Have you ever wished your CNC machine could grumble, clear its throat, and say, “Not today — I’m about to mutiny”?

Predictive CNC Maintenance: How 2026 Machines Prevent Failure Before It Happens

You’re about to read about machines that act less like obstinate appliances and more like sympathetic roommates who tell you when the plumbing’s going to burst. In 2026, CNC machines are smarter, chattier, and uncomfortably accurate about their own demise — and your job is easier because of it. This article walks you through the technologies, processes, benefits, and practical how-tos of predictive maintenance for modern CNC systems, written in a friendly, slightly bemused voice that assumes you keep one sticky note too many on your monitor.

Why predictive maintenance matters now

Predictive maintenance isn’t a fad. It’s the difference between an unscheduled 12-hour downtime that ruins delivery dates and a scheduled 30-minute fix that barely interrupts your coffee. You work in an environment where lead times and margins matter, and unexpected machine failure is expensive in both cash and credibility. Predictive maintenance turns signals that used to be noise into actionable insights.

You’ll learn why the shift from reactive to predictive maintenance is not just technical — it’s cultural. Machines in 2026 are designed to tell you what’s wrong and when, but your team must learn to listen and act.

What “predictive” means in practice

Predictive maintenance uses real-time data, historical patterns, and algorithms to estimate when a machine component will fail. That allows you to perform maintenance at a calculated time rather than after a breakdown or at arbitrary intervals. The goal is to maximize uptime, minimize costs, and plan work so it doesn’t interrupt production forecasts.

You’ll appreciate the difference between “scheduled every 500 hours” and “replace bearing in 48 hours” when you’re juggling orders, staff, and spare parts.

How 2026 CNC machines differ from older models

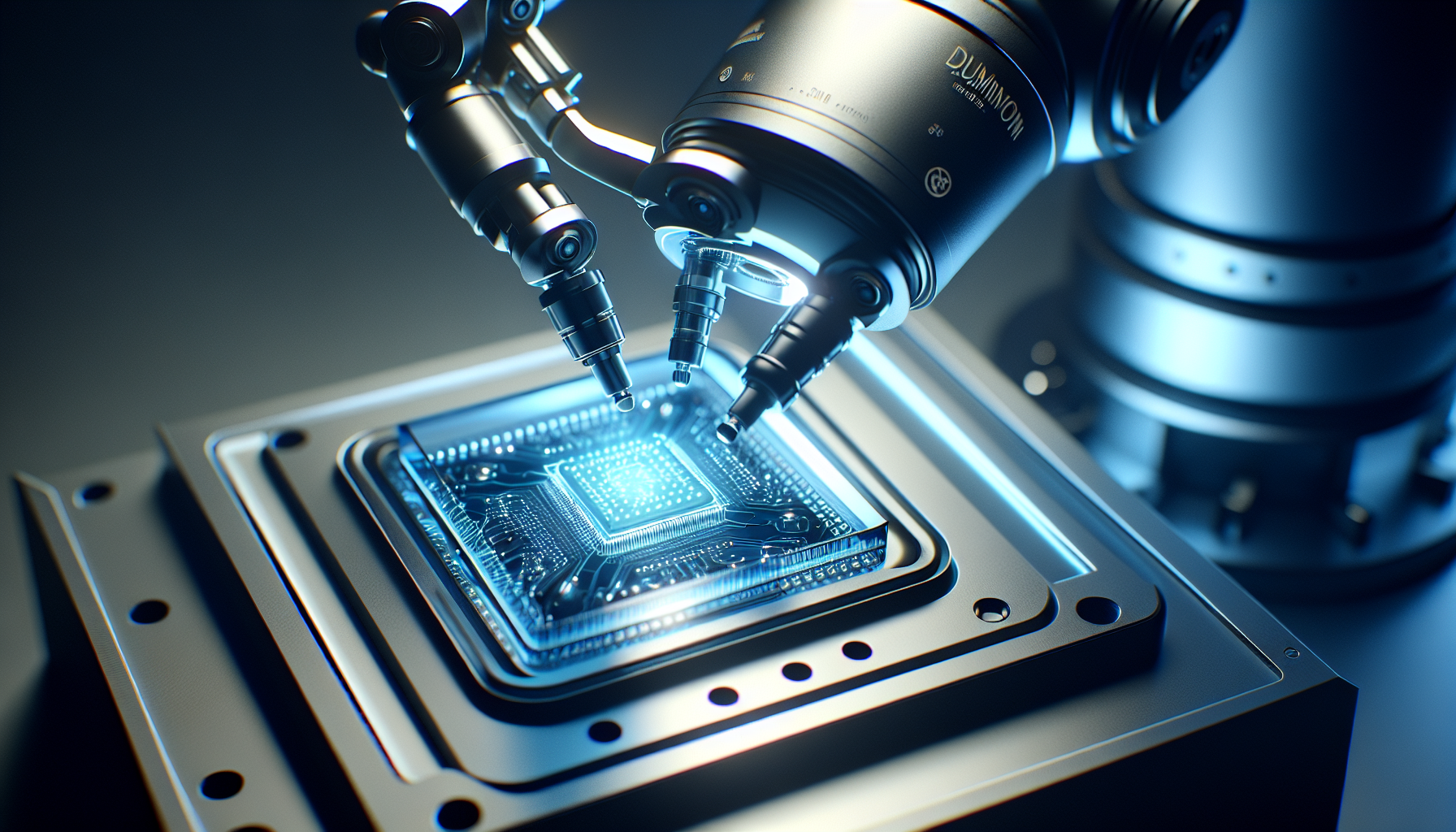

CNC machines built in 2026 ship with more than servo motors and a stubborn control panel. They’re equipped with edge compute, native AI inference, richer sensor arrays, standardized data outputs, and improved cybersecurity by design. These are not retrofits; they’re machines designed to speak and reason.

You’ll notice less wrestling with incompatible protocols and more plug-and-play analytics.

Key advances in 2026 machines

- Embedded AI inference chips that run lightweight models on-device for immediate detection. This reduces latency and dependence on continuous cloud connectivity.

- Broader sensor suites including accelerometers, acoustic emission sensors, thermal cameras, spindle current monitors, and high-resolution encoders.

- Standard protocols such as MTConnect and OPC UA for consistent telemetry across vendors.

- Support for federated learning and secure model updates, letting your machines improve without sending raw data offsite.

- Built-in security features to prevent tampered sensor streams and spoofed alerts.

You’ll find these features make predictive systems faster to setup and more trustworthy during operation.

Core components of a predictive maintenance system

A predictive maintenance system has several building blocks you’ll need to recognize and manage: sensors, data acquisition, edge computing, cloud analytics, alerting, and workflows. Each plays a role in turning raw signals into reliable predictions.

You’ll want a checklist for each component before you sign on for a new system or retrofit.

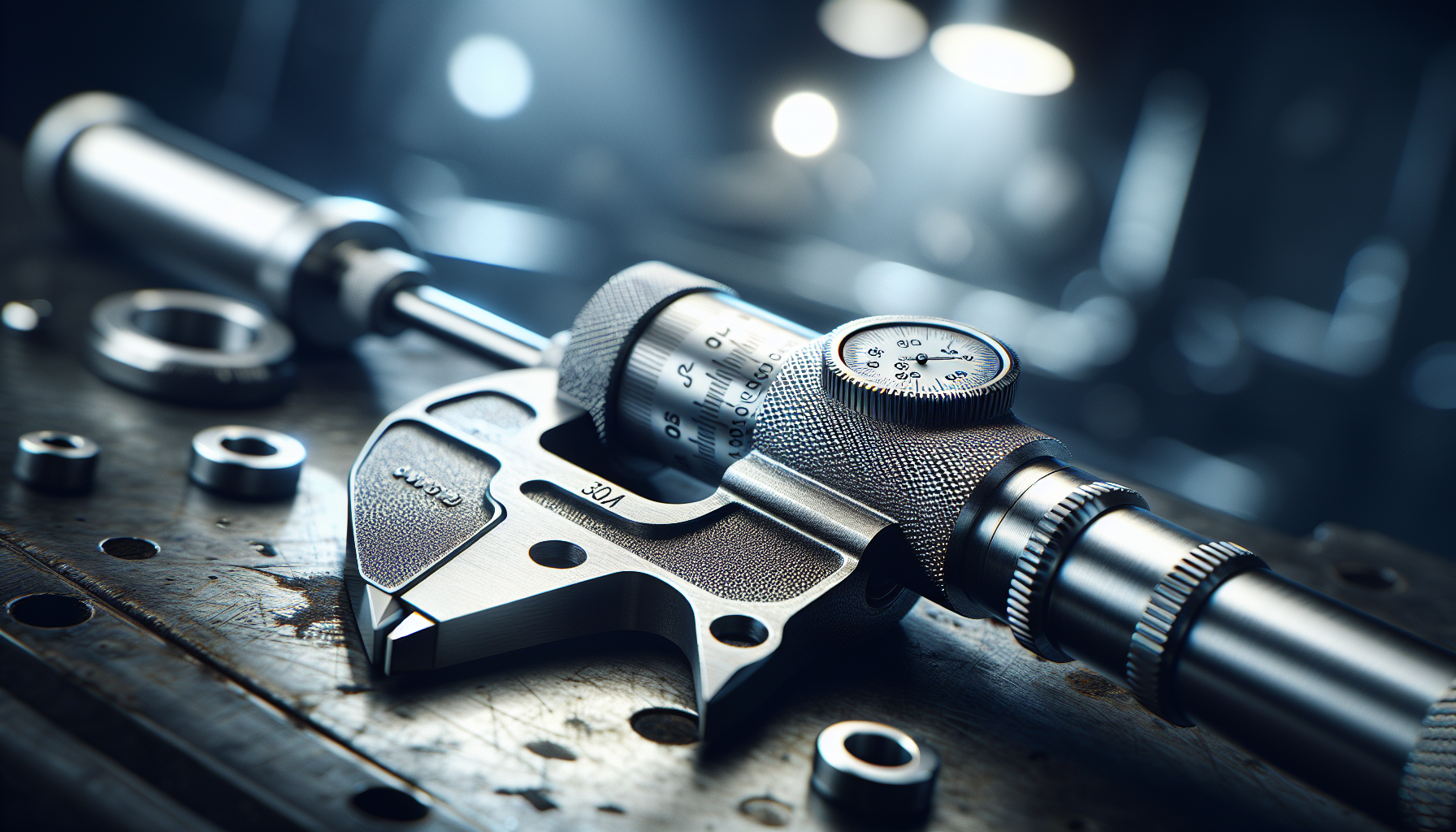

Sensors and signals

Sensors are your machine’s senses. They provide the raw data that feeds models and triggers alarms.

- Vibration sensors: Detect bearing wear, imbalance, misalignment.

- Acoustic emission sensors: Catch micro-cracks and tool failure moments earlier than vibration alone.

- Current/power monitors: Reveal spindle load anomalies, tool engagement, and cutting inefficiency.

- Temperature sensors and thermal imaging: Expose overheating bearings or thermal drift in axes.

- High-resolution encoders: Show subtle positional errors and backlash.

- Coolant quality and flow sensors: Indicate contamination, clogs, or pump trouble.

You’ll want the right sensor for the failure mode you care about. A spindle bearing will talk louder in vibration than in coolant conductivity.

Data acquisition and edge compute

Raw sensor data is noisy. Data acquisition systems sample, filter, and sometimes preprocess this data. Edge computers then perform initial anomaly detection and lightweight inference to reduce data sent to the cloud and provide real-time alerts.

You’ll appreciate edge compute when your internet flutters and yet the machine still warns you about a failing spindle.

Cloud analytics and model training

The cloud stores long-term data and trains models for remaining useful life (RUL) estimation, classification of fault types, and pattern discovery. Models are continuously updated as more data flows in and as you label incidents.

You’ll find cloud models help identify slow-developing problems that single machines alone can’t reveal.

Alerting, dashboards, and workflows

Insights are useless if they don’t prompt action. Alerting systems need to be clear, actionable, and integrated with your maintenance management tools. Dashboards allow you to prioritize actions and track KPIs.

You’ll want alerts tied to specific instructions — not “something’s wrong” — but “replace bearing X within 48 hours; spare part SN 12345”.

Table: Typical sensors vs. failure modes

This table helps you match sensors to the failure modes they best detect, making it easier to design your monitoring strategy.

| Failure Mode | Primary Sensors | Secondary Sensors | Typical Early Signal |

|---|---|---|---|

| Bearing wear | Vibration accelerometer | Temperature, acoustic emission | Increased high-frequency vibration |

| Spindle imbalance | Vibration, current | Encoder (for runout) | Periodic vibration amplitude rise at spindle speed |

| Tool wear/breakage | Spindle current, acoustic emission | Force sensors, vibration | Increase in cutting load or transient acoustic spike |

| Axis backlash/position drift | Encoder, torque sensors | Thermal camera | Slow drift in position with temperature changes |

| Overheating | Temperature, thermal imaging | Current | Thermal hotspots or rising bearing temp |

| Hydraulic/pneumatic failure | Pressure sensors | Flow sensors | Drop in pressure or flow interruptions |

| Coolant contamination/clog | Conductivity, flow sensors | Pressure | Reduced flow or increased conductivity |

| Chip conveyor jam | Motor current, vibration | Proximity sensors | Increased current and unusual vibration pattern |

You’ll be able to use this as a quick reference when planning sensor deployment.

Machine learning techniques you’ll encounter

Predictive maintenance uses several ML approaches: anomaly detection, classification, regression for RUL, and sometimes unsupervised clustering to find new failure modes. You’ll meet terms like supervised learning, transfer learning, and federated learning.

You’ll want to choose methods that balance accuracy with interpretability, because technicians like recommendations they can understand and verify.

Anomaly detection

Anomaly detection learns normal behavior and flags deviations. It’s useful for rare or new failure modes where labeled data is scarce.

You’ll rely on anomaly detection for early warnings on equipment that hasn’t failed enough times to build reliable supervised models.

Supervised learning for failure classification

When you have labeled failure data, supervised models can classify the fault type and suggest corrective actions.

You’ll prefer these models when your shop has documented incidents and repair logs.

Regression and RUL estimation

Regression models predict remaining useful life as a continuous estimate. These are helpful for scheduling maintenance windows and ordering parts.

You’ll appreciate RUL predictions for planning work to minimize production impact.

Federated and transfer learning

Federated learning lets machines share model improvements without sharing raw data, helping with privacy and bandwidth. Transfer learning applies knowledge from one machine type to another.

You’ll save time on model training when your machines can learn from each other across plants without sending sensitive data away.

Implementation roadmap: step-by-step

Implementing predictive maintenance is a project — but not a six-month odyssey if you plan. The roadmap below gives you a pragmatic sequence to follow.

You’ll find a staged approach reduces risk and wins buy-in from operators and managers.

-

Assess needs and define ROI goals

- Understand which machines cause the most pain and what failure costs you most.

- Set measurable goals: reduce unplanned downtime by X%, increase tool life by Y%.

-

Select pilot machines

- Start with a small number of critical machines with frequent failures.

- Choose machines that represent broader types in your shop.

-

Install sensors and data acquisition

- Use the sensor table above to pick the right instruments.

- Ensure robust mounting and routing to avoid signal noise.

-

Set up edge and cloud infrastructure

- Deploy edge devices for low latency detection.

- Connect to the cloud for long-term analytics and model training.

-

Train baseline models and set thresholds

- Use historical data to start supervised models; use anomaly detection for new failure modes.

- Tune alert thresholds with operators to reduce noise.

-

Integrate workflows

- Connect alerts to CMMS, spare parts ordering, and technicians’ schedules.

- Create playbooks for common alerts.

-

Measure, refine, and scale

- Track KPIs and adjust models.

- Scale from pilot machines to more equipment in waves.

You’ll reduce early frustration by starting small and showing wins before scaling.

Example pilot timeline

This table shows a realistic pilot schedule for one critical machine.

| Week | Activity |

|---|---|

| 1 | Project kickoff, define KPIs, select pilot machine |

| 2-3 | Sensor installation and validation |

| 4-5 | Edge device deployment, data collection begins |

| 6-7 | Baseline analytics, initial anomaly thresholds |

| 8-9 | Train supervised models using historic & new data |

| 10 | Integrate alerts with CMMS and create playbooks |

| 11-12 | Monitor, refine thresholds; first maintenance action executed |

| 13+ | Evaluate pilot results, plan scale-up |

You’ll notice you can get meaningful alerts in roughly two months with a focused effort.

KPIs and metrics to track

To prove value, you’ll need to measure outcomes. Here are core metrics that show your predictive system’s impact.

- Unplanned downtime hours per month

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

- Maintenance labor hours saved

- Spare parts inventory turns

- False positive/false negative rates of alerts

- Percentage of issues detected before interruption

You’ll want to track both technical metrics (model accuracy) and business metrics (downtime cost).

Example ROI calculation

This simple table helps you estimate initial ROI for a predictive install on one critical CNC.

| Item | Value |

|---|---|

| Annual unplanned downtime cost (lost production + labor) | $120,000 |

| Expected reduction in downtime with predictive maintenance | 40% |

| Annual savings from reduced downtime | $48,000 |

| Implementation and first-year operating cost | $25,000 |

| First-year net benefit | $23,000 |

| Payback period | ~7 months |

You’ll find ROI becomes favorable quickly on high-value, high-utilization machines.

Common pitfalls and how you’ll avoid them

Predictive maintenance sounds like magic until implementation reveals people, processes, and politics. Here’s what trips shops up and how you can prevent it.

- Over-sensorization: Buying every sensor under the sun creates noise and extra work. You’ll pick sensors based on failure modes and ROI.

- Alert fatigue: Too many false alarms erode trust. You’ll tune thresholds and add confidence scores.

- Poor data hygiene: Messy timestamps and misconfigured channels spoil models. You’ll enforce data standards and synchronization.

- Ignoring operator input: Technicians know machines; ignoring them reduces model quality. You’ll include operators in labeling and playbook design.

- Security gaps: Connected machines can be vulnerable. You’ll use secure protocols, segregated networks, and regular patching.

- Skipping pilot: Trying to change everything at once overwhelms teams. You’ll demonstrate value with a pilot first.

You’ll be more successful if you pair technology with good processes and people involvement.

Integrating with your maintenance culture

Predictive tools won’t help if technicians ignore them. You’ll need to weave predictions into existing workflows and assign clear responsibilities for acting on alerts.

- Create playbooks that show step-by-step fixes for specific alerts.

- Train technicians on interpreting confidence levels and model caveats.

- Set up escalation rules: when an alert requires immediate stop vs scheduled maintenance.

- Recognize teams for reductions in downtime and successful preventive actions.

You’ll improve adoption when predictions make technicians’ lives easier, not more complicated.

Security and data governance

In 2026, machines are connected by design. That’s convenient and vulnerable. You’ll need to protect sensor data and ensure models aren’t being poisoned by malintent.

- Use encryption in transit and at rest.

- Segment networks: keep control networks separate from general IT.

- Implement role-based access for dashboards and model deployment.

- Maintain audit logs for alerts and maintenance actions.

- Consider federated learning to avoid sharing raw production data across sites.

You’ll sleep better knowing your predictive system isn’t an open window for attackers.

Human-machine teaming: the role of the technician

Predictive maintenance doesn’t replace technicians. It augments them. You’ll rely on skilled personnel to validate anomalies, perform fixes, and bring context to alerts.

- Technicians provide labeled data and feedback that improve model accuracy.

- Shop-floor expertise speeds diagnosis beyond purely algorithmic suggestions.

- Continuous training helps staff trust and use predictive insights.

You’ll find the best results when technicians feel empowered rather than threatened by automation.

Case study vignette (short)

Imagine a small job shop that made precision gears. They had a habit of suffering catastrophic spindle failures every quarter that cost them $20k each time. They installed vibration sensors and a simple RUL model on a single critical mill. The system alerted them two days before a critical bearing failure, allowing a planned replacement during a low-production window. They avoided downtime, saved the $20k loss, and used the experience to tune the model. After one year, they reduced unexpected spindle failures by 80% and had a clear plan to roll the system to other machines.

You’ll recognize this story — small, practical moves leading to big results.

Tools, vendors, and standards you’ll encounter

When selecting vendors, prioritize openness, standards support, and good documentation over shiny dashboards. Look for MTConnect, OPC UA, and REST APIs for integration. Vendors that support federated learning and edge inference will save you headaches later.

You’ll favor suppliers who can explain their models in plain language and offer pilot programs.

Popular tool categories

- Sensor manufacturers (vibration, acoustic, thermal)

- Edge compute appliance vendors

- Industrial IoT platforms with OT/IT integrations

- Cloud analytics and ML model providers

- CMMS and ERP integrations

You’ll build a stack that balances capability with maintainability.

Prescriptive maintenance: the next step after predictive

Predictive maintenance tells you what will fail and when. Prescriptive maintenance recommends exactly what to do and how to schedule it to minimize disruption. In 2026, many systems combine predictive RUL with optimization algorithms to suggest the best timing and resource allocation.

You’ll use prescriptive cues when you need to coordinate multiple machines, parts, and technicians for minimal impact.

Sustainability and energy considerations

Predictive maintenance can reduce waste by replacing parts only when needed and optimizing machine efficiency. You’ll cut energy usage by identifying inefficient cutting conditions and flagging systems consuming excessive power.

You’ll meet sustainability goals more easily when maintenance becomes smarter.

Your first five actions to get started

If you want to move from curiosity to action, do these five things this week.

- Identify two machines that cause the most unplanned downtime or repair cost.

- Gather historical maintenance logs and failure reports for those machines.

- Talk to your lead technician about observable early warning signs they’ve seen.

- Map failure modes to sensors using the sensor vs failure table above.

- Reach out to two vendors for pilot quotes and request a staged pilot plan.

You’ll have momentum by the end of the week and a clear pilot plan in hand.

Final thoughts

Machines in 2026 don’t just run parts; they keep a running commentary on their own well-being, and predictive maintenance is the language they speak. You’ll find that adopting predictive practices saves money, reduces stress, and leaves you with a cleaner schedule and fewer emergency phone calls at three in the morning. The technology is mature enough, affordable enough, and practical enough to start small and scale quickly.

You’ll need to combine sensors, models, and human judgment. Do that, and your shop will run like a cooperative of reasonably honest appliances — the best possible outcome for someone who spends most of their day coaxing stubborn metal into submission.