?Have you ever bought a shiny new tool and felt as if you’d bought the whole factory?

The Difference Between Owning Tools And Owning Fabrication Capability

You’ll find that the sentence above is not only witty; it’s also true in ways that sting. Owning a tool is simple to describe: you possess a physical object. Owning fabrication capability means you possess a system that reliably turns raw inputs into finished products. The difference is less a matter of hardware than of process, people, and predictable outcomes.

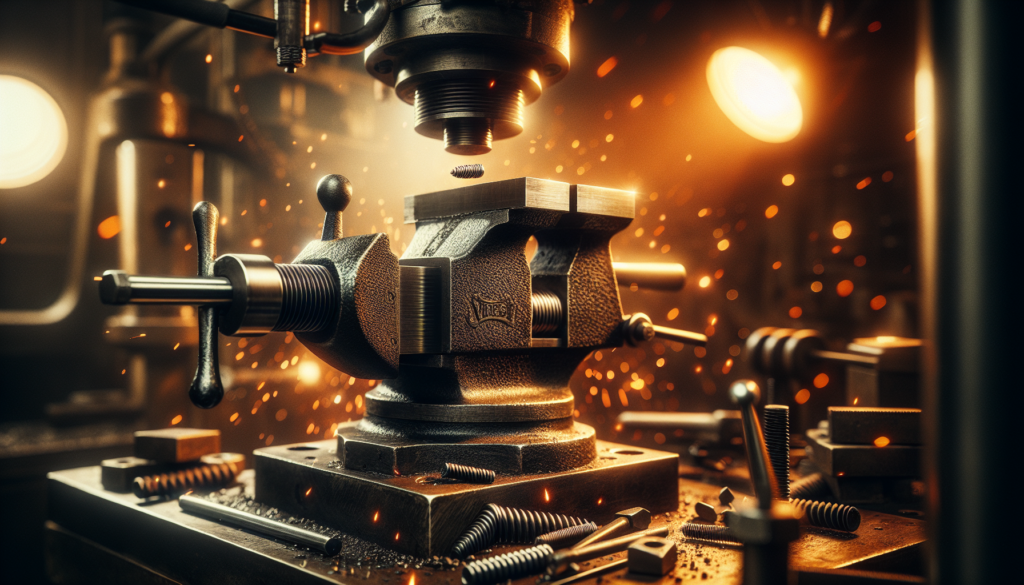

What counts as a “tool”

You probably picture a bench grinder, a CNC mill, or a 3D printer when you hear “tool.” A tool is a device that performs a defined function; it has specifications, an owner, and usually a manual that you’d skim on the first troubled morning. Tools are tangible, discrete, and often portable.

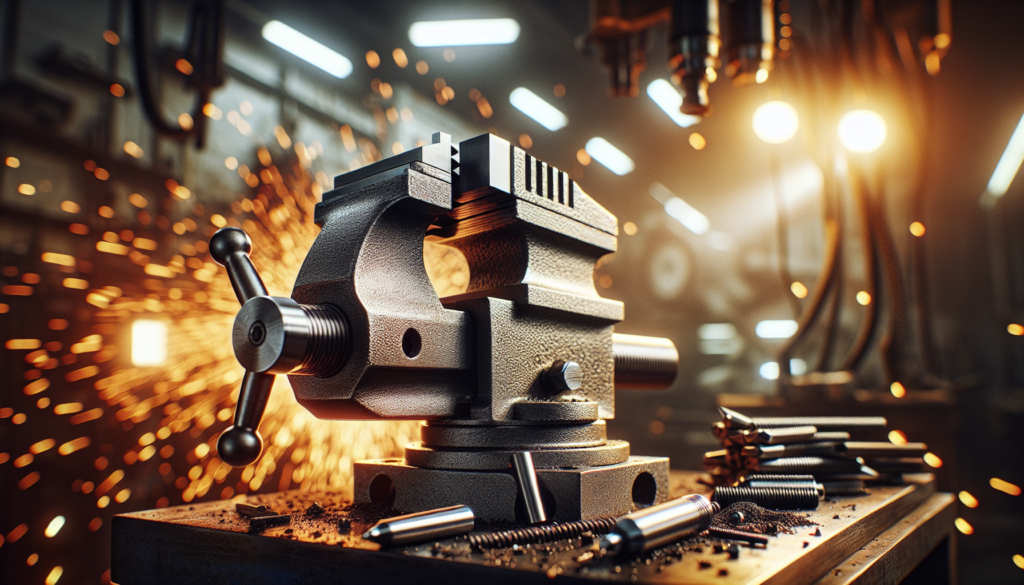

What counts as “fabrication capability”

Fabrication capability is an organized, repeatable method for making parts or assemblies at scale and quality. It includes tools, but also people, processes, materials, quality systems, supply chains, and the tacit knowledge that makes a part acceptable on the first pass. You don’t just have machines; you can reliably make what you say you can make, when you say you can make it.

Why the distinction matters

You’ll encounter the consequences of this distinction the moment delivery dates slip, quality audits fail, or costs balloon. Choosing between owning tools and owning fabrication capability is a strategic choice with operational and financial ramifications. A single tool will not keep production lines humming; capability will.

Strategic implications for your business

If your goal is short-term prototyping, a few tools might be enough. If your goal is repeatable, saleable products, you’ll need capability. Strategic clarity prevents the embarrassment of thinking a new machine eliminates the need for process planning, staff training, or supplier management.

Operational implications on the shop floor

Tools require maintenance; capabilities require orchestration. You’ll find that schedules, training plans, spare parts inventories, and process documents become as important as the machine. Operations without capability are improvisation disguised as production, and improvisation rarely survives a customer complaint.

A practical cost comparison

Numbers will make this less romantic. The table below compares owning one critical tool versus owning the capability to use that tool for production.

| Cost Category | Owning a Tool (initial focus) | Owning Fabrication Capability |

|---|---|---|

| Capital expenditure (CapEx) | High for the machine; one-time | High for machines plus fixtures, jigs, and multiple devices |

| Operational expenditure (OpEx) | Low to moderate (if you only occasional use) | High: labor, training, quality, utilities |

| Maintenance & spare parts | Moderate | High: planned downtime, inventory, contingency |

| Process documentation | Minimal | Extensive: SOPs, work instructions, audits |

| Skilled personnel | May be minimal | Essential: operators, engineers, quality staff |

| Supply chain management | Minimal | Extensive: raw materials, vendors, lead times |

| Time to scale | Slow | Faster once systems are mature |

| Risk of scrap/rework | Low if used casually; unpredictable for high-volume | Lower per unit with robust process control |

| Regulatory/compliance burden | Minimal | Potentially significant (ISO, FDA, etc.) |

You’ll notice that capability shifts the cost profile from a one-off capital story to an ongoing operational commitment. That’s where many businesses get surprised.

CapEx vs OpEx decisions you’ll make

When you buy a tool, you’re largely making a CapEx decision; the machine is an asset. When you build capability, you create a stream of OpEx commitments. Your finance team will squint at you differently depending on which you choose. You’ll need to justify not just the machine, but the people and systems that make the machine useful.

Hidden costs you’ll regret ignoring

Don’t forget installation, alignment, calibration, certifications, tooling, fixtures, software updates, training, and process validation. Those are the things that look innocent in a presentation and become urgent at 2 a.m. when an order is due.

Quality, traceability, and control

You’ll love the smell of a fresh part—but you’ll hate the smell of a recall. Owning fabrication capability is about controlling quality before it’s a headline.

Consistency and standards

A tool can produce a nice part once. Fabrication capability ensures each part meets tolerances thirty times in a row. You’ll want SPC (statistical process control), control charts, and acceptance criteria. These are the guardrails that convert good runs into predictable output.

Traceability and compliance

If regulations matter in your sector, you’ll need documented traceability: batch numbers, material certificates, inspection records. Owning a tool doesn’t automatically mean you can support an audit. Fabrication capability does — because traceability is built into the process.

Workforce and skills

People make machines productive. You’ll quickly discover that a high-tech mill without skilled operators is an expensive paperweight.

Hiring and training

When you choose capability, you commit to a human system. That means hiring for competence, investing in apprenticeship programs, and keeping training budgets alive. Your maintenance team will become heroes if you treat them well.

Culture and process adoption

Capability requires a culture that respects process over improvisation. You’ll need to encourage documentation, continuous improvement, and a willingness to stop the line when something is wrong. Changing culture is the long, quiet work that separates noisy tools from dependable capability.

Supply chain and lead times

You may imagine that owning a tool eliminates all supplier headaches. It doesn’t.

Managing suppliers and materials

Fabrication capability includes vendor selection, material qualification, and lead-time buffers. You’ll need alternate suppliers and contingency plans. A machine can sit idle without material, but capability requires a steady flow of validated inputs.

Flexibility and responsiveness

With capability, you can respond to market changes faster because your processes are tuned. With only tools, responsiveness depends on improvisation. That might work in a garage; it rarely suffices for repeat customers.

Intellectual property, know-how, and value capture

You’ll find that ownership of physical assets is not the same as owning the recipe for success.

Protecting designs and processes

Owning fabrication capability means owning the process knowledge that produces a unique part. You’ll need to protect process parameters, fixture designs, and inspection protocols. This is where trade secrets live. Physical tools are easier to copy than a mature, optimized process.

Capturing value

When you own capability, you capture more value because you control cost, quality, and timing. You can innovate on the process, reduce waste, and change materials to improve margins. Owning tools alone often means you pay external partners for that value capture.

When you should own tools versus capability

You’ll need practical heuristics to decide which path suits your situation. Below are scenarios to help you choose.

Situations favoring tool ownership

- Prototype development: You need a single part or a small series to validate a design.

- Hobbyist or learning: You’re experimenting and don’t require repeatability.

- Low-volume, high-mix operations: You can tolerate setup time and variability.

In these scenarios, tools give flexibility without the overhead of systems.

Situations favoring capability ownership

- High-volume production: You need predictable output and low unit costs.

- Regulated industries: You must support audits, traceability, and validation.

- Strategic differentiation: Your manufacturing process is part of your competitive advantage.

Here, capability reduces risk, enables scale, and protects quality.

A simple decision framework

You’ll appreciate a short checklist to guide decisions. Score each question 1–5 and add the numbers. Higher scores suggest building capability.

- How critical is consistent product quality?

- What is the expected production volume?

- How important is lead-time control?

- How much regulatory oversight exists?

- How strategic is production to your value chain?

If your total is high, capability is likely the better investment; if low, tools might suffice.

Implementation roadmap to build fabrication capability

You’ll find that a roadmap reduces panic moments. Treat this as a series of pragmatic steps rather than a heroic leap.

Step 1 — Assess current state

Document what tools you own, what processes exist, and where knowledge is tacit. You’ll want an honest inventory that includes the informal tricks people use to get parts through.

Step 2 — Define required capability

Translate product specifications and volumes into process requirements. Ask: what tolerances, cycle times, and quality metrics must be hit?

Step 3 — Design process and choose tools

Select machines, jigs, and fixtures that meet process needs. Think in systems: tool, operator, material, and inspection.

Step 4 — Build the workforce

Hire or train operators, maintenance staff, and quality personnel. Consider mentoring arrangements that preserve tacit knowledge.

Step 5 — Establish documentation and control systems

Write SOPs, create inspection plans, and set up SPC. Documentation is the nervous system of capability.

Step 6 — Pilot production

Run a pilot to validate the process, capture metrics, and refine work instructions. You’ll learn more in the first 100 parts than in any design meeting.

Step 7 — Scale and continuous improvement

Once results look stable, ramp up gradually. Use improvements to reduce cycle time and cost, not just to avoid disasters.

Case studies that make the point

You’ll find that examples stick better than abstractions. Here are two vignettes to glue the concepts to reality.

Furniture maker who bought tools

A small woodworking business bought an expensive CNC router because it looked decisive in a catalog. You’ll recognize the excitement—the bright blue LED indicators, the sense that a machine will solve messy workshops. The router sat in a corner for months. Install took longer than expected, bits wore out faster than the inbox promised, and joinery tolerances depended on operator skill. Orders slipped until you hired a trained CNC operator and created jigs for repeatability. What began as tool ownership evolved into capability, but only after avoidable pain and expense.

Electronics startup that built capability

An electronics company initially outsourced PCB assembly. When demand rose, outsourcing costs and long lead times threatened margins. The company invested not only in pick-and-place machines but also in ESD-safe workstations, solder-reflow characterization, in-circuit testing fixtures, and a small quality team. The initial CapEx was high and the first months were chaotic, but the new capability cut lead times from six weeks to ten days and reduced defects by half. Owning capability allowed the company to iterate quickly and protect IP in assembly processes.

Common myths and the reality

You’ll want to throw out some common half-truths that sabotage decisions.

- Myth: Buying the best machine means instant production mastery.

Reality: The machine is only as good as the process around it. - Myth: Outsourcing is always cheaper.

Reality: Outsourcing can hide costs in lead time, quality, and lost IP. - Myth: Small shops don’t need documentation.

Reality: Without documentation, process knowledge lives in people’s heads—fragile and expensive. - Myth: Capability is only for big companies.

Reality: Small firms can build capability scaled to their needs and get disproportionate advantages.

A balanced pros and cons list

You’ll appreciate a compact summary when planning.

Pros of owning tools:

- Lower initial barrier for prototypes

- Greater flexibility for one-off work

- Less immediate operational complexity

Cons of owning tools:

- Limited predictability

- Hard to scale efficiently

- Hidden costs emerge over time

Pros of owning fabrication capability:

- Predictable quality and output

- Faster response to customer demands

- Greater value capture and IP protection

Cons of owning fabrication capability:

- Larger ongoing expenses

- More complex management and compliance

- Requires investment in people and systems

A practical checklist before you commit

You won’t regret running through this checklist before signing purchase orders.

| Area | Questions for you to answer |

|---|---|

| Demand | What volume and cadence do you expect in 6–24 months? |

| Quality | What tolerances and acceptance criteria are required? |

| Lead time | How critical is time-to-delivery to customers? |

| Cost | What are the true unit economics including overhead? |

| Personnel | Do you have skilled operators and maintenance staff? |

| Documentation | Can you produce SOPs, inspection plans, and traceability? |

| Supply chain | Are materials and vendors qualified and reliable? |

| Compliance | Do regulations demand formal systems? |

| IP | Is manufacturing know-how a strategic asset? |

You’ll be equipped with better answers after this quick audit.

FAQs you might have

You’ll want short answers to common anxieties.

-

How long does it take to build capability?

Depending on complexity, a basic capability can take months; full maturity can take years. Start with a pilot and scale. -

Can you hybridize (own some tools, outsource others)?

Yes. Many companies keep critical processes in-house and outsource commodity operations. You’ll find hybrids minimize risk while preserving flexibility. -

What if demand fluctuates?

Build modular capability: cross-train staff, use flexible fixtures, and keep scalable contracts with suppliers. Overcommitment is the enemy. -

How do you measure success?

Track yield, scrap rate, on-time delivery, cost per unit, and defect escape rate. These metrics tell the story more honestly than pride.

Final thoughts and practical advice

You’ll end up owning fewer regrets if you treat capability as a system rather than a procurement line item. Tools are seductive—gleaming and finite—but capability is stubborn and encompassing. You’ll need patience, people, and a tolerance for the small, boring work of documentation and training. Those are the investments that make your machines sing in the long run.

If you’re choosing right now, do this: define the outcome you need (volume, quality, lead time), map the gaps between your current assets and that outcome, and prioritize investments that close the biggest gaps first. You’ll may feel like an alchemist turning raw metal into product; in truth, you’re building a repeatable recipe, and once the recipe works, everything tastes better.