Have you ever watched someone sand a piece of metal with the kind of tender concentration usually reserved for polishing heirlooms and wondered whether you had stumbled into a church?

How Fabrication Intelligence Separates Professionals From Hobbyists

You’ll notice that fabrication spaces have an odor that can’t be bottled: hot metal, coolant, and a faint aftershave of commitment. fabrication intelligence is what turns that aroma into repeatable outcomes, predictable timelines, and the quiet satisfaction of parts that fit together on the first try. In this article you’ll get practical definitions, comparisons, and steps you can use to move your practice — whether it’s hobbyist tinkering or fledgling entrepreneurship — toward professional-grade results.

What Is Fabrication Intelligence?

You might imagine fabrication intelligence as a mysterious algorithm, but it’s simpler and more human than that. It’s the combined set of knowledge, methods, data, and judgement that allows you to design, plan, and execute the making of physical parts or assemblies with consistent quality and efficiency. It includes technical knowledge, process control, tooling selection, data analysis, and a cultural inclination for continuous improvement.

You’ll find that fabrication intelligence exists at the intersection of craft and systems thinking. It’s not just doing things well; it’s knowing why you do them, measuring the effects, and using that feedback to improve.

Components of Fabrication Intelligence

You’ll want to think about several components when you evaluate or build fabrication intelligence: skill, process, tooling, data, and culture. Each component plays a role, and neglecting any one of them will compromise outcomes.

- Skill: Your hands-on experience, judgement, and tacit knowledge.

- Process: Standardized steps and procedures that reduce variability.

- Tooling: Appropriate equipment and fixtures that enable precision.

- Data: Measurements, logs, and analytics that inform decisions.

- Culture: Attitudes toward safety, learning, and collaboration.

You’ll notice that professionals invest in all of these areas deliberately, while hobbyists may excel in one or two but leave the rest to chance.

Why the Distinction Matters

You might be thinking that both hobbyists and professionals build things, so what’s the big deal? The difference shows up in what happens after the part leaves your bench.

Professionals deliver predictable performance, meet specifications, and produce repeatable quality. Hobbyists produce beautiful one-offs, creative solutions, and sometimes delightfully eccentric failures. Both are valuable, but if you want to scale, reduce risk, or win contracts, fabrication intelligence becomes a necessity rather than an accessory.

You’ll begin to see the distinction as soon as you compare lead times, scrap rates, or the number of late-night frantic reworks before a deadline.

Quick Comparison: Professionals vs Hobbyists

You’ll find it helpful to review a side-by-side comparison that summarizes practical differences. The following table condenses typical attributes you’ll observe.

| Attribute | Professionals | Hobbyists |

|---|---|---|

| Process Standardization | High — documented procedures and checklists | Low — informal and tacit |

| Quality Control | Systematic inspections & data records | Ad-hoc checks |

| Tooling Investment | Purpose-built fixtures & calibrated tools | General-purpose tools |

| Traceability | Material and process traceability standard | Limited or none |

| Safety Culture | Mandatory PPE, training, audits | Variable, often informal |

| Time Management | Project planning and buffer times | Flexible, interest-driven timing |

| Cost Control | BOMs, cost tracking, efficiency targets | Focus on enjoyment, not always costed |

| Data Usage | Metrology, SPC, digital logs | Minimal; memories and photos |

| Scalability | Designed for repeatability and volume | Focused on single or small batch pieces |

You’ll use this table as a mental checklist to identify gaps in your own practice and to prioritize what to improve first.

Tools and Technologies That Define Professional Workflows

You’ll find that the right tool at the right time saves you both sweat and imagination. Professionals match tools to tasks and maintain them like pets — with schedules and a mild menace if neglected.

Essential Shop Equipment

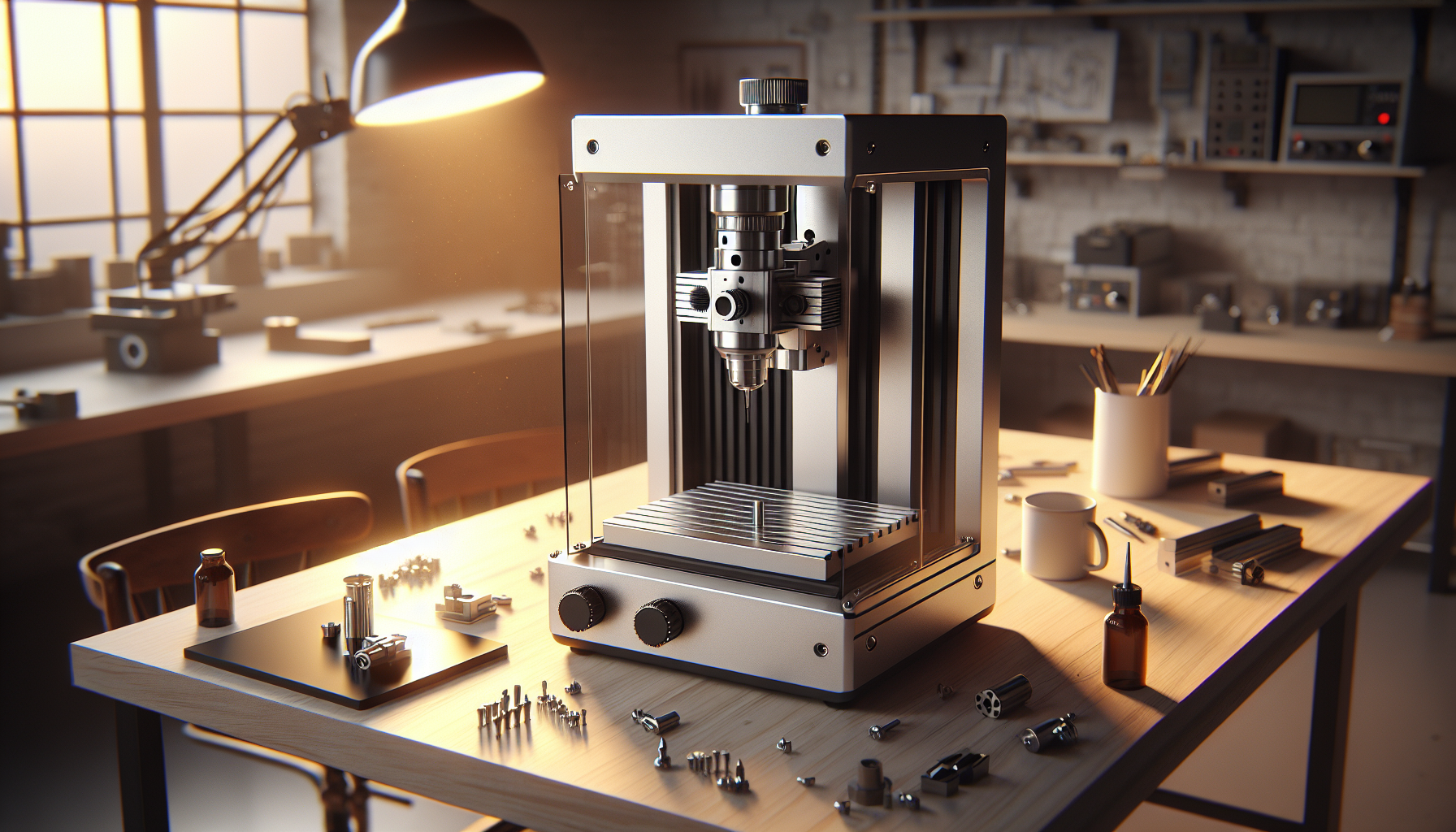

Professionals rely on a foundation of calibrated machines and fixtures. You’ll want to know which items provide the best leverage for your goals.

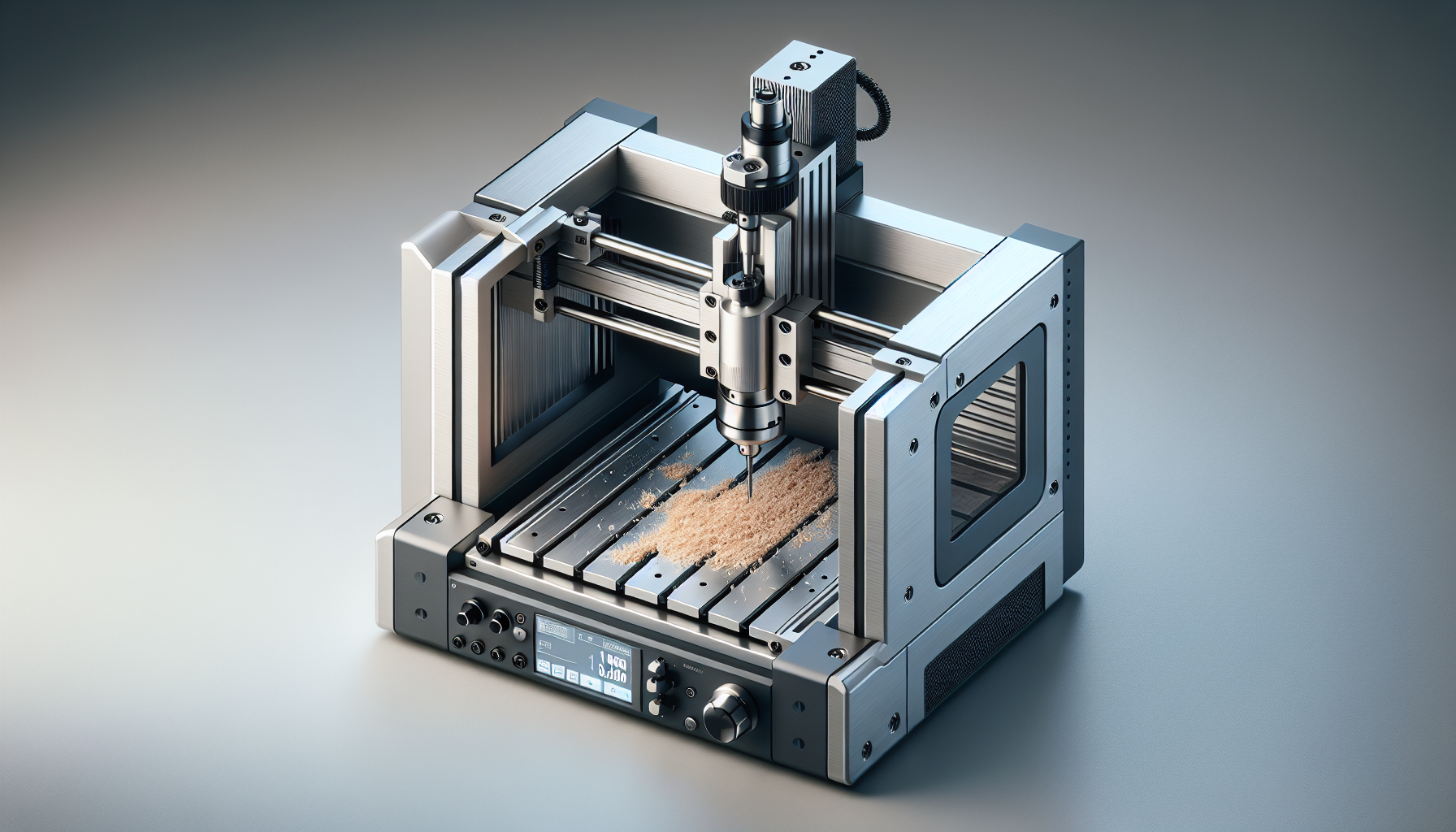

- CNC milling machines and lathes for repeatable precision.

- Laser cutters and waterjets for consistent cutting quality.

- Coordinate Measuring Machines (CMM) or portable probes for metrology.

- High-quality jigs and fixtures tailored to specific parts.

- Industrial-grade welding rigs with documented procedures.

You’ll notice that hobbyists might have 80% of the creative capacity with 20% of the equipment, but the missing 20% often accounts for 80% of the predictability and speed you’ll crave for professional projects.

Digital Tools and Software

You’ll need software that supports design, simulation, and production planning. This includes CAD/CAM, nesting software, and production planning or ERP systems for tracking.

- CAD/CAM software that outputs code directly compatible with your machines.

- Simulation tools that predict stresses and deformation.

- Manufacturing Execution Systems (MES) for shop-floor data.

- Statistical Process Control (SPC) software for monitoring quality trends.

You’ll adopt these tools more readily if you treat them as extensions of your thinking rather than mere complexity to be feared.

Processes and Workflows: Where Intelligence Shows Up

You’ll know fabrication intelligence is working when processes behave like well-trained employees — predictable, efficient, and occasionally surprising you with their reliability.

Standard Operating Procedures (SOPs)

You’ll need SOPs for consistent results. They aren’t just for bureaucrats; they’re concise instructions that help any team member reproduce results reliably.

- Create SOPs for setup, machining, welding, inspection, and maintenance.

- Keep them short, clear, and accessible where the work happens.

- Update SOPs based on lessons learned and near misses.

You’ll appreciate how much time SOPs save when you don’t have to retrain people from scratch every time a new project comes in.

Change Management and Version Control

Professionals treat changes to drawings, materials, or processes seriously. You’ll learn that even a small alteration can ripple through cost, schedule, and quality.

- Use formal change requests for revisions.

- Maintain single sources of truth for drawings and BOMs.

- Log who approved changes, when, and why.

You’ll minimize costly rework by making change management a ritual rather than an afterthought.

Data, Metrics, and Feedback Loops

You’ll discover that data isn’t just for managers; it becomes an ally. Measuring the right things lets you learn faster than trial and error alone.

Key Metrics to Track

Tracking metrics helps you quantify improvements and justify investments. Here are practical metrics you’ll want to monitor.

- First-pass yield (FPY): Percentage of parts meeting specs without rework.

- Scrap rate: Waste produced relative to output.

- Cycle time: Time to produce a single unit from start to finish.

- On-time delivery: Projects delivered according to schedule.

- Mean time between failures (MTBF): Equipment reliability indicator.

You’ll find that small improvements in these metrics compound into significant savings and reputation gains.

Statistical Process Control (SPC)

SPC allows you to distinguish between normal process variation and signals that require intervention. You’ll learn to appreciate control charts for their blunt honesty.

- Implement SPC on critical dimensions and repeatable operations.

- Use control limits to trigger investigation before parts go out of spec.

- Combine SPC with root cause analysis when patterns emerge.

You’ll end up spending less time firefighting and more time improving the process when SPC is embraced.

The Role of Metrology and Traceability

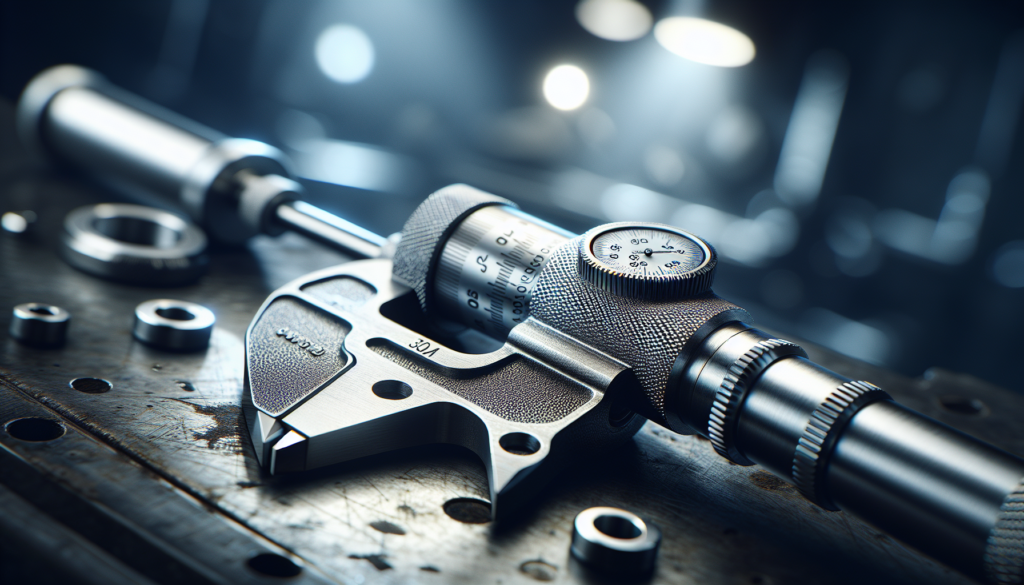

You’ll understand that precision without verification is a superstition. Measuring and recording allows professionals to prove compliance and diagnose problems.

Calibration and Measurement Protocols

Calibration keeps measurements trustworthy. Professionals keep a calibration schedule and log to demonstrate control.

- Calibrate tools at defined intervals and after impacts or repairs.

- Use calibrated instruments for final inspections and process control.

- Maintain traceability of materials with lot numbers and certificates.

You’ll feel more confident selling or certifying your parts when you can show provenance and compliance records.

Traceability Systems

Traceability is more than bureaucracy; it’s a way to minimize recalls and target fixes quickly.

- Assign serial numbers, lot codes, or batch IDs to parts.

- Link materials, process parameters, and operator records to each lot.

- Keep digital records to accelerate root cause investigations.

You’ll reduce finger-pointing during failures and increase the odds of an efficient corrective action.

Skills, Training, and Human Factors

You’ll quickly discover that fabrication intelligence depends heavily on people. The most elegant process won’t save a company if its people aren’t supported and trained.

Competency Frameworks

Professionals map out skills required at each role and offer clear progression paths. You’ll use this to recruit, train, and retain talent.

- Define competencies for machinists, welders, programmers, and inspectors.

- Use on-the-job training paired with formal assessments.

- Reward certification and continuous learning.

You’ll create a culture where people see investment in skills as a personal and organizational advantage.

Soft Skills and Team Dynamics

Technical skill isn’t everything. Communication, problem-solving, and a calm approach to failure matter. You’ll notice teams that communicate well solve problems faster and with less drama.

- Encourage daily stand-ups or short shift handovers with clear notes.

- Promote cross-functional problem-solving so knowledge isn’t siloed.

- Practice blameless postmortems to focus on fixes rather than blame.

You’ll sleep better when your team can talk through a part’s failure without immediately calling someone incompetent.

Cultural Differences: How Professionals Think

You’ll notice professionals think differently about risk, quality, and ownership. It’s less about perfection and more about predictability.

- You’ll see them measure trade-offs objectively: speed vs. accuracy, cost vs. longevity.

- You’ll observe habits like documenting near-misses and celebrating small process wins.

- Professionals accept constraints and design solutions within them rather than ignoring constraints and hoping for miracles.

You’ll find adopting this mindset is often more challenging than buying a new machine.

Business and Economic Considerations

You’ll understand that fabrication intelligence isn’t just a technical concern; it impacts profitability and competitiveness.

Cost of Poor Quality

Poor quality hides costs including rework, scrap, warranty claims, and lost reputation. Professionals calculate these and use them to justify improvements.

- Quantify scrap and rework costs per part and per month.

- Estimate the cost of late deliveries in terms of penalties or lost contracts.

- Factor in warranty or field-failure costs when pricing work.

You’ll justify investments in better tooling, training, or software by showing ROI using these numbers.

Pricing and Quoting

When you invest in predictability, you can quote with confidence. You’ll learn to break quotes into labor, materials, overhead, tooling amortization, and contingency.

- Use historical data to estimate cycle times and scrap.

- Include setup time and changeover in quotes for small batches.

- Offer tiered pricing for different levels of traceability or certification.

You’ll find customers are willing to pay for reliability once you can demonstrate it.

From Hobbyist to Professional: Practical Roadmap

You’ll appreciate a step-by-step guide that turns aspirations into tangible progress. The following roadmap helps you prioritize improvements.

- Standardize one process: Choose a repeatable part and create an SOP.

- Measure baseline metrics: Record cycle time, scrap rate, and setup time.

- Invest in one calibrated measurement tool: e.g., a micrometer or dial indicator.

- Implement a change log: Track drawing revisions and approvals.

- Build a simple fixture: Reduce variability in setup and improve throughput.

- Train and assess skills: Document who can perform critical tasks and at what level.

- Adopt basic SPC: Monitor a critical dimension for a month.

- Formalize material traceability: Start batch cards or digital logs.

- Automate where it makes sense: CAD/CAM nesting or CAM code generation.

- Review and expand: Move to another process and repeat.

You’ll see that each step is manageable if you allocate small, consistent efforts rather than expecting overnight transformation.

Common Pitfalls and How You’ll Avoid Them

You’ll make mistakes — everyone does — but professionals make fewer catastrophic ones because they plan for them.

- Investing in expensive equipment without training: Balance purchases with training budgets.

- Ignoring documentation: Build a habit of brief, accurate logs.

- Skipping small investments (fixtures, gages): They pay back faster than you’d think.

- Overcomplicating processes: Start simple and add control points where data says they’re needed.

You’ll save money and reputation by treating processes and people as the primary investments, not just the machines.

Case Studies: Practical Illustrations

You’ll learn faster with stories. These short scenarios show how fabrication intelligence changes outcomes.

Case Study 1: The Late Shipment

A small fabrication shop missed a client deadline because setups took longer than estimated. By documenting setup steps into an SOP and creating one simple fixture, they cut setup time by 40% and avoided penalty fees. You could replicate this by timing your setups and experimenting with basic fixtures.

You’ll notice that the cost of the fixture was justified within the first five jobs, and the shop’s reputation improved.

Case Study 2: The Mysterious Failures

A manufacturer had intermittent failures in assembly. After introducing traceability and recording heat-treatment batches, you’ll find the problem corresponded to one vendor lot. With that information, the supplier fixed a process parameter, and the failure rate dropped substantially.

You’ll see how traceability accelerates problem resolution and reduces customer claims.

Technology Trends That Will Affect You

You’ll want to stay aware of trends that change what fabrication intelligence looks like.

- Digital twins: Virtual replicas of parts and processes that predict outcomes.

- Additive manufacturing integration: Hybrid workflows combining subtraction and addition.

- Edge analytics and IoT: Real-time monitoring of machines and process parameters.

- AI-assisted CAM programming: Reducing programmer time for complex toolpaths.

You’ll benefit most by experimenting with one technology that aligns with your bottleneck rather than chasing every new gadget.

Hiring and Organizational Structure

You’ll hire differently when you prioritize fabrication intelligence. Job descriptions emphasize process orientation and data literacy in addition to technical skill.

- Look for candidates with experience in standardized workflows and documentation habits.

- Hire for curiosity and problem-solving rather than just tool proficiency.

- Create roles for quality engineers or process technicians early as you scale.

You’ll find that hiring for mindset reduces turnover and improves productivity.

Metrics Dashboard Example

You’ll find a simple dashboard helps focus improvement efforts. The table below shows a minimal set of KPIs you can track weekly.

| KPI | Why It Matters | Target |

|---|---|---|

| First-pass yield (FPY) | Shows process capability | >95% |

| Scrap rate | Directly impacts cost | <2%< />d> |

| Average setup time | Affects lead time and cost | Reduce 20% in 6 months |

| On-time delivery | Customer satisfaction | >98% |

| Machine uptime | Throughput and scheduling | >90% |

| Calibration compliance | Measurement integrity | 100% on schedule |

You’ll tailor targets to your context, but the act of tracking will itself drive improvements.

Certifications and Standards

You’ll consider certifications when you want to access regulated markets or large clients. ISO 9001, AS9100 (aerospace), and NADCAP (special processes) are common examples.

- Certifications require documented systems, audits, and a culture of continuous improvement.

- They aren’t magic, but they force you to implement many practices that embody fabrication intelligence.

- Use certifications as a roadmap — the process improves your internal controls even if you never advertise the badge.

You’ll weigh certification costs against market access and internal benefits.

How You’ll Measure Return on Investment (ROI)

You’ll justify investments by calculating ROI with realistic assumptions.

- Start with a baseline: current scrap, rework hours, and delivery penalties.

- Estimate the improvement from a change (e.g., new fixture reduces scrap by X%).

- Translate improvements into cost savings and increased capacity.

- Compare savings to the cost of investment and time to payback.

You’ll present ROI to stakeholders with clear numbers and a sensitivity analysis to show risk.

Final Thoughts: The Human Element

You’ll remember that fabrication intelligence is largely about people learning to work together with intention. Tools and data support you, but the decisions — the choices about what to measure, what to standardize, and what to let evolve — are human.

You’ll take comfort in knowing that moving from hobbyist flair to professional predictability doesn’t erase creativity; it amplifies it. You’ll be able to experiment more boldly because you’ll have systems that catch most problems before they become expensive. And when you find a solution that works, you’ll be able to repeat it, teach it, and perhaps, most gratifyingly, invoice for it without second-guessing.

If you take nothing else from this article, you’ll leave with a simple piece of advice: write things down. Start with a single SOP, measure one metric, and make one small investment in a measurement tool. You’ll be surprised how quickly those modest steps add up to the quiet competence that separates professionals from those who tinker for the love of it.