Have we ever wanted to press a single button and watch yesterday’s great idea come back to life without the ritual of cables, drivers, and muttered incantations?

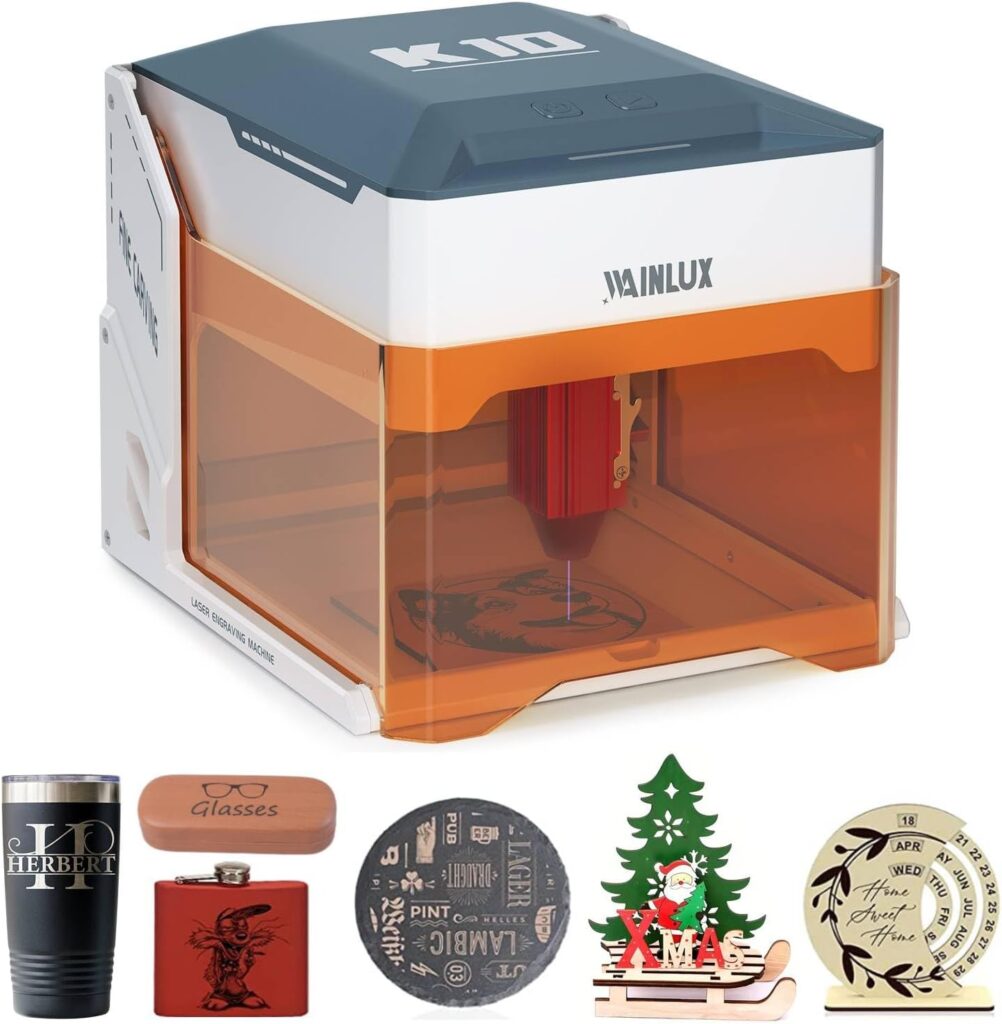

What We Learned Living With the WAINLUXPRO K10

We brought the WAINLUXPRO K10 Laser Engraver and Cutter into our home the way we once adopted a basil plant: cautiously optimistic and prepared to apologize to it when things went wrong. It never asked for much—no assembly, no drama—just a plug, a connection to the CutLabX app, and a little room on the desk.

The K10’s promise is simplicity first and seriousness second. It’s a compact, Class 1–safe, 5W laser with an 80×80mm work area, and it comes already put together. That alone earned our trust; we’ve had furniture that required more strategic thinking than this machine.

WAINLUXPRO K10 Laser Engraver and Cutter, 5W Portable Engraving Machine with Memory Mode | 80×80mm | No Assembly |WiFi/USB/Offline | Class 1 Safety | Premium Gift for DIY | Wood/Leather/Glass/Cloth

$199.99 In Stock

Unboxing and Setup: A Five-Minute Story

Opening the box, we were relieved to find nothing that required a tiny wrench or the patience of a saint. The unit is fully assembled, with a bright orange window that makes the laser visible without the need for safety goggles. We plugged it in, opened the CutLabX app on a phone, and were engraving within minutes.

It’s rare to find a machine this capable that doesn’t greet us with drivers and firmware updates before first use. The K10 let us begin immediately, which meant we could make mistakes right away—something we consider a productive start.

The 80×80mm Work Area: Limits That Spark Creativity

The engraving field is a neat 80×80mm (3.15″×3.15″). That’s small enough that we needed to think about scale, but big enough for keychains, coasters, patches, wallets, bookmarks, small plaques, and most of the gifts we actually give to people. Rather than seeing it as a restriction, we treated it like a writing prompt: what could we make to fit the square?

When we needed to work on items longer than the field, we created simple jigs—cardboard frames, painter’s tape outlines—and aligned successive engravings by referencing the corners. It’s not a replacement for a large-bed machine, but with a little care, it handles surprisingly ambitious projects in sections.

Memory Mode: The “Again” Button We Never Knew We Needed

We pressed the arrow button on the unit after finishing a small leather patch, and the K10 immediately repeated the last job without asking us to reconnect a computer. It’s a strange thrill to watch yesterday’s design reappear instantly, and it’s practical too. If we’re making batches—coasters for a party, patches for a club, bookmarks for a school fundraiser—Memory Mode turns repetition into a pleasant rhythm.

We found this especially helpful when someone said, “Could we make ten more just like that?” There were no files to reload and no cursing at our laptop’s Bluetooth whims. The manual explains the Memory Mode behavior, and once we understood it, we used it constantly.

Design, Build, and Safety: Friendly and Serious

The K10’s compact frame doesn’t shout “industrial equipment,” which helps when we share a workspace with food or books. The orange viewing window lets us watch the laser work up-close without goggles, and the machine shuts down if we tilt it around 13° or open the cover mid-job. In a world that expects us to be always-on, it’s nice that the laser refuses to be reckless.

As a Class 1 safety–certified device, it’s built for homes, studios, classrooms, and areas where safety isn’t just a checkbox. We still use common sense: good ventilation, a stable surface, and never ignoring the machine while it runs. But we appreciated that the K10 tries to be safe even when we’re too captivated by our phones.

Specs, Power, and Real-World Results

On paper, the K10 boasts professional-level accuracy: 0.01mm. In practice, that means fine text is crisp, geometric lines are reliable, and portrait engravings look surprisingly sharp on wood and leather. We had the best results with high-contrast designs—black artwork on a white background translates beautifully to engraving.

The laser cuts 3mm pine boards, which opens the door to lightweight ornaments, tags, mini signs, and delicate structures. Pine isn’t walnut, and 5W isn’t industrial power, but for small, thoughtful items, it hits the sweet spot. Noise levels are discreet—quiet enough for a shared apartment, a small classroom, or a late-night session when we’re trying not to advertise our hobbies to the neighbors.

Materials and What Works Best

If we had to sum up the K10’s materials list, we’d say: the useful everyday ones, the ones we actually enjoy touching. Wood, leather, fabric, coated metal, cork, cardboard, and plastics all behave well. With glass and ceramics, we simply marked the surface with a dark pen or applied black laser masking paper before engraving—then wiped it off afterward. That prep step makes the beam visible to the material and also helps protect the lens.

One important note the manual underlines (and we echo): avoid reflective materials without prepping them. Reflective surfaces can send laser energy back to the head and damage it. A quick coat of dark paint or marker solves this problem for glass and ceramics.

Quick Material Guide, Our Way

We like having a cheat sheet nearby, if only to spare us from heroic improvisation at the last second. Here’s the short version we used regularly.

- Wood (softwoods, plywood): Excellent for engraving; cuts 3mm pine. Grain adds character; test first.

- Leather: Engraves beautifully; use light air movement to help with smoke; edge darkening is normal.

- Fabric: Great for patches; test on scraps; consider masking if the fabric is delicate.

- Coated metal: Engraves the coating cleanly; raw bare metals generally aren’t the domain of 5W diodes.

- Cork and cardboard: Engravings look bold; cuts cleanly with patience.

- Plastics: Many engrave well; always test for odor and melting; avoid PVC entirely.

- Glass/ceramic: Prep dark layer first; clean after; results are elegant and subtle.

Software: CutLabX for Easy Wins, LightBurn and LaserGRBL for Control

We used the CutLabX app to get started—on phones, tablets, laptops—and never had to ask it to do anything heroic. It recognized the K10, connected via WiFi or USB, and let us drop in images from our camera roll. The app’s preset materials list saved time and prevented burns and undercooked lines we might otherwise have inflicted on innocent coasters.

Once we wanted more complex controls—speed/power tuning, multi-layer projects, photo dithering, and more advanced alignment—we moved to LightBurn and LaserGRBL, which the K10 supports. There’s a kind of joy in starting simple and then graduating to professional tools without switching machines. Tutorials in the manual helped us set everything up, and after one Saturday afternoon, we were comfortable moving between them.

What It’s Like to Actually Make Things

We started small: cork coasters with geometric patterns and single words that felt like fortune cookie advice (Choose Joy, Drink Water, Call Your Aunt). The engraving was crisp, the working time short, and the memory button quickly became a reflex. From there we moved to leather patches for a tote bag and personalized bookmarks for a school librarian who hoards kindness the way others hoard receipts.

Every time we thought we were done, we found another thing with a flat surface whispering, “Put my name on me.” Keychains. Recipe cards made of thin wood. A charm for a pet collar engraved with our dog’s actual phone number, because he has no credit history and cannot be trusted to call us otherwise. The K10 is a machine that invites a thousand small gestures.

Photo Engraving and Art Styles

We’re cautious with photos in lasers because expectations can outpace resolution. The 0.01mm accuracy helps, but the real secret is contrast. We prepped photos in grayscale, bumped up contrast a notch, and resized to fit the 80×80mm field. The results on wood were gentle and nostalgic—like a memory with a good complexion—and on leather they looked downright classic.

For logos and line art, vector images are king. Simple SVGs or high-res PNGs made the K10 look clever and professional, which in turn made us look competent, and maybe even thoughtful.

The Safety Talk We Have With Ourselves

The K10 is Class 1 safe and thoughtful. It stops if tilted (around 13°) or when the cover opens. The orange window protects our eyes. But laser safety is part device, part human. We always work in a well-ventilated space, avoid leaving it unattended, and keep materials that melt or off-gas toxic fumes far away. If we’re unsure about a material—especially plastics—we look it up or test a tiny sample.

We also never engrave anything reflective without blacking it out first, as the manual warns. Reflective rebound is a clever way to ruin a laser head, and while we admire cleverness in people, we prefer it not to appear in physics at our expense.

Cutting: What 5W Honestly Does Well

At 5W, the K10 isn’t meant to slice through thick hardwoods like a lumberjack. But it cuts 3mm pine boards cleanly, which covers ornaments, tags, small signs, and little project components. For harder woods or thicker materials, engraving is where the magic happens. We considered cutting as the way to add shape, engraving as the way to add soul.

We got better results by doing a test cut on every new batch of material. Slight variations in density, glue layers (in plywood), and surface treatment can affect cut quality. It’s a small price to pay for consistent results.

Noise, Smell, and the Domestic Truce

The K10 is pleasantly quiet, even during longer jobs. We could have a conversation nearby without raising our voices, and once, during a test run, someone in the next room thought we were reorganizing a drawer. Smoke is minimal with engraving and moderate with cutting; we placed the unit near a window fan. It’s not unscented—the wood aromas drifted like we’d lit a polite bonfire—but the smell dissipated quickly.

This made it viable in shared spaces: family rooms, small offices, classrooms during supervised lessons. We appreciated not having to explain to everyone in the house why it smelled like a woodshop in a backpack.

The Rotary Question: Curves Join the Party

By adding a rotary (sold separately), we extended what the K10 could handle—cylinders like wine glasses, tumblers, baseballs, and bottles. On coated metal tumblers, the results were solid and satisfying. On glass, we still applied the darkening step first. While the small work area is still the work area, a rotary opens up a new dimension—literally—and gives us more gift options for people who already have too many coasters.

We kept our expectations realistic. The K10 won’t engrave stainless steel directly without a coating. But for painted, powder-coated, or anodized surfaces, it’s a workhorse.

Maintenance: The Boring Stuff That Keeps Joy Alive

We found the K10 asked for attention in reasonable, predictable ways. The maintenance ritual is short and merciful, and it dramatically improves longevity.

- Weekly: Wipe internal smoke and dust with a dry cloth. Keep it stored in a dry environment, and add desiccant packs if we’re in a damp climate.

- Every 30 hours of use: Clean the laser head’s window lens using a cotton swab dipped in alcohol. Dust build-up can block or scatter the beam, causing heat spots that scar the lens. Clean lens = sharp engravings.

- Occasionally: Check the transmission screw lubrication. If it looks dry, reapply. Remove dust to keep motion smooth and position accurate.

When we stayed on schedule, cuts were consistent, lines were crisp, and we didn’t have to open our wallets for parts our laziness might have accidentally ruined.

Reliability, Warranty, and Support

We like machines that arrive fully tested. The K10 is 100% pre-shipping tested for reliability, which means fewer first-day surprises. The 12-month warranty and responsive customer service offer a backstop we hope never to need but feel calmer knowing exists. In our experience, the best customer service is the one that never appears because the machine won’t misbehave—but if it does, we want someone to actually write back.

The lack of subscription fees for the included software is also a relief. Our creativity depends on compulsion, not monthly billing cycles, and the K10 encourages the former without punishing us with the latter.

Everyday Projects We Kept Coming Back To

We could pretend we only made elegant keepsakes and museum-caliber art. Mostly, we made useful, cheerful things that made people smile. These became our staples:

- Personalized leather patches for bags and jackets

- Wooden coasters with simple patterns and monograms

- Cork trivets with comforting, slightly bossy kitchen phrases

- Pet tags with names and phone numbers

- Phone cases (especially faux-leather types) with minimal line art

- Fabric patches, badges, and labels for handmade gifts

- Keychains and bookmarks, because everyone who reads deserves a treat

- Small signs for desks and doors, the “Yes, I’m Busy” kind that we ignore

Each project taught us more about materials and the K10’s accuracy. The more we made, the more we wanted to make.

For Small Businesses, Fundraisers, and Classrooms

The K10 feels like it was made for side hustles and teaching. With Memory Mode and presets, we could create small batches quickly without losing an afternoon to reconfiguration. It’s perfect for craft fairs: quick personalization, neat workflows, and a machine that won’t scare anyone nearby.

We priced items like custom coasters, name tags, and patches in ways that made sense—low material costs, high perceived value. Equally, in classrooms and clubs, the K10 turned abstract ideas into tactile outcomes within a standard class period. We supervised students, talked about safety, and then let the machine do the part that makes them smile: putting their names on everything.

Honest Limitations (and How We Worked With Them)

We respect machines more when they tell us the truth. The K10 is not a giant industrial laser. It won’t slice through thick hardwoods or engrave raw stainless steel the way a high-power industrial unit might. The 80×80mm work area requires planning. Reflective materials need prep.

But once we embraced those truths, we realized we’d bought exactly what we needed: a compact, precise, safety-conscious, surprisingly versatile engraver that makes small things beautiful. The rest is project management and creativity, which are hard but free.

The Specs, At a Glance

Sometimes we like to see the essentials lined up, like shoes by the door. Here’s the breakdown that helped us compare the K10 to our expectations.

| Feature | Detail |

|---|---|

| Product Name | WAINLUXPRO K10 Laser Engraver and Cutter |

| Laser Power | 5W diode |

| Work Area | 80 × 80 mm (3.15″ × 3.15″) |

| Accuracy | Up to 0.01 mm |

| Cutting Capability | Cuts 3 mm pine boards |

| Operation Modes | WiFi, USB, Offline (Memory Mode) |

| Assembly | None required (ready out of the box) |

| Safety | Class 1; auto-stop on tilt (~13°) or cover open; orange viewing window |

| Noise | Quiet operation |

| Software | CutLabX (included), compatible with LightBurn and LaserGRBL |

| Presets and Templates | 100+ material presets; basic template library |

| Supported Materials | Wood, leather, fabric, coated metal, cork, cardboard, many plastics |

| Glass/Ceramic | Requires darkening (marker/black paper) before engraving |

| Rotary Support | Yes (sold separately) |

| Warranty | 12 months; pre-shipping tested |

| Ideal Uses | Custom gifts, small business creations, educational projects |

| Not For | Unprepared reflective materials; thick hardwood cutting; bare metal engraving |

Compatibility by Material Type

We loved having a material map nearby as our projects multiplied. It saved us from optimism where caution would have been wiser.

| Material | Engrave | Cut | Prep Needed | Notes |

|---|---|---|---|---|

| Soft wood (pine, basswood) | Excellent | Yes, up to ~3 mm | None | Fine detail; low smoke; cut cleanly. |

| Hardwood (walnut, maple) | Very good | Limited | None | Engraves well; cutting thicker stock is not ideal for 5W. |

| Plywood | Good | Limited | None | Varies by glue layers; test first. |

| Leather (veg-tan) | Excellent | Edge scoring only | None | Ventilate; engraving produces rich contrast. |

| Fabric (denim, canvas, felt) | Good | Thin only | Test scrap | Mask delicate fabric to prevent scorch marks. |

| Coated/painted metal | Good | No | None | Engraves coating; leaves metal visible. |

| Bare metal | Poor | No | n/a | Not a 5W diode strength. Use coatings if attempting marks. |

| Cork | Excellent | Thin sheets | None | Bold contrast, easy and clean. |

| Cardboard | Excellent | Yes | None | Low power; minimal scorching. |

| Plastics (acrylic, ABS) | Varies | Thin only | Test first | Avoid PVC; check odors and melting behavior. |

| Glass/Ceramic | Good | No | Darken surface | Wipe clean after; subtle, classy results. |

Working Offline Without Tears

We used WiFi and USB most days, but offline Memory Mode spared us from the clutches of finicky connections. Once a job ran successfully, pressing the arrow button re-ran it identically. We taped a simple jig on the work surface for repeats: a cardboard frame aligning our material in the same spot each time. That method turned batch work into clockwork.

It also made collaborations more relaxed—we could hand the unit to a friend or student with instructions like “Place coaster here, press the arrow.” Empowering, foolproof, and mercifully fast.

Using LightBurn and LaserGRBL When We Wanted More

CutLabX is terrific for beginners, but we couldn’t resist the lure of deeper controls. LightBurn gave us adjustable acceleration, ramping, dithering choices, and layered jobs that felt like orchestrating a tiny ballet. LaserGRBL offered reliable, lean control for simple runs when we were feeling spartan.

Switching between software didn’t require rethinking the machine. The K10 responded consistently, and the manual’s guidance shortened the learning curve to something measurable in hours rather than days.

The Giftability Factor: People Love Their Names on Things

We have relatives who would happily receive a custom engraved toothbrush if it meant we thought about them for more than five seconds. The K10 turns that impulse into a practical system. Birthdays, graduations, teacher gifts, retirements—every milestone becomes an excuse to engrave a little object that lives longer than the card it arrived with.

And because the K10 ships assembled and is Class 1 safe, it makes an excellent gift on its own. There’s no assembly debt to pay, no half-day lost to driver installations. It’s a machine we’d actually give to someone without worrying they’d resent us.

Tips We Wish We Knew on Day One

We won’t hoard what we learned. Here’s our short list of experience gifts.

- Start with presets, then adjust slowly. Raise or lower power in small increments to learn material behavior.

- Keep a scrap box of every material you use. Test first; save settings.

- Build simple jigs out of cardboard or 3D prints to align repeat jobs. Label them.

- Clean the lens on schedule. It’s the difference between crisp and fuzzy.

- For photo engravings, increase contrast and simplify. Small fields love bold images.

- Ventilate consistently. Even “quiet” materials still produce fumes.

- Darken glass and ceramic surfaces before engraving; clean with alcohol afterward.

- Avoid reflective materials unless prepped. Protect your lens like it’s your camera.

- Use blue painter’s tape as a non-residue guide for alignment marks on the bed.

- Remember: 80×80mm is a canvas, not a compromise. Design to the scale.

Classroom and Family Use: Gentle Learning, Quick Wins

The K10 made us look like a very organized teacher for once. We could discuss design basics, show how to prepare a file, and run projects within one class period. The machine’s safety features—enclosed design, tilt and cover sensors—kept the experience calm. We appreciated how the orange window let students watch the line work in real time, turning the process into a small theater.

At home, the K10 became a family project maker. We engraved bookmarks together, then fought over who got the one with the cat drawing. This is what we mean when we say the machine is friendly: it becomes part of shared routines without asking for a dedicated garage.

Performance With Quiet Confidence

We’ve used louder machines that sounded like they were negotiating peace treaties with their own screws. The K10 hums, moves, and gets on with the job. We could play music at normal volume nearby and still hear ourselves think.

The motion system is accurate and predictable. Straight lines are straight, circles are circles, and text is readable at sizes we’d normally reserve for business cards. The difference between “toy” and “tool” is reliability; the K10 lives firmly in the second camp.

Living With the 5W Power Ceiling

We respect physics, begrudgingly. With 5W of optical power, the K10 handles engraving on a broad set of materials and cuts thin softwoods well. It is not meant to power through thick hardwood or acrylic slabs. Rather than push it past its happy place, we let it be what it is: a precise engraver and a nimble cutter for thin materials.

That honesty made us more creative. We layered thin pieces, used adhesives thoughtfully, and made depth with design rather than brute force. It’s a satisfying way to work, like cooking something delicious on a single burner because you actually planned.

A Sensible Plan for Care and Upkeep

We treat the K10 like a bicycle we want to ride again: clean it, store it dry, check the moving parts. A little is enough, but neglect is cumulative. We set a recurring reminder on our phones to clean the lens every 30 hours and wipe dust weekly. If we noticed motion hiccups, we checked the transmission screw for lubrication and dust.

Protecting it from humidity with desiccant bags was an easy win. Machines have moods like people, and this one gets testy in damp basements.

Batch Work and the Quiet Thrill of Consistency

There’s a special joy in making twenty things that look exactly alike, not because conformity is thrilling but because it means we can keep a promise—to ourselves, to customers, to friends. The K10’s Memory Mode and repeat positioning made batch runs almost meditative. We set up material, pressed the arrow, removed, repeat.

Watching the exact same line appear over and over has a charm we didn’t expect. It’s like watching a signature practice itself into elegance.

Quiet Business Math

We ran a few price scenarios to see if a small shop could make sense with the K10. Material costs for coasters, leather patches, and small wooden signs were low; personalization brings value. We added a rotary and expanded into tumblers and glasses. The machine paid for itself in a modest number of orders. It’s rare that a creative tool also encourages good bookkeeping.

Pair that with no subscription fees for the included software and we had fewer monthly mysteries showing up on our credit card.

When to Choose the K10 and When to Keep Looking

We love the K10 for people like us: practical romantics with a small desk and a list of people to surprise. It’s excellent for homes, classrooms, and small studios. Perfect if we want to engrave everything flat, add a rotary for cylinders, and keep the process safe and quiet.

If we need to engrave giant boards, cut thick hardwoods, or mark bare metal professionally, a larger or more powerful machine will be happier. But if our goal is to create personal, polished, small-scale projects with minimal fuss, the K10 belongs on our shortlist.

Pros and Cons We Actually Felt

We wrote these down after a month, when the novelty had settled and the routine had formed.

-

What we loved:

- No assembly, no excuses. Five minutes to first engraving.

- Memory Mode makes batches easy with a single button.

- Class 1 safety, tilt and cover sensors, orange window—safe without drama.

- Quiet operation; friendly in shared spaces.

- Great engraving on wood, leather, cork, coated metals; photo engraving is surprisingly strong.

- CutLabX is beginner-friendly; LightBurn/LaserGRBL compatibility for growth.

- 100+ presets and basic templates help us work fast and avoid guesswork.

- 12-month warranty; pre-tested reliability; responsive support.

- Compact footprint that doesn’t require rearranging our lives.

-

What we accepted:

- 80×80mm area requires planning. It’s a small canvas.

- 5W power: great for engraving and thin cuts, not for thick hardwoods or bare metal engraving.

- Prep needed for glass/ceramic and any reflective surface.

- Ventilation still matters; plan for fume management.

Our Favorite Projects, Step by Step

We don’t always need to start big to feel accomplished. Here are two bite-sized builds that made us look capable.

-

Leather Bookmark with Monogram

- We used 2 mm veg-tan leather, masked with painter’s tape to minimize soot.

- In CutLabX, we chose a serif font for initials and added a tiny border.

- Engraved at moderate power with a slow speed. Removed tape, applied leather conditioner.

- Result: crisp, classic, giftable. We pretended it came from a bespoke boutique.

-

Cork Coaster Set with Simple Geometry

- Found a repeating line pattern online and simplified it to thick lines.

- Used the coaster’s outer edge as a jig reference to align repeat jobs.

- Memory Mode did the rest. Ten coasters, identical, in under an hour.

- Result: conversation pieces that kept tables safe and relatives impressed.

A Simple Safety and Prep Checklist We Actually Use

We taped this to the wall behind the machine like a polite manifesto.

- Is the material safe? No PVC, no mystery plastics. When in doubt, test a scrap.

- Is the surface stable and flat?

- Is ventilation adequate? Window fan or nearby airflow on.

- For glass/ceramics: darkened surface applied?

- For repeated jobs: jig placed and taped?

- Lens cleaned recently? If not, alcohol swab time.

- Memory Mode behavior confirmed with a test piece.

- Do we plan to watch the entire job? Yes, yes we do.

Quick Answers to Our Own Frequently Asked Questions

We didn’t know we were going to become the household help desk, yet here we are.

-

Can we engrave photos well?

- Yes, with contrast tweaks and careful sizing. Wood and leather are our favorites.

-

Can we cut thick wood?

- Not beyond thin softwoods like 3 mm pine. For thicker materials, the K10 is an engraver first.

-

Do we need goggles?

- The orange viewing window means we can watch safely without goggles. Still, never stare at a laser point source directly, and keep the cover closed during operation.

-

Will it engrave bare metal?

- Not in a durable way with 5W. Coated metals (painted, powder-coated, anodized) engrave beautifully.

-

What about glass and ceramics?

- Darken the surface first with a marker or black laser masking paper. Clean afterward.

-

Is it noisy?

- No. It’s quiet enough for shared spaces.

-

Can it run offline?

- Yes. Memory Mode repeats the last job with the arrow button.

-

Is there a subscription?

- No. CutLabX is included without subscription fees.

-

What’s the maintenance time sink?

- Minutes per week: dust wipe, lens cleaning every ~30 hours, occasional lubrication.

What Surprised Us Most

Honestly, how often we used the Memory Mode. We thought it would be a niche feature and instead it became second nature. We also underestimated how good small photo engravings could look on leather and how satisfying it is to produce an entire set of matching items without losing our minds.

We were also surprised by how reassuring the safety design felt. It’s easier to be creative when we’re not worried about eye protection, open beams, or awkward rigging.

The Bottom Line We Wish Someone Had Told Us

The WAINLUXPRO K10 isn’t here to be a factory. It’s here to be a companion: the quiet, reliable studio friend that turns a lot of small ideas into small, beautiful realities. It arrives assembled, it behaves safely, it works with devices we already own, and it respects our time with presets and Memory Mode.

If we want to make thoughtful gifts, run a tidy side business, or bring hands-on projects into a classroom, it’s an easy yes. If our ambitions include slicing thick hardwoods or engraving raw metals, it’s not the right tool. But for the objects we actually hold and give, the K10 shines.

Final Verdict

We keep the WAINLUXPRO K10 Laser Engraver and Cutter within arm’s reach because it earns the space. It turns free time into finished work without demanding a workshop or a hardware degree. It’s quiet, safe, and steady, with software that grows alongside us and a maintenance routine that’s more like light housekeeping than a second job.

We’re glad we have it. We’ve given better gifts since it arrived, made a bit of money, learned new tricks, and turned odd bits of wood and leather into keepsakes with stories. Not many tools make life prettier in such a compact square. This one does, and it does it with a single, satisfying button that says, in essence, “Again.”

Disclosure: As an Amazon Associate, I earn from qualifying purchases.