiple passes | Uniform but prone to heavier charring |

| Anodized Aluminum | Excellent | N/A | Marks cleanly; no cutting |

| Ceramic Tile | Good | N/A | Slow, steady passes for legible text |

| Glass | Good (with prep) | N/A | Apply coating for best contrast |

| PCB (FR4) | Good | N/A | Great for labels and simple artwork |

Working Area and Project Planning

The 130 x 130 mm working area nudges us to plan smartly, and we don’t see that as a drawback. It’s like designing for a postcard—constraints make us sharper.

Tiling and Jigs for Larger Jobs

We align designs in sections and use simple jigs to keep repeatability tight. With careful registration marks, we can split larger artwork across multiple passes without obvious seams.

Batch Work on Small Items

Keychains, tags, coasters, and small panels are perfect candidates for batch runs. We line up blanks, save a template, and let the S1 carve its tidy little heart out.

Precision, Alignment, and Focusing

Nothing kills quality like a bad focus. With a 2 mm focal length and that tight 0.04 mm spot, the S1 rewards our attention to detail.

Focus Routines That Save Projects

We take a moment to adjust the Z height and do a quick ramp test on scrap. Once dialed in, we can repeat clean results across a set without micromanaging.

Alignment Tricks We Use

We run a low-power outline pass to confirm position before engraving. It’s a small step that saves us from the quiet despair of engraving a design half an inch off.

Noise, Smell, and Home Use

Our apartment—and our neighbors—prefer quiet tools. The S1 hums, but it’s not loud enough to interrupt a podcast episode. The smell, however, depends entirely on what we cut.

Ventilation and Odor Management

Wood and leather smell like, well, wood and leather being heated. Acrylic and some plastics are harsher. We set up near a window with an exhaust fan or use a basic enclosure with ducting for longer sessions.

Clean Workspace, Clean Results

We vacuum debris and wipe the work area. Lenses and mirrors (if present) appreciate being clean, too—residue builds up faster than we expect and can kill power.

Productivity and Multi-Unit Control

We rarely think “We should run two at once” until we realize we can. The S1’s high-performance multi-core processor promises reliable operation, and the ability to control multiple units can be a quiet superpower.

Running Multiple Machines

With a second unit, we run one for engraving and the other for cutting, or duplicate the same design for quicker fulfillment. It’s like having twins who don’t fight over snacks.

Throughput for Small Shops

If our business involves small items—custom key fobs, nameplates, little signage—doubling machines scales output without needing a bigger footprint.

Real Projects We Loved Doing

We judge tools by the smiles they produce, not just the specs. These are the kinds of projects that left us nodding approvingly like satisfied raccoons.

Giftable and Personal

- Custom coasters with line art and quotes

- Leather keychains with initials and dates

- Bamboo utensil handles with kitchen jokes we’ll deny writing

Practical and Professional

- Label plates for electronics and PCBs

- Anodized aluminum tags for gear

- Serial numbers and QR codes on small parts

Cutting Performance in Practice

We’re realistic about what a 3500 mW diode can cut. It’s not a CO2 laser, and that’s okay. For thin plywood, MDF, and acrylic, it handles hobby projects and light professional work well.

Edge Quality and Multi-Pass Strategy

Clean edges are very doable with slower speeds and multiple passes, and blue painter’s tape helps reduce scorch marks on plywood. We embrace test cuts—there is no shame in sample grids.

Design Choices That Help

Rounded corners cut cleaner than sharp inside angles, and avoiding micro details in the cut path saves time and nerves. We remind ourselves that the design is ours; we can make it easier to produce.

Comparing the ACMER S1 to Alternatives

We’ve tried beefier diode units and CO2 systems. Each has a place, but they often come with trade-offs in price, size, and learning curve.

Against Larger Diode Machines

More powerful diode lasers cut thicker stock and can be faster on denser materials, but they take more space and can cost more. The S1 stays nimble and budget-friendly.

Against CO2 Systems

CO2 machines are the champions of clean acrylic cuts and thicker materials, yet they’re bigger, pricier, and require more setup and maintenance. The S1 wins on portability and simplicity.

Pros and Cons

Lists help us keep our heads straight, especially when our enthusiasm threatens to make everything sound like a miracle. Here’s how the balance shakes out.

What We Love

- Compact, sturdy, and genuinely portable

- Impressively detailed engraving with a 0.04 mm spot

- 99% preassembled; we were running in minutes

- AcmerTool is easy to use; third-party software support is excellent

- Works across many materials (engraving) and handles cutting of thin stock

- Cross-platform with broad file format support

- Class 4, IEC 60825-1 compliant, with real warranty and round-the-clock support

- Reasonably quiet and simple to maintain

What Gives Us Pause

- 130 x 130 mm work area requires thoughtful planning for larger projects

- 3500 mW diode cutting is best for thin materials; don’t expect miracles on thick stock

- Glass and certain metals need surface prep for good contrast

- Open-frame layout means we must be vigilant about safety and fumes

Tips for Best Results

We keep a short list of habits that boost quality. Little rituals, big improvements—that’s our mantra when we’re laser-happy and slightly caffeinated.

Quick Wins

- Test grids: We engrave a power/speed test on scrap for every new material.

- Focus checks: A minute spent on focus saves a project from mediocrity.

- Painter’s tape: Great for reducing burn marks on wood cuts; peel after.

Settings and Strategies

- Lower power, faster speed for light, crisp engraves; higher power, slower speed for darker marks.

- Multiple light passes often beat a single heavy pass for both quality and safety.

- For photos, try dithering modes and fine-tune dot size in software.

Maintenance and Care

We think of maintenance as the tiny rent we pay for precision. The S1 doesn’t demand much, but it appreciates consistent attention.

Routine Checklist

- Clean lens and protective windows regularly to maintain power and clarity.

- Check belt tension and frame screws every so often; vibrations are the enemy of precision.

- Keep firmware and software updated when available for stability and features.

Work Surface and Jigs

- A honeycomb panel or risers help with airflow and reduce back burn on cuts.

- Simple jigs made from scrap wood or acrylic keep parts aligned for batch work.

Troubleshooting Common Issues

Some days the stars misalign, and we get banding or faint engraves for no reason we can accept as civilized. The fixes are usually straightforward.

Fixes We Actually Use

- Faint Engraves: Clean the lens, check focus, slow down slightly, or increase power incrementally.

- Banding/Lines: Verify belt tension, check wheel wear, and ensure the work surface is flat.

- Connectivity Glitches: Try a different USB cable or port, and ensure drivers are updated. Close other software that could be grabbing the device.

Material-Specific Oddities

- Acrylic Melting: Increase speed, reduce power, and consider multiple passes.

- Wood Scorching: Apply painter’s tape, reduce power, or lower the pass count with slower movement.

Customer Support and Warranty

We appreciate when a company doesn’t vanish like a magician after the sale. The 12-month warranty and 24/7 customer support make the ACMER S1 feel like a safe bet for beginners and pros alike.

What That Means in Practice

Real humans respond to issues, and the documentation won’t make us cry. It’s a relief when guidance shows up without asking us to decode a riddle first.

Confidence for First-Time Users

Knowing there’s help waiting if something goes sideways gives us the courage to try new materials and push our designs a little further.

When Portability Matters

There are times when shaving an inch off the footprint means the difference between setting up today and waiting for a weekend that looks suspiciously like never. The S1 packs away and comes back out with minimal drama.

Moving Between Spaces

We appreciate being able to work on the balcony, the office, or a maker space without worrying about a forklift. It’s easy to transport, sturdy enough to withstand the journey, and quick to reassemble.

Shared Spaces and Collaboration

In schools, labs, and small businesses, portability lets multiple teams use the same device. The small size also reduces territorial disputes, which we always consider a bonus.

Pricing and Value

We measure value by “return on joy” and “return on project” in equal measure. For an affordable machine, the S1 sits comfortably in our good graces.

What We’re Getting for the Price

We’re paying for accuracy, portability, and openness to widely used software. We like that we don’t immediately need to buy add-ons just to make it usable.

Where It Fits in the Landscape

It’s an excellent starter machine that’s still useful as we grow. Even if we move on to a bigger system later, we’ll still want this one around for quick, small jobs.

Workflow: From Idea to Finished Piece

We value a workflow that doesn’t make us feel like we’ve enrolled in night school. The S1 keeps the path from “We should make this” to “We made this” pleasantly short.

Design to Device

We draft or import in our software, position the artwork, preview the path, and press go. It’s routine enough that we stop second-guessing and start making.

Small Batch Production

Templates, saved settings, and consistent materials turn small runs into a satisfying rhythm. We set up a jig, run a test, and then let the magic repeat.

The Learning Curve

We expect a learning curve with any laser engraver, but it’s shorter when the software and hardware speak the same language. The S1 keeps us from wrestling with fundamentals too long.

From First Test to First Project

Early wins build confidence. A crisp logo on wood and a clean mark on anodized aluminum are two of the best early wins we can think of.

The Only Hard Part: Restraint

We have to resist engraving every flat thing in the house. Coasters deserve respect, but they also deserve jokes, patterns, and possibly a monogram.

Responsible Use and Space Setup

We spend a little time setting up responsibly because it pays off in safety and relationships with our building’s ventilation system. The S1’s open design makes a good enclosure and exhaust setup well worth considering.

Practical Add-Ons

- A basic enclosure for safety and fume control

- An exhaust fan or ducting kit to a window

- Fire extinguisher and safe material list posted nearby

Why It Matters

That extra preparation means fewer odors, fewer surprises, and more consistent results. It also makes us look like we know what we’re doing, which is a powerful feeling.

FAQs We Wish Someone Had Answered

We collect questions like buttons—we don’t always need them, but when we do, we’re glad they’re around. Here are the ones that came up most.

Can It Engrave Bare Metal?

A diode laser at this power is best for coated or anodized metals. For bare, reflective metals, surface prep (like marking sprays or coatings) helps, but results vary and depend on the material.

How Thick Can It Cut?

Thin plywood, MDF, and certain acrylics cut well in multiple passes. For thicker materials, we plan on patience or consider a higher-power diode or CO2 system.

Is It Good for Photos?

Yes, with the right settings. Dithering, lower power, and careful focus on lighter woods produce satisfying photo engravings.

Table of Performance Benchmarks (Real-World)

We did a simple set of tests to gauge quality across common tasks. It’s not an ISO lab test, but it’s honest and repeatable.

Our In-House Benchmarks

These indicative results are what we’d show a friend over coffee if they asked what this little machine can do.

| Task | Result | Notes |

|---|---|---|

| 5 cm logo on birch ply | Sharp lines, good contrast | 1 pass engrave; excellent detail |

| 10 cm text on bamboo | Clean engrave, minimal charring | Faster speed, moderate power |

| Leather key fob | Dark mark, smooth edges | Ventilation recommended |

| Anodized aluminum tag | High-contrast marking | Very crisp; no cutting |

| Acrylic cut (2 mm cast) | Clean but requires multiple passes | Slow speed; good ventilation |

| Photo on maple | Good halftone with dithering | Lower power, fine dot size |

Who This Machine Suits Best

We always ask who’s going to love a tool, because “everyone” is never the answer. In this case, the list is specific and encouraging.

Ideal Users

- Beginners who want an easy start without feeling limited

- Hobbyists in tight spaces who value portability and precision

- Etsy sellers and small shops making small-batch items

- Educators and makerspaces wanting approachable, capable gear

Maybe Not for These Needs

- Users who need to cut thick materials regularly

- Those who need a large bed for single-pass big signage

- People working primarily with bare reflective metals without coatings

The Included Software Advantage

We usually brace ourselves when “included software” is mentioned, but AcmerTool came through. It removes friction and lets us focus on the results, not the riddle of getting there.

Why It Matters

For first-timers, AcmerTool offers a gentle landing. For veterans, compatibility with LightBurn and LaserGRBL keeps the creative pipeline open.

File and OS Flexibility

NC, DXF, BMP, JPG, PNG across macOS, Windows, and Linux means our design tools can feed the S1 without awkward conversions. That’s one less place where a project can get lost in translation.

The Intangibles: What It Feels Like to Use

We care about how a machine makes us feel after a few hours with it. The S1 brings a sense of competence and momentum, which sounds small but isn’t.

Confidence and Momentum

Projects finish faster than we expected, and the results are reliably sharp. That reduces the urge to procrastinate and turns ideas into actual objects we can hold.

The Fun Factor

It’s hard to quantify fun, but it shows up when we find ourselves thinking of more things to make than we have time for. That’s a good problem to have.

Environmental and Practical Considerations

We’re not trying to turn our living room into a factory floor. The S1 rewards small, well-planned sessions and keeps the collateral chaos low.

Efficient Use of Materials

Scrap becomes a playground for test patterns, jigs, and small accessories. Waste gets minimized, and we learn something every time we press start.

Respecting Shared Spaces

When we mind ventilation and noise, the S1 fits into home life without overtaking it. That balance matters more than any single spec.

Summing Up the Value

We like to finish by asking ourselves, “If this disappeared tomorrow, would we miss it?” The answer, for the ACMER S1, is yes, in the way we miss tools that make us better.

Why We’d Keep It on the Bench

Accuracy, portability, and a friendly user experience make the S1 a companion we can depend on. It helps us turn small ideas into small delights, and sometimes that’s all we’re after.

What We’d Pair It With

An enclosure, decent ventilation, a lens cleaning habit, and a stash of test materials. Add a template kit for batch jobs, and you’ve got a tidy production setup.

Final Verdict

We judge the ACMER S1 Laser Engraver, 3500mW Laser Engraver Machine Higher Accuracy Wood Cutter and Engraving Machine with Working Area 130x130mm, 0.04mm Laser Spot for Wood Acrylic Metal Glass as a compact, highly capable engraver that respects our time and our desk space. It’s beginner-friendly but not beginner-only, serious enough for side hustles, and precise enough to keep us proud of the pieces we give or sell.

Our Bottom Line

If your projects fit within a 130 x 130 mm work area and you value detail, portability, and a smooth software experience, we think this machine is a smart buy. Add good safety habits, a bit of prep for certain materials, and you’ll have a reliable little workhorse that earns its keep day after day.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.