Have you ever stared at a block of aluminium and imagined it turning into the one thing that finally makes your startup feel legitimate?

CNC Manufacturing For Startups: How 2026 Lowered The Barrier To Industrial Production

You’ll find this is less about magic and more about a sensible set of changes that make industrial production look almost reasonable for a small team. The year 2026 did not wave a wand, but it rearranged tools, software, economics, and expectations in a way that shrank the gap between “prototype” and “product.”

Why this matters to you

You’re probably wearing three hats, sleeping in bursts, and promising a launch date that sounds optimistic even to you. The improvements in CNC manufacturing make those hats less hazardous and your promises easier to keep, because production is more accessible, predictable, and affordable than it used to be.

What CNC manufacturing is — and why it’s still a big secret to most founders

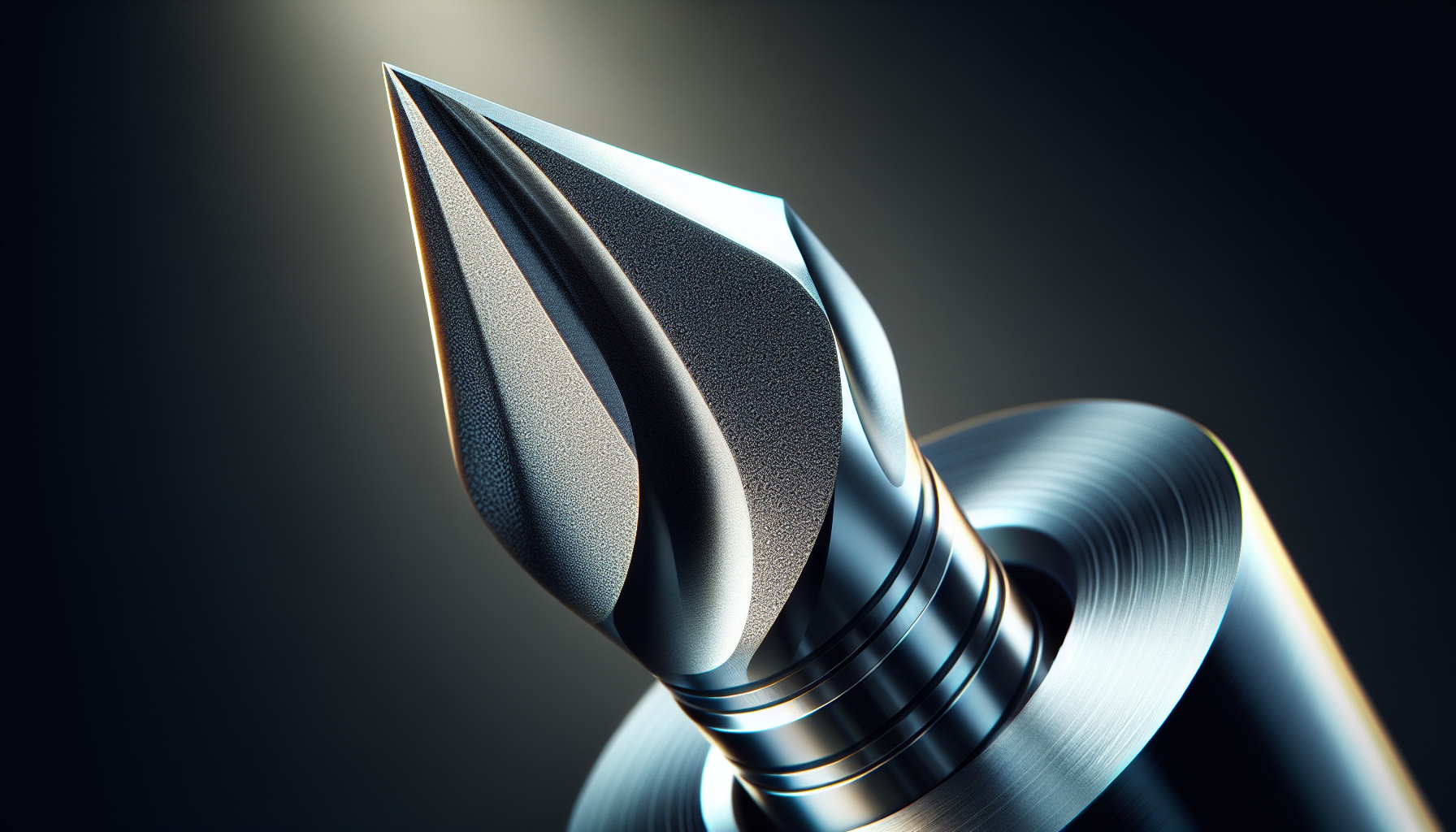

CNC stands for Computer Numerical Control, and it’s the process where machines translate code into precise movements to cut, mill, or shape materials. You may have heard of 3D printing stealing the limelight, but CNC is the old-school workhorse that still makes your product robust, durable, and fit for purpose.

The basic parts of a CNC workflow

A CNC workflow has a CAD model, CAM programming, machine setup, tooling, and the physical machining process. If one of those steps misbehaves, you’ll learn a new vocabulary of swear words and a keen appreciation for patience.

CNC versus additive manufacturing

CNC is subtractive: it removes material; additive builds up layers. You’ll prefer CNC for metals, tight tolerances, and finishes that don’t look like layer cake, while additive keeps winning at complex internal geometries and rapid iteration.

What changed in 2026: a quick overview

Several interlocking shifts in 2026 made CNC friendlier for startups: software commoditization, smarter machines, subscription manufacturing services, improved supply chains, and AI-assisted programming. These changes didn’t happen overnight, but their combined effect was to shrink lead times, lower costs, and reduce technical friction.

Software became less arcane

CAM packages embraced clarity and automation, letting you go from CAD to toolpaths with fewer cryptic parameter screens. You don’t need an ex-CAM specialist on staff to produce production-ready G-code anymore; the software now holds your hand without being condescending.

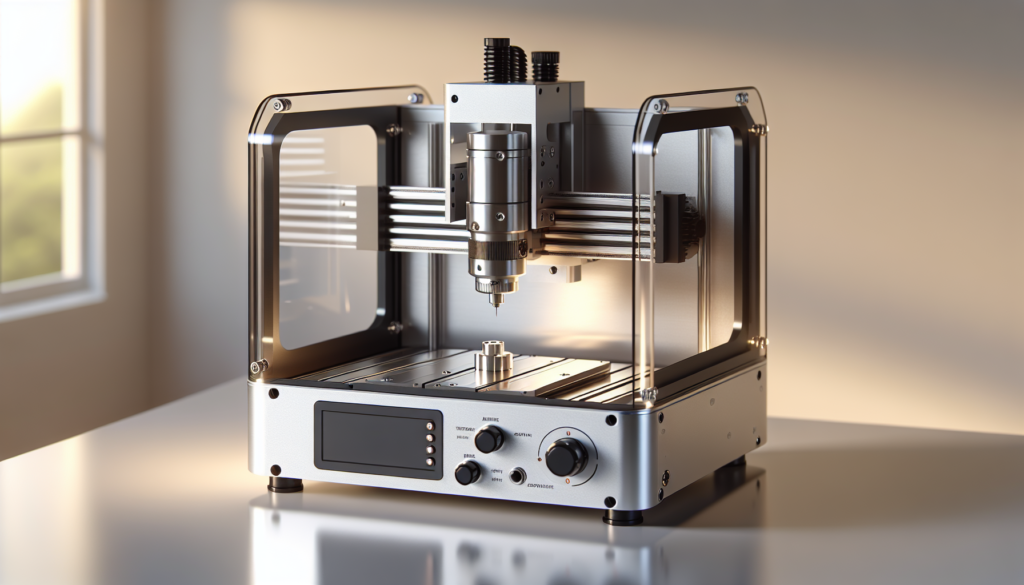

Machines got smarter and cheaper

Hardware manufacturers optimized controller electronics, brought higher performance to desktop and benchtop machines, and offered cost-effective multi-axis machines. As a result, the hardware you can lease, share, or rent is no longer a monstrous capital expense that eats your runway.

Manufacturing-as-a-Service matured

On-demand and subscription manufacturing platforms moved beyond simple quoting to integrated production management, traceability, and small-batch economies. That means you can place repeatable orders with predictable pricing, quality, and delivery schedules.

The 2020 vs 2026 comparison: what actually improved

Here’s a concise table to help you visualize the differences between earlier years and 2026. You’ll notice specific gains in cost, speed, and accessibility.

| Area | Pre-2020 | 2026 |

|---|---|---|

| Entry cost for small-batch metal CNC | High capital, specialist training | Subscriptions, leasing, networked shops |

| CAM usability | Complex, expert-only | Intuitive, AI-assisted, templates |

| Lead times | Weeks to months | Days to low-weeks for small batches |

| Quality control | Manual and inconsistent | Integrated SPC, digital traceability |

| Materials and finishes | Limited, costly tooling | Wider palette, affordable finishing |

| Access to 5-axis | Niche and expensive | More affordable multi-axis options |

| Supply chain resilience | Fragile with single suppliers | Distributed networks, local hubs |

Why those changes actually matter for startups

You won’t need to mortgage your future to order a thousand machined brackets, and your first production run can happen on a plausible timeline. This is important because you can now iterate with real parts instead of euphemistic prototypes that look like they were made in a closet.

The hardware ecosystem you should know about

The types of CNC machines relevant to startups span from simple mills to hybrid systems that combine additive and subtractive processes. Knowing their strengths will help you choose a path that matches your product’s needs and your budget.

Common machine types and uses

You should know the common platforms: 3-axis mills for flat parts, 4/5-axis mills for complex geometries, lathes for round parts, and multi-axis turning centers for high-value small parts. Each machine type has trade-offs in cost, complexity, and lead time that should influence your decision.

| Machine Type | Best for | Typical startup use |

|---|---|---|

| 3-axis mill | Flat faces, pockets | Enclosures, brackets, jigs |

| 4-axis / 5-axis mill | Complex contours | Housings, impellers, ergonomic parts |

| Lathe / turning center | Cylindrical parts | Shafts, threaded components |

| CNC router | Large, light materials | Panels, wood parts, composites |

| Hybrid (additive + subtractive) | Internal geometries + finish | Lightweight aerospace parts, internal channels |

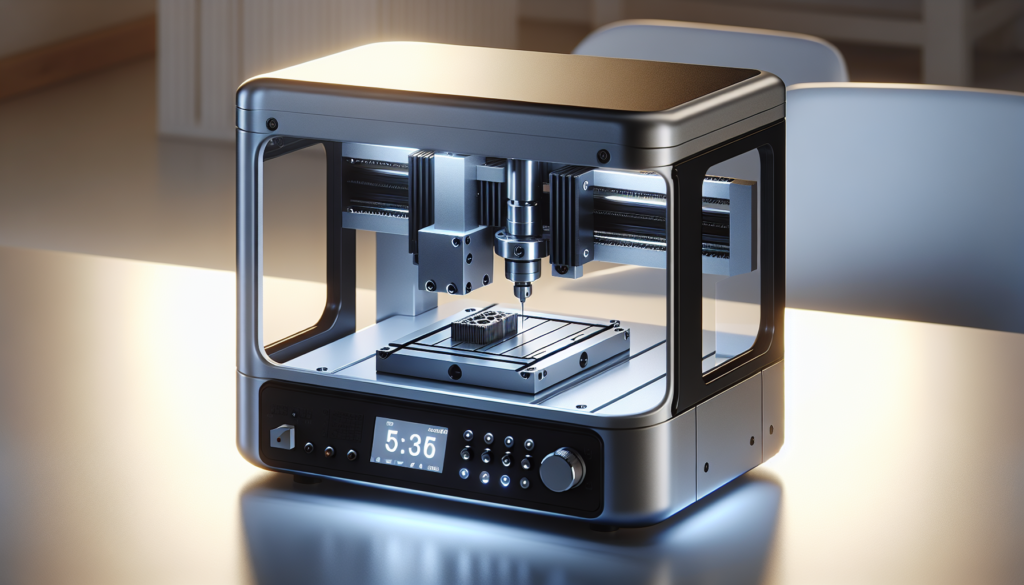

Desktop and benchtop machines

Benchtop CNC units are now more capable and reliable, which will allow you to validate form, fit, and function in-house. They aren’t a replacement for an industrial shop, but they’re terrific at shortening feedback loops so you can test quickly.

Software advances — why you’ll breathe easier

Toolpath generation and post-processing used to be the province of arcane knowledge and lots of coffee. The 2026 wave of software improvements automated much of the routine decision-making, recommended tooling, and optimized feeds and speeds based on real-world data.

AI-assisted CAM and smarter post-processors

AI in CAM recommends optimal toolpaths, simulations, and roughing/finishing strategies based on part geometry and material. You’ll save time and reduce scrap because the software learns from similar parts and factory conditions.

Cloud integration and version control

Your CAD, CAM, and production data now live in the cloud with robust versioning and permissions, so you’ll avoid the “which_file_final_really_v4_FINAL” tragedy. This means fewer costly mistakes and clearer audit trails when you need to show traceability.

Materials and finishing options expanded

In 2026 you’ll find a broader palette of machinable alloys, composite-friendly strategies, and finishing services that used to be expensive. The better availability of specialty alloys and coatings lets you design for performance without immediate compromise.

Conventional and specialty materials

Startups now have easier access to machinable stainless steels, aerospace alloys, and engineered plastics with reliable supply. This means you can prototype in the actual production material sooner, preventing nasty surprises later.

Finishing services and surface treatments

Finishing options such as anodizing, PVD coating, specialized painting, and micro-blasting are more integrated with CNC suppliers. You’ll be able to order parts with the finish you need and a known process window, rather than playing a guessing game.

Economics: how the cost structure shifted

Lower capital expenditure, better capacity utilization, and competitive service platforms changed the economics significantly. The result for you is that unit economics improve much earlier, and the break-even point for small runs moves in your favor.

Capital versus operational expense

Leasing, short-term rentals, and pay-per-part services turned capital expense into operational expense you can budget more predictably. You’ll breathe easier at board meetings because your balance sheet will look less like an interrogation.

Small-batch pricing dynamics

Lower machine overhead, automation, and distributed manufacturing reduced setup costs per part. That means a 100- to 500-piece initial run is economically feasible; you’ll stop pretending 10,000 units is the only way to get decent pricing.

Production planning you can actually manage

Production planning used to require a spreadsheet the size of a novel and the patience of someone who enjoys reading legal documents. In 2026, integrated production management tools let you schedule, track, and audit runs the way you track marketing metrics—except it actually changes the product in your hands.

Lead time predictability and just-in-time options

You can choose predictable lead times with local hubs or adopt JIT deliveries to keep inventory lean. This allows you to scale without hauling a warehouse through your living room.

Quality control baked-in

Statistical process control, in-process measurement, and machine learning-based anomaly detection give you early warning signs that something is going wrong. You’ll catch errors before shipping them to customers and sleep slightly better.

Design for Manufacturability (DFM) — the habits that save you money

The smartest part of lowering the barrier is not a machine or an app—it’s the way you design. DFM practices reduce cycle time, tooling costs, and rework, making small-batch production both cheaper and faster.

Basic DFM rules for CNC parts

You should minimize thin walls, avoid deep pockets without proper fixturing, and prefer standard tool sizes where possible. These simple rules keep machining time down and help your jobs look less like they were attacked by an amateur jeweler.

Tolerances and fits: where to spend effort

You only need tight tolerances where function demands it; otherwise, give the machinist a break. Specifying ±0.01 mm across the board will float your bill higher and turn the machining process into a brittle, high-stress negotiation.

Selecting a manufacturing partner or service

Choosing who makes your parts is part personal and part forensic accounting. You’ll want to combine references, capabilities, and cultural fit because a good supplier can become a co-conspirator in product quality and delivery reliability.

Questions to ask a potential supplier

Ask about material traceability, inspection processes, lead times, batch repeatability, and how they handle change orders. You’ll sleep better knowing they have been asked the inconvenient questions you were afraid to ask.

The hybrid approach: in-house + distributed

Many startups use a hybrid model: you machine prototypes in-house, then move to a trusted supplier for small production runs. This mixes control with scale and keeps your options open as demand changes.

A practical step-by-step roadmap for your first CNC production run

You don’t need a PhD to get this right, but you do need a checklist and the patience to follow it. The steps below are a pragmatic guide for turning a prototype into a reliable small-batch production run.

- Finalize CAD model with DFM feedback. You’ll reduce costly changes by validating geometry and tolerances first.

- Choose materials and finishing based on function, not fashion. You’ll get closer to final performance by using production-grade materials sooner.

- Create or obtain a CAM-ready model. You can use modern AI-assisted tools if you don’t have CAM expertise.

- Prototype on a benchtop machine or via a trusted shop. You’ll validate assembly, fit, and function before committing to larger runs.

- Run a pilot batch of 10–100 parts. You’ll catch repeatability issues before scaling.

- Perform inspection, gather SPC data, and lock down suppliers. You’ll formalize quality and reduce surprises.

- Move to production with planned reorders and traceability. You’ll manage cash flow and inventory better by planning reorder points.

A checklist table you can use

| Task | Why it matters | Done? |

|---|---|---|

| Final CAD/DFM review | Prevents costly downstream changes | |

| Material/spec confirmation | Ensures performance and compliance | |

| Prototype machining | Validates form/fit/function | |

| CAM setup with simulation | Reduces scrap and tool breakage | |

| Pilot batch with QC | Confirms repeatability | |

| Finish and assembly test | Ensures final look and function | |

| Supply chain/lead time plan | Keeps inventory predictable |

Pricing, quoting, and negotiating bids

Quoting can feel like haggling at a flea market, but better data and clearer processes made it more straightforward in 2026. You’ll benefit from transparent price breakdowns and predictable markups.

How quotes are structured now

Quotes often break down into material, machine time, tooling amortization, setup, finishing, and inspection. You’ll appreciate transparency because it helps you identify where to optimize.

Tips for negotiating better pricing

Buy batching, standardize materials, and commit to rolling orders to secure lower margins. You’ll win price concessions by promising predictable demand rather than one-off chaos.

Quality standards, certifications, and compliance

If you plan to sell into regulated industries, certifications matter more than clever marketing. The good news is that traceable machining and standardized reporting in 2026 make compliance less painful.

Common standards to be aware of

ISO 9001 for quality management, AS9100 for aerospace, and specific industry standards for medical devices are frequent requirements. You’ll need paperwork and rigorous processes to satisfy auditors, but the integrated data environment helps.

Traceability and documentation

You should expect full batch traceability, material certificates, and inspection reports from suppliers. This reduces liability and gives you real proof of quality when customers ask uncomfortable questions.

Intellectual property and tooling considerations

If your product is novel, IP protection matters, but tooling is not always a moat. You’ll need to balance protection with practical manufacturing.

Protecting IP while using external shops

Use NDAs, control critical data, and consider splitting production steps across suppliers. You’ll sleep more easily if you don’t hand over every secret at once.

Tooling ownership and amortization

Some suppliers amortize tooling cost; others expect you to buy it outright. You’ll save money by understanding who owns what and negotiating amortization schedules that reflect volume.

Sustainability and waste reduction

You’ll want customers to like your product and not hate you for the environmental cost. CNC has always produced chips and waste, but 2026 introduced better recycling, closer material sourcing, and less wasteful processes.

Material recovery and efficient machining

Optimized nesting, smarter toolpaths, and material reclaim programs reduced scrap rates and lowered costs. You’ll feel less guilt about machining your way through a prototype run.

Lifecycle and end-of-life considerations

Design for disassembly and choose recyclable materials where possible. You’ll build a product that not only sells but can be responsibly retired when its time has come.

Realistic timelines and what to expect

You won’t magically go from idea to shipment overnight, but you can shrink the timeline dramatically. Expect a few weeks for prototyping and validation, and then days to low-weeks for small production batches if you’ve done your homework.

Typical timeframes

A well-run schedule: 1–3 weeks for prototype iterations, 1–4 weeks for a pilot batch, and ongoing lead times of 3–14 days per reorder for local suppliers. You’ll find that predictability is the real luxury here.

Bottlenecks to watch

Material availability, tooling lead times, and insufficiently detailed drawings will still be your likely hold-ups. You’ll avoid delays by planning ahead and maintaining a small buffer for surprises.

Case studies: how startups used 2026 CNC improvements

You’ll find that many small teams transformed their approach once production became predictable, accessible, and reasonably priced. These stories aren’t fairy tales; they’re the result of planning and the right partnerships.

Example: Consumer electronics enclosure

A two-person company moved from 3D printed prototypes to 5-axis machined enclosures for a premium product. They used AI-assisted CAM and a local small-batch shop to produce 500 units with consistent finishes and reduced per-unit cost by 40%.

Example: Medical device component

A medtech startup improved their part tolerancing and worked with a certified supplier with integrated traceability. That allowed them to pass regulatory audits more quickly and reduced time-to-market by months.

Risks and limitations you must consider

None of this is a silver bullet. You’ll still face risks: machine downtime, supplier bankruptcy, design mistakes, and regulatory surprises. Preparedness, not optimism, will protect your product and your business.

How to mitigate common risks

Diversify suppliers, maintain documented processes, keep a small buffer stock, and validate designs thoroughly. You’ll sleep better and ship more reliably if you treat manufacturing like a serious part of your business, not a hopeful appendage.

Final checklist before you place your first production order

Here’s a compact checklist to make sure you’ve covered the essentials before you hit “order.” You’ll feel smarter, calmer, and slightly more adult.

- Final CAD/DFM review completed and documented.

- Material and finish specified with certificates.

- CAM and simulation signed off.

- Pilot batch plan and QC criteria defined.

- Supplier capabilities, certifications, and traceability confirmed.

- Lead time and reorder points established.

- IP protections and tooling ownership clarified.

- Contingency plan for supplier failure in place.

Looking ahead: what this means for your startup beyond 2026

The lowering of barriers in 2026 is not merely a moment; it’s a structural shift that changes how you think about product development. You’ll iterate faster, validate real-world parts sooner, and be able to scale production in ways that would have seemed implausible a few years earlier.

How to leverage these changes for growth

Use small-batch runs to test product-market fit, not just for inventory. You’ll be able to adapt designs quickly based on real customer feedback and avoid the dread of being stuck with a warehouse of obsolete parts.

The mindset shift that will pay dividends

Treat manufacturing as a set of choices you can optimize instead of an intractable barrier. You’ll find that small adjustments in design, supplier selection, and scheduling yield outsized benefits for product quality, cost, and time-to-market.

If you take away only one piece of advice from this long conversation, let it be this: treat production like another design discipline. You’ll stop being surprised by manufacturing and start using it to make your product better. And if you’re lucky, the parts will look as good as your pitch deck sounded.