Have we ever wished we could personalize a gift without learning an entire trade or turning the kitchen into a sawdust sculpture?

Why We Reached for the ATOMSTACK P1 5W

We were looking for a laser engraver that didn’t make us feel like we needed a PhD or a fire extinguisher at the ready. The ATOMSTACK P1 5W Laser Engraver, Laser Cutter, Unibody Laser Engraving Machine, 10000 mm/min, 5000mW Diode for Beginners DIY, Wood, Leather, Acrylic, Metal, Portable, Single Laser, Class 1 Safe promised to be simple, safe, and actually fun.

What we wanted was something compact, plug-and-play, not intimidating, and safe for the home or office. What we found was an oddly charming machine that did what it said: it got us engraving within minutes, without the usual dread.

ATOMSTACK P1 5W Laser Engraver, Laser Cutter, Unibody Laser Engraving Machine, 10000 mm/min, 5000mW Diode for Beginners DIY, Wood, Leather, Acrylic, Metal, Portable, Single Laser, Class 1 Safe

$219 Only 20 left in stock - order soon.

What This Machine Is (and What It Isn’t)

The ATOMSTACK P1 is a compact, enclosed diode laser engraver rated at 5W output power. It arrives ready to use—no toolkits, no belt tensioning, and no tense arguments about what “square” means in assembly instructions.

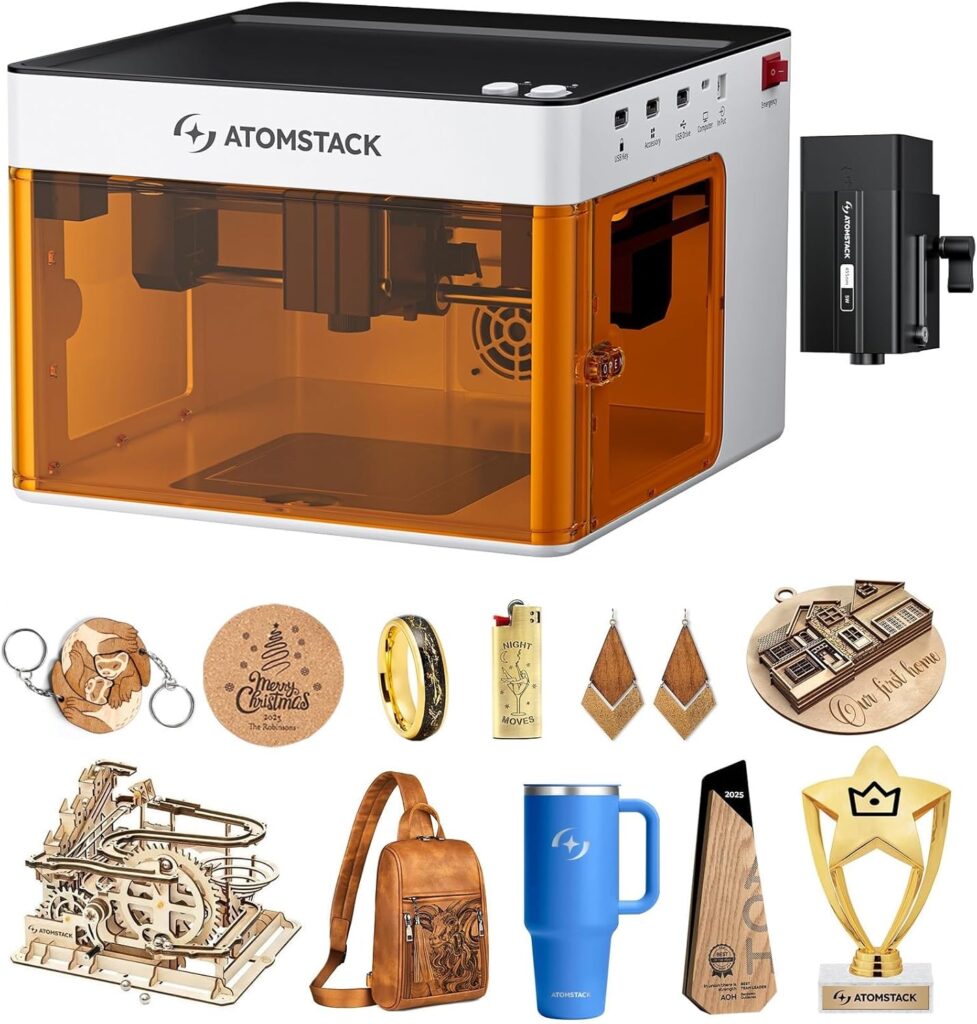

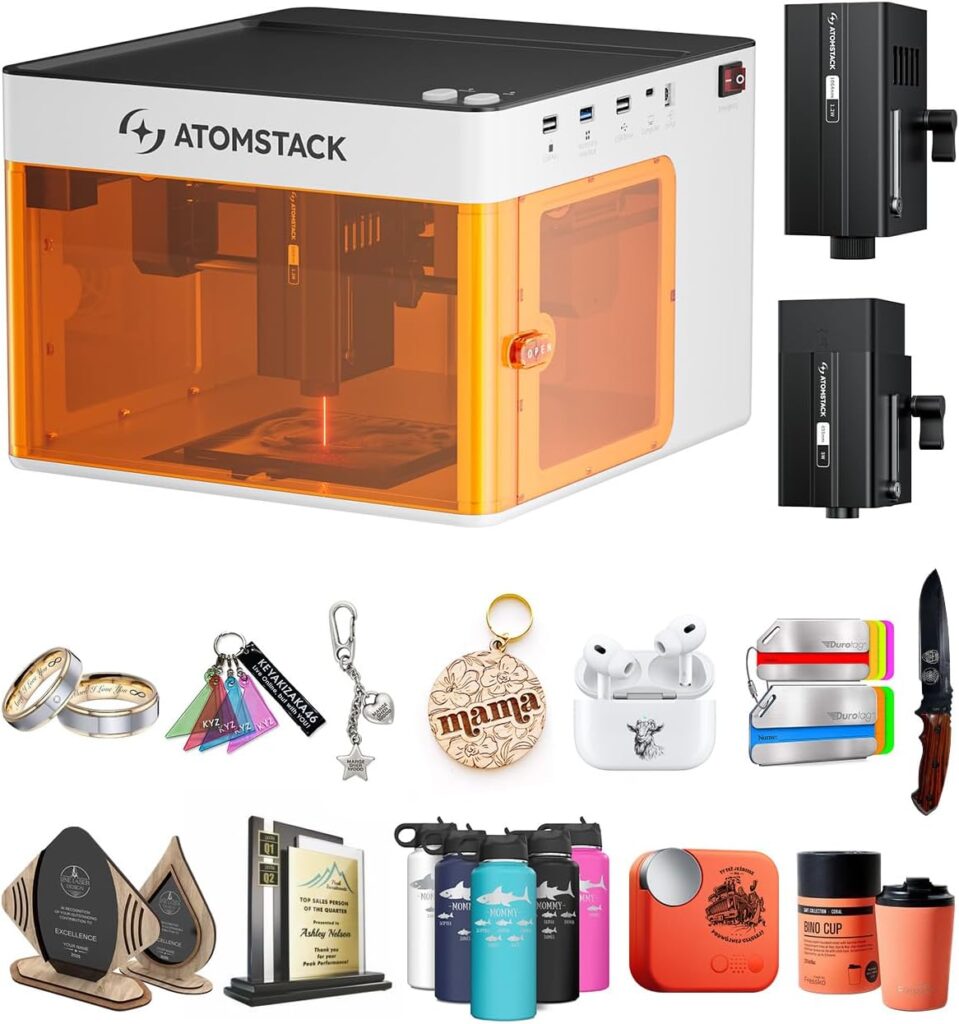

It’s designed for small projects: coasters, wallets, pet tags, ornaments, phone cases, small signage, and thoughtful gifts that don’t look like they came from a craft store. With a 110×110mm working area and max object height of 50mm, it plays in the small-to-medium arena—and it plays very well.

Setup in Minutes, Not Hours

We powered it on, signed into the AtomStack software, and engraved a test design before the coffee cooled. That’s not our usual speed.

The built-in fixed-focus rod makes focusing almost foolproof. Place the object, flip down the focus rod, set height, and you’re good. No guessing, no measuring twice, no cutting once. It’s refreshing, like a blender with exactly one button.

The Safety Story: Class 1 and Actually Tidy

This is the world’s first entry-level Class 1 laser engraver. Translation: the enclosure and safeguards are robust enough that during normal operation, we didn’t need goggles. There’s a viewing window that lets us keep an eye on things without peering through sunglasses indoors like a questionable celebrity.

The safety features are plentiful: fully enclosed shell, auto-shutdown if the machine tilts, enclosure detection so it knows if someone opens it mid-job, and a USB safety lock to keep unauthorized hands (or curious kids) from experimenting. It feels thoughtfully engineered for living rooms, offices, and classrooms instead of a bunker.

Design and Build: Small, Unibody, and Surprisingly Sleek

At around 3kg (about 6.7 lbs), the P1 is easy to reposition or take with us for a workshop day. The unibody construction gives it a solid, rattle-free feel. It doesn’t command the desk like a big industrial machine; it politely borrows a corner.

The CoreXY motion system with dual motors keeps movement precise and smooth. We noticed it immediately in how clean diagonal lines looked—less wobble, more confidence.

Precision That Makes Small Things Look Remarkably Good

We tested the advertised 0.06mm ultra-fine engraving claim by etching small vector artwork and QR codes. The results? Impressively crisp lines and readable QR codes. Positioning accuracy of 0.1mm meant we felt safe doing multi-pass engravings without the dread of misalignment.

At up to 10,000 mm/min, it moves quickly. Cutting 3mm basswood in one pass worked as promised when we matched the speed and air assist sensibly. For engraving, we could run faster and still retain detail. It gave us that satisfying feeling of efficiency without feeling reckless.

The Table We Wish We Had on Day One

We don’t all start as laser whisperers, and it’s easy to get lost in settings. Here’s a quick-reference table with starting points we found useful. Your material and finish will vary—think of this as a launchpad.

| Material | Action | Power (%) | Speed (mm/min) | Passes | Notes |

|---|---|---|---|---|---|

| Basswood (3mm) | Cut | 100 | 600–900 | 1 | Use air assist or good ventilation; slow for cleaner edges |

| Basswood (3mm) | Engrave | 35–55 | 4000–6000 | 1 | Good for logos and patterns |

| Bamboo | Engrave | 40–60 | 4500–6000 | 1 | Grain darkens beautifully |

| Leather (veg-tan) | Engrave | 20–40 | 5000–7000 | 1 | Masking tape reduces scorching |

| Cardboard | Cut | 60–80 | 1500–2500 | 1–2 | Watch closely; edges can char |

| Cork | Engrave | 30–50 | 4000–6000 | 1 | Soft material, great contrast |

| Anodized/Coated Metal | Mark | 60–90 | 2000–4000 | 1 | Not for bare reflective metals |

| Dark Opaque Acrylic | Engrave | 50–80 | 2000–3500 | 1 | Diode lasers don’t cut clear acrylic well |

| Fabric/Felt | Engrave | 15–30 | 6000–9000 | 1 | Test small patch first |

| MDF (2–3mm) | Cut | 100 | 400–800 | 1–2 | Watch for smoke; slow and steady |

These numbers are meant to prevent a headache, not prescribe every job. Always test a small corner and adjust. We learned more in two hours of playful testing than a week of guessing.

The Software Experience: Beginner-Friendly Without Feeling Trapped

We’ve used our share of confusing CNC software. The AtomStack app is not one of them. It’s available for Android, iOS, Windows, and macOS, and it’s reasonably intuitive. We drew, imported, tweaked, and started jobs without deciphering a secret code.

The software includes a big library of materials—over 1,000 profiles—and automatic accessory recognition, which sounds like the machine saying, “I see you attached a rotary tool; I’ll behave accordingly.” It’s a gentle nudge in the right direction when we’re uncertain.

If we prefer familiar third-party tools, it plays nicely with LightBurn and LaserGRBL (licenses not included). We appreciate options. Some days we want simple. Other days we want every knob available.

Connectivity: Phone-to-Engraver in Minutes

We launched our first job from the phone, sitting three feet away, mostly because we could. Uploading a design via the AtomStack app felt pleasantly modern. For fancier jobs, we kicked over to the PC. It’s nice to have both pathways; not everything needs a laptop.

Materials: What It Can and Can’t Do

The ATOMSTACK P1 handles wood, bamboo, paper, leather, cardboard, cork, rock, felt, fabric, MDF, coated metal, and some dark opaque acrylic. For small keepsakes, nameplates, coasters, and practical labels, it’s ideal.

Two important caveats:

- Reflective or bare metals are not appropriate for engraving with this diode laser. Coated or anodized metals are fine for marking; shiny stuff is not our friend here.

- Clear or light acrylic typically doesn’t absorb diode laser light effectively. Stick to dark, opaque acrylic for best results.

Projects We Actually Enjoyed

We engraved a leather wallet with initials—deep enough to feel, tidy enough to look store-bought. Coasters became a canvas for jokes we’ll deny writing. A bamboo cutting board took a recipe engraving along one side and suddenly looked like it had a story to tell.

QR codes for Wi-Fi credentials impressed our most skeptical friends. Pet tags looked delightfully official. And a layered acrylic sign turned out better than we expected, particularly with the 0.06mm fine detail on thin lines.

Class 1 Safety, in Practice

We’re not cavalier with lasers, and we don’t recommend anyone else be either. That said, the Class 1 classification allowed us to operate the machine normally without extra eyewear. The enclosure, tilt detection, and automatic shutoff reduced the low-level anxiety we’d grown used to with open-frame machines.

We still ventilated the area. We still stayed nearby while it ran. But we spent more time designing and less time grimacing.

Cutting vs. Engraving: The 5W Reality

A 5W laser is not a lumberjack; it’s a skilled illustrator with a utility knife. It cuts thin woods like 3mm basswood in a single pass and can handle MDF or thicker material with slower speeds or multiple passes.

For engraving, it shines. Logos, photos, patterns, and text come out sharp, with good tonal control. To our eyes, this machine is primarily an engraver that can also cut thinner materials—perfect for most hobby needs and many small business products.

A Word on Photos and Fine Art

Photo engravings on wood and anodized metal are often the acid test. We preprocessed images for contrast and dithering in LightBurn and fed them into the P1. The result was detailed enough to make a seasoned hobbyist nod thoughtfully. We could capture facial features, hair texture, and shadows without that muddy, charred look that ruins subtlety.

If portraits are our goal, a little practice with image prep pays off. Process the image, test small, and note the speed and power that give a smooth gradient rather than harsh edges.

Size Constraints and Creative Workarounds

The 110×110mm work area might sound small until we think in terms of objects: pendants, patches, mugs, phone cases, badges, ornaments, coasters, notebook covers, nameplates, and tiny signage all fit within that footprint.

We got creative by tiling longer designs—moving the object and re-indexing for a second pass. It’s not as fast as a larger bed, but the precision makes it doable when a longer design is worth the effort.

Rotary Add-Ons and What They Unlock

With an optional rotary accessory, we could wrap text and graphics around mugs, tumblers, bottles, and even baseballs. Cylindrical engraving turns a one-dimensional logo into a small piece of theater. It’s the difference between a flat bookmark and a 360-degree story.

The machine recognized the accessory through the software, which saved us from manual gymnastics. If personalization is our business, rotary capability is a quiet superpower.

Air Management: Purifiers and Practicality

Smoke and odor are facts of life with lasers. The optional air purifier is not a gimmick; it’s a courtesy to our lungs and our neighbors. In a small room, we noticed how quickly the purifier made the session feel more like a craft and less like grilling indoors.

Even with the purifier, basic ventilation is wise. Engraving different materials creates different fumes, and we prefer breathing things that don’t smell like campfire glue.

Noise, Vibration, and Domestic Harmony

At full speed, the P1 hums but doesn’t shout. The CoreXY motion system and unibody frame dampen the rattling that made our older machine sound like a rolling suitcase on cobblestones. We carried on a conversation at normal volume, though the occasional beep did make the cat file a complaint.

The Learning Curve We Actually Enjoyed

We played with test cards—small squares of material with a grid of settings—and the P1 rewarded us with clear differences between each square. Seeing how a 10% bump in power or a 500 mm/min speed change affected results made us feel less like we were gambling.

After a weekend, we had a little library of “known good” settings for common materials, which made subsequent projects go smoothly.

Classroom and Workshop Friendliness

For teaching environments, the safety features alone make this enticing. Class 1 rating, enclosure detection, tilt auto-shutdown, and a visible viewing window add up to a machine we would use in front of students without breaking into a sweat.

The interface is approachable. The results are quick enough to satisfy the short attention spans that come with learning something new. And USB safety lock helps maintain control over who’s doing what.

Small Business Use: Where It Fits

If we’re running an Etsy shop or a local booth selling personalized gifts, this machine earns its space. It’s reliable for small, repeatable jobs: leather patches, wooden coins, custom coasters, keychains, ornaments, bag tags, nameplates, and branded packaging.

For bulk cutting of thick materials, we’d look to a higher-wattage model. But for variety, detail, and small objects, the P1 makes a convincing case. And because it’s portable, we can bring it to on-site events or pop-up demos.

Power, Speed, and the CoreXY Confidence

We noticed fewer artifacts in diagonal lines than we’ve seen with simple belt-and-rail setups. The dual-motor CoreXY architecture keeps the head movement precise, especially at higher speeds where wobble tends to creep in.

On materials that benefit from speed—like light engravings or certain dithered images—we got sharper results because the motion system stayed steady.

Maintenance and Everyday Care

It’s easy to keep tidy. We brushed residue off the honeycomb or bed (depending on setup), wiped the viewing window, and checked the lens for smoke microbuild-up. For repeat cutting, air assist helps keep edges clean and the lens happier.

A quick maintenance loop:

- Inspect lens and clean gently with appropriate wipes

- Check that the fixed-focus mechanism flips and locks smoothly

- Vacuum or brush debris from the bed

- Keep rails dust-free

- Confirm the enclosure latch is snug and sensors respond

Nothing felt fussy or fragile. The unibody design means fewer alignment moments and more making.

When Things Go Sideways

We tried lifting the unit mid-run (purely for science), and the tilt shutoff worked. Opening the enclosure mid-job also triggered a pause. These aren’t parlor tricks—they save workpieces and sanity.

If settings seemed off, we ran a calibration test to verify focus and steps. The machine held its squareness and accuracy, which isn’t glamorous but is essential.

Expanding with Accessories and Upgrades

The ecosystem matters. AtomStack’s optional rotary tool, air purifier, and jigs help extend the P1 beyond flat, small pieces. Because the machine recognizes accessories automatically in the software, we spent less time troubleshooting.

We also like that the P1 is compatible with LightBurn. Even if we start with the free AtomStack software, it’s comforting to know the machine won’t outgrow us.

The Warranty and Support That Make Risk Feel Smaller

The P1 comes with a 365-day warranty and 24/7 support. AtomStack says they respond within 6 hours via the Amazon platform, which is good, because when things go wrong, “48-72 business hours” feels like a geological epoch.

Being sold in over 50 countries means the user base is large enough to crowdsource advice. We found tips and tricks shared by users who were clearly having as much fun as we were.

Comparing 5W to Bigger Lasers We’ve Used

We’ve used 10W and 20W diode lasers, as well as CO2 machines. Here’s where the P1 stands out:

- Safety and simplicity: Class 1 enclosure with beginner-friendly features beats open-frame tinkering any day for home settings.

- Engraving detail: It holds its own on fine work. Photos and small text look excellent.

- Cutting thickness: It’s not meant for thick hardwoods or acrylic sheets. Accept its limits and it excels.

If we plan to cut 6–8mm wood all day, we’d choose a more powerful machine. If we want to personalize and prototype with precision, this one’s delightful.

Real-World Performance: The Truth in Numbers

We hit 10,000 mm/min on engravings that didn’t require deep burns and were pleasantly surprised that the lines stayed clean. On darker woods, we pulled back the speed or increased power to hit the contrast sweet spot.

The claimed 0.06mm engraving line width felt accurate in practice when using well-prepared vector files. The difference is noticeable on delicate lettering, fine filigree, and intricate borders.

Quality-of-Life Notes We Appreciated

- The viewing window reduces anxiety—we can see progress and catch mistakes early.

- The USB safety lock is comforting in shared spaces.

- The fixed-focus rod improves the “I didn’t do this right” odds.

- Auto accessory recognition reduces software fidgeting.

Tiny things add up to an experience that feels thought through rather than cobbled together.

Things We Wish Were Different

No product is perfect. We have a short wish list:

- A slightly larger work area would open up more signage and art projects.

- A bundled air purifier would make the kit feel more complete out of the box.

- Default cut profiles could be more conservative for beginners to avoid accidental overburn.

None of these are dealbreakers. They’re more like dreams we write on a napkin and leave where the engineers might see it.

Tips That Saved Us Time (and Materials)

- Masking tape on wood or leather reduces scorch marks; peel after engraving for cleaner lines.

- Photo engraving: preprocess in software to control contrast and dithering; don’t rely on auto.

- Keep a settings notebook or digital doc. Future us is grateful every time.

- Dark, opaque acrylic works best; avoid clear or lightly tinted acrylic with diode lasers.

- Test on scraps. Two minutes of testing beats forty minutes of regret.

- Ventilate, even with the purifier. Comfort equals longer sessions and better results.

A Few Favorite Project Ideas

- Personalized coasters with coordinates of a special place

- Leather patches for hats or bags with a minimalist logo

- QR code plaques for Wi-Fi, digital menus, or personal portfolios

- Pet tags with a micro-engraved phone number on the back

- Mini signage for events, dessert buffets, or craft fair displays

- Stylized recipe engraving on bamboo cutting boards

- Custom phone case backplates with fine patterns or monograms

Each of these fits easily in the P1’s work area and takes advantage of the precision.

Who This Machine Is For

- Beginners who want safety and ease, not a semester of setup

- Hobbyists who love detail and small project variety

- Small businesses selling custom goods that fit within the 110×110mm area

- Educators who need reliable safety features and quick visual results

- Makers who prefer a tidy, portable machine to a sprawling workshop footprint

If we want heavy-duty cutting or large format signage, it’s not a match. If we crave convenience, detail, and a quick path from idea to finished object, it’s a strong fit.

The Warranty and Global Presence, Revisited

It matters that support is responsive and that parts, accessories, and advice are findable. The 365-day warranty and 24/7 support give confidence to learners and tinkerers alike. We like knowing that if something goes strange, we’re not stranded.

Being sold in over 50 countries isn’t just a brag; it means when we search for “best P1 settings for cork,” we probably won’t be alone.

Common Questions We Had (and Figured Out)

Do we need safety goggles?

Under normal, enclosed operation, no. This is a Class 1 laser system with a protective shell and viewing window. If we defeat the enclosure or perform maintenance with the shell open, protective eyewear appropriate for the diode’s wavelength is wise.

Can it engrave metal?

It can mark coated or anodized metals. Bare, reflective metals are not suited for engraving with this diode laser. We got great results on anodized aluminum tags.

Will it cut thick wood?

It will cut thinner woods like 3mm basswood in one pass. For thicker material, we needed slower speeds, multiple passes, or a different machine.

Is it noisy?

No. It hums rather than howls. We’ve had louder dishwashers and quieter fans.

Can we use it with LightBurn?

Yes. It’s compatible with LightBurn and LaserGRBL (licenses purchased separately). The AtomStack software is free and a good starting point.

How portable is it?

Very. At about 3kg, we moved it between rooms or events without grumbling.

What about smell and smoke?

It’s a laser. There’s smoke. Use good ventilation, and consider the optional AtomStack air purifier for comfort.

How quickly can we start?

Realistically within minutes. Plug it in, focus using the built-in rod, load software on a phone or PC, and press go.

Our Favorite Things About the P1

- Safety features that are practical, not performative

- Clean, detailed engraving on small objects

- Simple setup and reliable autofocus

- CoreXY motion that keeps detail crisp even at speed

- Compatibility with both free and pro software

- Portable, tidy, and living-room friendly

We found ourselves firing it up on a whim to try an idea. That spontaneous creativity is a big deal.

Limitations Worth Respecting

- The 110×110mm area is intentionally compact—great for small goods, limiting for large art

- 5W power is not meant for thick material cutting marathons

- Clear acrylic and bare reflective metals are off the menu

- We’d love a bundled air assist and purifier, even as a higher-tier package

Accept these boundaries and the machine rewards us with consistency.

A Short Case Study: From Sketch to Sale

We designed a set of coaster patterns with a simple geometric motif. After a 30-minute test session dialing in settings on basswood and cork, we batch-engraved a dozen in under an hour. Edges were clean, lines were precise, and the result looked boutique rather than “handmade” in the uneven sense.

We priced them reasonably, and they sold. The customer asked if we could add initials next time. We smiled because, of course, we could.

Safety Sidebar: Practical Habits We Keep

- We never leave it running unattended, even with auto-shutdown features

- We ventilate the space and consider the air purifier essential for frequent use

- We keep a small fire blanket nearby because being prepared is not the same as being worried

- We avoid engraving any material we can’t identify, especially plastics that may off-gas harmful fumes

These aren’t rules to dampen enthusiasm. They’re how we keep making things comfortably.

Performance Over Time

After weeks of use, we saw no shift in alignment. The integrated frame and low-maintenance motion system helped. Lens cleaning intervals depended on our material choices; wood cutting sessions are messier than light leather engraving days.

Nothing creaked. The door latch held firm. We never once said, “Where did that rattle come from?”

What Surprised Us Most

We expected “entry-level” to mean “you’ll buy the real thing later.” Instead, the P1 felt like the real thing for the projects we most enjoy—thoughtful, detailed, giftable items that people actually keep.

We also expected the software to be the weak link. It wasn’t. The free AtomStack app is approachable, and compatibility with LightBurn expands capabilities without forcing us into a corner.

Value: What Our Money Bought Us

For the price of a mid-tier smartphone, we got a machine that let us personalize almost anything flat and small, with professional detail. Add a rotary, and we extended that to cylinders. Add a purifier, and we sliced the smell out of the equation.

We saved time by not assembling or tinkering with the hardware. We saved stress by leaning on Class 1 safety features. The rest of the value came from the little projects that turned into grins, gifts, and the occasional sale.

If We Could Whisper to Our Past Selves

- Start with wood and leather; they teach you a lot, quickly

- Try a stencil project to understand edge quality

- Take photos of your settings and results to build a visual library

- Keep projects small at first; let precision be your party trick

- Don’t be shy about using the support resources—AtomStack’s team is responsive

We would have learned faster if we’d dropped the fear sooner.

The Fine Print That Helps Us Sleep

- Laser output: 5000mW

- Laser classification: FDA Class 1

- Max speed: 10,000 mm/min

- Work area: 110×110mm

- Max object height: 50mm

- Weight: ~3kg (6.7 lbs)

- Motion: CoreXY with dual-motor drive

- Positioning accuracy: 0.1mm; engraving line width down to 0.06mm

- Software: AtomStack app (Android/iOS/Windows/macOS); compatible with LightBurn and LaserGRBL

- Safety: Fully enclosed, enclosure detection, tilt auto-shutdown, USB safety lock, viewing window

- Supported materials: wood, bamboo, paper, leather, cardboard, cork, rock, felt, fabric, MDF, coated metal, some dark opaque acrylic (avoid reflective metals or clear acrylic)

On paper, those numbers are tidy. In practice, they translate to confidence.

Pros and Cons, as Honest as We Can Be

Pros

- Truly beginner-friendly with real safety engineering

- Engraving quality that flatters detailed designs and small type

- Portable and quiet enough for home use

- Solid CoreXY motion for stable lines at speed

- App is easy; advanced software options are available

- Great for classrooms and workshops

- Responsive support and a global user community

Cons

- Small work area; not suited for big signage

- 5W power limits thicker cutting

- Air purifier and rotary accessories cost extra

- Clear acrylic and bare metals are not compatible engraving targets

For our use—small, detailed, frequent projects—the trade-offs are more than acceptable.

Our Verdict: A Friendly, Capable Companion for Creative Work

The ATOMSTACK P1 5W is the rare machine that makes us feel clever rather than cautious. It’s safe without being smothering, precise without being prickly, and compact without feeling compromised. We set it up, we made things we liked, and we kept making more.

If we want a machine for small, polished projects, for personalized gifts, for classroom demonstrations, or for a modest but meaningful side hustle, this is a wonderful fit. It’s the kind of tool that nudges us toward new ideas because the friction is gone.

We began with a simple question: could we make something lovely without fuss? With the P1, the answer was yes—again and again, one tidy line at a time.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.