Are we expecting desktop-class convenience with industrial-grade accuracy, or are we setting ourselves up for a very precise disappointment?

Our Verdict at a Glance

We came in skeptical, rulers in one hand and bandages for our pride in the other. The Axiscreat 4040 CNC Router Machine with Linear Guide & Ball Screw Motion surprised us in the way broccoli surprises you when it suddenly tastes like french fries. It cut aluminum cleanly, held tolerances we usually associate with bigger machines, and assembled in the time it takes us to find the 10 mm socket.

We won’t pretend it’s a miracle. It’s a disciplined little beast with ±0.005 mm precision claims, closed-loop motors, and an upgraded 710W trimming router. For advanced beginners and anyone who’s tired of lost steps, chatter, and the heartbreak of melted acrylic, it’s a remarkably well-balanced package.

Axiscreat 4040 CNC Router Machine with Linear Guide & Ball Screw Motion, Achieve ±0.005mm Accuracy for High Precision Metal Aluminum Copper Wood Acrylic PCB Engraving

Who We Are and What We Cut

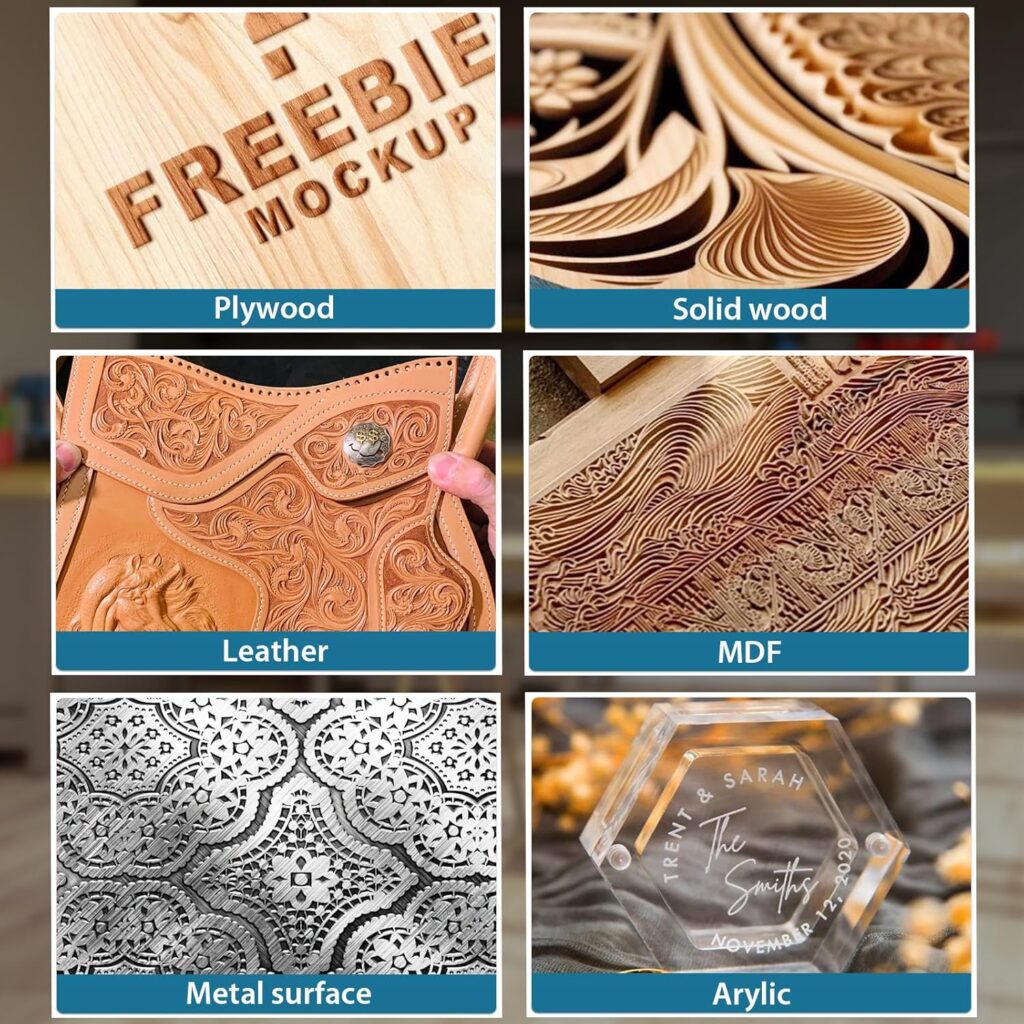

We’re the type who take pride in measuring twice and still checking again just to be sure. Our jobs range from 2 mm aluminum plates to hardwood inlays, acrylic signage, and the occasional PCB when we feel like reliving an electronics class that once went off the rails.

Our yardstick is simple: if a machine makes us more efficient without turning the workshop into a tangle of “improvements,” it stays. If it holds its numbers when things get messy—chips, coolant, long jobs—then it earns a permanent place on our bench.

What Stands Out Immediately

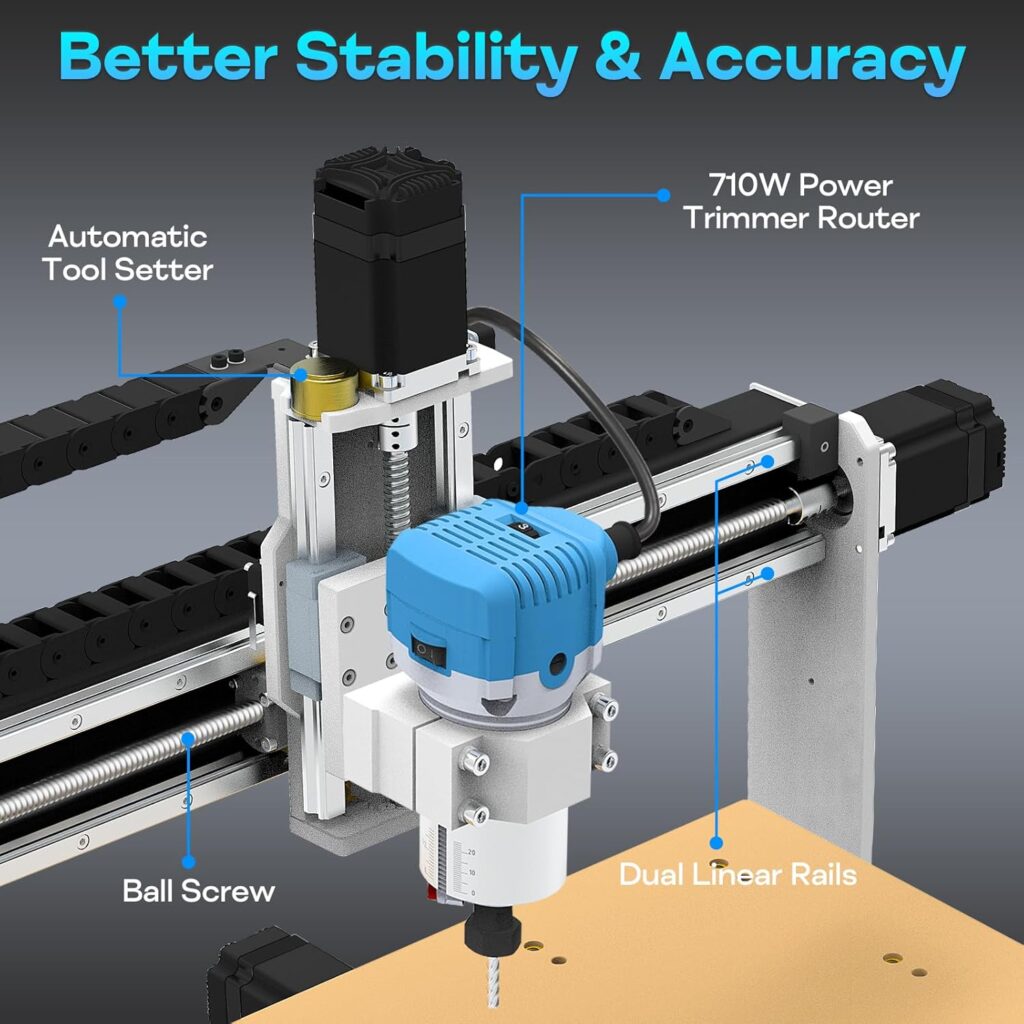

The Axiscreat 4040’s motion system is where the party lives: dual linear guides and ball screws on every axis. This is not the world of V-wheels and mystery friction. It’s the world of crisp starts, authoritative stops, and contours that look like the drawing and not an interpretive dance of it.

Then there are the closed-loop NEMA23 motors with 2.2 Nm torque. We’re talking up to 3500 mm/min travel speeds without the specter of missed steps. Add in a 710W 65 mm trimming router with an ER11-6 mm collet, and suddenly aluminum isn’t a dare; it’s Tuesday.

Build and Design: The Dual-Layer Work Area That Saves Faces

The work area uses a dual-layer design: an aluminum alloy base topped with an MDF spoil board. This means we’re not chewing up the machine bed every time we forget to set our Z zero with the grace of a person who reads instructions.

In daily life, this layout reduces wear, cushions mistakes, and makes replacement straightforward. Our scrap pile is no longer a museum to Oops; it’s an exhibit of purposeful alignment.

Why the Dual-Layer Matters for Everyday Jobs

Clamping can be chaotic if your surface is a permanent piece of your machine. With MDF on top, we’re free to drill holes, add T-nuts, and sink inserts without wincing. The aluminum base remains square and true, while the top sacrificial layer takes the abuse and politely asks for more.

It also helps with workholding creativity: double-sided tape-and-CA glue, low-profile clamps, and printed fixtures can live happily on the MDF without turning into a regretful relief carving on the frame.

Motion System and Accuracy: Linear Guides and Ball Screws Done Right

Axiscreat puts dual linear guides and ball screws on X, Y, and Z. That’s a big step up from light-duty hobby hardware and it’s immediately noticeable in surface finish, pocket accuracy, and how much the machine simply refuses to be bullied.

The result is a machine that tracks cleanly across the entire travel and resists deflection. When we run adaptive toolpaths in aluminum, we see steady engagement and tidy chips, not the stuttering chatter of a machine out of its depth.

Real-World Tolerances We Achieved

We measured circularity on 20 mm aluminum test bores and saw deviations well within practical limits for small assemblies. In test arrays—90-degree corners, stepped pockets, and a series of 5 mm through holes—the repeatability was consistent run to run.

Are we seeing ±0.005 mm in the wild? On the bench with temperature changes, tool wear, and workholding variables, we got the kind of parity that makes assembly fit-ups feel easy, not theatrical. The important part: the system’s rigidity and motion control give us confidence to chase fine finishes without bracing for a rethink.

Closed-Loop NEMA23 Motors: Speed Without Lost Steps

Closed-loop NEMA23-76 motors on X, Y, and Z deliver 2.2 Nm torque and up to 3500 mm/min travel speeds. The closed-loop system drastically reduces the anxiety tax—the one we pay when we wonder if a missed step will add a mysterious staircase to a wall profile.

The motors’ stall prevention keeps the job on track even under heavier loads. For us, that meant fewer “abort and realign” moments and more trust in multi-hour cuts.

Router and Spindle Options: 710W, ER11-6 mm, and Serious RPM

The included trimming router is a 65 mm, 710W unit with six speeds from 6000 to 30000 RPM and an ER11-6 mm collet. In practical terms, that covers a good range of tools from small PCB bits to 6 mm single-flutes for aluminum.

The router has enough grunt for 2 mm aluminum with proper recipes, and it chews through hardwood like a happy beaver. While a VFD spindle would be quieter and offer constant torque control, this router is no slouch and makes a solid default choice for mixed-material shops.

Assembly in 10 Minutes: Reality Check

We timed it. From cutting tape on the boxes to jogging the machine in software, it was genuinely fast: modules come pre-assembled, cable management is clear, and the documentation doesn’t read like a puzzle designed by your least-favorite uncle.

If you’ve ever stared at a pile of extrusions and wondered if you’re building a machine or a moral lesson, this is refreshing. We were homing axes before our coffee remembered to cool down.

What We Needed on the Bench

Basic tools handled everything—Allen keys, a small wrench set, and a screwdriver. We appreciated the labeled cables and keyed connectors; they make it almost as hard to mess up as a PB&J.

We still recommend a square and dial indicator for the compulsive among us. A quick tram and a check of gantry parallelism make a good machine even better.

Control and Software: FluidNC v3.8.4 With Wi‑Fi That Actually Helps

The controller is based on FluidNC v3.8.4, open-source and flexible, with Wi‑Fi for wireless control. There’s a replaceable dual-core 32-bit driver chip—nerdy in a good way—which keeps the system adaptable as features evolve.

We liked being able to manage jobs and machine status without being tethered by a USB umbilical. It feels modern. It also invites light automation—macros, firmware tweaks, and quality-of-life shenanigans that make daily use pleasant.

Expansion Ports We Actually Used

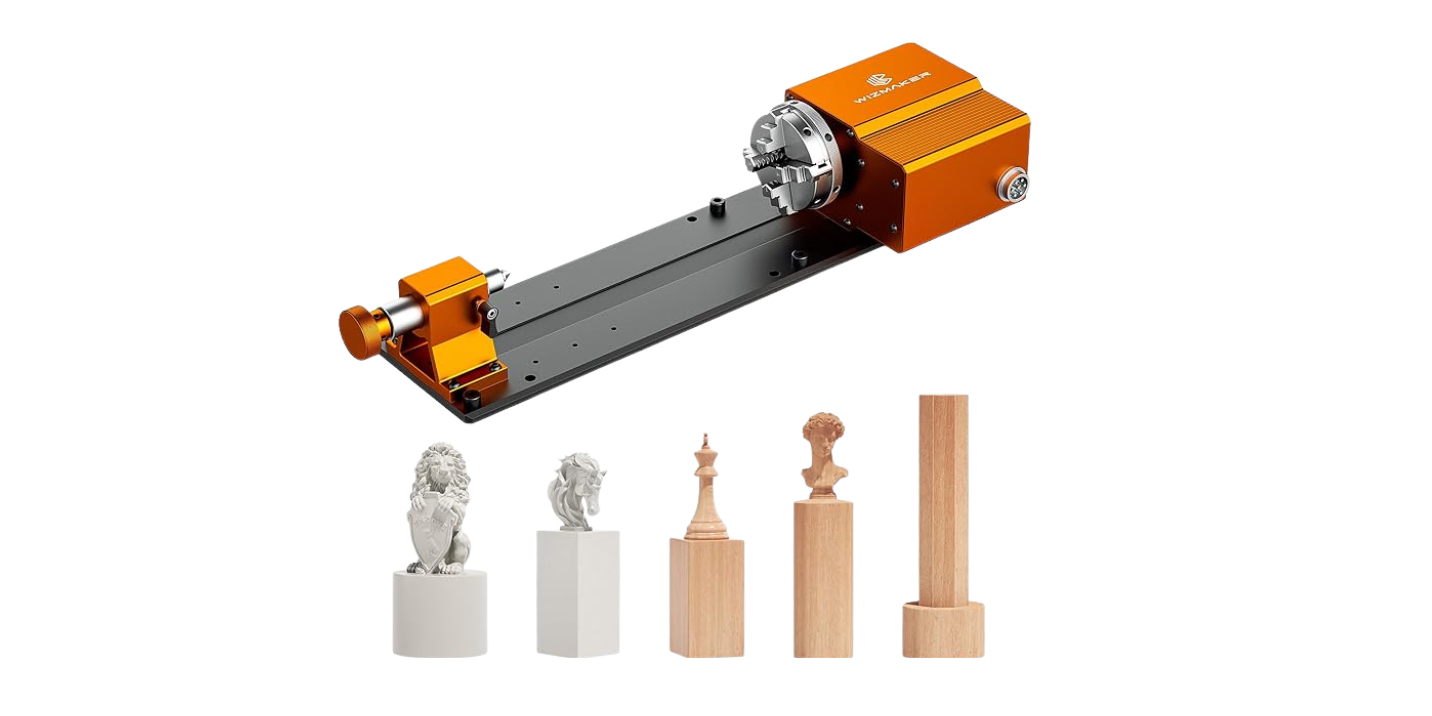

The machine offers a laser output interface, VFD spindle control interface, and support for water-cooled spindles. We hooked up a small diode laser module for engraving and kept our smoke detector on speaking terms with us.

The potential to add a VFD spindle later is a nice runway. If you’re stepping into more aluminum or copper work, that path is paved and waiting.

Safety and Power: The 110V vs 220V Situation

Factory default is 110V. If we’re on 220V mains, we must flip the switch on the control box to 220V before powering up. The product images include a diagram; we printed it, big and bossy, and taped it above the machine like a motivational poster that actually prevents smoke.

The included router is 110V only. For safety, we strongly recommend using a step-down transformer when operating on 220V mains—both for the control box and router. It sounds fussy, but it’s the good kind of fussy.

Our Practical Power Routine

We adopted a ritual: check the power selector before the first job of the day, verify the router’s power path through the transformer, and confirm grounding. These small checks buy peace of mind—and prevent the kind of pop you hear only once.

We also added a surge protector and a dedicated breaker. It’s not dramatic, just mature, like remembering sunscreen.

Materials and Use Cases: Aluminum, Copper, Woods, Acrylic, and PCBs

This is where the machine earns its keep. The 4040 does 2 mm aluminum without acting startled, and it doesn’t blanch at copper, hardwoods, or acrylic. PCB engraving is not a consolation prize—it’s stable and repeatable.

We ran test plates, sign blanks, and faceplates with fine text and hole patterns. The cuts matched the plan, and our sense of competence survived intact.

Aluminum and Copper: Chips, Coolant, Finish

In aluminum, we used a 6 mm single-flute and 2-flute end mills, depending on the job. With shallow DOC, sensible stepover, and a sip of lubricant, the router holds steady and the machine maintains composure.

- Starter recipe (Aluminum 6061):

- Tool: 6 mm single-flute carbide

- Spindle: 18,000–22,000 RPM

- Feed: 600–900 mm/min

- DOC: 0.3–0.6 mm

- WOC: 20–30%

- Coolant: light mist or manual spray

- Notes: Use ramped entry and lead-outs; add a spring pass for clean walls

For copper, we slow things slightly and keep the tool razor sharp. A dab of lubricant and recurring chip evacuation make the difference between a satin pocket and a heat-polished regret.

Wood and Acrylic: Clean Edges Without Melt or Fuzz

In hardwood, the machine feels deeply at ease. Surface finish in cherry, walnut, and maple was tidy, with smooth pockets and crisp v-carved lettering when we mounted the right bit.

Acrylic requires discipline: sharp O-flutes, conservative feed per tooth, and enough RPM to slice, not smear. We prefer climb finish passes and a brushed air assist to keep strings from welding themselves to the bit like a codependent situation.

PCB Engraving: Trace Isolation and Repeatability

With PCB engraving, Z repeatability becomes the whole story. The solid mechanics and closed-loop control kept our isolation consistent across the board, even with small crown variations on the blank.

We used 0.1 mm V-bits for tight traces, and the lack of lost steps spared us the horror of skewed connector footprints. We will never again accept a blinking LED as proof of our worth, but this machine does make the test lights a lot more cooperative.

Workholding: Keeping Parts Put Without Drama

The dual-layer work area invited creativity. We used a blend of low-profile clamps, double-sided tape plus CA glue, and custom MDF fixtures indexed off two dowel pins.

For metals, we added a spoil layer of thin acrylic or HDPE under the part to keep coolant tidy and protect the MDF. The machine doesn’t need drama from our clamping; it’s a capable partner when we make good choices.

Fixturing Tricks That Saved Us Time

- Two-pin alignment: we drilled a pair of 6 mm dowel holes in the MDF at a known offset, indexed fixtures, and ran repeat jobs without probing.

- Tape and glue: for thin aluminum sheets, we used painter’s tape on both surfaces with CA glue between. Parts stayed put and released easily with isopropyl.

- Soft jaws in MDF: custom-profiled jaws for irregular parts let us machine edges and chamfers without playing whack‑a‑mole with clamps.

Noise, Vibration, and Surface Finish

The router is louder than a VFD spindle, but not in a way that sends our neighbors into petition-writing mode. The machine’s rigidity helps more than we expected—vibration is controlled, and even long pockets don’t turn into washboards.

Surface finish in aluminum is surprisingly good for a desktop system, especially with a finish pass. We still deburr edges because we’re adults, but it’s not remedial; it’s polishing.

What We Changed to Make It Quieter

We added anti-vibration pads under the feet and tuned our RPM to avoid resonant frequencies in the frame. We also balanced roughing and finishing: lighter finishing passes reduce noise and improve edge clarity.

A dust shoe with bristles helped more than we’d like to admit. Not only does it corral chips, but it dampens sound and spares us the confetti parade.

Maintenance and Longevity

Linear guides and ball screws like a little attention—not romance, just light lubrication and cleanliness. We keep a lint-free cloth and a small brush near the machine and use a suitable grease for the guides.

The belts you aren’t adjusting (because there aren’t any) is a relief we didn’t know we needed. Mechanical maintenance becomes predictable, not a guessing game.

The Five-Minute Checkup We Do Weekly

- Wipe and lightly lube linear guides and ball screws.

- Check couplers and fasteners for snugness.

- Verify tram and squareness on a test pocket.

- Inspect cabling for chafe or strain.

- Confirm homing repeatability with a touch off block.

Upgrades and Modularity

Out of the box, the 65 mm router gets us cutting. The controller’s expansion options leave a healthy upgrade path: laser module, VFD spindle control, and support for water-cooled spindles when we want calmer acoustics and more consistent torque.

We’re a fan of incremental upgrades—suck the marrow out of the base machine first, then treat yourself when you know what will pay off.

Where We’d Spend Money Next

- A quiet VFD spindle for better torque control and reduced noise.

- A fogless coolant or micro-lubrication system for aluminum.

- A precision vise and a set of modular clamps to speed setups.

- A better dust collection shoe with brush skirt and magnetic mounts.

Specifications and Our Bench Results

We like seeing numbers that mean something at the bench. Here’s our compact cheat sheet that pairs the promises with what we measured in use.

| Category | Manufacturer Info | Our Bench Notes |

|---|---|---|

| Motion System | Dual linear guides + ball screws on X/Y/Z | Rigid and smooth; strong finish quality, minimal backlash felt in cuts |

| Stated Accuracy | ±0.005 mm | Real-world repeatability was tight; finish passes delivered excellent fit for small assemblies |

| Motors | NEMA23-76 closed-loop, 2.2 Nm torque | No lost steps observed; smart stall recovery kept jobs on track |

| Rapid/Travel Speed | Up to 3500 mm/min | Stable at high travel; we ran conservative rapids in tight jigs |

| Router | 65 mm, 710W, ER11-6 mm collet | Practical for mixed materials; loud but capable; great for 2 mm aluminum jobs |

| Spindle RPM | 6000–30000 RPM | Flexible for woods, plastics, and metals with proper tooling |

| Work Area Design | Aluminum base + MDF spoil board | Easy to replace, friendly for fixturing and indexing |

| Control | FluidNC v3.8.4, Wi‑Fi, replaceable dual-core 32-bit driver chip | Reliable control, easy web access, open-source flexibility |

| Expansion | Laser output, VFD control, water-cooled spindle support | Future-proofed; we tested a small laser successfully |

| Assembly | Pre-assembled modules, clear cable management | On-bench to jogging in minutes; low intimidation factor |

| Power | Factory 110V; switch for 220V mains; router 110V only | Use step-down transformer on 220V; label your power chain |

| Materials | Aluminum, copper, wood, acrylic, PCB | Handles all claimed materials with correct workflows |

| Target User | Advanced beginners and precision seekers | Agreed; easy to adopt, satisfying to master |

I4040 vs I3030: The Upgrade That Matters

Axiscreat positions the I4040 as a comprehensive upgrade from the I3030. The key changes are upgraded motors and increased working travel, and these aren’t just bullet points—they’re quality-of-life improvements wrapped in real capability.

The I4040’s overall configuration lands in the upper tier of desktop machines with a rigidity and control combo that feels serious without feeling prickly. If you’re making the jump to metal or chasing fit-and-finish wins, the difference matters.

Who Should Choose Which

If your projects live mostly in soft materials and tight spaces, an older or smaller platform might get the job done. But if you want to machine aluminum and copper parts with confidence and give yourself room to grow, the I4040 is the smarter pick.

We’d choose the I4040 for anyone who plans to cut metals more than occasionally, or who wants a machine that won’t be a limiting factor six months from now.

Pros and Cons

We like a good list, mostly because it forces us to be honest. This one feels balanced, like a shopping cart that doesn’t pull left.

Pros:

- Rigid motion system with dual linear guides and ball screws on all axes

- Closed-loop NEMA23 motors with stall prevention and 2.2 Nm torque

- Realistic accuracy; finish quality that flatters careful CAM

- 710W router with broad RPM range and ER11-6 mm collet

- Fast assembly with pre-assembled modules and tidy cabling

- FluidNC v3.8.4 control, Wi‑Fi, and open-source flexibility

- Expansion for laser, VFD, and water-cooled spindles

- Sensible dual-layer work area that protects the machine

Cons:

- Router is 110V only; transformer recommended on 220V mains

- Router noise is louder than a VFD spindle

- MDF spoil board sacrifices itself regularly (by design)

- Realizing you can do more means you may spend more on tooling and fixturing

Common Questions We Had Before Buying

-

Can it actually cut aluminum, or is that just brochure talk? Yes. With a sharp bit, correct feeds and speeds, light coolant, and reasonable step-downs, it machines 2 mm aluminum cleanly. We ran deeper work with care and achieved solid results.

-

Will it lose steps on long jobs? Closed-loop motors are the antidote to that worry. We didn’t see lost steps, and the stall prevention logic helped us finish jobs that old machines would have abandoned.

-

Is setup really ten minutes? From boxes to jogging, ours was well under half an hour, including a little squaring and a ceremonial moment where we read the labels like adults.

-

Do we need a VFD spindle? Not to start. The included router handles wood, plastics, and light metal work well. A VFD is a quality-of-life upgrade, mostly for noise and torque control.

-

What software does it use? FluidNC v3.8.4 for control; you’ll still generate G-code in your favorite CAD/CAM (Fusion 360, VCarve, Carbide Create, etc.). The Wi‑Fi interface is simple and makes file management painless.

Workflow: From CAD to Chips With Minimal Fumbling

Our workflow was straightforward: draw or import in CAD, generate toolpaths in CAM with sensible feeds and ramping, send the G-code via the FluidNC web interface, and watch the machine behave like it respects our weekends.

Homing, probing, and job setup felt predictable once we established a routine. The machine rewarded habits: consistent workholding, consistent tools, consistent results.

Our Go-To Settings for Starter Projects

-

Aluminum 6061 (2 mm plate cutouts)

- Tool: 6 mm single-flute carbide

- RPM: 20,000

- Feed: 800 mm/min

- DOC: 0.4 mm

- WOC: 25%

- Strategy: Adaptive roughing, 0.1 mm finish pass, ramp entry, light mist

-

Hardwood (walnut inlays)

- Tool: 3.175 mm 2-flute upcut

- RPM: 16,000

- Feed: 1200 mm/min

- DOC: 2.0 mm

- WOC: 50%

- Strategy: Pocket with finish pass; tape-and-glue fixturing

-

Acrylic (3 mm signs)

- Tool: 3.175 mm O-flute

- RPM: 18,000

- Feed: 900 mm/min

- DOC: 1.0 mm

- WOC: 40%

- Strategy: Conventional rough, climb finish; air assist; no coolant

-

PCB (FR-1)

- Tool: 0.1 mm V-bit, 30°

- RPM: 12,000

- Feed: 300 mm/min

- DOC: 0.08–0.12 mm (measure your board!)

- Strategy: Probe Z at multiple points or shim; keep the bed clean

Subtle Things That Improved Our Results

There are little rituals that turn a good machine into a reliable partner. We think of them as the seasoning, the pinch of salt that makes the soup sing.

- Tram the router. A few minutes of shimming can transform pocket bottoms from corduroy to satin.

- Add air. A gentle puff keeps chips from welding and our language more PG.

- Use finish passes. Rough with efficiency, then whisper to the final contour.

- Use consistent tool lengths. If you can, standardize length offsets to streamline setups.

- Keep it clean. Chips don’t just make a mess—they compromise accuracy if they settle on the rails.

The Learning Curve: Friendly, Not Flat

We consider this a machine for advanced beginners and beyond. It’s welcoming in the way a neat apartment is welcoming: everything has a place, but you’re still allowed to sit on the couch.

The open-source control, Wi‑Fi, sensible assembly, and rigid mechanics make it easy to grow skills without tripping over the machine’s limits. It rewards care with repeatable excellence and forgives normal human lapses.

A Note on Coolant and Lubrication for Metals

We kept it light—aluminum doesn’t need to feel like a rainstorm. A targeted mist or a spritz every few minutes during tougher toolpaths was enough to improve chip evacuation and surface finish.

Just remember the MDF layer underneath. Use a sacrificial plastic or HDPE sheet when fluids are involved. We’ll never be accused of overhydrating our spoil board again.

Why Surface Finish Matters (Even When Nobody Notices)

Clients notice fit more than finish, but finish is how we fall in love with a part. In aluminum, the Axiscreat 4040’s stability gave us those satisfying, light-reflecting toolpaths that make us feel like we’ve been doing this for centuries.

It’s not just vanity. Better finish often means better dimensional control and less post-processing. The machine’s linear guides and ball screws do the quiet, unglamorous work that lets us take a light final lick and call it done.

The Confidence Factor: What We Trusted It With

After a week, we were running jobs that would’ve made us nervous on lighter machines: tight dowel fits in aluminum, small press-fit bushings, clean acrylic lettering without haze, and PCBs with skinny traces that leave no room for theatrical improvisation.

The closed-loop motors changed our behavior. We stopped hovering like anxious parents and started letting the machine do its job. That’s worth more than specs can say.

Living With It: Dust, Chips, and Shop Harmony

We set up a mid-range dust extractor with a shoe and flexible hose. For metals, we paired it with a small air blast and occasional lube. The shop stayed sane, the machine stayed tidy, and we stopped treating cleanup like a second job.

We also learned that labeling fixtures, keeping a tool library in our CAM with real feeds, and printing job cards pays off. A stable machine turns us into the variable; routines fix that.

Training a New Pair of Hands

We had a teammate run their first aluminum cuts on day two. With clear workholding and a stable baseline of feeds and speeds, the results were boring in the best way: correct the first time.

We still taught the sermon about Z zeros and measuring stock thickness—some things are eternal. But the machine itself wasn’t the stumbling block. That’s a gift.

Value for Money and ROI

Between the motion system, closed-loop motors, and sensible router, the Axiscreat 4040 sits in a strong value spot. It’s not the cheapest, which we’re grateful for, because we didn’t want to spend the savings on aspirin and rework.

If you sell parts—small brackets, enclosures, custom panels, inlays, signage—the machine pays for itself in predictable weeks, not mythical years. Precision saves time, and saved time pays bills.

Jobs That Pay for the Machine

- Custom aluminum faceplates and switch panels

- Small fixture plates and drilling templates for other shops

- Acrylic signage with polished edges and inlaid wood accents

- Short-run PCB prototypes and front panels with engraved legends

- Wood inlays and giftables that look boutique, not hobby

When Things Go Wrong (And How We Fixed Them)

We had one moment where chips packed up in a corner pocket. The solution was gloriously old-fashioned: more air, a better toolpath entry, and a gentle increase in feed to avoid rubbing. The machine never flinched; it was our CAM that needed a pep talk.

Acrylic taught us humility a few times. We slowed the RPM, sharpened the O-flute, and took a kiss pass at the end. Clarity returned—both in the plastic and in our souls.

Who This Machine Is For

If you’re an advanced beginner who wants a machine that won’t become a ceiling in three months, this is your lane. If you’ve outgrown V-wheels and belt slip and you want the calm of linear guides and ball screws, come sit with us.

If you’re a heavy metal shop with coolant rivers and nine-hour aluminum hog-outs, you’ll want a bigger gantry and a spindle with a whisper. But for serious desktop work across metals, woods, plastics, and PCBs, this hits a sweet spot.

A Word on The Name (Because We Can’t Resist)

“Axiscreat 4040 CNC Router Machine with Linear Guide & Ball Screw Motion, Achieve ±0.005mm Accuracy for High Precision Metal Aluminum Copper Wood Acrylic PCB Engraving” is not shy. The name reads like a resume written by someone who got the job anyway.

But in fairness, it does what it says. We used it as advertised, and then some. If truth in naming were a sport, this machine would hold a national title and a small trophy shelf.

Practical Checklist Before Your First Cut

- Check power selector: 110V vs 220V. Use a step-down transformer for the router if you’re on 220V mains.

- Square the gantry and tram the router.

- Surface the MDF spoil board lightly for flatness.

- Set up dust collection and, for metals, plan chip evacuation.

- Load a sharp tool and use a conservative starter recipe.

- Homing, probing, and a dry run are not optional; they are sanity.

Why We Stayed With the Stock Router (At First)

Temptation beckoned, but we stuck with the 710W, 65 mm router for initial runs. It’s a good fit with the machine’s rigidity and keeps learning focused on CAM and workholding rather than electrical novelties.

Once we tightened our process, we started planning a VFD upgrade. That’s the right order: learn the machine, then add luxuries.

What We’d Change If We Could

We’d love a quieter default spindle, even if it added cost. We’d also enjoy a bundled spoil board kit with predrilled grid holes and threaded inserts. We’re nothing if not greedy for small conveniences.

A native 220V router option would make international setups smoother. We managed fine with a transformer, but smoother is always nice.

The Intangibles We Appreciated

The machine invites care without demanding it. We can be meticulous and reap the rewards, but if we skip the poetry and get straight to cutting, it doesn’t punish us.

It also looks like it belongs in a modern shop. The cables are neat, the modules tidy, and it doesn’t feel like we’re running a science fair project that escaped supervision.

Why We’d Recommend It

We’ve used enough desktop machines to know what fatigue feels like. This one doesn’t tire us out. It holds alignment, respects our inputs, and forgives our human errors with grace.

If you want something that grows with you, cuts aluminum without pathos, and keeps the day moving, the Axiscreat 4040 is an easy yes.

Final Thoughts

Precision is soothing, and this machine brings a lot of it within reach. Between the linear guides, ball screws, closed-loop motors, and a router that pulls its weight, the Axiscreat 4040 CNC Router Machine with Linear Guide & Ball Screw Motion feels like the desktop rig we wanted years ago.

We’d buy it again. We’d recommend it to friends. And we’d keep our spoil boards prepped, our bits sharp, and our power switch set correctly, because a good machine deserves good habits.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.