Have you noticed how factories used to be full of machines, and now they’re full of questions?

Why Fabrication Is No Longer About Machines, But Systems

You remember the old images: a hulking lathe, a single punch press, a solitary robotic arm that could have been an extra in a science fiction film. Those machines were the stars, and you could name them, dust them, and occasionally coax them with a wrench and a mallet. Today, the spectacle has shifted. Fabrication isn’t just about isolated machines anymore; it’s about how every tool, piece of software, person, and process talks to one another, reacts, and learns.

A short scene-setting aside

You can be forgiven if you still anthropomorphize a milling machine — it’s comforting to imagine it sipping espresso between cycles. But manufacturing systems are more like messy families: some members argue, others keep secrets (data), and everyone shares the same electricity bill (energy consumption). Your job is less about worshipping the hero machine and more about managing the family.

From Lathes to Living Networks: The Historical Shift

You should understand how we got here so you can stop blaming the newest gadget for all your problems. In the early industrial era, machines were singularly critical — you measured success by the machine’s cycle time, uptime, and torque. Over time, as products grew complex and markets demanded variety and speed, people started to join machines with processes, suppliers, sensors, and software.

How the transition happened

You moved from mechanization to automation to intelligent, networked systems. At first, a machine that could repeat a task was revolutionary. Next came machines that could be programmed. Now what matters is the entire chain: does the design file reach the machine correctly, does the material arrive on time, does the control system optimize energy use, and can a human override safely when the unexpected happens?

Machines vs Systems: A Practical Comparison

You like clarity, and nothing clarifies better than a table. Below is a high-level comparison to show how your priorities shift when you treat fabrication as a system rather than a collection of machines.

| Aspect | Machine-centric view | System-centric view |

|---|---|---|

| Focus | Individual equipment performance | Interaction and flow across components |

| Success metric | Uptime, cycles per minute | Throughput, quality, flexibility, resilience |

| Decision unit | Operator or technician | Cross-disciplinary teams and software agents |

| Data usage | Local logs, manual readings | Real-time, aggregated, predictive analytics |

| Flexibility | Re-tooling by physical change | Software-configurable workflows, modular components |

| Maintenance | Reactive or scheduled | Predictive, condition-based, integrated into operations |

| Change impact | Isolated to one machine | Ripple effects across supply chain and production lines |

| Investment | CapEx on machines | CapEx + OpEx on platforms, data, integration, people |

Why that matters to you

You’re not just keeping machines running; you’re stewarding an interdependent ecosystem. That changes what you budget for, how you hire, and how you measure success.

Core Components of Modern Fabrication Systems

You can’t build a system with only machines, any more than you can build a family with only grandparents. A modern fabrication system has several core components that must be designed and managed together.

The essential elements — quick list

- Hardware: machines, sensors, robots, conveyors.

- Software: CAD/CAM, MES (Manufacturing Execution Systems), ERP (Enterprise Resource Planning), analytics tools.

- Networks: secure and low-latency connectivity, edge computing.

- Data: process data, quality measurements, inventories, maintenance logs.

- People: operators, engineers, data scientists, maintenance teams.

- Processes: workflows, SOPs, safety protocols.

- Supply chain: vendors, logistics, material quality controls.

How these parts interact

You should view these elements as nodes in a living network; a change to any one node — a new sensor, a supplier delay, or a software patch — will influence behavior across the system. Success comes from orchestrating, not just owning, these components.

Key Technologies That Enable System-Based Fabrication

You’ll want to be familiar with the core technologies that make systems-based fabrication possible. They aren’t magic; they’re tools that, when combined with good processes and people, change outcomes.

Internet of Things (IoT) and sensors

You’ll find sensors on everything: motors, chucks, filters, and pallets. They’re your system’s senses, providing temperature, vibration, energy use, and location. When you aggregate that data, you convert a black box into a transparent process.

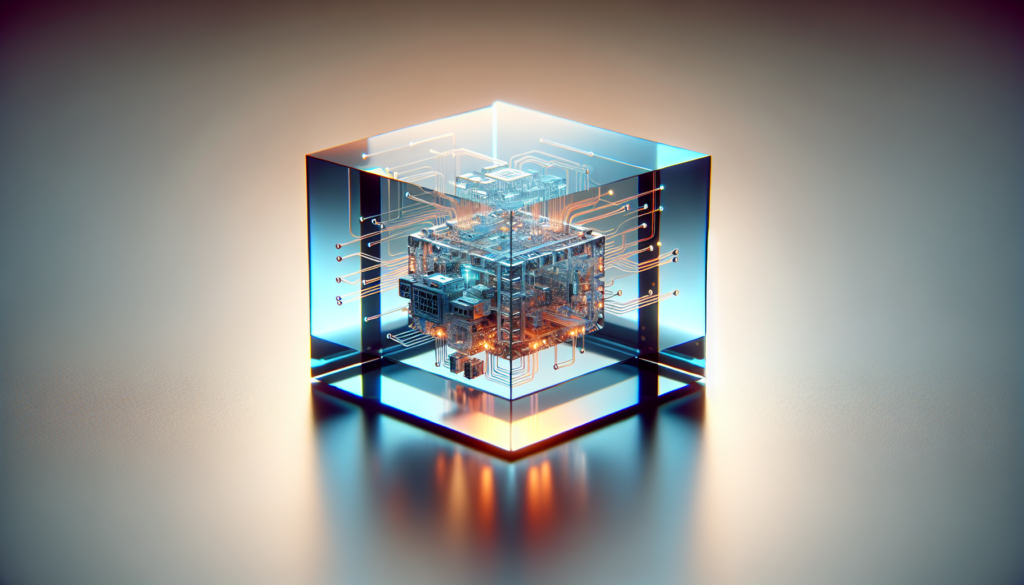

Digital twins

You can create a virtual replica of your production line and run scenarios without risking scrap. Digital twins help you experiment virtually, optimize layout, and predict failures before they happen.

Artificial intelligence and machine learning

You won’t replace intuition with AI; you’ll augment it. ML models help you predict defects, optimize parameters, and detect anomalies faster than human eyes alone.

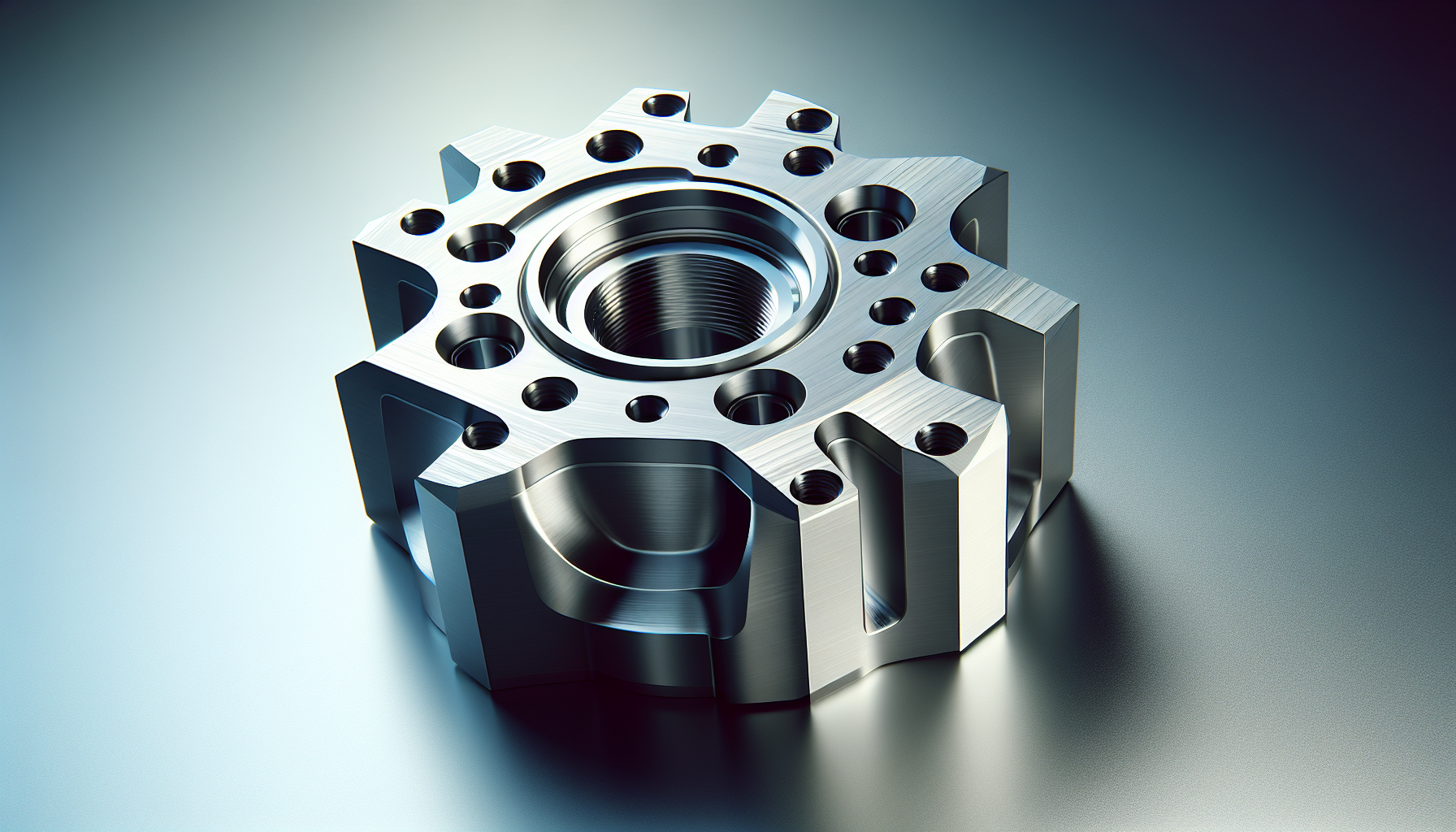

Additive manufacturing (3D printing)

You should see additive manufacturing as a component, not a panacea. It shines in customization and complex geometries, and when integrated into a system, it changes inventory strategies and part obsolescence timelines.

Robotics and collaborative robots (cobots)

You’ll use robots for repetitive or hazardous tasks, and cobots to work alongside humans. The key is orchestration: safe and adaptive programming, not just blind repetition.

MES and ERP systems

You need both: MES manages the shop floor; ERP manages business flows. Integration between them prevents information silos that create delays, errors, and finger-pointing.

Edge computing and cloud platforms

You’ll push some computation to the edge for latency-sensitive tasks, and use cloud platforms for heavy analytics, historical data, and cross-site coordination. The balance affects security, cost, and agility.

Cyber-physical systems and control software

Control loops, safety interlocks, and synchronized movements are all cyber-physical. You’ll need robust design and testing to ensure safety and performance.

What “System Thinking” Looks Like in Practice

You probably thought “systems thinking” was jargon until you had to fix a bottleneck that lived in a spreadsheet nobody knew how to use. Here’s how to think like a systems person.

Principles to adopt

- Optimize for flow, not for local efficiencies.

- Make decisions with cross-functional data.

- Build modularity and standard interfaces.

- Emphasize feedback loops for continuous learning.

- Design for resilience and variability, not perfection.

Example: treating quality as a system

Instead of blaming an operator for a crack in a part, you’ll ask about material batch history, machine vibrations, tool wear, environmental conditions, and the software that generated the CAM code. You’ll fix the upstream causes so defects stop appearing downstream.

Organizational Shifts: People and Culture

You can’t digitize people out of a job and call it progress. The system-oriented approach needs different skills and a different culture.

New roles you’ll encounter

- Systems integrator: aligns machines, networks, and software.

- Data engineer/scientist: converts raw signals into actionable insights.

- Process engineer with software skills: designs flows across tools and teams.

- Change manager: helps people adopt new ways of working.

Cultural adjustments you’ll need to make

You’ll have to foster curiosity, cross-disciplinary collaboration, and an appetite for iterative improvement. Mistakes will happen; your job is to make them less costly and more instructive.

Interoperability, Standards, and APIs

You like things that fit together. Systems thrive on standards and well-documented APIs. Without them, you’ll be stuck with a digital Tower of Babel.

Key standards and protocols

- OPC UA: a widely adopted industrial communications standard.

- MQTT: lightweight messaging for IoT devices.

- RESTful APIs: integrate applications across your enterprise.

- ISO 9001 / ISO 26262 / AS9100 and similar: quality and safety standards for specific industries.

Practical tips

You’ll insist on open protocols and modular architectures when buying equipment. If your vendor’s machine is a lovely black box that refuses to speak, expect integration costs that make the machine’s sticker price look tiny.

Metrics That Matter in System-Centric Fabrication

You’ll need new metrics to measure success. Traditional KPIs focused on machine uptime and labor hours are necessary but insufficient.

A useful KPI table

| KPI | What it measures | Why it matters |

|---|---|---|

| Overall Equipment Effectiveness (OEE) | Availability × Performance × Quality | Shows combined impact across machines and processes |

| Throughput per shift | Completed units/time | Measures flow efficiency across the system |

| First-pass yield | % of parts meeting spec without rework | Reflects integrated quality controls |

| Cycle time variability | Standard deviation of cycle times | Indicates process stability and predictability |

| Mean time to repair (MTTR) | Average downtime after failure | Reveals maintenance efficacy in a networked environment |

| Inventory turns | How often stock is cycled | Reflects supply chain and production synchronization |

| Energy per part | kWh/part | Ties sustainability to process optimization |

| Time to market | Release of product from design to production | Captures cross-functional coordination effectiveness |

Interpreting these numbers

You won’t just chase one KPI. The system perspective requires balancing trade-offs: higher throughput might erode first-pass yield if upstream variability isn’t managed. Your job is to interpret patterns, not isolated beacons.

Supply Chain and Logistics as Part of the System

Your factory isn’t an island; it’s a node in a global network. Supplier variability, transportation delays, and material quality all feed into your system.

Strategies to integrate supply chain

- Real-time supplier telemetry to flag incoming part anomalies.

- Shorter, more frequent orders enabled by better production predictability.

- Multi-sourcing and modular design to reduce single-point failures.

- Vendor-managed inventory and digital contracts for transparency.

Example: raw material variability

You’ll find that a subtle change in material hardness from a supplier can increase tool wear, which increases downtime and scrap. In a system, you’ll detect that pattern earlier and change suppliers, adjust feeds, or tweak tool paths proactively.

Security, Privacy, and Compliance

You might prefer being naïve about cyber risk, but if your machines are networked, they’re attack surfaces. Systems bring new vulnerabilities and regulatory responsibilities.

Practical security measures

- Network segmentation between corporate IT and OT (operational technology).

- Strong access controls and multi-factor authentication for control systems.

- Regular patching and vulnerability assessments for software and firmware.

- Encryption and secure boot for edge devices and sensors.

- Incident response plans that include physical safety contingencies.

Regulatory checklist example

- Data residency and privacy requirements for cross-border telemetry.

- Safety standards for automated systems (e.g., ISO 13849).

- Industry-specific certifications (e.g., FDA for medical manufacturing).

Implementation Roadmap: How You Actually Move from Machines to Systems

You can read the theory and nod sagely, and then you’ll need a practical plan. Here’s a roadmap that reduces risk and maximizes learning.

Phased approach

- Baseline: map current processes, assets, data flows, and pain points.

- Pilot: choose a low-risk, high-impact area and test connectivity, analytics, and processes.

- Scale: replicate successful patterns across more lines and sites.

- Optimize: continuously refine models, feedback loops, and governance.

- Institutionalize: embed system thinking into training, procurement, and strategy.

Governance and change management

You’ll need cross-functional steering committees, clear KPIs, and a budget for both CapEx and ongoing OpEx. Communicate early, celebrate small wins, and treat resistance as data, not drama.

Common Pitfalls and How to Avoid Them

You can be optimistic and still be prudent. Here are the stumbles that hurt the most — and how to prevent them.

Pitfall: buying point solutions that don’t integrate

You’ll feel proud of each shiny purchase until the integration bill arrives. Insist on open APIs and integration roadmaps before signing.

Pitfall: neglecting people and training

Technology without training is sculpture. Invest in training, shadowing, and incentives that reward cross-functional behavior.

Pitfall: poor data quality

If your AI is trained on garbage, expect garbage outputs and more trouble. Start with basic data hygiene: standardized naming, timestamps, and metadata.

Pitfall: underestimating cybersecurity

Assume attackers will find your weakest link. Prioritize OT security early; retrofitting protection is expensive and embarrassing.

Case Studies: Practical Examples You Can Relate To

You like stories because they stick. Here are short, practical vignettes that show systems thinking in action.

Electronics manufacturer: reducing defect propagation

You introduced inline optical inspections and linked the results to your MES. When a micro-solder issue appeared, the system flagged a specific stencil supplier batch. Because procurement, quality, and production were connected, you quarantined parts, rerouted production, and avoided a costly recall.

Shipbuilding: synchronizing big, slow processes

You digitized parts lists and used digital twins to visualize assembly sequences. Suppliers uploaded 3D models, and your planners ran collision checks months before physical parts arrived. As a result, you cut rework and reduced dockside delays.

Small job shop: gaining flexibility with cobots and modular fixturing

You standardized interfaces on fixtures and used cobots for variable part handling. The shop went from lengthy setup times to agile changeovers, allowing you to accept smaller orders profitably.

Financial Considerations: ROI and TCO

You’ll need to justify investments. Systems investments are often a mix of CapEx and recurring OpEx, and benefits can be both direct (reduced scrap) and indirect (faster time to market).

Simple ROI framework

- Estimate benefits: reduced scrap, increased throughput, lower labor costs, energy savings, fewer recalls.

- Estimate costs: equipment upgrades, software licenses, integration, training, change management.

- Calculate payback: (Total Costs) / (Annual Savings).

- Consider qualitative benefits: improved customer satisfaction, faster design cycles, better compliance.

A hypothetical example

Assume a line generates $1M/year revenue with 5% scrap. Reducing scrap to 2% yields $30k/year savings. Add $50k/year from improved throughput and $20k/year energy savings. If integration and software cost $300k with $50k annual maintenance, simple payback could be under 3 years. Your numbers will vary, but the pattern is consistent: systems investments pay off by reducing hidden costs across the value chain.

Measuring Progress and Continuous Improvement

You won’t get perfection in one go. Systems evolve. You’ll measure, adjust, and repeat.

A cadence for improvement

- Daily: shop-floor KPIs and exceptions.

- Weekly: cross-functional reviews of quality and throughput.

- Monthly: strategic KPIs and trend analysis.

- Quarterly: roadmap adjustments and investment reviews.

Building feedback loops

You’ll close the loop by sending production outcomes back to design and procurement. When designers see real-world part performance, they design better next time.

The Environmental and Social Angle

You may not be motivated by ethics alone, but sustainable systems lower costs and reduce regulatory risk. System-level thinking naturally supports circular economy practices: fewer wasted materials, better end-of-life planning, and energy optimization.

Sustainability actions you can take

- Monitor energy per part and set reduction targets.

- Design for disassembly and reuse.

- Use predictive maintenance to extend machine life.

- Select suppliers with transparent environmental footprints.

The Future: Where Systems Will Take Fabrication Next

You should be ready for a near future where factories act more like coordinated services. Expect production-as-a-service, autonomous replenishment, and marketplaces for spare capacity.

Emerging trends

- More pervasive edge AI for localized decision-making.

- Federated learning across sites to improve models without sharing raw data.

- Greater modularity so production becomes reconfigurable quickly.

- Increased use of blockchain-like systems for traceability and contracts.

Practical Checklist for Your Next Move

You like lists that you can cross off. Here’s a pragmatic checklist to move toward system-based fabrication.

- Map your current processes and data flows.

- Identify a pilot line with clear KPIs and low risk.

- Require open interfaces in procurement specs.

- Build cross-functional time into people’s calendars.

- Start a data hygiene program.

- Implement basic cybersecurity measures early.

- Train staff on new tools and collaborative practices.

- Set measurable targets for throughput, quality, and energy.

- Plan for scale and budget recurring costs.

- Celebrate small wins and institutionalize what works.

Final Thoughts

You might cling to the romance of a single machine doing heroic work, but the truth is more interesting: fabrication has become a symphony where the music matters more than any single instrument. When you shift your attention from machines to systems, you open the door to resilience, agility, and sustainable performance. You’ll still admire a well-tuned milling machine, but you’ll know that its true value comes from the notes it plays with everything else.

One last practical nudge

Start small, be methodical, and remember that systems are social as well as technical. You’ll need patience, curiosity, and the willingness to look beyond the grease and the gauges to the conversations that keep your factory alive. If nothing else, you’ll stop apologizing to the machines when things break — because the problem, more often than not, isn’t a temperamental lathe; it’s a system that needs a little attention.