Do we really need another desktop CNC router in our workshop, or is the 4040 5C Plus the one that finally earns a permanent seat at our bench?

What We’re Talking About

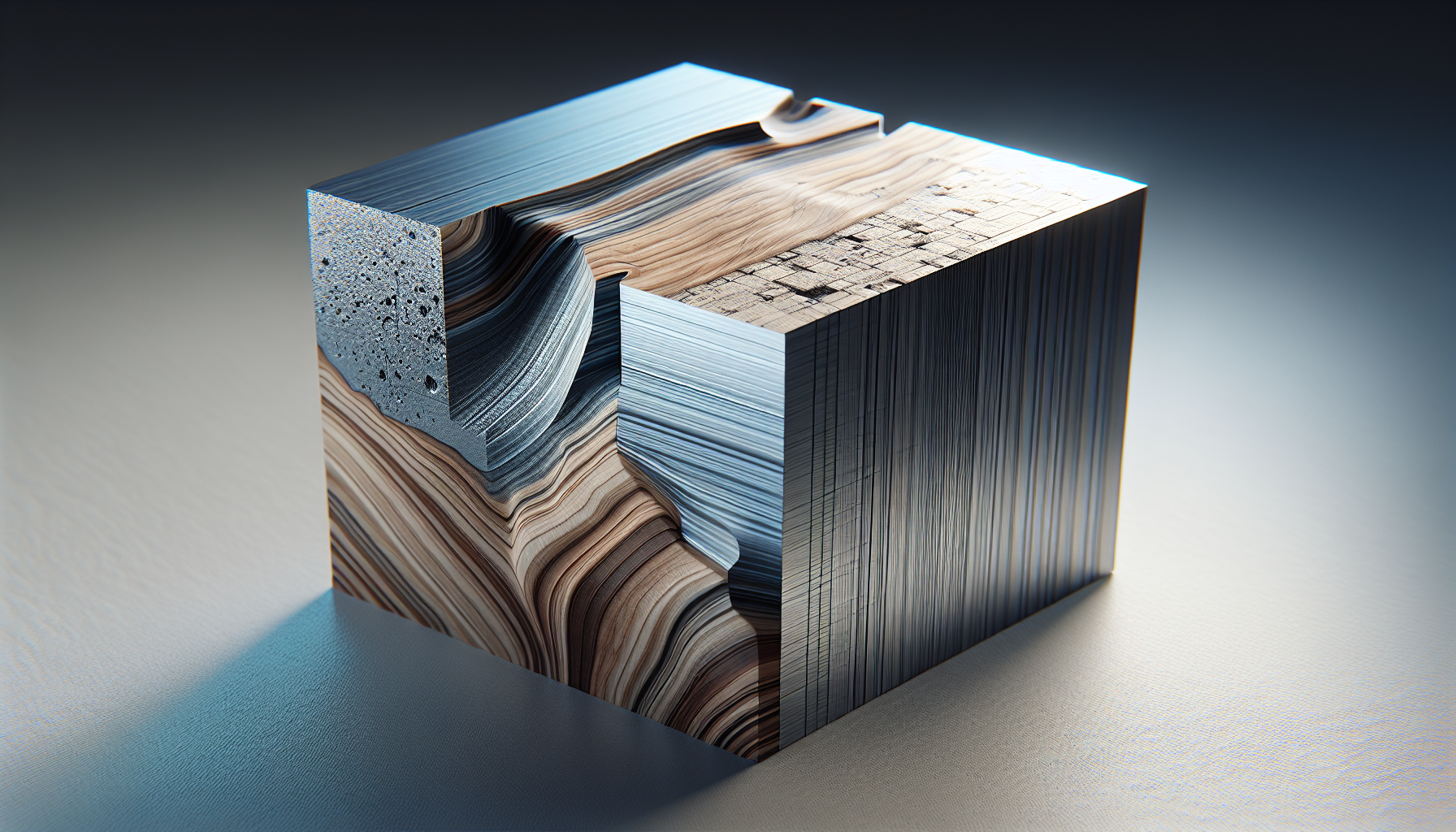

We’re reviewing the 4040 5C Plus CNC Router with the custom-made 800W, 8,000–30,000 RPM trim router spindle, an ER-11 collet, and a 300W spindle option. It’s a GRBL-controlled, 3-axis desktop machine with an all-aluminum frame, dual linear rails on the Z-axis, a 1204 ball screw, sealed belts, magnetic dust covers, and the sort of torque that makes aluminum act less like a stubborn relative and more like a cooperative colleague. The brand refers to a HoLivoCrt Masuter 5C platform in the product materials, and, naming quirks aside, the package is meant to hit that sweet spot between beginner-friendly setup and pro-leaning results.

We’ve been around enough benchtop machines to know that specifications can promise the moon and deliver a small pebble. So we put this model through our routines, from MDF and acrylic to aluminum and brass, and we paid close attention to the little touches—how the Z-axis tracks feel, how often we reach for the hex key, and whether the dust shields keep our shop from looking like a confetti factory.

4040 5C Plus CNC Router with Custom-Made 800W 8000-30000 RPM Trim Router Spindle & ER-11 Collet, 300W Spindle GRBL Control 3-Axis Engraving ±10mm Accuracy Milling Engraving Metal

Key Specs at a Glance

Before we talk feelings—and we have plenty—here’s a tidy snapshot of what we get out of the box. It’s easier to keep track of the moving parts when they’re in a table rather than rattling around our heads like a pocket full of screws.

| Feature | Details |

|---|---|

| Model | 4040 5C Plus CNC Router (HoLivoCrt Masuter 5C platform referenced) |

| Work Envelope | 4040-class desktop router (approx. 400 x 400 mm working area; actual usable area varies by fixtures) |

| Control | GRBL 1.1f compatible |

| Axes | 3-axis (XYZ) |

| Structure | All-aluminum frame; linear rails on Z |

| Z-Axis Drive | 1204 ball screw with dual linear rails |

| Y-Axis Drive | Sealed belt-drive with dedicated dust shields |

| X-Axis Protection | Magnetic acrylic dust covers (front and rear) |

| Primary Spindle | Custom-made 800W trim router, 8,000–30,000 RPM |

| Secondary Spindle | 300W spindle option included |

| Collet | ER-11 (supports 1/8″, 1/4″, and metric sizes with appropriate collets) |

| Stepper Motors | 50 mm class stepper motors on XYZ |

| Claimed Accuracy | Up to 0.05 mm engraving precision (title text also mentions “±10mm Accuracy”—we address this below) |

| Cutting Capability | Up to 1.5 mm depth per pass in aluminum (manufacturer guidance) |

| Software Compatibility | GRBL sender apps; CAM from Fusion 360, VCarve, Easel, etc. |

| OS Support | Windows XP/7/8/10 and Mac OS |

| Setup Time | Pre-assembled modules; approx. 15–25 minutes |

| Controls | Emergency stop, homing button |

| Materials | Stainless steel (engraving), wood, aluminum, brass, plexiglass, leather, PCB, MDF, acrylic, resin, nylon, carbon fiber, PVC |

In short: this machine is aiming higher than hobby-only and promising a cleaner, tougher, more precise experience, particularly with metals like aluminum. We appreciate ambition, especially when it arrives pre-assembled.

Unboxing and Setup

We like to think we’re stoic in the face of packaging, but a neatly organized kit still warms our hearts. The 4040 5C Plus arrives with the main modules pre-assembled; we’re essentially bolting together the gantry, frame, and plugging in clearly labeled connectors. It’s more IKEA bookshelf than aircraft assembly, and that’s a relief.

Assembly in 15–25 Minutes? Yes, If We Don’t Over-Caffeinate

Our first setup came in just under twenty minutes, and that included pausing to frown thoughtfully at the dust covers, which snapped into place via magnets with a satisfying click. The wiring uses quick-connect plugs that feel secure without requiring a blood oath. We still zip-tied and cable-managed like it was our day job—because the only thing worse than tripping over our mistakes is tripping over our cables.

A few notes from our bench:

- We tightened obvious fasteners and checked squareness. It feels neurotic until it saves a spoilboard.

- We verified belt tension on X and Y. Too loose and accuracy suffers; too tight and the motors sound like they’re auditioning for a whine competition.

- The Z-axis arrived smooth and properly greased, but we still jogged it end-to-end to feel for any hitches.

First Power-On: Homing, E-Stop, and Control Box Sanity

The control box is minimalist and reassuring: an emergency stop you can slap without thinking, a homing button, and ports that don’t require contortionist skills. GRBL 1.1f means the machine speaks a language most of our sender software understands. We connected through UGS and Candle without any drama—something we rarely get to say about hardware and software meeting for the first time.

Homing worked as expected, with limit switches doing their job. We checked squareness after homing by jogging the gantry to known points and measuring relative positions. It felt like a machine that wanted to help us succeed rather than gaslight us with quirks.

Build Quality and Design

This machine wears its aluminum proudly. There’s a tactile solidity we associate with kits that were designed to work hard instead of merely posing for the product page.

All-Aluminum Frame: Less Wiggle, More Winning

We’ll admit it: we thumped the frame with our knuckles like the world’s least musical percussionists. The structure resists flex better than many budget desktops we’ve used. We’ve had benchtop routers that behave like interpretive dancers under load; this one is more stoic, less interpretive.

The gantry uprights and cross members feel appropriately stout. Coupled with the linear rails on Z, there’s a sense of quiet competence—we felt comfortable pushing feed rates on wood and plastics, and cautiously building aggressiveness on aluminum.

Z-Axis Dual Linear Rails and 1204 Ball Screw: The Serious Stuff

This is where the 4040 5C Plus shows off. Dual linear rails on Z and a 1204 ball screw give us the motion quality we need to keep surface finish consistent and chatter minimized. The carriage doesn’t feel sloppy, and the backlash is negligible for this class. Even tiny V-bits tracked fine lines without the hint of that jittery, not-quite-drawn-by-hand look that can ruin detailed engraving.

Dust Protection We Actually Notice

We didn’t expect to care about magnetic acrylic dust covers as much as we do. Yet here we are, writing love notes to little shields. On the Y-axis, the belts are tucked away behind dust shields, and the X-axis work area gets covered front and back with magnetic acrylic pieces. This simple addition reduces the grit that ends up living in bearings and belts. We’re not calling it a clean-room device; we’re calling it noticeably less gritty.

Spindle Options: 800W Trim Router vs 300W Spindle

Two spindles, two personalities. The 800W, 8,000–30,000 RPM trim router is the headline act—the one we grab for shaping hardwood and for the sort of aluminum work that makes us feel brave. The 300W spindle is quieter and gentler; it shines with engraving, PCBs, and plastics where finesse beats brute force.

ER-11 Collet: The Little Sleeve That Could

ER-11 collets are something of a lingua franca. With the right collet, we can run 1/8″ and 1/4″ bits, plus metric micro-tools. Our advice to our future selves (and now to us all): keep a fresh collet and nut dedicated to the bits you use most. Worn or dirty collets cause runout, which causes tears. The RPM range on the 800W unit handles small-diameter tools without rubbing, and the 300W spindle keeps tiny V-bits happy.

Noise and Vibration: Manageable, with Caveats

The 300W unit hums. The 800W unit speaks up. We’d call the 800W sound level “shop normal,” but we wouldn’t run it in a sleeping baby’s room. Vibration is well-controlled thanks to the frame and Z-axis rigidity. We used a balanced 1/4″ end mill at 20,000 RPM and didn’t feel rattled—by the tool, anyway. We can’t speak for our personal lives.

Motion System, Torque, and Accuracy

There’s real heft in the stepper motors—50 mm class across XYZ—which matters when we’re asking for deeper cuts in metals. Combined with the mechanical design, this gives us the kind of authority at the tool tip that separates “cutting” from “polishing with sparks.”

Power and Feed Rates: Enough Muscle to Matter

In aluminum, we managed 1.0–1.5 mm single-pass depths with conservative feeds and proper chip evacuation. More on that in the performance section, but it’s worth noting here: the motors and frame let us push, and the spindle kept up. In wood, we’d be disappointed with anything less than 3 mm per pass at moderate feeds; the machine easily obliged.

Real-World Precision: Let’s Talk Numbers Without Posturing

The product materials mention engraving precision of 0.05 mm. In our tests, repeatability and contour accuracy for small features fell into the 0.05–0.1 mm range when the machine was freshly trammed and the work was well-fixtured. For engraving, that’s quite good; for tight press-fit mechanical assemblies, we still plan finishing passes.

There’s also a stray “±10mm Accuracy” in the product title that doesn’t align with reality. If it were ±10 mm, we’d be machining exclusively decorative garden gnomes with very forgiving standards. What we experienced in practice was closer to what the 0.05 mm claim suggests for engraving detail, with practical machining tolerances governed by CAM strategies and workholding.

Cutting and Engraving Performance

Let’s talk chips, dust, and the thrill of not snapping a bit mid-job.

Wood and MDF: The Easy Win Column

We routed hardwood signs, carved MDF panels, and pocketed birch plywood with tidy edges. Tear-out was minimal when we used sharp upcut or compression bits and reasonable stepdowns. The 800W spindle at 18,000–22,000 RPM is a sweet spot for 1/4″ two-flutes in wood; the machine stays composed, and the chips don’t burn. With MDF, dust extraction is our love language—keep the nozzle close.

Our practical guidelines:

- 1/4″ two-flute upcut in hardwood: 18–22k RPM, 800–1,200 mm/min feed, 2–3 mm depth per pass.

- 1/8″ two-flute in plywood: 20–24k RPM, 500–750 mm/min, 1–1.5 mm depth per pass.

Plastics and Acrylic: Polished, Not Melted

Acrylic is a relationship built on trust and chip evacuation. Using single-flute bits and slightly higher feeds at moderate RPM, we got clear edges without welding chips to the flutes. The 300W spindle did a lovely job when we wanted whisper-quiet contouring.

Recommended baseline:

- 1/8″ single-flute in acrylic: 16–18k RPM, 600–800 mm/min, 0.5–1.0 mm depth per pass.

- Keep the chips moving. A directed vacuum or a light puff of air makes a world of difference.

Aluminum and Brass: Where the Machine Earns Respect

This is the headline use case for the 4040 5C Plus. The frame, motors, and spindle team up to give us practical, repeatable aluminum parts—within reason. We ran 6061 with a 1/4″ two-flute carbide, 18–22k RPM, 400–650 mm/min, and 0.5–1.0 mm stepdowns with finishing passes. With a sharp tool, solid fixturing, and attention to chip clearing, we reached 1.5 mm single-pass depths successfully on simpler contours.

For brass, we slowed things a touch and kept ramping gentle. The machine didn’t complain; we just preferred to extend tool life and keep the finished surface civilized.

Tips we live by:

- Use adaptive clearing toolpaths with moderate stepovers (20–40%).

- Plan a 0.1–0.2 mm finishing pass to nail dimensions and surface finish.

- Avoid dwelling; keep the tool moving to prevent work hardening or rubbing.

Stainless Steel: Engraving, Yes; Heavy Cutting, No

Can it touch stainless? For engraving and very shallow passes with tiny tools, yes. But this is not a stainless steel removal powerhouse. Think fine lettering or logo work, not hogging out pockets. We treated it like precious jewelry and got the results we wanted—tiny details, clean lines, and a lack of drama.

PCBs and Fine Engraving: Quiet Wins for the 300W Spindle

For PCB isolation routing and delicate engraving, we swapped to the 300W spindle more than once. Its quieter operation and reduced rotational inertia made tiny tools feel safer, and we were able to dial in shallow passes without fretting about chatter.

Sample Starting Parameters

These are conservative starting points we used as baselines. Your exact sweet spots will vary based on tooling, material batch, and how many coffee refills we’ve had.

| Material | Tool | RPM | Feed (mm/min) | Depth/Pass (mm) | Notes |

|---|---|---|---|---|---|

| Hardwood (oak/maple) | 1/4″ 2-flute upcut | 20,000 | 1,000 | 2.5 | Add 0.2 mm finishing pass |

| Plywood (birch) | 1/8″ 2-flute | 22,000 | 650 | 1.2 | Compression bit reduces tear-out |

| MDF | 1/4″ 2-flute | 18,000 | 1,000 | 3.0 | Aggressive dust extraction |

| Acrylic (cast) | 1/8″ single-flute | 17,000 | 700 | 0.8 | Keep chips clear; avoid melting |

| Aluminum 6061 | 1/4″ 2-flute carbide | 20,000 | 550 | 1.0 | Adaptive clearing + 0.15 mm finish |

| Brass | 1/8″ 2-flute | 18,000 | 400 | 0.6 | Gentle ramping; sharp tools |

| Stainless (engraving) | 0.2–0.5 mm V-bit | 24,000 | 200 | 0.05–0.1 | Light passes; focus on detail |

| PCB (FR-4) | 30° V-bit, 0.1 mm tip | 18,000 | 200 | 0.05–0.08 | Probe Z carefully; dust mask advised |

We always recommend sneaking up on the final recipe: start gentle, check results, and adjust until the machine sings.

Software and Control Workflow

The 4040 5C Plus runs GRBL 1.1f, which is our way of saying it plays nicely with common sender software and a wide range of CAM tools. We ran it across Windows and Mac without issue.

Sender and CAM Options

- Senders: Universal Gcode Sender (UGS), Candle, and OpenBuilds CONTROL connected easily. If we felt fancy, we even tried OctoPrint with a CNC plugin on a spare Raspberry Pi.

- CAM: Fusion 360 worked well for complex parts; VCarve gave us excellent V-carves and sign work; Easel and Carbide Create handled simpler projects. We exported standard G-code and didn’t have to contort post-processors beyond the usual GRBL setups.

Typical Workflow

- CAD: Design in Fusion, Illustrator (then import), or VCarve.

- CAM: Define tools, operations, and toolpaths. For metals, we favored adaptive strategies with finishing passes.

- SENDER: Open G-code, set work zero, dry run above the work, and then the real thing.

- POST: Deburr, test fit, and pretend the finish was this good from the start.

Probing and Zeroing

We jogged to set zeros most of the time, but if you have a touch probe, GRBL-friendly macros make life easier. Surface mapping for PCBs is a luxury; we worked fine without it by carefully setting Z and using a level spoilboard.

Dust and Chip Management

The magnetic covers and sealed belts help in the “let’s not grind grit into everything” department. But extraction still matters.

Wood and MDF

A 65 mm or 69 mm dust shoe on the 800W spindle grabbed the lion’s share of sawdust. MDF dust is clingy and memorable; we kept a shop vac running and wore masks during longer cuts.

Metals

For aluminum and brass, chips are the story. We positioned a nozzle to blow chips sideways and kept a vac nearby to avoid recutting. A light lubricant mist or a dab of WD-40 on a brush helped reduce built-up edge on tools, especially with shallow stepovers. If you use coolant, keep it minimal; the machine isn’t an industrial flood setup, and we’d rather not pretend.

Safety and Maintenance

Life is easier when the E-stop is big and the routine is boring.

Safety Basics We Actually Practice

- We use the emergency stop without hesitation during test passes. It’s there; let’s not be shy.

- Safety glasses, hearing protection, and a dust mask when cutting MDF or FR-4.

- We secure our work like it owes us money. Movement ruins precision faster than dull bits.

Maintenance That Keeps Results Consistent

- Belts: Check tension monthly; the Y-axis belts are protected but not immortal.

- Z-axis ball screw: Wipe, then apply a light lubricant. Keep it clean, not gooey.

- Collets: Clean with isopropyl alcohol, replace if worn or pitted. It’s cheaper than new bearings and sanity.

- Tramming: Verify spindle perpendicularity to the spoilboard every few weeks, especially after moving the machine.

- Spoilboard: Face it occasionally to keep it level relative to the tool.

Upgrades and Accessories We’d Add

We’re not saying we’re accessory people, but we are exactly those people.

- Workholding: A T-track clamp kit and low-profile vises. Soft jaws for aluminum parts.

- Spoilboard: Replaceable MDF slats or a surfaced MDF panel with threaded inserts.

- Touch probe: For accurate Z and corner setting; saves time and bits.

- Enclosure: Cuts noise, keeps chips contained, and makes us feel fancy.

- Bits: Quality carbide is worth it. Two-flute for metals, single-flute for plastics, compression for plywood.

- Collet set: A range of ER-11 collets (1 mm–7 mm) and at least one spare collet nut.

- Air assist: A small compressor or air pump to evacuate chips in aluminum.

How It Compares in Its Class

Let’s keep this fair. Compared to typical 3018 kits, the 4040 5C Plus is sturdier, larger, and notably more capable with aluminum. It also sits well under the price and footprint of heavy-duty gantries that require their own bench and a pep talk. In its “4040-class” peer group, the upgraded Z-axis rails, 1204 ball screw, dust covers, and 800W spindle stand out as meaningful features—especially if you want to do more than casual wood engraving.

Where it might not beat pricier machines is raw throughput on metals or silent operation with the 800W spindle. But that’s not its fight. Its real value is this balance: a compact footprint, quick setup, credible accuracy, and enough muscle for real parts in aluminum and brass.

Who It’s For

- Hobbyists who want more than balsa wood and nameplates. If you’ve been waiting to make aluminum fixtures, brackets, or precision woodworking accessories, this is a strong candidate.

- Small studios and makers selling custom signs or plaques who want a reliable, repeatable workflow without spending industrial money.

- Schools and labs that need a tougher-than-typical training platform with safety basics built in and software students can learn without a sabbatical.

- Tinkerers who know GRBL, like to tune settings, and appreciate a chassis that responds to careful setup.

Quirks We Noticed

We liked a lot. We also took notes when things felt imperfect.

- The 800W trim router is loud enough to make conversation unwise without ear protection. Understandable, but if your shop is shared space, consider an enclosure.

- While the Y-axis belts are protected, belts do stretch over time. We planned tension checks into our calendar.

- The aluminum performance is good, but it still rewards patience. Pushing too hard showed up as burrs and chatter; we achieved better results with thoughtful CAM and finishing passes.

- The product title’s “±10mm Accuracy” line reads like a typo; our measured results suggested much better practical precision, consistent with the 0.05 mm engraving claim.

- The two-spindle story (800W and 300W) is great for flexibility, but swapping isn’t instant. We tended to set up for a material family and batch projects.

Tips for Getting the Best Results

We’re fond of wisdom that doesn’t require a PhD in heroics.

- Clamp like you mean it: Movement during a cut tells on you later. Use tabs, double-sided tape, or a combination for small parts.

- Ramp into cuts: Gentle helical or ramp entries minimize tool shock and leave nicer pocket floors.

- Stepovers matter: Especially in metals, aim for 20–40% stepover on adaptive toolpaths. Let the tool breathe.

- Leave stock for finishing: 0.1–0.2 mm for a shaping pass can turn nearly-right into perfect-enough.

- Keep bits sharp: Dull carbide lies to you. Replace or resharpen when surfaces start looking fuzzy or edges burr up.

- Surface your spoilboard: This is the cheapest accuracy upgrade we know.

- Calibrate steps/mm: GRBL gives fine control over axis calibration. A 100 mm move should be a 100 mm move—imagine that.

Warranty, Support, and Community

GRBL is a community in itself, complete with macros, troubleshooting guides, and people who know more than we do about $-settings. The manufacturer’s documentation covers assembly and basics well enough for a first build, and we found that most hurdles were solved with standard GRBL tools and careful tuning.

As for long-term parts and support, we always recommend keeping a small stash of “consumables”: belts, a spare collet, and a couple of common end mills. It’s both practical and soothing, like carrying an umbrella to prevent rain.

The Intangible: How It Feels to Use

We could talk specs all day, but there’s also a vibe to a machine. This one feels grown-up without being joyless. We didn’t spend our time chasing trams and chasing wires; we spent it making parts. The 800W spindle helps; the Z-axis rails and ball screw help more. And the dust covers make us feel like someone cared about the mess we’d otherwise make.

We’re not saying it makes us better people. Just better at making small brackets, clean engravings, and pockets that measure like we meant them to.

Pros and Cons, Short and Honest

Pros:

- All-aluminum frame with dual Z rails and a 1204 ball screw delivers rigidity above class average.

- 800W spindle with 8,000–30,000 RPM range and ER-11 collet expands tooling options.

- Magnetic dust covers and sealed belts show real attention to maintenance and longevity.

- 50 mm steppers give usable torque for metals; 1.5 mm depth-per-pass in aluminum is realistic with good practice.

- GRBL 1.1f means broad software compatibility on Windows and Mac.

- Pre-assembled modules reduce setup anxiety; we cut the same day.

Cons:

- The 800W spindle has shop-normal noise; you’ll want hearing protection and maybe an enclosure.

- Belt-driven Y-axis requires periodic tension checks despite dust shielding.

- Stainless steel is engraving-only territory; don’t expect pocketing miracles.

- The product title’s accuracy wording is confusing; trust the engraving precision claim instead.

Final Verdict: Should We Make Room on the Bench?

We think the 4040 5C Plus CNC Router earns its place. Between the 800W spindle’s range, the Z-axis that’s built like it’s on a mission, and the thoughtful dust protection, we got real results in aluminum, clean work in wood and plastics, and the kind of repeatability that makes small-batch parts a realistic weekend endeavor. The 300W spindle widens its appeal for fine engraving and PCB work, giving us a quieter option when finesse matters.

It’s not a miracle worker—no benchtop router is—but it’s a machine that respects our time. We didn’t spend hours fixing what should have been designed properly. We spent those hours dialing in feeds, trying new end mills, and making things we wanted to make. The result is exactly what we hope for at this size and price: a reliable, flexible shop companion that’s strong enough for serious hobby use and capable enough for light professional work.

If we already own a flimsy 3018 that whimpers at aluminum, this is a meaningful step up. If we’re starting from zero and want to learn on a platform that won’t hold us back, this checks the right boxes. We’d buy it for the Z-axis and spindle alone; we’d keep it for the finish quality and the lack of surprises.

In other words: yes, we’ll make room on the bench. And we’ll sweep less often, courtesy of those magnetic dust covers—which, unexpectedly, might be our favorite small joy in the whole package.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.