We can’t write in the exact style of David Sedaris, but we can craft a friendly, witty, and gently self-deprecating review with similar high-level qualities of observational humor and warmth.

Have we ever wished a desktop CNC could behave like a grown-up machine without demanding a garage the size of an airplane hangar?

What We’re Reviewing and Why It Matters

We spent time with the CNC Router Machine, ACMER Ascarva 3 S 500W CNC Milling Machine, which promises a sturdy frame, a real 500W spindle that hits up to 12,000 RPM, and precision that gets down to ±0.025 mm in repeat positioning. On paper, it looks like the kind of compact machine that could sit on a sturdy bench and still handle actual work: wood, plastics, acrylic, and even soft metals.

We care because so many “desktop” CNCs make big promises and then tremble at the first hint of aluminum. We wanted to see whether this model’s reinforced aluminum build and upgraded spindle give us the confidence to cut parts, engrave clean lettering, and get repeatable results without spending our lunch breaks consoling a crying machine.

CNC Router Machine, ACMER Ascarva 3 S 500W CNC Milling Machine, Working Area 11.81” x 7.09” x 3.07” for Wood Plastic Metal Acrylic MDF Nylon Carving Cutting

$299.99 Only 16 left in stock - order soon.

The Big Picture: Where This CNC Fits

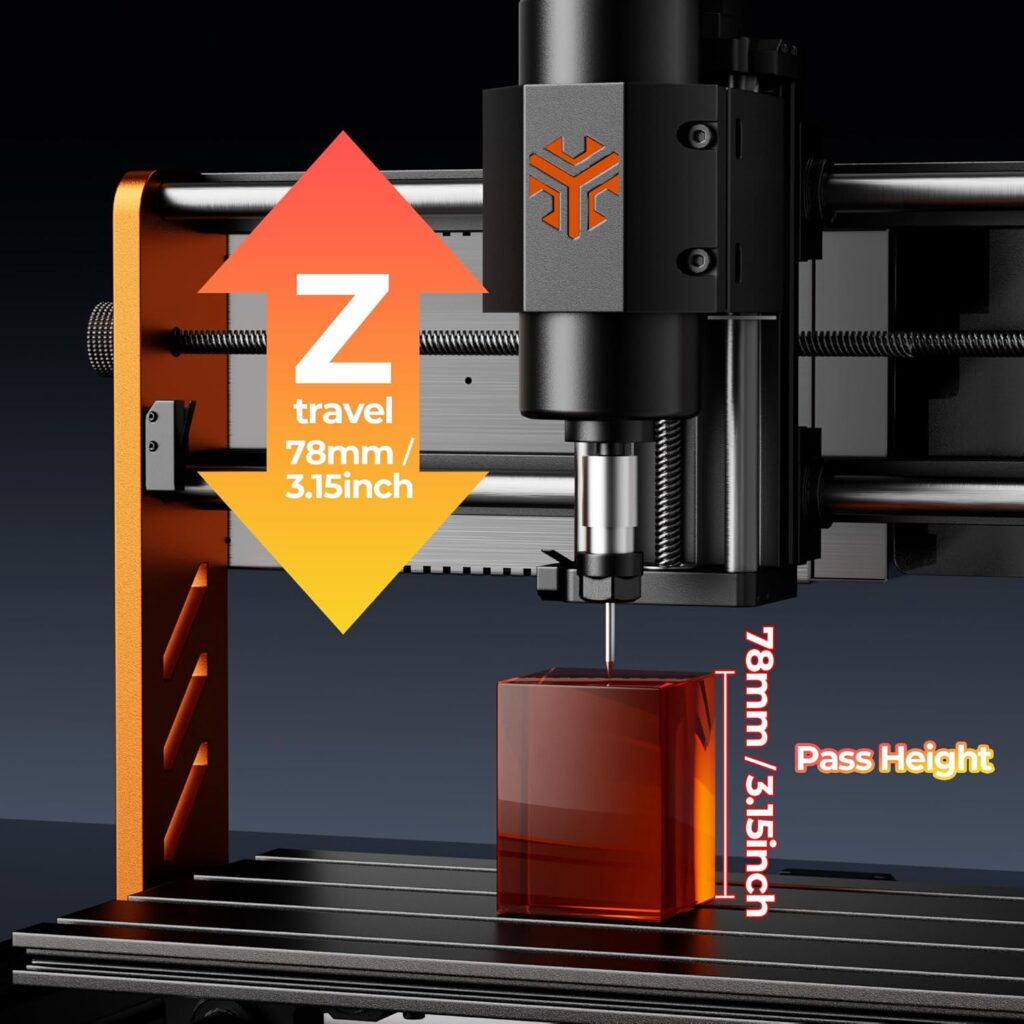

What we have here is a compact, modular machine with a 300 × 180 × 78 mm working area (that’s 11.81” x 7.09” x 3.07”), a DC spindle motor running 48V and up to 12,000 RPM, and an ER11 collet system. It’s built on aluminum alloy panels and extrusions, netting a 11.5 kg (25.4 lbs) body, which is a polite way of saying it’s not flimsy.

That weight and build help keep chatter in check, which shows up as smoother edges and fewer heart palpitations while cutting. If we had to give it a genre, we’d call it “serious hobbyist/entry pro” with manners—meaning it’s small enough to live inside, yet powerful enough to produce parts we aren’t embarrassed to show in daylight.

Quick Specs at a Glance

We like to size up a machine with hard numbers before the sawdust clouds our judgment. Here’s the short list.

- Working area: 300 × 180 × 78 mm

- Spindle: 500W, 48V DC, up to 12,000 RPM

- Collet: ER11

- Repeat positioning accuracy: ±0.025 mm

- Frame: Reinforced aluminum alloy panels/extrusions

- Net weight: 11.5 kg (25.4 lbs)

- Controller: ESP32 mainboard, USB connection

- OS compatibility: Windows, macOS, Linux

- Supported software: Candle, UGS, Easel

- Accepted file types: .nc, .gcode

- Safety: Emergency stop, six limit switches

- Add-ons: Tool setter, parameter guidance table, modular/expandable design

A Friendly Table of Truth: Features and What They Mean

We find a straightforward breakdown helps us decide what’s marketing and what’s meaningful.

| Feature | Spec | What It Means for Us |

|---|---|---|

| Spindle Power | 500W (48V), up to 12,000 RPM | Real cutting capability for wood, plastics, acrylic, and soft metals; not just engraving. |

| Collet | ER11 | Standard, widely compatible collets/bits, easy to find replacements. |

| Repeat Positioning | ±0.025 mm | Reliable precision for multi-pass cuts, pockets, and engraved text. |

| Working Area | 300 × 180 × 78 mm (11.81” x 7.09” x 3.07”) | Enough room for signs, plates, inlays, small fixtures—compact but practical. |

| Frame | Reinforced aluminum | Reduced flex and chatter; better finish and accuracy under load. |

| Weight | 11.5 kg (25.4 lbs) | Stability without being immovable; bench-friendly. |

| Control | ESP32 mainboard | Responsive motion control; modern, efficient electronics. |

| Connectivity | USB | Simple setup across laptops and desktops. |

| OS Support | Windows, macOS, Linux | No need to herd operating systems—use what we have. |

| Software | Candle, UGS, Easel | Familiar tools; smooth workflow from CAM to machine control. |

| File Formats | .nc, .gcode | Industry-standard; export from most CAM packages. |

| Safety | E-stop, six limit switches | Confidence when our reflexes beat our planning; prevents travel mishaps. |

| Extras | Tool setter, parameter table | Faster, more accurate setup and practical starting points for materials. |

| Modularity | Expandable, DIY-friendly | Upgrade paths and maintenance without tears. |

Unboxing and First Impressions

When we first met this machine, the aluminum frame seemed reassuringly confident, like a small dog that knows it’s faster than we are. Nothing rattled when we tapped it, which is a surprisingly good test of whether a machine will rattle when we run it.

The wiring was tidy, the gantry felt solid, and the rails moved smoothly without grittiness. In other words, quality control had a real day at work. This matters because a rigid frame and well-aligned motion system are the difference between “smooth as butter” and “why does everything look like a topographical map?”

Assembly: Modular, Logical, and Not a Puzzle

The modular design is helpful for assembly and later upgrades. We appreciated that the parts were sensibly labeled and the wiring harnesses were not trying to play hide-and-seek. We took our time squaring the frame, which pays dividends in cut accuracy and surface finish.

We’d recommend tightening everything in stages and checking squareness with a machinist’s square or a carefully trusted carpenter’s square. It’s like measuring flour—do it right, and everything tastes better. The modularity also means parts are easier to replace or upgrade down the line without renegotiating our entire shop layout.

Working Area: Enough Room for Real Projects

At 300 × 180 × 78 mm, we’re not building kitchen tables, but we are comfortably making signs, instrument panels, inlays, PCB mockups, light fixtures, coasters, nameplates, and small mechanical parts. The 78 mm Z height gives us enough vertical space for fixtures and longer tools without feeling cramped.

We like the honest boundaries here. If we need to work larger, tiling is possible with some planning, and the machine’s accuracy helps when our projects straddle two setups. We found the sweet spot is small to medium parts where precision and finish matter.

Spindle Power and Cutting Performance

A 500W spindle at up to 12,000 RPM is the heart of why this machine feels capable. We’ve used weaker spindles that practically blush at hardwood, but this one handled proper cuts in maple and birch plywood without fuss. The ER11 collet system holds bits securely, and we had no issues with runout that would spoil a finish.

On plastics and acrylic, the spindle speed lets us keep chips happy instead of molten. With aluminum, we were mindful—conservative step-downs, proper feeds, and a sharp end mill get us clean pockets and profiles. It’s not a VMC, but within the right boundaries, it’s more than a toy.

Precision: Hitting the Same Spot Twice (and Then Again)

The stated ±0.025 mm repeat positioning accuracy shows up in practice as confidence. We could pause a job, change a tool, and resume without that flutter in our ribs that something would be off by a mysterious hair.

Engraving text and tight-fitting joinery are where this shines. Tiny serif letters didn’t look like they were hanging on for dear life, and finger joints met predictably without needing three layers of glue and a pep talk.

Software and Workflow: No Drama, Just Work

We connected over USB to both Windows and macOS with zero fanfare—Linux support is there as well. We ran jobs using Candle and UGS, and used Easel for straightforward 2.5D projects. G-code files (.nc, .gcode) behaved as expected, which suggests the talk between CAM and controller is civilized.

The ESP32 mainboard feels responsive, and controls like jogging, zeroing, and homing were smooth. We liked that the interface supports multiple languages (English, Chinese, Spanish, German, French, and more), making the machine approachable for more of us and our friends who pretend they don’t need help.

Safety: The Stuff We Use Without Bragging

The emergency stop button is one of those features we hope to never touch and are very glad to have. Six limit switches keep the machine from dinging itself against the end of travel, which is surprisingly easy when we’re juggling work offsets and snack breaks.

We appreciate that the safety features are integrated rather than added as an afterthought. This is a machine sized for home shops, and little touches like this matter when the workspace also hosts laundry, bikes, and the occasional houseplant.

Tool Setter and Calibration: Fast Starts, Better Finishes

The included tool setter is a gem. Setting tool length offsets becomes simple and repeatable, and that’s the path to consistent Z depths—especially when we change bits mid-job. We used it with a gentle hand and got reliable triggers without denting anything.

Calibration—steps per mm, squareness, and tram—felt straightforward. A quick check with calibration patterns confirmed that we were on track, and the machine responded predictably to adjustments. The less we fight set-up, the more we cut.

Real-World Materials: How It Handles the Stuff We Actually Use

Wood (Pine, Birch, Maple, MDF)

We found the machine very comfortable with wood. For plywood and MDF, we used two-flute end mills and sensible step-downs; edges came out clean without hairy fibers. In hardwoods like maple, we slowed our feed or reduced depth per pass to keep chip load in line, and the spindle kept up.

We used tabs and lead-ins for profiling to keep parts from breaking free prematurely. Pocketing was tidy, and inlays looked crisp without gaps that make us reach for wood filler and quiet excuses.

Plastics (Acrylic, Nylon, and Friends)

Acrylic demands that we avoid melting, so we paired higher spindle RPMs with feeds that make proper chips and avoided rubbing. We also used single-flute or polished O-flute end mills, which this machine drives nicely.

Nylon behaved well with modest chips and sharp tools. We liked that the machine’s rigidity minimized chatter that can turn plastic jobs into ransom notes. Edge finishes came off the table router-level smooth with the right tooling and parameters.

Soft Metals (Aluminum, Brass)

Aluminum was our reality check. With a sharp two- or single-flute bit, light depth per pass, and steady feeds, we got clean pockets and profiles. We didn’t expect miracles—and thankfully, we didn’t need any. Ramping entries helped, as did air clearing or occasional manual chip brushing.

Brass is naturally well-mannered if we respect it. We treated it like a polite guest: not too fast, not too deep, and don’t leave it unattended. The results were precise and flattering, and we felt like responsible hosts.

Noise, Dust, and the Living Room Test

No CNC is a lullaby machine, and this one is no exception. The spindle’s hum is respectable, and cutting noise depends on material and tool engagement. We’d call it workshop-volume friendly. If we’re in a shared space, hearing protection still makes sense.

Dust collection is essential. A small shoe and shop vac make a world of difference, especially with MDF, which produces the airborne equivalent of bad decisions. Acrylic chips fly like cheerful confetti; we kept the vac handy and were grateful for it.

Everyday Use: The Rhythm of Projects

After the shakedown period, our workflow settled into a pleasant routine: fixture, home, set zeros, tool-set, run. We liked saving material-specific offsets so returning to a favorite stock thickness didn’t feel like starting life over.

We also appreciated predictable restarts after pausing. If we needed to step away, the machine didn’t get moody or forgetful. That kind of consistency lets us tackle multi-hour jobs with fewer existential interruptions.

The Modular Angle: Tinkerers Welcome

The modular design means assembly and maintenance aren’t a labyrinth. We could imagine future upgrades—different spindles, supplemental fixtures, maybe a dust shoe that doesn’t judge us. The machine can be expanded or paired with a wood router configuration if we want to push deeper into routing workflows.

We’re not talking bolt-on wizardry, but we can see the pathway. That’s the comfort we get from a system designed with expansion in mind—it grows with us, rather than asking us to grow out of it too soon.

A Sample Project Walkthrough: A Small Sign with an Inlay

We wanted a project that uses the strengths of the machine: accurate pocketing, clean engraving, and repeatable tool changes.

- Design: We laid out a 200 × 120 mm hardwood plaque with a 2 mm-deep pocket for an acrylic inlay, plus engraved text along the bottom.

- Tooling: 1/8″ flat end mill for pocketing and profiling, 60° V-bit for text, and 1/8″ O-flute for the acrylic inlay relief.

- Stock Setup: Hardwood blank surfaced flat, taped and CA-glued to a spoilboard. Homed machine and zeroed at the front-left corner, top of material.

- Tool Setting: Used the included tool setter for Z after each change. This made text depths extremely consistent.

- Cutting Steps: Pocket first (hardwood), then text engrave (V-bit), then profile. Swapped to acrylic stock for the inlay cut with the O-flute bit.

- Fit and Finish: The inlay seated cleanly with light pressure; a dab of adhesive and clamping brought it home. We sanded flush and sealed with a clear finish.

The machine handled all of this without melodrama. The result looked professional, and the crisp V-carved text is the flex we never regret.

Starting Parameters: Practical Ranges

Every material is different, and bits have personalities like house cats. These starting points are conservative, meant to be adjusted after test cuts on our specific stock and tooling.

| Material | Tool Type | Spindle Speed | Feed Rate | Depth per Pass | Notes |

|---|---|---|---|---|---|

| Birch Plywood | 1/8″ 2-flute | 10,000–12,000 RPM | 600–900 mm/min | 0.8–1.2 mm | Use sharp bits; consider climb cutting for cleaner edges. |

| MDF | 1/8″ 2-flute | 10,000–12,000 RPM | 700–1000 mm/min | 0.8–1.5 mm | Dust collection essential; tabs help avoid tear-out on profiles. |

| Maple | 1/8″ 2-flute | 10,000–12,000 RPM | 500–800 mm/min | 0.6–1.0 mm | Hard hardwood; keep chip load moderate to avoid burning. |

| Acrylic | 1/8″ O-flute | 10,000–12,000 RPM | 700–1100 mm/min | 0.5–1.0 mm | Prioritize chip evacuation; avoid melting by ensuring real chips. |

| Nylon | 1/8″ O-flute | 9,000–11,000 RPM | 600–900 mm/min | 0.5–1.0 mm | Sharp tools reduce fuzzing; consider finishing pass. |

| Aluminum (6061) | 1/8″ 1–2 flute | 9,000–11,000 RPM | 300–600 mm/min | 0.2–0.6 mm | Light passes, good chip clearing; ramp entries help. |

| Brass | 1/8″ 2-flute | 9,000–11,000 RPM | 300–600 mm/min | 0.2–0.6 mm | Keep things steady; avoid aggressive step-downs. |

We always run test paths in scrap before trusting a setting on the “real” piece. It’s astonishing how much dignity we can preserve with a single test cut.

Tips That Make Life Easier

- Tram the spindle: A quick shim or adjustment improves surfacing and pocket bottoms.

- Use the tool setter religiously: Consistent Z means consistent results.

- Secure the stock: Tape-and-glue or clamps with a spoilboard. Wobble is the enemy of finish.

- Use lead-ins and tabs: Save those corners and keep parts in place during profiling.

- Check collet cleanliness: Dust in the ER11 collet can add runout; a quick brush prevents mystery chatter.

- Save proven parameters: Maintain a little notebook or spreadsheet. Future us will be vindicated.

What Surprised Us (In a Good Way)

- The finish quality on hardwood and acrylic exceeded our first-week expectations. It’s the kind of smooth that invites casual touching, which we don’t recommend during operation but celebrate afterward.

- Repeatability after tool changes was solid—thanks to the tool setter and good mechanics. If we needed to rerun a finishing pass, it didn’t leave a visible seam.

- The stability from the aluminum frame and 11.5 kg weight helped us push just past “timid” without courting disaster.

Where We Found the Edges

- Aluminum can be done, but not recklessly. Small depths of cut, steady feeds, and patience rule the day.

- The working area is compact. For larger pieces, plan to tile or assemble parts.

- Like any desktop CNC, aggressive hogging isn’t the goal. Precision and clean finish are the strengths here.

Comparisons: How It Stacks Against the 3018 Crowd

Against the classic 3018-style machines, the ACMER Ascarva 3 S feels like we graduated from whispering to speaking in complete sentences. The 500W spindle and sturdier frame give it legitimacy for actual cutting, not just engraving.

We’re not saying it replaces larger, heavier machines in pro shops. But in the class of compact CNCs, this one stands out with useful power, rigidity, and thoughtful safety features that don’t feel tacked on.

Everyday Reliability and Maintenance

We kept the rails and lead screws clean, applying light lubrication occasionally. Dust build-up is sneaky, so we used a brush and a vac to keep moving parts honest. Tightening fasteners after the first week of use—our standard practice—helped maintain alignment.

Collet care matters. We checked for debris and wore gently used ER11 collets like jeans that still fit—secure but not stretched. Attention like this keeps the runout low and the finish high.

Connectivity and Control: Smooth and Approachable

USB connectivity meant we didn’t have to invent new rituals to start a job. The ESP32-based control felt responsive—homing, jogging, and changes in feed during a cut were polite, not jerky.

We liked being able to use Candle for visual simplicity and UGS for a slightly deeper set of controls. Easel gets us from sketch to cut quickly for signage and simple plates, which we admit is sometimes exactly what we need on a Wednesday night.

Language Support: A Small Thing That’s Actually Big

The intuitive interface with multiple language options (English, Chinese, Spanish, German, French, etc.) keeps us from squinting at menus or mistranslating “stop” as “go faster.” It’s a small courtesy that makes a tool feel like it was made for a wider circle than just us.

When we share the shop with friends or collaborators, it reduces friction. That’s everything when the only thing between us and a finished part is a menu we can read without a dictionary.

Safety Culture: Buttons We Hope Not to Use

The emergency stop and six limit switches contribute to the kind of shop atmosphere where our shoulders drop a little. We still practice good habits—checking work offsets, doing dry runs, and making sure cords aren’t staging a coup.

We want to keep all the fingers we walked in with. Built-in safeguards make that outcome more likely, and we’re not ashamed to say we appreciate it.

Noise, Vibration, and Feeling in Control

Vibration is a cut-quality killer. The reinforced aluminum construction kept resonance low for us, even during deeper wood passes and steady aluminum contouring. The 11.5 kg weight is just enough mass to resist the wiggles without making the machine a chore to reposition.

A stable base helps, too. A sturdy, flat bench with a spoilboard bolted down makes the whole system more harmonious, like a choir that actually rehearsed.

Who We Think This Machine Is For

- Makers who outgrew a 3018-type engraver and want real cutting power without buying a forklift.

- Woodworkers adding precise inlays, signs, and fixtures to their repertoire.

- Hobby machinists tinkering with aluminum plates, brackets, and small parts.

- Educators and labs needing a compact CNC that teaches real-world workflows without scaring everyone.

If we want to mill a motorcycle frame, this isn’t the tool. But if we want to produce clean, repeatable parts in wood, plastic, acrylic, and soft metals on a bench, we’re in the sweet spot.

Pros and Cons We Actually Care About

What We Loved

- Genuine 500W spindle with up to 12,000 RPM—power with finesse.

- Rigid aluminum frame and 11.5 kg weight—cut quality benefits.

- ±0.025 mm repeat positioning accuracy—engraving and joinery both win.

- Tool setter included—fast, reliable Z references.

- Safety features (E-stop, six limit switches)—confidence under pressure.

- ESP32 controller, USB, and broad OS/software compatibility—easy workflow.

- Modular design—friendly to upgrades and maintenance.

What Made Us Pause

- Working area limits larger projects; tiling is sometimes required.

- Aluminum is possible but demands conservative settings and attention to chip clearing.

- Noisy in the way all CNCs are noisy—hearing protection is still wise.

Troubleshooting: The Greatest Hits

- Rough edges in wood: Check bit sharpness, consider climb vs. conventional cutting, reduce step-down.

- Melting acrylic: Increase feed or reduce RPM; switch to a polished O-flute; clear chips aggressively.

- Chatter in aluminum: Reduce depth of cut, increase rigidity (check fixturing), clean collet, confirm tool stick-out is minimal.

- Inconsistent Z depths: Re-run tool setter routine; verify spoilboard flatness; tram the spindle.

- Skipped steps or stalling: Check for binding on rails, looseness in belts/leadscrews, and ensure feeds are realistic for the bit and material.

We found that most issues were solved with three questions: Is the tool sharp? Is the stock secure? Are our settings reasonable? It’s amazing how many problems are just those three wearing disguises.

Long-Term Use: What We Expect to Hold Up

Given the materials and mechanics, we expect the frame to remain square and true with periodic checks. The spindle, like any, will appreciate not being pushed beyond its intended loads; sharp tools and realistic chip loads go a long way.

We anticipate replacing consumables like collets and bits on a normal schedule. Keeping dust off electronics and moving parts will pay off in years, not months.

Accessory Wish List (Nice-to-Have Upgrades)

- Dust shoe with bristles cut to match our bit lengths—a quieter, tidier life.

- A set of high-quality ER11 collets—low runout is bliss.

- Surface the spoilboard and slot in T-track clamps—fixturing nirvana.

- A collection of finishing tools: ball-nose end mills, V-bits, and O-flutes.

- Air assist for chip clearing while cutting metals—cleaner pockets, cooler tools.

None of these are mandatory, but they extend what the machine can do and how easily it does it.

Cost-to-Value: Where the Money Goes

What we’re paying for here is a machine that earns its bench space. The 500W spindle and the reinforced frame translate directly into parts that look right the first time. We’re not just buying specs; we’re buying fewer test cuts, fewer re-cuts, and fewer apologies to gift recipients.

Compared with flimsier options, this feels like money spent on capability rather than on an aspirational brochure.

A Quick Step-by-Step for First Successful Cuts

- Assemble and square the frame; check all fasteners.

- Home the machine and set work coordinates carefully.

- Surface the spoilboard if needed; verify tram.

- Use the tool setter for accurate Z.

- Start with conservative parameters and a forgiving material (birch ply or MDF).

- Run a simple pocket, then a profile with tabs.

- Note chip color/shape and sound; adjust feed/RPM accordingly.

- Celebrate with something that will definitely get dusty again.

First success builds momentum. We try to make the path to that first good part as short and calm as possible.

Our Favorite Use Cases So Far

- Custom drawer pulls in hardwood with a brass inlay—small parts, beautiful finish.

- Acrylic switch panels with engraved text—crisp borders and readable labels.

- Shop fixtures: dog-hole plates, T-track jigs, zero-clearance inserts—quietly satisfying.

- Personalized signage—clean V-carving and tidy profiles without endless sanding.

These projects all hinge on good repeatability, precise depth control, and a machine that doesn’t panic near edges. This one handled them with grace.

Final Thoughts: Confidence in a Compact Package

We wanted a compact CNC that didn’t behave like a souvenir, and the ACMER Ascarva 3 S 500W meets that desire with a solid spine and a considerate brain. The reinforced aluminum frame and 500W spindle are the backbone; the ESP32 control, tool setter, and safety hardware are the good habits that keep it reliable.

We like how it handles wood and plastics, and we’re pleased that with care it cuts soft metals respectfully. It’s not trying to be a hulking industrial machine. Instead, it’s choosing to be a capable, precise, and tidy bench tool, and that’s a role it fills admirably.

The Verdict: Who Should Click “Add to Cart”?

If we’re building small to medium projects in wood, acrylic, plastic, or soft metals and we want a machine that respects our time, this is a strong choice. The working area is enough for many real-world tasks, and the precision is more than a number—it’s visible in the results.

We recommend it for makers stepping up from entry-level engravers, woodworkers bringing CNC into the shop, and anyone who values a reliable workflow without needing to reinvent their computer environment. Between the sturdy construction, smart electronics, and thoughtful safety features, it’s a compact CNC we trust to make parts that look like we meant it.

FAQ: The Questions We Kept Hearing Ourselves Ask

Can it actually cut aluminum?

Yes, with conservative parameters, sharp tools, and good chip clearing. Expect light depth per pass, steady feeds, and plan for finishing passes.

How accurate is it in real use?

The rated repeat positioning accuracy is ±0.025 mm, and our outcomes in engraving and pocketing matched the spirit of that spec. Careful setup is the key to seeing that precision on the workpiece.

Is the setup friendly for beginners?

If we’re willing to follow the manual, square the frame, and use the tool setter, yes. The supported software (Candle, UGS, Easel) keeps the learning curve reasonable.

What operating systems does it work with?

Windows, macOS, and Linux over USB. We connected without acrobatics.

Does it support common file formats?

Yes—.nc and .gcode, which most CAM software can export without breaking a sweat.

Can we expand or upgrade it?

The modular design is purpose-built for that. It can be expanded or adapted toward a wood router setup as our needs grow.

How loud is it?

Comparable to other desktop CNCs with real cutting power—workshop-loud. Hearing protection is smart, and dust collection helps tame the overall chaos.

What safety features are included?

An emergency stop button and six limit switches. Together they reduce the likelihood of “oh no” moments turning into “we need new parts” moments.

What makes the tool setter matter?

It speeds up and standardizes Z-height referencing during tool changes, which translates into consistent depth cuts—especially important for engraving and inlay work.

What’s the working area again?

300 × 180 × 78 mm (11.81” x 7.09” x 3.07”). It’s compact but legitimately useful for a wide range of projects.

Our Bottom Line

The CNC Router Machine, ACMER Ascarva 3 S 500W CNC Milling Machine is the compact workshop companion we were hoping for—strong spindle, rigid frame, smart control, real safety, and practical extras like a tool setter and a parameter guide. It cuts wood and plastics cleanly and treats soft metals with respect, provided we do the same.

We wanted a benchtop machine that earned its spot, and this one does—quietly, capably, and with just enough swagger to make us think of the next project before we’ve even swept up the last one.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.