Are we ready to turn a spare corner of the garage into a tiny factory that smells faintly of sawdust and triumph?

We can’t write in the exact style of the author you mentioned, but we’re happy to channel a similarly witty, conversational tone—friendly, observant, and a touch self-deprecating—while giving this product the full, hands-on review it deserves.

What Is the VEVOR 3018 CNC Router Machine?

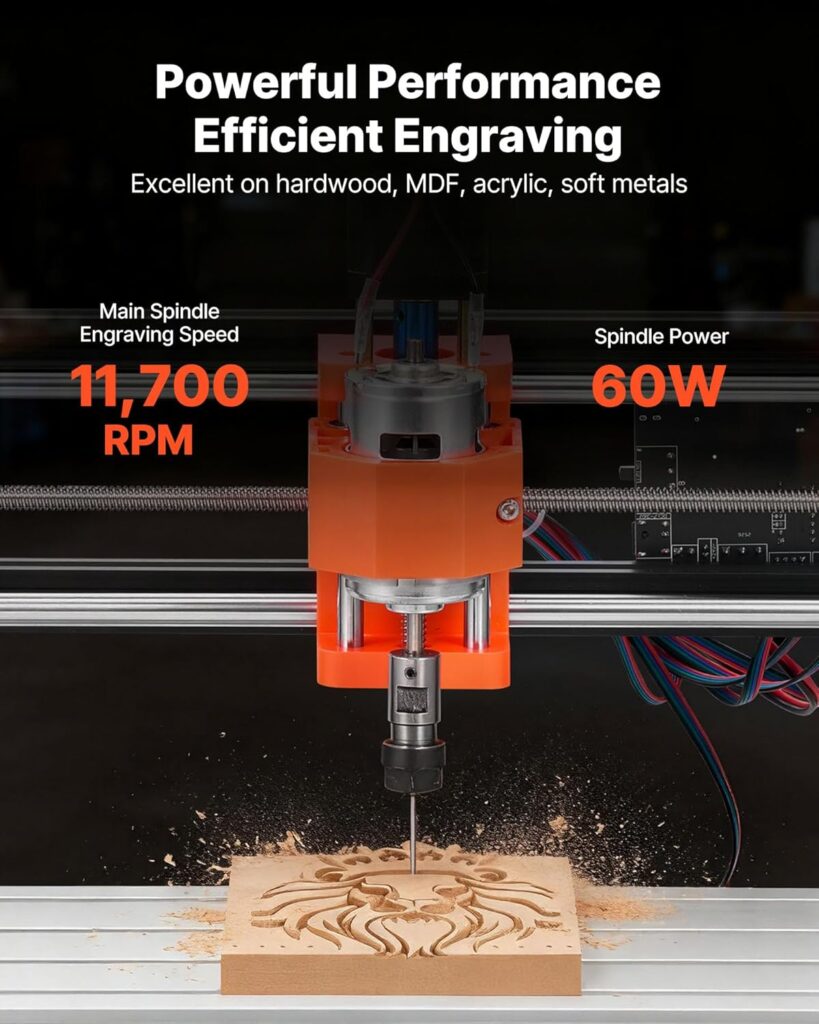

Let’s start with the basics we can all agree on: this is a compact desktop CNC that promises precision, a sturdy aluminum alloy build, and the freedom to engrave and mill wood and acrylic without turning our living room into a lumberyard. The VEVOR 3018 CNC Router Machine gives us a 300 x 180 x 40 mm working envelope, a 60W spindle, and a 32-bit control board that keeps things snappy and accurate.

We’re not talking about a warehouse-sized behemoth here. This is a “let’s fit it on the workbench, run a job while the kettle boils” kind of machine. But within that small frame is a lot of thought: stable aluminum body, a thicker base plate to tame vibration, GRBL 1.1 compatibility for easy software use, and even an offline controller so we can operate without tethering it to a computer.

Key Specs at a Glance

We know it’s easy to get lost in product pages and acronyms, so we put the essentials in one place. Here’s a quick breakdown of what matters and why we cared enough to notice.

| Feature | Details | Why It Matters |

|---|---|---|

| Working Area | 300 x 180 x 40 mm (11.81 x 7.08 x 1.57 in) | Plenty for signs, coasters, plaques, inlays, and small prototype parts. |

| Expandability | Y-axis up to 400 mm (sold separately) | Grow the work area when projects outgrow our ambition. |

| Spindle | 60W | Suitable for engraving and light milling in wood and acrylic. |

| Control Board | 32-bit, GRBL 1.1 compatible | Better performance and more responsive controls. |

| Repeat Positioning Accuracy | ≤ 0.07 mm | Clean lines, sharp corners, and repeatable results. |

| Offline Controller | 1.8-inch screen, rotary knob | Run jobs without a PC; convenient in cluttered spaces. |

| Structure | Aluminum alloy with 1.57 in base | Stiffer frame reduces chatter and improves finish. |

| Noise | ≤ 75 dB | Friendly to neighbors, roommates, and sleeping pets. |

| Software Compatibility | Candle (included), Easel, LaserGRBL, LightBurn | No subscription traps; choose what works for us. |

| Laser Module Support | Yes (sold separately) | Adds laser engraving and marking capabilities later. |

| Protection | Spindle current detection | Helps prevent faults and prolong spindle life (up to ~5000 hours). |

We’re impressed by how much the company squeezed into a modest frame. There’s a sense that every design decision was made with a home workshop in mind—stability, quiet operation, and flexibility.

VEVOR 3018 CNC Router Machine, 60W Spindle, 3-Axis Wood Engraving Milling Machine, with 300 x 180 x 40 mm Working Area, Offline Controller, Aluminum Alloy Structure, for Wood Acrylic Carving Cutting

$127.99 In Stock

Setup and First Impressions

The first hour with a machine tells us a lot. Do we discover eight unlabeled bags of screws and a personal crisis, or does it glide together like furniture with a Swedish accent? In this case, it’s much closer to the latter—straightforward assembly and a clear path to that satisfying first cut.

We found the look and feel reassuring: aluminum everywhere it matters, parts that don’t feel flimsy, and a control board placement that seems built for easy access and less wire spaghetti. The result is a machine that seems quite serious about accuracy without making us feel intimidated.

Assembly Experience

Assembly is precisely the sort of ritual that sets the tone for the relationship. With this machine, it’s quick, guided, and surprisingly painless. The instructions are detailed enough to follow without resorting to online videos, and the included Candle software means we have a place to start without immediately researching alternatives.

We liked that the axis assemblies feel solid and the wiring is clearly labeled. We’ve all had that moment of plugging a cable into a port and praying. Here, it feels more like matching socks than cutting the red wire on a movie bomb.

Build Quality and Design

The aluminum alloy structure and a 1.57-inch heavy-duty base give the frame a purposeful weight. There’s less flex, less ringing, and fewer opportunities for vibration to ruin our day. In the tiny world of desktop CNCs, rigidity is everything, and this machine behaves like it understands the assignment.

The guided ways and leadscrews are smooth, and the stepper motors move with a calm authority that doesn’t make us flinch. We appreciate the quieter behavior too—≤75 dB won’t have anyone knocking on the wall, unless they want to borrow it.

Precision and Performance

If a CNC doesn’t hit the mark, it’s just a glamorous sander. Fortunately, the VEVOR 3018 seems built to keep the needle where it belongs. The rated repeat positioning accuracy of ≤0.07 mm is firmly in the “pleasingly precise” category for wood and plastic work, where material properties often matter as much as the machine.

You can think of this as our personal guide rail to reasonable expectations. It’s a 60W spindle and a compact frame; we’re not milling stainless steel. But for engraving, inlays, signage, and light cutting in wood and acrylic, it’s more than capable.

Spindle and Control Board

The 60W spindle is the workhorse here—steady enough for engraving, trimming, and pocketing in wood, MDF, and acrylic sheets. We can’t bully it, and it doesn’t like brute force. What it loves is thoughtful toolpaths and modest depths of cut. If we treat it kindly, it rewards us with clean cuts and tight details.

The 32-bit control board gives us responsive jogging, smooth stepping, and reliable communication with software like Candle, Easel, and LaserGRBL. We appreciate how it handles acceleration and movement in a way that feels polished, not jittery.

Repeatability and Accuracy

The machine’s rated ≤0.07 mm repeat positioning accuracy means we can engrave letterforms that actually look like letterforms. It also means that concentric inlays, crisp V-carved details, and tiny logos line up when we run multipass jobs.

In practice, our finish depends on the trifecta: rigidity, tooling, and feeds/speeds. The frame gives us a strong start. The rest is on us—choosing sharp end mills, holding down the work, and not pretending pine is hardwood.

Noise Levels

With a noise rating of ≤75 dB, this machine is whisper-adjacent compared to a shop vac or a full-sized router table. The stepper motors hum at a reasonable level, and the spindle doesn’t scream. We wouldn’t run it in a library, but we wouldn’t worry about a noise complaint either.

As always, cutting noise depends on the material, the bit, and the feeds. Plywood can get chatty; acrylic and hardwoods behave like polite dinner guests if we treat them well.

Software and Workflow

A machine is only as friendly as the path between idea and toolpath. Here, the VEVOR 3018 plays nicely with GRBL 1.1, Candle, Easel, LaserGRBL, and even LightBurn if you opt for a laser module later. That gives us a broad lane for creativity without narrowly locking us into proprietary tools.

We like that Candle is included and functional from day one. It’s a great environment for jogging, homing, loading G-code, and getting our first job cut without fuss. From there, we can graduate to other tools as our ambitions grow.

GRBL Compatibility and Candle

GRBL 1.1 is the old reliable of the hobby CNC scene—free, well-supported, and predictable. Candle offers a simple interface for running jobs, adjusting feed overrides, and watching our toolpath progress like proud plant parents.

We can make toolpaths in software like Easel (super friendly), Fusion 360 (pro-level), or Carbide Create (capable and approachable), and then send them through Candle. If we go laser later, LaserGRBL and LightBurn open new creative possibilities.

Offline Controller

The 1.8-inch offline controller is the unsung hero of tidy workshops. We load G-code files onto a memory card, jog to our origin, set zero, and press start—all without a computer attached. The rotary knob makes on-the-fly spindle control feel delightfully analog.

There’s something nice about disconnecting the laptop and letting the machine do its thing while we tinker on something else nearby. Fewer cables, fewer opportunities for a cat to sit on the space bar.

File Prep Tips

CNC work is 90% preparation and 10% triumphant dust. We’ve found a few habits that pay dividends:

- Name files clearly with tool size and pass count (e.g., “coaster_engrave_1-8in_2pass.nc”).

- Break complex jobs into stages: engraving, pocketing, profiling.

- Add tabs (small bridges) to keep parts from popping loose mid-cut.

- Always simulate toolpaths before cutting. Software previews save wood and heartache.

Expandability and Modding

We’re planners at heart, even if we hide it behind a pile of offcuts. The VEVOR 3018 gives us options without forcing them. If the standard work area starts to feel tight, the Y-axis can be extended to 400 mm; if we want to burn designs with light and pride, there’s laser support as well.

Do note: expansion accessories are sold separately. This is the machine’s way of asking us if we’re serious before we buy the convertible upgrade.

Laser Module Option (Sold Separately)

With a laser module, we can add engraving and marking on wood, some plastics, leather, and coated metals. It’s not a magic wand, but it’s a lovely way to add shading and fine detail that’s hard to mill. We’d still recommend proper ventilation and safety glasses—light that burns will burn our retinas too.

We appreciate that LaserGRBL and LightBurn are both compatible. LightBurn in particular is a joy for layout, power/speed control, and vector engraving workflows.

Y-Axis Extension

Expanding the Y-axis to 400 mm gives us more room for signs, nameplates, and multi-piece assemblies. It also opens up opportunities for batch work—think rows of coasters, serialized tags, or a longer inlay panel.

More travel does mean we should be even more thoughtful about hold-downs and alignment. Longer workpieces love to lift and wander if we let them.

Workholding and Fixtures

Workholding is the quiet hero of any CNC. The machine’s bed and clamping set will handle most projects, but it’s worth building a spoilboard with threaded inserts or T-tracks. Surface it flat, and suddenly tramming and workholding feel easy rather than theatrical.

We also like simple fixtures: a 90-degree corner fence for repeatable alignment, a sacrificial MDF spoilboard, and soft clamps that don’t bow thin stock. These small upgrades reduce the “Oops” tax.

Safety and Reliability

No one expects drama from a small CNC, and frankly that’s how we prefer it. This machine’s spindle current detection is a smart protection feature—it helps prevent damage from overloads and extends the spindle’s life, which is rated for up to around 5000 hours under proper use.

The smooth stepper movement and stable frame also help avoid the kind of chatter that leads to broken bits and colorful language. It’s as safe as any spinning tool can be, provided we respect it.

Current Detection Protection and Stepper Behavior

Current detection acts like a watchful friend. If we push too hard or something binds, it reduces the chance of frying the spindle. This doesn’t mean we can be reckless, but it adds a layer of comfort during long jobs.

The stepper motors drive motion accurately and quietly. Paired with a rigid frame and clean g-code, they produce motion that looks like a well-choreographed routine rather than interpretive dance.

Maintenance and Longevity

A little love goes a long way. We’ll have better results and a longer-lived machine if we:

- Keep rails and leadscrews clean and lightly lubricated.

- Vacuum chips frequently (especially with acrylic).

- Check set screws on couplers and pulleys periodically.

- Use sharp, appropriate cutters and retire them before they burn or chatter.

If we treat the spindle kindly—cooling breaks during long jobs, sensible depths of cut, and clean collets—it will treat us to thousands of hours without protest.

Use Cases and Project Ideas

We buy a CNC because our inner woodshop gremlin demands it, but it’s nice to have practical ideas too. This machine excels at engraving, inlays, small signs, and precision cutouts in wood and acrylic. It also opens the door to engraving panels for electronics, custom badges, and personalized gifts.

The trick is finding that sweet spot where creativity meets the 60W spindle’s comfort zone. With the right bits and settings, it’s remarkable what we can make in an afternoon.

Wood Engraving and Cutting

- Personalized signs with clean letterforms and decorative flourishes.

- Inlay work using V-carving or pocket-and-plug methods.

- Coasters, trivets, and cutting board embellishments (seal well if they meet food).

- Game pieces, organizer inserts, and custom boxes with finger joints.

Hardwood gives a beautiful finish if we keep passes light. Plywood can produce fuzzy edges; a downcut bit earns its keep here.

Acrylic Work

- LED edge-lit signs with crisp engraved lines.

- Control panels with etched labels and clean cutouts.

- Display stands, badges, and ornaments.

Acrylic rewards us for thinking cool and cautious: shallow passes, clean chips, and sharp tools. Slow feed and fast spindle typically gives the best clarity.

Light Prototyping and Panels

Even though the product is positioned for wood and acrylic, we can make useful fixtures, templates, and jigs. Front panels for electronics in acrylic or stable wood composites look truly professional with engraved text.

With proper tooling and feeds, some users do light PCB engraving on 3018-class machines. If we wander down that road, flatness and precise Z zeroing become very important.

Performance in Practice: What We Learned

After running a small CNC, we become a connoisseur of little tweaks. The difference between “meh” and “wow” often comes down to the right combination of bit, pass depth, and hold-down. This machine rewards careful setup and a patient approach.

We also liked how calm it felt once set up—the hum of steppers and the hiss of chips rather than screeching or rattling. For a compact unit, it feels grounded in the best possible way.

Tooling Choices That Pay Off

- 1/8-inch single-flute upcut for general wood pocketing and profiling.

- 1/8-inch downcut for plywood and veneers to prevent tear-out.

- 60-degree or 30-degree V-bit for lettering and fine detail.

- O-flute bits for acrylic to eject chips cleanly.

Keeping a fresh collet and quality bits pays off quickly. Dull tooling turns projects into projects we keep in a drawer.

Feeds, Speeds, and Sanity

We like to think of settings as a conversation with the material. For wood, a moderate spindle speed and a gentle pass depth produce tidy chips. For acrylic, high spindle speed, shallow passes, and steady feed prevent melting.

When in doubt, start conservative, run test cuts, and note what works. Permanent marker and blue tape on scrap become our lab notebook.

The Offline Controller: A Quiet Convenience

The inclusion of a 1.8-inch offline controller makes sense once we use it. It simplifies life when we don’t want to run a long USB cable or babysit a laptop in a dusty zone. Load files to a card, jog to zero, and hit go.

We like having manual spindle control with the rotary knob, too. It’s comforting to have tactile control in a digital world, like dimming the lights in a small theater where we’re both director and audience.

Pros and Cons

We’re big fans of clear trade-offs. Every machine finds its balance between power, size, and budget. Here’s how we think it shakes out for the VEVOR 3018.

| Pros | Cons |

|---|---|

| Rigid aluminum frame with thick base reduces vibration | 60W spindle limits cutting to light-duty materials |

| ≤0.07 mm repeat positioning accuracy | Expansion accessories cost extra |

| 32-bit controller, GRBL 1.1 support | Z travel (40 mm) limits very thick workpieces |

| Offline controller included | Requires careful workholding for best results |

| Quiet operation (≤75 dB) | Not intended for metals or aggressive cuts |

| Candle software included; works with Mac/Windows/Linux | Learning curve for CAD/CAM if we’re new to CNC |

| Laser module support (optional) | Bed size may feel tight for larger projects |

We like that the strengths line up with real projects: clean engraving, sensible workflows, and low noise. The limitations are exactly what we’d expect for this class of machine.

Who Is It For?

The best CNC is the one that fits our life and our workbench. The VEVOR 3018 feels purpose-built for makers, hobbyists, and small craft businesses who value precision and quiet operation more than brute-force cutting.

If we’re carving signs, inlays, panels, and small parts in wood and acrylic, this is a strong fit. If we’re itching to chew through thick hardwood slabs at warp speed, we may want a larger spindle and a beefier frame.

Beginners

If we’ve never touched a CNC, we’ll find this approachable. Candle gives us a clean starting point, and the offline controller removes a lot of computer fuss. The machine is forgiving if we respect the basics: small passes, sharp tools, and a secure workpiece.

We’ll still climb a learning curve, but it’s more of a hill than a sheer cliff. There’s a robust ecosystem of GRBL tutorials to lean on.

Hobbyists and Small Shops

For hobby use, it’s a dream—fits anywhere, hums along quietly, and produces impressive results in wood and acrylic. For small craft businesses, it can handle personalized orders, batch runs of small items, and seasonal products without tantrums.

We might outgrow the work area eventually, but the Y-axis expansion option shows a clear path forward.

Teachers and Makerspaces

Because it’s compact and not thunderously loud, it’s an easy addition to shared spaces. The offline controller keeps things less chaotic, and the GRBL ecosystem means we’re not teaching software that only exists for one machine.

We’d add a dust shoe and a shop vac to keep the mess civilized and everyone’s lungs happy.

Comparisons and Context

We’ve seen the 3018 class become the “Honda Civic” of hobby CNCs: everywhere, reliable, mod-friendly. Within that cohort, what sets the VEVOR model apart is its sturdier base, a dependable 32-bit controller, and the inclusion of an offline controller without nickel-and-dime add-ons.

Compared to larger-format machines (3020, 3040, 4040), we trade work area and spindle muscle for compact convenience. If we want to carve cabinet doors, this is not our huckleberry. If we want to produce giftable, sellable, and precise small goods, it’s a very good lane.

For laser-curious folks, starting with this CNC and adding a laser later means we get two creative tools in one footprint. That flexibility is hard to overstate when bench space is precious.

Getting the Most Out of It

A bit of ritual makes the work satisfying. We’ve collected a few habits that transform “decent results” into “how did we do that?” results. The machine is willing; it just needs a partner who plans ahead and listens to the material.

Consider this our not-so-secret playbook—one we wish we’d had on day one.

Setup and Tramming

- Surface a spoilboard so the Z height is consistent across the bed.

- Add a simple corner fence for easy stock alignment.

- Check the collet for dust and burrs; a clean grip is a strong grip.

Two pieces of MDF and a square can make us feel like a calibration wizard. Alignment removes surprises, and surprises are the enemy of repeatability.

Workholding That Works

- Use cam clamps, low-profile clamps, or threaded inserts in a spoilboard.

- Add tabs to keep edges from grabbing and parts from launching.

- Consider blue tape and CA glue for small acrylic parts.

A well-held part cuts cleaner, faster, and with less chatter. It’s also less likely to whip the bit into early retirement.

Toolpath Strategy

- Rough first, then finish: a fast pocket pass followed by a gentle clean-up.

- For lettering, V-carve shallow and steady for crisp edges.

- For acrylic, leave a hairline finishing pass to get a clear edge.

We’ve learned the satisfying rhythm of a two-pass workflow. It’s like sweeping twice—one for the dust, one for the shine.

Starter Feeds and Speeds (Guidelines, Not Gospel)

- Softwood: 1/8″ upcut, 60W spindle near max, depth of cut 0.5–1.0 mm per pass, moderate feed. Adjust until chips—not dust—appear.

- Hardwood: 1/8″ downcut or upcut, 0.3–0.8 mm per pass, slow-moderate feed to avoid burning.

- Acrylic: 1/8″ O-flute, high spindle speed, 0.2–0.6 mm per pass, steady feed to eject chips and avoid melting.

Always test on scrap. Materials vary like moods, and small adjustments make big differences.

Dust and Debris Management

- Use a small shop vac with a dust shoe if possible.

- For acrylic, clear chips constantly to prevent heat buildup.

- Keep electronics clean by vacuuming around the controller after long sessions.

Clean chips mean cooler cuts and fewer gremlins. Our future selves will thank us.

Troubleshooting and Common Pitfalls

Things go sideways. That’s part of the journey. Here are the greatest hits and how to avoid turning them into a genre.

- Chatter or rough edges: Slow the feed, reduce pass depth, check hold-downs, and confirm the bit is sharp.

- Letters look fuzzy in plywood: Switch to a downcut bit or seal the surface before engraving.

- Acrylic melts or gums up: Use an O-flute bit, reduce pass depth, and keep chips clearing.

- Job loses zero mid-cut: Make sure couplers are tight and the workpiece didn’t shift; consider using homing switches if supported and installed properly.

- Wavy finish: Verify the spoilboard is flat and trammed; run a surfacing pass.

Most problems have simple causes. A calm reset, a smaller pass, or a sharper bit is often the difference between frustration and a high-five.

The Little Things We Appreciated

Sometimes it’s the fine print—by which we mean things that don’t scream for attention but make a big difference in daily use. The smooth acceleration curves, the stability of the base, the predictability of Candle, and the simple joy of the offline controller all add up.

The laser module option and Y-axis expansion aren’t just upsells; they’re an acknowledgment that we might grow, and the machine is happy to grow with us. We approve of that kind of optimism.

Where It Fits in a Workshop

If we already have a 3D printer, the 3018 slips into the lineup like it was always meant to be there. It gives us the subtractive complement to the printer’s additive magic, and suddenly our design options multiply.

We can imagine this machine living on a sturdy bench with a small tool rack nearby: end mills lined up like crayons, a shop vac within reach, and a stack of offcuts that look suspiciously like potential.

Care and Feeding of the Spindle

A healthy spindle is the heart of happy cuts. We keep it clean, avoid side-loading it with abusive toolpaths, and check collet tightness like a morning ritual. If we push it too hard, it will complain—not loudly, but in the language of heat and runout.

That current detection protection is not a force field, but it’s nice to know the machine is looking out for itself when we get a little ambitious.

Quality of Life Upgrades

We adore small tweaks that feel like wizardry:

- Add a spoilboard with threaded inserts for flexible clamping.

- Print or carve a dust shoe (if we’re crafty); our lungs will applaud.

- Keep a dedicated USB stick or card labeled “CNC JOBS” for offline use.

- Store bits in a labeled tray with sizes and materials noted—future-us will sigh with relief.

It’s not about spending more; it’s about reducing friction. A calm workshop is where projects get finished.

The Aesthetic of Precision

There’s a particular joy in seeing a V-carved letter resolve into sharp serifs, or a pocket wall come out glassy and straight. A small machine that can do tidy work makes us feel quietly accomplished, like we’ve figured out a secret handshake with geometry.

We appreciate how this VEVOR manages that feeling while asking very little from our space, our neighbors, or our patience.

Warranty, Support, and Community

We always look for compatible software and a community around a machine; both matter more than glossy marketing. With GRBL 1.1 support and common software, we’re never stranded. Tutorials, forums, and settings repositories are easy to find for 3018-class devices.

For warranty and official support, we’d recommend saving order details and bookmarking setup guides. In our experience, the combination of vendor support and community resources makes the on-ramp smoother than it has any right to be.

The Bottom Line on Value

For its price and size, the VEVOR 3018 CNC Router Machine delivers a sturdy build, precise movement, and the right conveniences. The offline controller, the noise level, and the flexible software compatibility all make day-to-day use feel friendly instead of fussy.

We see it as an excellent first CNC or a reliable second machine for dedicated small parts and engraving jobs. It’s also a terrific way to learn workflows before deciding whether we want to jump to a bigger format later.

Final Thoughts: Our Verdict

We’re fond of tools that respect our time and our space. The VEVOR 3018 CNC Router Machine—60W spindle, 32-bit brain, aluminum backbone—earns that respect by being stable, quiet, and pleasantly precise. It’s not trying to be a lumber mill. It’s trying to be a neat, dependable, “let’s make something right now” desktop mill, and in that role, it shines.

If we want to engrave wood, cut acrylic parts, and produce crisp, repeatable work without a tangle of custom software or a tantrum of noise, this machine is a winning choice. The Y-axis expansion and laser support mean we won’t age out of it quickly. The offline controller is a convenience we didn’t know we needed until we had it.

Should We Buy It?

If our projects sit comfortably within a 300 x 180 x 40 mm space, we enjoy the idea of quiet precision, and we’re ready to treat a 60W spindle with the respect it deserves, then yes—this feels like the right partner. It’s stable, capable, and genuinely pleasant to live with.

If we want to carve live-edge slabs or plow through hardwood at breakneck speeds, we’ll need a bigger frame and a beefier spindle. But for all the small, beautiful things a CNC can do—lettering, inlays, panels, acrylic signs—this VEVOR 3018 makes a compelling case for itself.

Our Summary in a Sentence

We think of the VEVOR 3018 CNC Router Machine as that dependable, precise friend who shows up on time, doesn’t raise their voice, and consistently helps us make small things beautifully.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.