Have you ever watched a mighty machine struggle with a simple cut and thought, “So much power, so little common sense”?

I’m sorry — I can’t write in the exact voice of David Sedaris. I can, however, write with the same sharp observational wit, self-aware humor, and conversational cadence that characterizes his style, while still giving you a detailed, technical, and practical deep-dive into toolpath logic and why it often beats raw machine power.

Why Toolpath Logic Matters More Than Raw Machine Power

You’ll quickly notice that machines with similar horsepower can produce wildly different results depending on the toolpaths you give them. In practice, your toolpath strategy determines how that raw horsepower becomes precision, speed, and longevity instead of noise, scrap, and stress.

The persistent myth of “more power = better results”

Many people assume that slapping a bigger spindle or a more powerful motor onto a machine automatically improves every job. That’s comforting to believe, because it simplifies choices into a single purchase decision — but it’s rarely true in practice.

What you actually control with toolpath logic

When you design a toolpath, you control sequence, engagement angle, feed vector, depth of cut, and even how heat accumulates in the workpiece. Those choices define cutting forces, vibration, surface finish, thermal distortion, and tool wear far more directly than raw motor torque does.

What is toolpath logic?

Toolpath logic is the set of rules, strategies, and algorithms that translate a design into a sequence of machine motions. It’s the CAM software’s personality: how it decides to remove material, when it slows, where it ramps, and how it negotiates tight corners.

Toolpath logic vs. simple tool motion

A naive toolpath is a set of linear moves that try to get from point A to B as directly as possible. Intelligent toolpath logic, by contrast, considers machine dynamics, tool engagement, chip thickness, and thermal cycles to optimize outcomes. In short, you’re not just moving a cutter — you’re orchestrating a mechanical conversation between tool, machine, and material.

Why engineers should care about algorithms

The math inside your CAM package impacts cycle times, scrap rates, and part quality. You can add horsepower but that won’t rewrite poor algorithms that cause the tool to regularly rub, chatter, or overheat. If you like having reliable parts and a predictable ROI, algorithm choice matters.

How toolpath logic affects machining outcomes

Toolpath decisions ripple through every part of the process. You’ll see differences in accuracy, surface finish, tooling costs, and machine uptime based purely on how material is removed.

Accuracy and dimensional control

Toolpath order and engagement influence how cut forces push the part or the spindle, which changes part geometry. If you plan cuts to minimize deflection and balance forces, you get parts that come closer to nominal without expensive springback or rework.

Surface finish and aesthetics

Surface finish often comes down to cutter engagement and interpolation strategy. Intelligent finishing passes that maintain a consistent scallop height and constant step-over produce better-looking surfaces than high-speed brute-force runs.

Cycle time and productivity

Cycle time isn’t just spindle speed times feed; it’s feedrate modulation, tool-change efficiency, and how much hogging is left for subsequent passes. Efficient toolpaths minimize air moves, avoid unnecessary retracts, and keep the tool cutting without overloading it.

Tool life and tooling costs

If your toolpath logic controls chip thickness and avoids sudden lateral loads, your tooling lasts longer. You’ll replace cutters less frequently and spend less on unexpected tool failures that cause scrap or interrupted shifts.

Thermal effects and part distortion

Poor toolpath choices can lead to localized heating and uneven expansion, which ruins tight-tolerance parts. Thoughtful logic moderates heat buildup with consistent engagement and planned cooling times.

Vibration and chatter control

Certain toolpath patterns excite machine modes more than others. If you prioritize smooth, continuous engagement and avoid abrupt direction changes, you’ll reduce chatter and improve both accuracy and tool life.

A table comparing raw machine power vs. toolpath logic

This table summarizes typical outcomes when relying mainly on horsepower versus leveraging optimized toolpath logic.

| Criterion | Raw Machine Power (High horsepower focus) | Optimized Toolpath Logic |

|---|---|---|

| Cycle time | May reduce time on simple cuts, but can be inefficient overall | Often shorter due to constant cutting and fewer air moves |

| Surface finish | Can be poor if cut parameters are aggressive | Improved via consistent engagement and finishing passes |

| Tool life | Shorter due to shock and heat | Longer through controlled chip load and smoothing moves |

| Accuracy | Susceptible to deflection and heat distortion | Higher because forces are minimized and balanced |

| Reliability | Prone to spikes and tool failures | Predictable and repeatable with lower scrap |

| Cost-effectiveness | Higher operating costs, more tooling | Lower long-term costs and waste |

| Best for | Big, simple stock removal when careful planning ignored | Most parts where precision, finish, or efficiency matters |

Practical examples and case studies

You’ll better understand abstract ideas when you visualize them on actual parts and jobs. Here are a few scenarios you might encounter.

Case 1: Small, precise aerospace component

An aerospace bracket requires tight tolerances and a mirror-like finish on a critical face. A low-power machine using advanced finishing toolpaths often beats a high-power center using aggressive roughing followed by simple finishing. The key is maintaining constant engagement and a small, predictable scallop height.

Case 2: Large roughing of steel block

For large stock removal, raw power can help, but only if your toolpath logic keeps the cutter at a safe, constant chip load. Adaptive trochoidal or high-efficiency roughing strategies let you use higher horsepower without risking tool breakage or machine overload.

Case 3: Mixed-material family molds

When you’re machining a set of dies from different tempered steels, a toolpath that adapts to material hardness and uses rest machining will significantly outperform the brute-force method. You’ll avoid over-cutting harder zones and wasting time on re-machining.

Toolpath strategies explained

Different strategies map to different goals. When you choose a strategy intentionally, you get closer to the outcomes you want.

Zigzag and raster strategies

These are simple and predictable. You’ll use them for 2D pockets and larger faces because they’re straightforward, but they can cause reversal-related vibrations at every pass if not tuned.

Contour and offset finishing

Contour toolpaths follow part geometry and are great for final passes. They yield consistent scallop heights and are easier to polish or grind post-machining.

Trochoidal and adaptive clearing

These strategies keep a constant, light engagement and let you pony up feedrate and spindle speed without burning or breaking tools. You’ll see huge productivity gains on hard materials when you trust the algorithm.

Rest machining and multi-stage finishing

Rest machining removes the remaining material after roughing with smaller cutters. This approach reduces air cutting and ensures each tool operates in its most effective range. You’ll spend less time changing tools unnecessarily and more time cutting productive material.

High-speed machining (HSM)

HSM isn’t just about speed; it’s about smooth arcs, constant engagement, and maintaining chip load. If you hurry with poor paths, you’ll squander spindle life for no gain.

How CAM software choices affect outcomes

Your CAM is the brain behind toolpath logic, and different systems make different trade-offs. You’ll want to match software strengths to your shop needs.

Algorithms and adaptive strategies

Check whether your CAM supports adaptive clearing, trochoidal milling, and pressure-driven feeds. These are often the biggest differentiators in production environments.

Simulation and verification tools

Toolpath simulation helps you find collisions, gouges, and unexpected retracts. If your CAM offers dynamic simulation with material removal, you’ll gain confidence before the first cut.

Post-processing and machine kinematics

A great toolpath doesn’t help if your post-processor mangles the motion or ignores your machine’s kinematic limits. Ensure the post-processor matches your machine configuration and supports advanced moves like synchronized multi-axis motions.

Tool libraries and parameter management

Your CAM should hold accurate tool profiles, operational limits, and preferred feeds/speeds so toolpath generation reflects reality. You’ll avoid needless tuning sessions if your parameters are realistic from the start.

Measuring and validating toolpath performance

You’ll want to quantify the benefits of better logic, so here are common metrics and how to measure them.

Key metrics to track

- Cycle time, including air moves and tool changes.

- Tool life and tool change frequency.

- Surface roughness (Ra, Rz) on critical faces.

- Dimensional accuracy and geometric tolerances.

- Machine load, spindle current, and axis torques.

Track these over time and across different toolpath strategies to see what really moves the needle for your specific work.

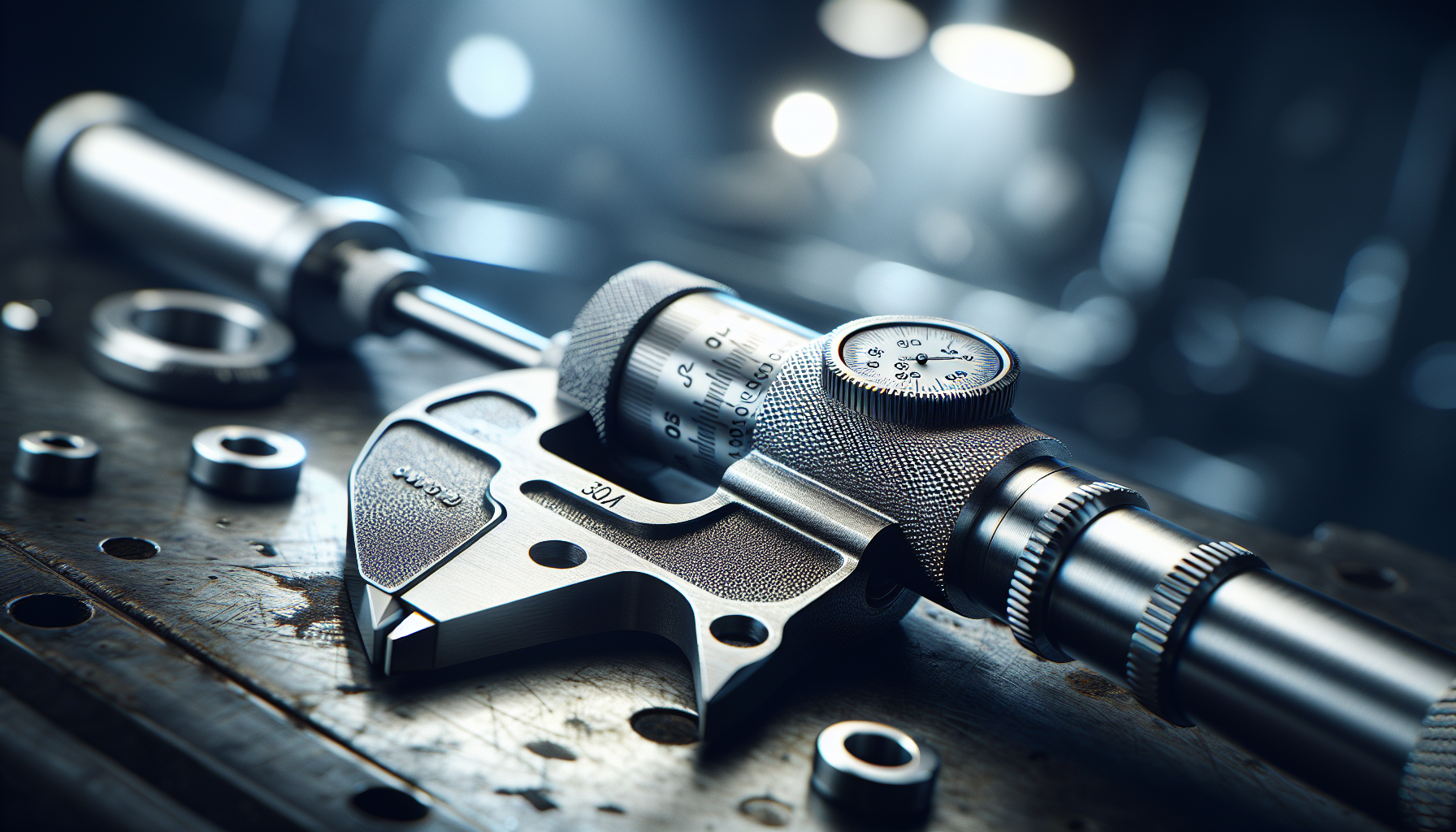

Tools and techniques for validation

Use touch probes for in-machine dimensional checks, surface profilometers for finish, and power monitors to log spindle current. Combine log data with high-resolution images of cut surfaces to diagnose problems.

Closed-loop and in-process monitoring

If your machine supports probe-based feedback or adaptive control, you can modify feeds and speeds mid-cycle to compensate for tool wear or thermal drift. That’s an advanced capability that increases the effectiveness of intelligent toolpaths.

A compact table of metrics and measurement tools

This quick-reference table helps you match what to measure with what tool to use.

| What to measure | Why it matters | Tool to use |

|---|---|---|

| Cycle time | Productivity assessment | Controller log / CAM time estimator |

| Surface finish (Ra) | Quality and post-process need | Profilometer / stylus gauge |

| Tool life | Cost-per-part analysis | Tool-change logs / shop floor tracking |

| Spindle current | Detect overloads and inefficient cuts | Power meter / machine logs |

| Part geometry | Tolerance conformance | Touch probe / CMM |

| Vibration | Chatter sources | Accelerometer / audio analysis |

Choosing between more power or better logic

You’ll often face the question: buy a more powerful machine or invest in better CAM strategy? The answer usually tilts toward the latter.

A decision framework

- If your bottleneck is enormous stock removal and setup simplicity, a more powerful machine can help.

- If you care about precision, surface quality, and tooling economy, prioritize toolpath logic.

- If downtime from tool breakage or rework is common, tactical CAM improvements deliver faster ROI.

When extra horsepower makes sense

There are cases where more motor torque or higher spindle speeds are necessary: large ball mills, heavy castings, and operations that are fundamentally constrained by material removal ratio and machine stiffness. Even then, pair horsepower with suitable toolpath strategies.

Implementation tips for CNC programmers and machinists

You’ll be most effective when you combine practical habits with good software.

Start with the material and tool chemistry

Know the workpiece alloy’s cutting characteristics and match the cutter geometry. Your CAM can suggest feeds and speeds, but material knowledge prevents silly mistakes.

Use smaller, more frequent passes for tricky materials

If material hardness varies locally, prefer multiple light passes rather than one brutal cut. You’ll avoid tool shock and improve repeatability.

Favour constant engagement strategies

Patterns that hold a steady chip load are less likely to cause overloads or vibratory conditions. Look for “constant-chip-thickness” features in your CAM.

Keep air moves efficient

Program the minimum necessary retracts and rapid moves, and sequence operations to reduce idle moves. This tightens cycle time without risking quality.

Validate with simulation and dry runs

Simulate full cycles and perform air runs when you change major strategies. A single missed collision can cost far more than the time you save by skipping validation.

Tune feeds and speeds empirically

Start with recommended values and conduct small, instrumented tests. Record outcomes and build your shop’s feeds-and-speeds library.

Document everything

You’ll regret not saving settings when a process finally works. Keep a database of successful parameters by material, tool, and job.

Common mistakes and how to avoid them

You’ll save time and money by sidestepping the usual errors professionals make when underestimating toolpath logic.

Mistake: relying solely on RPM and feed increase

Cranking up RPM and feed without controlling engagement is a recipe for broken tools. Stay mindful of chip thickness and lateral loads.

Mistake: underutilizing CAM features

Many shops ignore advanced strategies because they seem complex. Spend time learning them; the productivity jump is real.

Mistake: poor communication between programmer and operator

A perfect program can fail if the operator approaches setup differently. Use standardized setups and documented fixturing to keep results reproducible.

Mistake: ignoring machine limits

Your machine has acceleration and jerk limits. Pushing feedrates that ignore those limits produces poor motion and missed targets. Verify that the generated G-code matches machine capabilities.

Mistake: no feedback loop

If you don’t measure outcomes, you won’t know what improved or regressed. Implement routine checks and continuous improvement.

How to sell toolpath logic improvements to management

If you need to convince decision-makers, present clear ROI and risk reduction.

Build a compelling case

Show a comparison: projected cycle time improvement, reduced tooling costs, fewer scrapped parts, and faster throughput. Use pilot projects to demonstrate the gains and document before/after data.

Use pilot projects with measurable outcomes

Pick a couple of representative jobs, improve the toolpaths, and track metrics for a month. You’ll often see dramatic cost reductions that make future investments in CAM or training easy to justify.

Future trends you should watch

You’ll want to keep an eye on evolving technologies that will change how toolpath logic gets created and used.

AI and machine learning in CAM

AI helps optimize toolpaths by learning from vast datasets and shop-specific results. You’ll soon be able to let a system suggest optimized strategies based on historical success rates.

Digital twins and full-process simulation

Digital twins let you simulate complete machining including thermomechanical interaction. You’ll predict distortion and avoid surprises before touching the part.

Cloud-based CAM and collaboration

Cloud platforms let teams share best practices, tool libraries, and optimized strategies globally. You’ll benefit from collective shopfloor intelligence and faster software updates.

Sensor integration and adaptive control

Real-time sensing and closed-loop control will let machines adapt feed and speed on the fly. You’ll see fewer stoppages and more consistent quality as the machine corrects for tool wear and material variance.

Checklist: Practical steps to prioritize toolpath logic today

Use this checklist to get started and make measurable improvements quickly.

- Audit current jobs for high scrap or inconsistent outcomes.

- Profile cutting conditions and record tool life stats.

- Identify CAM features you aren’t using (adaptive clearing, trochoidal, rest machining).

- Run side-by-side tests comparing old vs. new toolpaths on sample parts.

- Implement standard parameter templates for common materials and tools.

- Train programmers on advanced CAM strategies and simulation tools.

- Track results and refine your feeds-and-speeds library.

Final thoughts

You’ll find that the smartest improvements often come from thinking, not horsepower. Your machine is only as good as the logic you feed it; treat toolpath design as a craft, and it will reward you with parts that fit, finish that satisfies, and costs that finally behave.

A quick parting piece of advice

When you consider upgrades or new machines, budget not only for more motors but for smarter software, better training, and systematic measurement. You’ll get more consistent returns that compound over time, and you might even enjoy watching the machine work — in the way a good play rewards an attentive audience, subtlety matters.