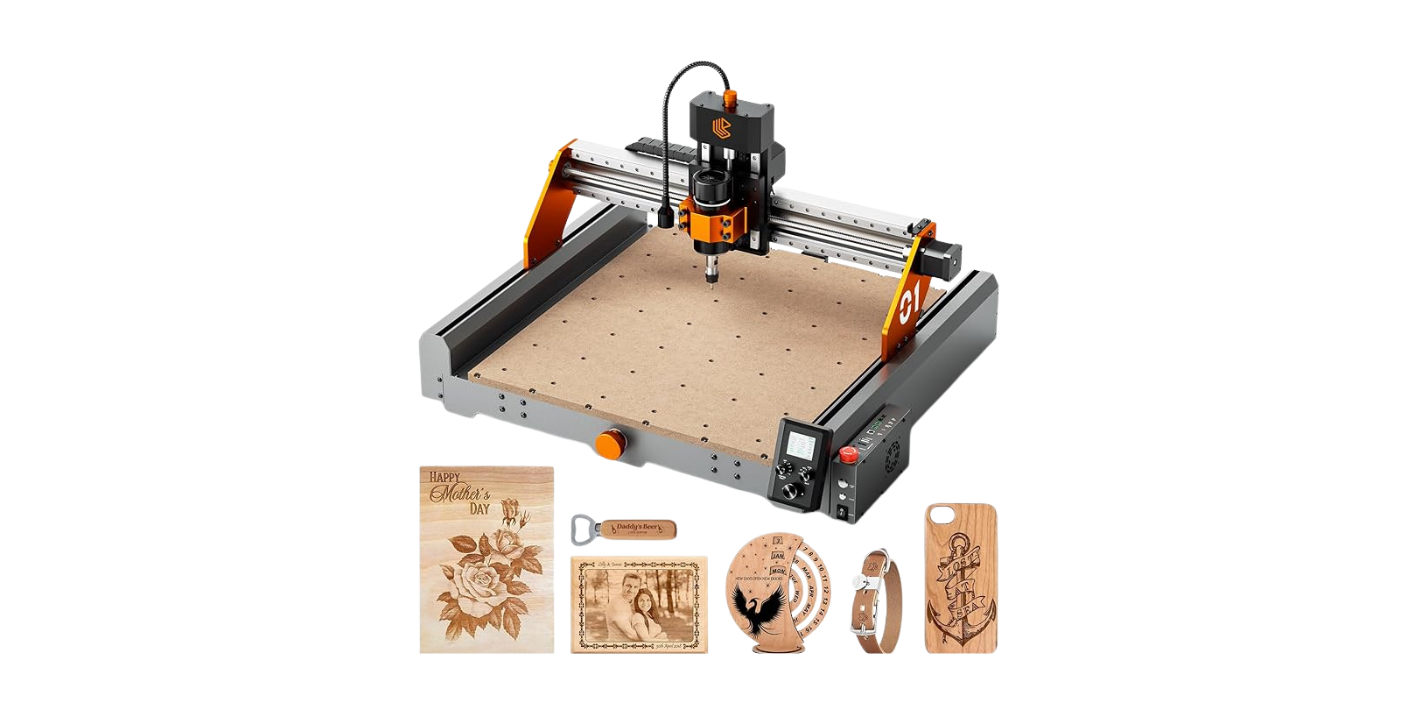

Have you ever stood in a shop and wondered how a machine the size of a small refrigerator could carve things to tolerances so fine you start to question whether your ruler is emotionally prepared for precision?

Inside The CNC Revolution: How 2026 Machines Achieved Sub-Micron Accuracy

You’re about to follow the story of how CNC machines crossed an invisible finish line between “very accurate” and “sub-micron accurate,” and why that matters for whatever you make — whether it’s lenses that laugh at light, medical implants that behave like tissue, or tiny aerospace parts that would make Swiss watchmakers blush. Read this like a long conversation with a slightly sarcastic expert who knows the field and assumes you’ve already been inconvenienced by at least one misaligned fixture.

What “sub-micron” means and why it mattered in 2026

You know a millimeter. A micron is one-thousandth of that. Sub-micron means less than one micron — tolerances measured in fractions of a millionth of a meter. To you, that might sound like insisting your coffee be served at an angle of 0.0001 degrees, but in optics, semiconductors, and advanced metrology that precision is the difference between something that works splendidly and something that is discarded with the despair reserved for overcooked soufflés.

Sub-micron accuracy became more than a bragging right by 2026 because industries demanded tighter form and fit, and because measurement tools finally stopped lying to you with plausible deniability.

How sub-micron accuracy compares across everyday scales

You can use this table as a practical anchor when your hands begin to sweat at the mention of 0.5 µm.

| Object or scale | Approximate size | Comparison |

|---|---|---|

| Human hair | 50–100 µm | Roughly 100x larger than 1 µm |

| Red blood cell | ~7 µm | ~7 times larger than 1 µm |

| 1 micron (1 µm) | 1 µm | 0.001 mm |

| Sub-micron target | <1 µm< />d> | Smaller than most microbes; relevant to optics & semiconductors |

| Atomic scale | 0.1 nm (0.0001 µm) | Orders of magnitude smaller; not the target here |

The state of CNC before the final push (pre-2024): limitations you might remember

Your shop probably reached respectable tolerances long before 2026, but several stubborn errors kept you from sub-micron territory. They read like a litany of small betrayals:

- Mechanical backlash and stick-slip from screw drives and linear guides.

- Thermal drift as spindles and bearings warmed up, betraying your careful alignment.

- Encoder resolution limitations that turned precise intent into fuzzy execution.

- Surface vibrations from external sources — trucks, HVAC, your coworker’s dramatic heel taps.

- Tool deflection and wear that quietly shifted geometry mid-run.

You could mitigate many of these, but mitigation felt like trying to herd cats while baking a soufflé — possible, but messy.

Breakthrough technologies that made sub-micron routine by 2026

By 2026, several technologies matured and assembled into a package you could actually buy and rely on. Here’s what changed and why it mattered to you.

Summary table: key breakthroughs and their role

| Technology | Practical benefit | Why you care |

|---|---|---|

| Linear encoders (nanometer-class) | Real-time position feedback at sub-micron resolution | You can control position with honesty |

| Direct-drive linear motors | Fewer mechanical linkages = less backlash | Motion is faithful to commands |

| Air bearings & hydrostatic guides | Near-frictionless motion with minimal wear | Smoothness reduces stick-slip & hysteresis |

| Advanced thermal control | Active cooling, materials with low CTE, ambient conditioning | Shapes don’t wander as temperature changes |

| AI-driven error compensation | Predictive corrections based on models and sensors | Errors get corrected before you notice |

| Integrated in-process metrology | Measure-while-you-machine | You correct issues in real time |

| Additive monolithic structures | Reduced assembly-induced misalignments | Greater inherent rigidity & stability |

| Quantum-enhanced or enhanced interferometers | Higher sensitivity metrology | You measure the truth, not a best guess |

Linear encoders and position feedback

You want to know where the tool actually is, not where a ball screw thinks it should be. High-resolution linear encoders, mounted directly on the motion axis, removed much of the historical uncertainty. By 2026 these were available with nanometer-class resolution, low latency, and industrial-grade robustness.

Direct-drive linear motors

Cut out the mechanical transmission chain and you cut out the noise it introduced. Direct-drive linear motors gave you force where you needed it exactly, and with control loops tight enough that the motor’s behavior was nearly identical to the command signals you sent.

Air bearings and hydrostatic guides

Those dreamy, frictionless motion systems became practical as manufacturers solved sealing and contamination problems. You got motion that didn’t age the way ball screws did; instead, it behaved the same way for months, sometimes years, and that consistency is the secret sauce.

AI-driven control and predictive compensation

You might suspect that relying on machine learning to correct errors feels a little like letting your dog finish your crossword. It worked because models were trained on real physics, not just patterns. Neural controllers began to predict thermal expansion, tool wear, and vibrational coupling — nudging commands in advance so the final geometry showed up correct on the first try.

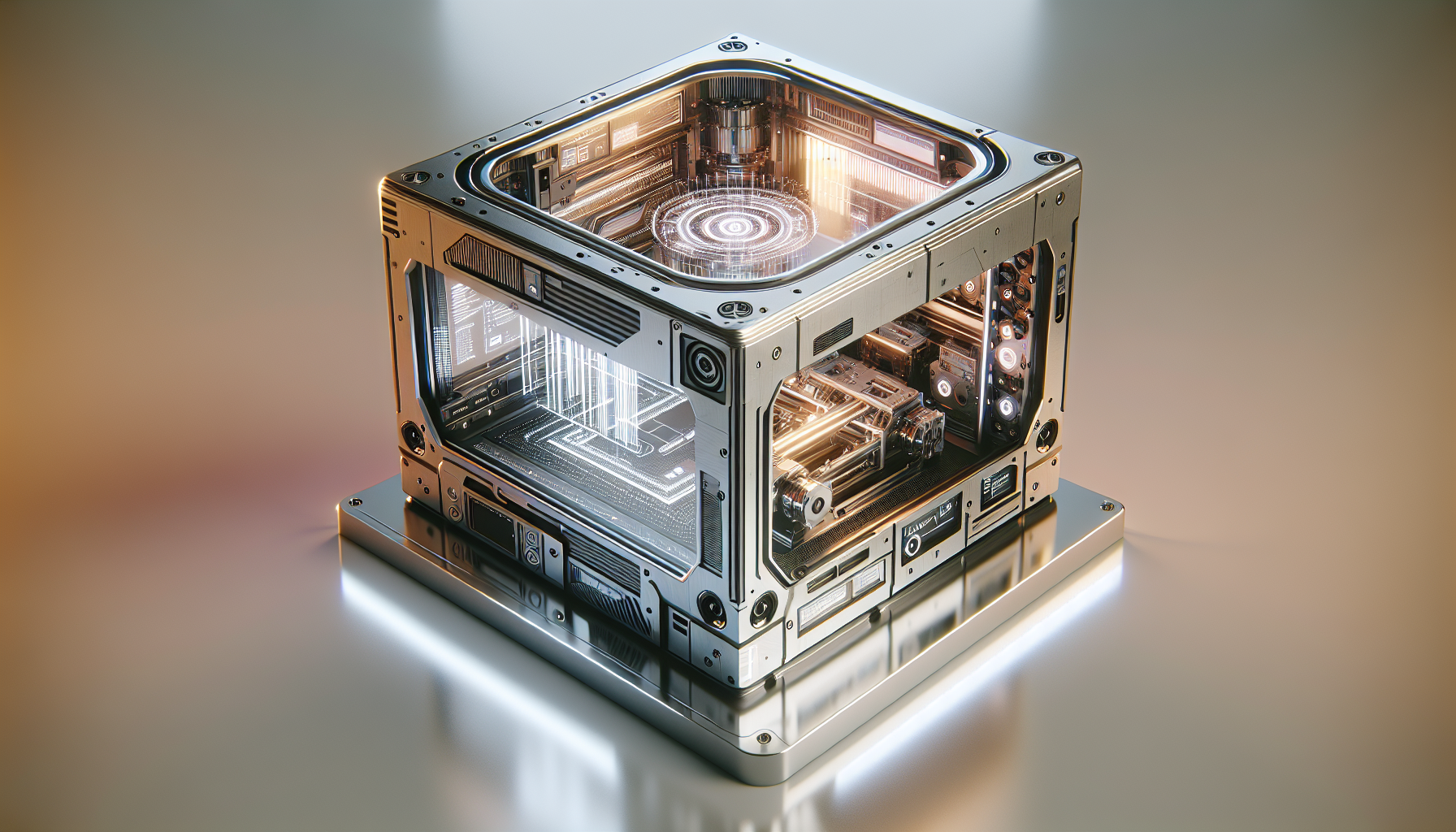

New materials and structural designs

If your machine frame used to be built like a bookshelf, think of 2026 frames as sculptures engineered not just to be stiff but to misbehave in predictable ways. Designers used materials with ultra-low coefficients of thermal expansion (CTE) such as Zerodur, silicon carbide (SiC), and engineered composites to make structures that refused to grow with heat.

They also used additive manufacturing techniques to create monolithic frames where previously many assembled components introduced cumulative alignment errors. Monolithic parts reduced assembly variability and offered integrated internal passages for coolant and sensors, keeping your parts steady.

Control algorithms, digital twins, and the role of AI

The control stack matured beyond PID loops. Imagine control algorithms that were part physicist, part therapist — understanding where the machine wanted to go and gently persuading it.

- Model-predictive control (MPC) anticipated future errors by considering system dynamics over a time horizon.

- Adaptive feed-forward filters corrected periodic disturbances.

- Neural networks learned your machine’s personality: how it warmed up, how tools bent at particular feed rates, how the spindle flirted with resonance at certain speeds.

- Digital twins — highly accurate virtual representations of your machine — ran scenarios faster than real time and recommended corrections or parameters before you ran the physical process.

These changes meant the machine was less a dumb obedient tool and more like a coworker who understands nuance and bad moods.

Machine components redesigned for sub-micron accuracy

Every subsystem got an overhaul with specific attention to repeatability and predictability. You might approach purchasing a machine with a checklist like this:

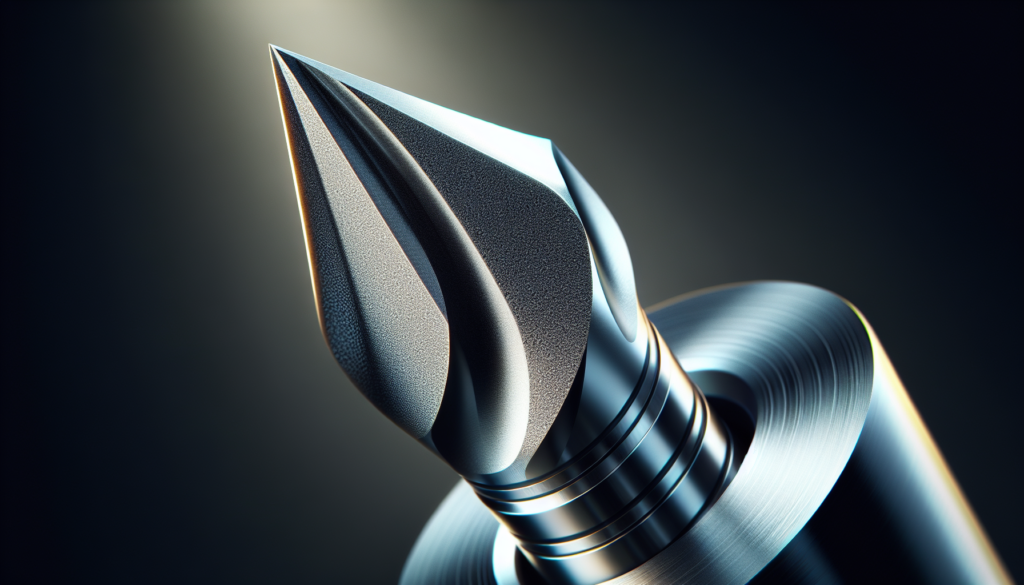

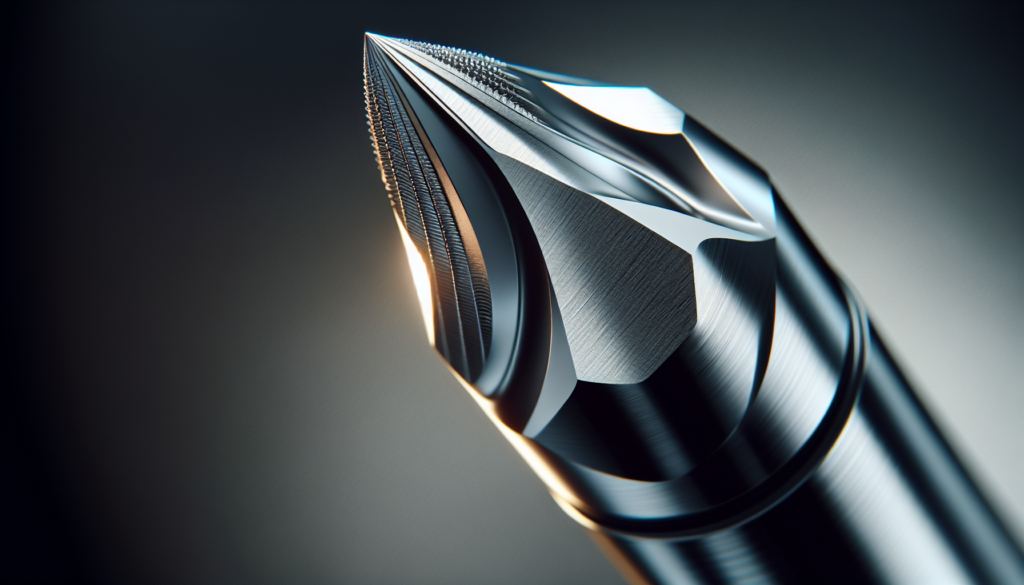

- Spindle: ultra-high stiffness, low runout, integrated temperature sensors.

- Bearings: air or hydrostatic, designed for near-zero friction and wear.

- Guides: preloaded cross-roller or linear air bearings to remove play.

- Encoders: direct linear feedback with nanometer resolution.

- Tool holders: kinematic, 4-6 point locating to repeat tool change positions.

- Tool changers: ultra-precise, sensor-rich, with in-situ calibration.

- Enclosure: thermally managed, isolated from shop-floor vibration.

- Lubrication: centralized, contamination-controlled, and monitored.

Component comparison table

| Component | Traditional design | 2026 sub-micron design | Impact on accuracy |

|---|---|---|---|

| Bearings | Ball/roller | Air/hydrostatic | Eliminates stick-slip & wear-induced drift |

| Motion transmission | Ball screw + gearbox | Direct-drive linear motor | Removes backlash and transmission errors |

| Feedback | Rotary encoders on motors | Direct linear encoders | Direct measurement of axis position |

| Spindle | High-speed, standard sensors | Low runout, integrated metrology | Reduces radial error and misalignment |

| Frame | Assembled castings | Additive monolithic, low-CTE materials | Fewer assembly tolerances, lower thermal growth |

Thermal management: the invisible war

Temperature is a quiet traitor. A spindle heating by 1°C can add microns of error through expansion. You don’t typically see this until you hold a part and wonder why it’s off by what seems like nothing and probably shouldn’t matter, and yet it ruins your batch.

By 2026, thermal strategies combined active and passive methods:

- Active cooling loops for spindles, motors, and encoders.

- Insulated enclosures with controlled ambient temperature and humidity.

- Embedded temperature sensors throughout the frame to feed compensation algorithms.

- Materials with matched or near-zero CTE for critical kinematic paths.

- Warm-up routines that use learned motor patterns to bring the entire machine to a thermally predictable state before cutting.

You got to the point where you scheduled warm-up time the way chefs preheat ovens — it’s an investment of minutes that saves hours of grief.

Metrology integration: measuring while machining

It’s one thing to measure before and after; it’s another to measure during. Inline metrology turned quality control from a final exam into an ongoing conversation.

Inline strategies included:

- Touch probes that registered with micron-level repeatability.

- Laser interferometers for checking straightness and position during operation.

- Optical scatterometry and autofocus interferometers for surface profiles.

- In-situ microscopes for microfeatures and micro-geometry checks.

This in-process measurement allowed closed-loop corrections. A tool that began wearing would be compensated in path planning; a clamping that relaxed was detected and adjusted for on the fly.

Table: In-process metrology comparison

| Method | Typical resolution | Use case | Correction latency |

|---|---|---|---|

| Touch probe | ~0.1–1 µm | Position checks, bores | Seconds |

| Laser interferometer | ~0.001–0.1 µm | Straightness, position | Milliseconds–seconds |

| Optical interferometry | ~0.001 µm | Surface form, waves | Seconds–minutes |

| In-situ microscope | ~0.1 µm | Micro-structure | Seconds |

Software and the role of CAM/CNC synergy

You can have a perfect machine, but if the program drives it like it’s trying to write calligraphy with a chainsaw, you’ll never see sub-micron results. Software caught up in multiple ways:

- CAM systems generated motion with micro-optimized toolpaths that reduced acceleration-induced errors.

- High-order interpolation (spline-based trajectories) replaced crude linear segments that coaxed vibrations.

- Motion controllers executed trajectories with microsecond determinism on real-time operating systems.

- Closed-loop tool path modification where measurement data altered the remaining cut program.

Best practice: treat CAM not as a static translator but as an active participant in your process, one capable of producing paths that account for dynamics, wear, and measurement feedback.

Process chain changes: from prototype to production

The entire process chain tightened up. It wasn’t enough to have a great machine; you had to rethink how you held pieces, what tools you used, and how you defined quality.

Key process changes:

- Fixturing became kinematic and repeatable; dedicated fixtures were often preferred over generic vices.

- Tooling materials and coatings were chosen to minimize runout and maintain micro-geometry.

- Cutting parameters were tuned to keep forces in regimes that minimized deflection.

- Multi-step strategies (roughing, semi-finishing, finishing) incorporated in-situ measurement to adjust final passes.

- Post-process treatments (stress relief, thermal stabilization) were integrated earlier to prevent surprises.

You learned to treat the part as a drama with acts and an audience of sensors.

Case studies: industries transformed by sub-micron CNC in 2026

Stories stick better than statistics. Here are condensed case studies showing exactly what sub-micron CNC enabled.

Semiconductors: backend tooling and precision fixtures

Your parts for semiconductors required patterning features at sub-micron levels. Previously expensive lithography steps were trimmed because mechanical features could now be produced with predictable geometry. That reduced cycle times and allowed smaller companies to enter markets previously gated by facility-level capital.

Optics: lenses and micro-optical components

You could machine primary optical surfaces and rely on measurement-in-process to produce form errors below a fraction of a wave of light. That meant fewer corrective polish cycles and faster time to finished optics — critical when you’re making high-NA lenses for AR devices.

Medical implants: micro-scale surfaces and features

Surface roughness and tiny features affect how tissue interacts with implants. Sub-micron control produced surfaces that encouraged bone in-growth predictably, leading to higher success rates for implants. You could now machine features previously manufactured only with expensive EDM or lithographic processes.

Microfluidics and MEMS: channels and microstructures

Creating consistent micro-channels with tight cross-section control allowed flow properties to be reproducible. That’s how diagnostic devices became more reliable and accessible.

Quality assurance and standards

As capability increased, so did the need for standards and traceability. You had to demonstrate metrological credibility.

Important standards and practices by 2026:

- Traceability to national measurement institutes for critical gauges and interferometers.

- ISO 230-2 and related standards for machine tool geometric accuracy measurements adapted to sub-micron reporting.

- Regular calibration schedules keyed to machine usage, not just calendar days.

- Process capability indices (Cp, Cpk) reported with micron-level sensitivity.

- Structured data logging for metrology results to support audits and continuous improvement.

Standards and their relevance

| Standard | Relevance to sub-micron manufacturing |

|---|---|

| ISO 230 series | Machine tool test codes for geometric accuracy |

| ISO 9001 with metrology traceability | Quality systems integrating measurement traceability |

| ASTM and ASME specific test methods | Material and measurement protocols for specialized parts |

| National metrology institute traceability | Ensures instruments report absolute standards |

Economics: costs, ROI, and what changed for your bottom line

You might assume sub-micron machines were a luxury, and sometimes they were. But by 2026, economies of scale and technological maturity made the ROI compelling in cases where precision reduced downstream costs.

Key economic considerations:

- Capital cost: higher than traditional machines, but lower than equivalent multi-step processes combining lithography and polishing.

- Cycle time: sometimes longer per specific operation (because you cut gentler), but overall throughput improved due to lower scrap and rework.

- Yield: improved dramatically for precision parts; a single percentage point increase in yield can pay for upgraded machines quickly.

- Labor: required more skilled operators initially but reduced rework and inspection-intensive tasks.

- Supply chain: allowed consolidation because fewer vendors could meet sub-micron requirements; you paid a premium for partner reliability.

Example ROI snapshot (illustrative)

| Metric | Traditional process | Sub-micron 2026 process |

|---|---|---|

| Capital expense per machine | $250k | $1.2M |

| Yield | 92% | 98% |

| Rework rate | High | Low |

| Time to market (for precision product) | Longer | Shorter |

| Break-even (months) | N/A | 12–36 (dependent on volume) |

Practical considerations for adopting sub-micron CNC

If you’re thinking, “this is perfect, where do I sign?”, pause for a minute. There are practical things to consider before you buy a machine or revamp a process.

Checklist to prepare:

- Evaluate part need: Are sub-micron tolerances truly required for functional performance?

- Shop environment: Do you have or can you create a controlled environment for temperature, vibration, and air cleanliness?

- Metrology plan: How will you measure and verify parts? Can you integrate in-process metrology?

- Training: Plan for operator training on maintenance, measurement, and process tuning.

- Maintenance regime: Establish predictive maintenance, sensor logging, and spare parts plans.

- Pilot projects: Start with a single part or run to work out kinks before scaling.

- Supplier vetting: Choose vendors with documented metrology and references.

- Data infrastructure: Plan for secure storage, traceability, and analysis of process data.

Human factors: the shop-floor reality you’ll live with

Technology didn’t magically remove human error. But it redefined roles. Your operators became more like process technicians and less like button-pushers. Metrology technicians gained prominence. Your shop floor might look more like a laboratory than a garage — and that’s intentional.

You’ll need to lead cultural shifts in:

- Acceptance of longer setup/warm-up routines.

- Respect for environmental controls (no open doors, no air drafts).

- Careful handling of parts to prevent surface contamination that can masquerade as machining errors.

Common pitfalls and how to avoid them

You can avoid making mistakes the way other people did: by reading their diaries of humiliation. Common pitfalls include:

- Underestimating the effect of temperature cycles between shifts.

- Skipping calibration because “it looked fine yesterday.”

- Expecting older tooling to perform at sub-micron levels without verification.

- Integrating measurement systems without a data strategy — you end up with lots of numbers and little insight.

How to avoid them:

- Build thermal management plans and enforce them.

- Automate calibration prompts and verification steps.

- Use dedicated tooling and holder systems designed for the precision required.

- Implement data dashboards that flag trends, not just snapshots.

Future directions beyond 2026

If 2026 looked like a quantum leap, the next decade looked like careful refinement. Trends to watch:

- Increased use of quantum and optical sensors for even finer measurement.

- Broader adoption of in-situ additive finishing — blending subtractive and additive for surface control.

- Collaborative machines that coordinate across a cell, sharing metrology data for synchronized production.

- Standardization of data exchange formats for metrology to make cross-vendor analytics trivial.

- Autonomy in optimization — controllers that will tune themselves overnight based on performance data.

You might also see miniaturized CNC systems integrated directly into lab-on-chip production lines, bringing manufacturing right to the experiment.

How you can prepare or adapt (a practical roadmap)

If you’re serious about bringing sub-micron capability into your workflow, follow this pragmatic roadmap:

- Define need and scope: Identify which parts truly require sub-micron accuracy.

- Audit environment: Measure current shop temperature stability, vibration, and cleanliness.

- Pilot procurement: Acquire or lease one machine for pilot runs.

- Build metrology: Invest in traceable metrology instruments and training.

- Develop process recipes: Document cutting parameters, fixture drawings, warm-up routines.

- Integrate measurement: Add in-process checks and closed-loop feedback.

- Train staff: Cross-train operators, programmers, and metrology techs.

- Scale: Use data from pilots to justify additional machines or shifts.

- Iterate: Use production data to refine models and parameters.

- Maintain: Implement predictive maintenance and calibration schedules.

Closing thoughts: a slightly sentimental nudge

You’ll find that precision at this scale is as much about patience and process as it is about sheer technological wizardry. The machines themselves are remarkably obedient; it’s the ecosystem around them — your fixtures, your environment, your software, your willingness to warm the spindle — that decides whether you get miracles or just good intentions.

If you treat the machine like a demanding but honest collaborator — one that must be understood, fed correct data, and given time to warm up — it will reward you with parts so precise you’ll feel mildly guilty for expecting anything less. And that, in the end, is what made the CNC revolution of 2026 less like a single event and more like the slow maturing of a craft you already practiced, but with better tools and slightly higher standards for coffee.

Now, you know what changed, why it mattered, and how to bring some of that magic into your shop. If you take one thing away, let it be this: invest in measurement and environment before you invest in anything else. Machines can be taught to be perfect — but they refuse to lie to you about it.