Have we ever met a machine that makes us want to clean the garage, rearrange our tool drawers, and pretend we’ve had a plan all along?

CNC Router Machine 4030-Evo Ultra 2 Review: What We Signed Up For

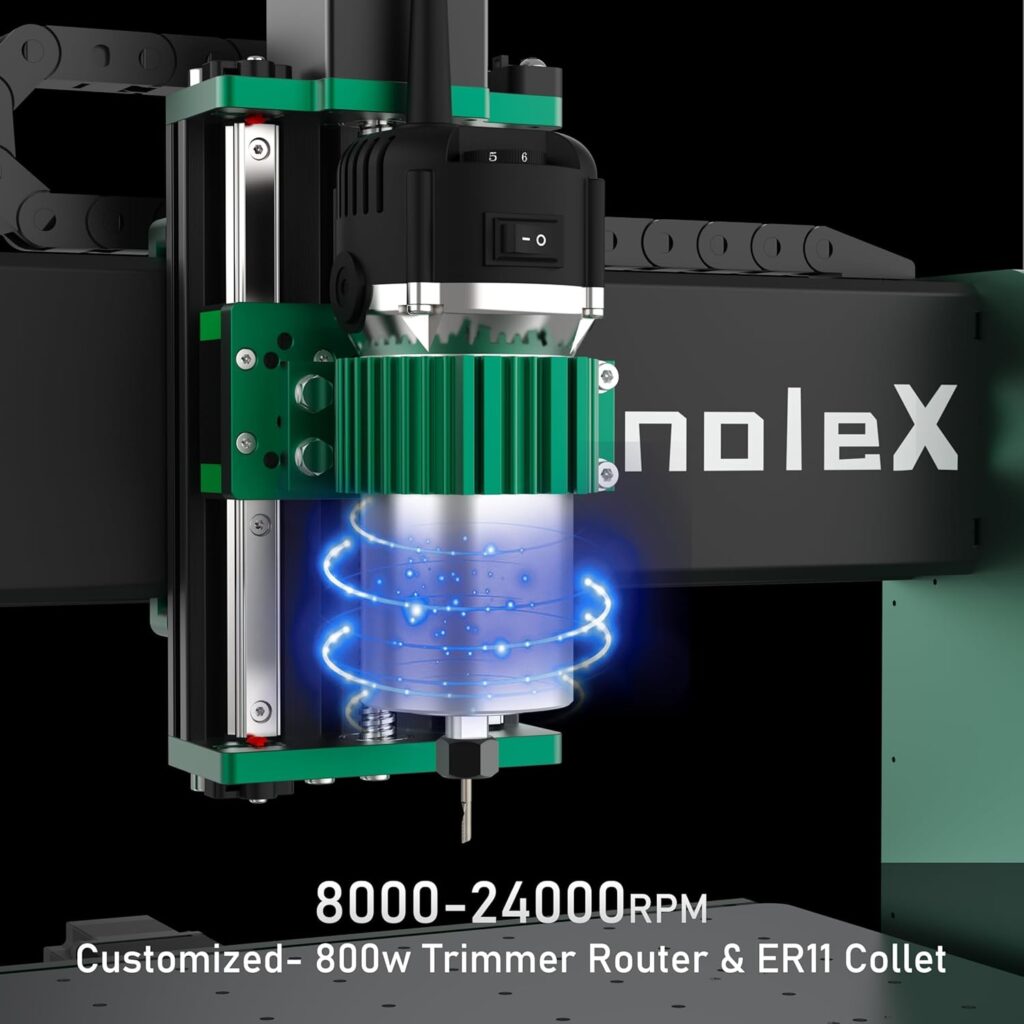

We first met the CNC Router Machine 4030-Evo Ultra 2, All-Metal XYZ Axis Dual Steel Linear Guides & Ball Screws with 800W Trim Router for Metal Aluminum Brass Wood Acrylic PCB under the impression that we’d mostly be using it for neat little coasters and polite signs. Then we read the spec sheet, noticed the dual HGH-15 linear rails and 1204 ball screws on every axis, and realized we were about to pretend we always meant to mill aluminum brackets. The machine puts its seriousness on display: an all-metal motion system, 800W trim router with ER11-1/8” collet, GRBL_ESP32 board running GRBL 1.3a, and thoughtful touches like XYZ dual limit switches, an emergency stop, and a Z probe.

We’ll admit it: we like gear that’s honest about what it can do. This one tells us it’s ready for aluminum and brass, while also making wood, acrylic, and PCB work feel tidy and predictable. That’s not a small promise.

CNC Router Machine 4030-Evo Ultra 2, All-Metal XYZ Axis Dual Steel Linear Guides & Ball Screws with 800W Trim Router for Metal Aluminum Brass Wood Acrylic PCB

Quick Summary of Features We Actually Use

We understand the distinction between marketing checkboxes and real-world utility, so we put the essentials in one place. We care about rigidity, motion control, and a workflow that doesn’t make us sleep in the shop.

Key Specs and Why They Matter

| Feature | What It Is | Why It Matters |

|---|---|---|

| 800W Φ65mm trim router with ER11-1/8″ collet | 6-speed settings, 8000–24000 RPM; software run/stop; speed via manual dial | Enough power for aluminum and brass with small cutters; wide RPM range for different materials; easy start/stop from software |

| Dual HGH-15 linear rails on X, Y, Z | Two steel linear guides per axis | Rigidity, smoother motion, reduced chatter; better surface finish, especially in metal |

| 1204 ball screws on all axes | 12 mm diameter, 4 mm lead ball screws | Low backlash and high repeatability; precise movements and better dimensional accuracy |

| GRBL_ESP32 controller with GRBL 1.3a | 32-bit MCU, ESP3D Web UI | WiFi control from PC/phone/tablet; advanced G-code support; no USB cable required |

| Supported features | Laser engraving, 4th axis (rotary), M07/M08 coolant, closed-loop stepper support, 3-pin touch probe | Future expansion without replacing the brain; easier probing and potential coolant control |

| NEMA 23 stepper motors | 2.8A, 1.2 N·m; closed-loop interfaces available | Stronger torque than NEMA 17; more reliable motion under load; upgrade path for closed-loop |

| Safety and setup | XYZ dual limit switches, home switch, emergency stop, Z probe | Safer homing, better soft limits, rapid setup for tool length and job zeros |

| Software compatibility | Windows, Linux, Mac; UGS, Fusion 360, VCarve, Easel, LightBurn | Familiar tools and workflows; no forced software subscription |

| Assembly | Major components pre-assembled; clear cabling; paper manual + videos | We actually finished before lunch; tidy wiring; fewer mistakes |

We didn’t have to squint to find the important stuff. This machine centers on rigidity, controlled movement, and an interface we don’t dread. It’s clear the intent is real cutting in real materials.

Unboxing and Assembly: Our Saturday Well Spent

We opened the boxes and immediately noticed the pre-assembly work. Gantry components arrived together, wiring was labeled, and the cable management looked like someone who cares about order had been in the room. The paper manual walked us through the steps we needed, and the assembly and demo video made sure we didn’t interpret anything too creatively.

Within a few hours, we had the frame squared, the axes moving, and the 800W trim router––Φ65mm mount and all––seated confidently. We still had enough energy left to argue over who gets naming rights for the machine (we settled on Ultra, pronounced with unnecessary grandeur).

Build Quality and Mechanics: All-Metal XYZ, Dual Rails, Ball Screws

We love that each axis runs on dual HGH-15 linear rails. There’s a world of difference between machines that glide on rails and those that shimmy on wheels. Paired with 1204 ball screws, we get a motion system that feels planted. It resists chatter and wandering, which is precisely the kind of personality we want when cutting aluminum brackets or brass inlays.

Those ball screws help keep backlash in check, and the dual rails fight torsional forces when the tool is cutting off to one side. We’ve done enough work on hobby machines to recognize the moment when the tool starts to sing and the cut quality falls apart. This machine gives us a lot more room before that song starts, and that translates to better finishes, straighter edges, and less sanding.

We also appreciate the improved dust protection on the X and Y axes. Dust isn’t just a nuisance; it shortens the life of bearings and rails. Better sealing means smoother motion over time.

The 800W Trim Router: Power, Speed, and Control

A router that can run from 8,000 to 24,000 RPM with an ER11-1/8″ collet gives us a wide playfield. We can slow things down for aluminum and brass, then crank it up for small V-bits in wood and engraving bits on acrylic. The run/stop is software-controlled, which is a subtle but meaningful comfort; we don’t need to reach for a switch mid-job. The speed itself is adjusted by a manual dial, which is refreshingly honest. We set it, we test it, and it stays put.

In practice, the 800W motor has enough guts for light metal work when paired with the right feeds, speeds, and step-downs. We keep our end mills sharp, our expectations sane, and our material clamped like it owes us money. It’s not a 2.2 kW spindle, but this router punches above its weight for a machine at this scale.

Speed Ranges and Real-World Comfort

We’ve had success with:

- Aluminum: 10,000–16,000 RPM using 1/8″ single-flute end mills; light step-downs; generous chip evacuation.

- Brass: 10,000–14,000 RPM with 2-flute tools; eased feeds; attention to heat.

- Wood: 16,000–22,000 RPM, depending on bit size and grain; the clean edges in hardwoods made us feel almost professional.

- Acrylic: 14,000–18,000 RPM with single-flute bits; keep chips big and moving to avoid melting.

We test on scrap, listen for chatter, and adjust our courage level accordingly. The manual speed dial encourages us to be hands-on, which suits our workshop temperament.

Electronics and Firmware: GRBL_ESP32 Running GRBL 1.3a

We appreciate brains that aren’t stuck in 2015. The GRBL_ESP32 control board gives us a modern 32-bit platform with WiFi through ESP3D Web UI. We control jobs from a laptop, a tablet, or—with slightly too much pride—our phones. No USB tether required. That’s not just convenience; it’s fewer snags and accidental yanks when we forget the cable exists.

GRBL 1.3a support brings features that matter as we grow:

- Laser engraving support, for those of us who love a good etch on anodized aluminum or wood.

- 4th axis (rotary) capability, to tempt us into cylindrical objects and spiraling ambition.

- M07/M08 coolant commands, opening the door to mist or air blast control.

- Closed-loop stepper compatibility, which means upgrades without circuitry wizardry.

- 3-pin touch probe support, paired with the included Z probe tool for easier setup.

We can also reprogram the onboard macro button. It ships as a homing button, but we can set it for pause, stop, reset, or even to pull and run G-code from an SD card. The first time we re-homed with a single tap, we felt like a slick production shop, even though our “shop” includes a retired coffee maker whose only job now is to hold calipers.

WiFi Control: Less Cable, More Calm

ESP3D’s Web UI is wonderfully straightforward. We open a browser, connect to the machine, jog the axes, zero the workpiece, and send a file. If we wander off to make tea, we still keep an eye on things from the next room. We tend not to wander far—routers are loud—but the freedom is nice.

We also enjoy that firmware updates and settings are part of a living system. Rather than a locked-down black box, we get a platform that grows with us.

Motion Performance: Stepper Motors, Repeatability, and Trust

NEMA 23 stepper motors with 2.8A current and 1.2 N·m of torque are a step up from the daintier motors we’ve seen on smaller rigs. The axes hold position with more authority, and the machine takes direction changes without flinching. When we ask for a circle, we get a circle. When we ask for a pocket, it closes properly, not like a shrug.

We also like knowing there’s an easy path to closed-loop stepper motors if we ever want them. The interfaces are there, so when ambition outgrows bravery, we won’t need to redesign the electrical system. It’s a thoughtful nod to longevity.

Workholding and Dust Management: Keeping the Job in Place

We’ve learned that half the battle in CNC is keeping the material from moving, and the other half is getting chips out of the way. This machine’s rigidity helps, but we still plan like carpenters and clamp like sailors.

- For aluminum and brass, we use step clamps or a vise, keep the surface clean, and apply air blast or mist if we’re feeling fancy. The firmware’s M07/M08 support means we can integrate coolant or air control directly into our toolpath.

- For wood and acrylic, we use tape-and-glue when the job allows, or tabs and clamps if we need more security. The machine’s consistent motion makes tabs reliable.

- Dust collection matters. While the X and Y axes have improved dust protection, we still run an external dust shoe for wood and plastics, and an air blast for metals to keep chips moving.

We respect the machine’s motion more when we treat workholding as a first-class citizen. No cutter will ever make up for a wiggly workpiece.

Software Workflow: CAD, CAM, and Control Without Drama

We appreciate compatibility that doesn’t require a secret handshake. Our workflow usually looks like this:

- CAD: Fusion 360 for parametric designs; VCarve for sign-making and wood inlays; Inkscape for simple vector art; LightBurn for laser plans.

- CAM: Fusion 360 and VCarve generate our toolpaths; Easel is handy for quick jobs without fuss; LightBurn handles laser operations gracefully.

- Control: UGS (Universal Gcode Sender) remains a faithful companion, and the ESP3D Web UI steps in when we want wire-free control.

Everything runs on Windows, Linux, or Mac. The machine doesn’t lock us into a single ecosystem. We prefer familiarity over reinvention—our attention belongs on cutters and material, not battling software.

Metal Cutting: Aluminum and Brass, Without Heroics

We’ve cut enough aluminum on hobby-class machines to understand the variables: rigidity, chip load, heat, and modest step-downs. With the CNC Router Machine 4030-Evo Ultra 2, we found that the dual linear rails and ball screws give us a wider margin before the cut deteriorates. We run 1/8″ single-flute carbide bits, keep the RPM in a practical window, and focus on chip evacuation. It’s not a “hog it out” affair; it’s deliberate, steady, and well-supported by the machine’s mechanical confidence.

Brass rewards us with luxurious edges when we lean conservative. We keep the tool engaged, avoid rubbing, and use sharp cutters. With light coolant or air, the machine produces finishes that we’d happily show off closer than arm’s length. The ball screws make a difference in contour fidelity and hole roundness.

We can’t claim it replaces a dedicated industrial VMC (we like our wrists un-slapped by reality), but it slots comfortably into small workshop metalwork. Brackets, nameplates, custom knobs, enclosures, and inlays—these are the sweet spot.

Non-Metals: Wood, Acrylic, and PCBs With Fewer Surprises

If metal is the machine’s proof of backbone, wood and acrylic are where it shows its grace. We’ve cut intricate V-carved signs without fuzz, acrylic letters with clean edges, and plywood panels with pockets that actually measure what we drew.

- Wood behaves beautifully. We push a little harder and enjoy the crisp corners in hardwoods.

- Acrylic demands a balance of speed and chip clearance. Single-flute bits and medium RPM keep the plastic from melting into a philosophical comment on impermanence.

- PCBs remain our favorite “we are clever” moment. A sharp V-bit or small end mill with the included Z probe and careful leveling yields clean traces. We like that the machine has enough repeatability to keep tiny isolation cuts consistent.

Safety and Sanity: E-Stop, Limit Switches, and Good Habits

We appreciate the safety hardware. An emergency stop button is a non-negotiable, and here it’s big and satisfying. XYZ dual limit switches keep the machine honest and help avoid painful collisions. The home switch and included Z probe make setup safer and faster—fewer frantic jogs at the start of a job.

We wear safety glasses, hearing protection, and a stubborn respect for spinning metal. The 800W router is lively. We keep hands clear, long hair tied, and sleeves disciplined. Our pets are banned from the workshop during machining, and not just because they judge our feed rates.

Calibration and Tuning: The Ritual That Pays Off

We like to treat calibration as an act of affection. It takes time, and in return the machine runs smoother.

- Tramming the router: We gently adjust the mount to ensure the spindle is square to the table. Surfacing passes tell us the truth.

- Squaring the gantry: We measure diagonals and jog the machine to confirm orthogonality. The dual linear rails make this a stable affair once set.

- Steps per millimeter: We verify with a dial indicator and adjust only if necessary. The ball screws usually come within a whisper of correct.

- Backlash checks: We cut test pockets and measure. Ball screws keep this minimal; if we see it drift, we investigate couplers or bearing blocks.

- Z probe calibration: We confirm that the probe thickness is correctly accounted for. Nothing sours a job faster than a gouged workpiece on pass one.

We write down our settings. The future version of us is a forgetful creature.

Real Projects We Built and Loved

We like machines that inspire real projects. This one did.

- Aluminum brackets for a small fixture: 6061 plate, 1/8″ single-flute, 0.3 mm step-downs. With air assist, the parts came off accurate and square. We felt like capable adults.

- Brass inlay monogram: Pocketed walnut with a brass inlay cut to fit. Slight chamfer, a tap fit, and an adhesive we now treat like family. The result looked gift-worthy.

- Acrylic signage: Polished edges and crisp corners. We ran a flame pass afterward for a glossy finish and told ourselves we’d planned it.

- PCB prototype: A tiny controller board for a personal gadget. The traces came clean, the drill holes aligned, and we managed to avoid lifting pads. That’s a good day’s work.

Pros and Cons We Actually Noticed

We’re fond of balanced views. Here’s our honest list.

Pros:

- Dual linear rails and 1204 ball screws on every axis give the machine real composure, especially in metals.

- 800W trim router with wide RPM range handles diverse materials with confidence.

- GRBL_ESP32 with GRBL 1.3a brings WiFi, macro buttons, and advanced features like coolant and rotary support.

- NEMA 23 motors provide torque we trust for heavier cuts.

- XYZ dual limit switches, home switch, emergency stop, and Z probe included—excellent safety and workflow basics.

- Pre-assembled components and tidy wiring make setup feel civilized.

- Broad software compatibility on Windows, Linux, and Mac.

Cons:

- Manual speed dial means RPM changes aren’t automatic mid-job; we plan around it.

- It’s still a trim-router-based system; noise is substantial, and we manage heat carefully in metals.

- Work area and expansion options aren’t the machine’s headline (we plan jobs within reasonable bounds).

- Serious metal work benefits from air or mist; we had to add that ourselves, though M07/M08 support helps integrate it.

Who It’s For: The Right Kind of Ambitious

We see this machine as a confident step up for:

- Makers who want reliable metal capability without jumping straight to industrial equipment.

- Woodworkers ready to incorporate precise joinery, inlays, and repeatable parts into their workflow.

- Small labs and prototyping teams that value WiFi control, a stable mechanical platform, and a reasonable learning curve.

- Anyone who wants an expandable controller—laser, rotary, coolant, and closed-loop stepper support—without swapping the brains later.

We think it’s also a great fit for classrooms or maker spaces where the safety hardware, pre-assembly, and durability matter as much as the cutting ability.

Who Should Consider Alternatives

We adore what this machine can do, but we’re not trying to sell illusions.

- If we need heavy metal removal, deep cuts, or long production runs in steel, we’d look for a higher-power spindle and a heavier frame.

- If we demand automatic spindle RPM control through G-code, we’ll either adapt or seek a VFD spindle solution.

- If silence is important, no trim-router machine will make us happy; we’d need sound management or different tooling.

Maintenance: The Small Things That Keep It Great

We keep rails and ball screws happy with periodic cleaning and light lubrication, as recommended for linear motion components. Dust is an enemy; we brush, vacuum, and avoid packed chips. We check couplers, bolts, and mounts after the first week of use and again monthly. If a cut starts to sound different, we investigate. A little attention here saves cutters, materials, and patience.

We also back up settings and document our workflow. Nothing beats a repeatable process when we return to a job months later.

Troubleshooting: The Familiar Gremlins and Our Fixes

We’ve met these characters before:

- Chatter or poor finish: Slower feed, lower step-down, higher RPM within a safe range, or a stiffer workholding setup. We also check that the router is trammed and the material is flat.

- Inaccurate pocket sizes: Confirm tool diameter, check for runout, and verify steps per millimeter. We also perform a finishing pass at a lighter cut.

- Melting acrylic: Use a single-flute bit, increase chip load, keep chips clear, and avoid rubbing at high RPM.

- Aluminum welding to the tool: Increase chip evacuation, reduce RPM or increase feed slightly, and use a lubricant or air blast.

- Lost steps: Check for over-aggressive accelerations, binding in motion, or under-tight belts/couplers (though belts are not the primary motion here, we still inspect couplers and screws). NEMA 23 torque helps, but settings matter.

Using the Macro Button and Touch Probe: Small Wins

The default macro button homes the machine with a single press, and we love that simplicity. Reprogramming it to pause or to run a favorite G-code routine from SD gives us a comfort level that feels “shop-grade.” The included Z probe tool eliminates the guesswork from tool length zeroing. With the 3-pin touch probe support in the firmware, we can bring our workflow closer to push-button reliable.

We didn’t realize how much time we spent doing small chores until the chores were gone.

A Few Practical Cutting Recipes We Return To

These aren’t commandments—just combinations that won our trust:

- 6061 Aluminum with 1/8″ single-flute: 12,000 RPM, 0.3 mm step-down, 800–1200 mm/min feed, light finishing pass; air blast for chip control.

- Brass with 1/8″ 2-flute: 12,000 RPM, 0.2–0.3 mm step-down, patient feeds, minimal dwell; a touch of coolant if we have it.

- Walnut sign, 60-degree V-bit: 18,000 RPM, moderate depth; finish pass with reduced feed for crisp detail.

- Acrylic letters, 1/8″ single-flute: 16,000 RPM, 0.5 mm step-down, aggressive chip clearance; flame polish if desired.

We always test on scrap. It makes us brave later.

The Learning Curve: Friendly, Not Flat

This machine respects our time. The pre-assembly, labeled cabling, and thoughtful inclusion of the Z probe and limit switches mean we’re not solving basic puzzles before making chips. The ESP3D interface and standard GRBL ecosystem keep the lights on for common workflows. It still demands attention—we’re cutting real materials with real forces—but the process feels coherent.

We also like that the machine grows with our curiosity. Laser support, 4th axis capability, coolant integration, and closed-loop stepper compatibility make this more than a one-season purchase.

Value: Where the Money Goes, and Why We’re Fine With It

We can feel where the budget landed:

- Dual linear rails and ball screws for each axis aren’t cheap or performative—they’re where accuracy begins.

- NEMA 23 motors make a meaningful difference in holding power and cut stability.

- The GRBL_ESP32 setup with WiFi and macros keeps us future-ready and spares us a controller upgrade down the line.

- Safety hardware included—e-stop, limits, Z probe—means accessibility without nickel-and-dime add-ons.

We’ve built and run lighter-duty machines. They’re fine for balsa and dreams. This one handles aluminum and brass with sensible settings, gives us gorgeous results in wood and acrylic, and makes PCBs a happy weekend project. The value equation makes sense if we care about precision as much as possibility.

What We’d Add to Make It Sing

We’re perfectly satisfied out of the box, and still we’re tinkerers:

- Air blast or mist coolant to take advantage of M07/M08. It’s a game-changer for metal.

- A set of sharp single-flute bits for plastics and aluminum, and a small collection of 2-flute end mills for brass and wood.

- A simple tramming gauge for peace of mind.

- A vise or modular clamps that make repeat setups painless.

- An external dust shoe for wood and acrylic, and a shop vacuum that doesn’t lose its will to live.

Day-to-Day Use: What We Notice After the Honeymoon

We start to trust a machine after we mess up and it forgives us. This one forgave a rushed clamp, gave us a second chance on a paused job, and kept its squareness after we nudged the gantry by hand in a moment of confusion. The limit switches save our nerves, the e-stop sits there like a seatbelt, and the Z probe eliminates the kind of micro-errors that snowball into regrets.

The noise is real, because trim routers sing. We run during civilized hours, share the shop with ear protection, and keep the neighbors on the good side with free gifts—a lovely walnut key holder goes a long way.

Where It Shines, Plain and Simple

We reach for this machine when:

- We need aluminum parts that fit together without drama.

- We want wood inlays and V-carves with crisp detail and minimal sanding.

- We aim for acrylic signage that looks store-bought, not school-project.

- We’re prototyping a PCB and want to skip the etching mess.

It’s the dependable middle ground between featherweight hobby toys and industrial giants. We respect that space.

Closing Thoughts: Our Verdict on the 4030-Evo Ultra 2

We came to the CNC Router Machine 4030-Evo Ultra 2 with polite expectations and left with a more organized shop and a suspiciously proud stance. The all-metal XYZ axes with dual HGH-15 linear rails and 1204 ball screws give it the backbone to handle aluminum and brass without flinching. The 800W trim router with ER11-1/8″ collet covers the RPM range we need, and the software-controlled run/stop keeps life orderly.

GRBL_ESP32 with GRBL 1.3a and ESP3D Web UI feels modern. WiFi control, macro reprogramming, laser and 4th axis support, M07/M08 coolant commands, closed-loop stepper compatibility, and a 3-pin touch probe interface turn the control board into a friendly co-conspirator. NEMA 23 motors and included safety hardware—XYZ dual limit switches, home switch, emergency stop, and Z probe—complete a package that feels complete rather than cobbled.

We’d describe the machine in three words: rigid, capable, approachable. It’s for makers who want to cut metals responsibly, get excellent results in wood and plastics, and build a repeatable workflow that doesn’t require wizardry. We plan to keep it busy, keep it clean, and keep pretending we had this level of organization the whole time.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.